Targeted Proteomics: Leveraging Mass Spectrometry for Precise Proteotypic Peptide Detection in Complex Food Matrices

This article provides a comprehensive overview of the application of mass spectrometry (MS) for the detection and quantification of proteotypic peptides in complex food matrices, a critical methodology for food...

Targeted Proteomics: Leveraging Mass Spectrometry for Precise Proteotypic Peptide Detection in Complex Food Matrices

Abstract

This article provides a comprehensive overview of the application of mass spectrometry (MS) for the detection and quantification of proteotypic peptides in complex food matrices, a critical methodology for food safety, allergen control, and authenticity. Aimed at researchers, scientists, and drug development professionals, the content explores the foundational principles of proteotypic peptide selection, details advanced methodological workflows from sample preparation to LC-MS/MS analysis, and addresses key challenges in troubleshooting and optimization. It further examines validation strategies and compares MS performance against other detection technologies. By synthesizing current research and emerging trends, this article serves as a vital resource for implementing robust, sensitive, and accurate targeted proteomics approaches in food analysis and related biomedical fields.

The Foundation of Proteotypic Peptides: Principles and Significance in Food Analysis

Defining Proteotypic Peptides and Their Role as Unique Protein Biomarkers

In the realm of targeted proteomics, proteotypic peptides are defined as peptide sequences that uniquely represent a specific protein or protein isoform within a complex biological sample and are consistently and reliably observed in mass spectrometry (MS) experiments [1] [2]. These peptides serve as surrogate representatives for their parent proteins, enabling precise identification and quantification [3]. Their selection is crucial for developing highly specific and sensitive MS-based assays, as they must fulfill two primary criteria: uniqueness within the proteome of interest to avoid ambiguous identifications, and favorable physicochemical properties that ensure good detectability by liquid chromatography-tandem mass spectrometry (LC-MS/MS) [3].

The critical importance of proteotypic peptides lies in their ability to bridge the gap between protein discovery and clinical or industrial application. In biomarker research, they form the analytical foundation for Multiple Reaction Monitoring (MRM) or Selected Reaction Monitoring (SRM) assays, providing a highly specific method for quantifying candidate proteins in complex matrices like plasma, tissue, or food products [4] [5]. Unlike immunoassays, which rely on antibody recognition of often conformational epitopes, MS-based methods targeting proteotypic peptides identify proteins based on their fundamental amino acid sequence, reducing the risk of cross-reactivity and increasing specificity [6] [5].

Selection Criteria for Proteotypic Peptides

The selection of optimal proteotypic peptides is a meticulous process that extends beyond simple sequence uniqueness. A peptide's suitability is governed by a combination of bioinformatic predictions and empirical validation. Key selection criteria are consolidated in the table below.

Table 1: Key Criteria for Selecting Proteotypic Peptides

| Criterion | Description | Rationale |

|---|---|---|

| Sequence Uniqueness | The peptide sequence must be unique to the target protein within the background proteome. | Ensures specific monitoring of the target protein without interference from other proteins [3]. |

| MS Detectability | Exhibits consistent observation, high signal intensity, and efficient fragmentation in MS. | Provides sensitivity and robust quantification; often predicted from discovery datasets [7] [2]. |

| Absence of Problematic Residues | Should avoid methionine (oxidation) and cysteine (incomplete alkylation). | Prevents quantitative inaccuracies from variable chemical modifications [3] [7]. |

| Efficient Enzymatic Cleavage | Should have high cleavage efficiency by the protease used (e.g., trypsin). | Minimizes variability from incomplete digestion, improving quantitative accuracy [6] [3]. |

| Optimal Length | Typically between 7-25 amino acids. | Too short can be non-specific; too long may ionize or separate poorly [3]. |

| Absence of Polymorphisms/PTMs | Should not contain sites for common SNPs or post-translational modifications unless specifically targeted. | Prevents unexpected quantitative variations in clinical or population samples [3]. |

Furthermore, in specialized applications like the analysis of xenograft models (e.g., human tumors grown in mice), the selection process must ensure that the chosen peptides are unique to the species of interest (e.g., human) and are not present in the host proteome (e.g., mouse) [3]. Tools like PeptideManager have been developed to expedite this cross-species peptide selection process [3].

The following workflow diagram illustrates the logical process for selecting proteotypic peptides for a targeted MS assay.

Application in Food Allergen Detection

The detection and quantification of food allergens represents a premier example of how proteotypic peptides are applied to solve real-world analytical challenges in complex matrices. For individuals with food allergies, the accurate detection of trace amounts of allergens like milk, egg, peanut, and soy in manufactured foods is a critical safety requirement [6].

The Analytical Challenge

Food matrices are notoriously complex and are often subjected to thermal processing (e.g., baking, frying) which can denature proteins, degrade epitopes, and cause chemical modifications (e.g., Maillard reaction) [6] [8]. These processes can severely compromise the accuracy of traditional antibody-based methods like ELISA, which may fail to recognize altered protein structures [6]. Mass spectrometry, targeting stable proteotypic peptides, offers a promising alternative due to its ability to multiplex (detect multiple allergens simultaneously) and its robustness to changes in protein conformation caused by processing [6] [8].

Selection of Robust Peptide Markers

The core of the MS approach is the identification of proteotypic peptides that are stable and detectable even in processed foods. A comprehensive survey of the literature has confirmed that such peptides exist for major allergenic proteins in milk, egg, and peanut [6]. The robustness of a peptide marker is determined by its resilience to variations in the food matrix, sample preparation protocol, and MS instrumentation [6]. For instance, within the ThRAll project, a multi-allergen MS method was developed, and 16 proteotypic peptides were identified and validated for detecting milk, egg, peanut, soybean, hazelnut, and almond in incurred food materials [8].

Table 2: Exemplary Proteotypic Peptides for Food Allergen Detection

| Allergenic Food | Target Protein | Proteotypic Peptide Sequence | Key Characteristic |

|---|---|---|---|

| Peanut | Ara h 1, Ara h 3, Ara h 6 | Selected peptides from discovery | Peptides validated in incurred chocolate and bakery goods [8]. |

| Milk | Caseins, Beta-lactoglobulin | Selected peptides from discovery | Differentiates whey and casein fractions independently [6]. |

| Egg | Ovalbumin, Ovomucoid | Selected peptides from discovery | Robust to thermal processing in baked goods [8]. |

| Soy, Wheat, Tree Nuts | Various | Guidance provided via Allergen Peptide Browser | Peptide selection tools for less-studied allergens [6]. |

Experimental Workflow for Allergen Detection

The standard bottom-up proteomics workflow for allergen detection is outlined below, from sample preparation to data analysis.

Detailed Protocol: SRM-Based Allergen Quantitation in Bakery Products

The following protocol is adapted from methods used to detect allergens in incurred cookies and rusks [8].

Protein Extraction:

- Homogenize the food sample (e.g., cookie or rusk) into a fine powder.

- Extract proteins using a suitable buffer (e.g., Tris-HCl, ammonium bicarbonate) often containing additives like SDS or urea to enhance solubility and disrupt the food matrix.

- Clarify the extract by centrifugation and filtration to remove insoluble debris.

Protein Digestion:

- Reduction: Add dithiothreitol (DTT) or tris(2-carboxyethyl)phosphine (TCEP) to a final concentration of 5-10 mM and incubate at 37-60°C for 30-60 minutes to break disulfide bonds.

- Alkylation: Add iodoacetamide (IAA) to a final concentration of 15-20 mM and incubate at room temperature in the dark for 30 minutes to alkylate cysteine residues and prevent reformation of disulfide bonds.

- Proteolytic Digestion: Add sequencing-grade trypsin at an enzyme-to-protein ratio of ~1:20 to 1:50. Incubate at 37°C for 4-16 hours. The digestion is often quenched with acid (e.g., formic acid).

Peptide Clean-up:

- Desalt the resulting peptide mixture using C18 solid-phase extraction (SPE) cartridges (e.g., Waters Sep-Pak C18).

- Elute peptides in a solvent compatible with LC-MS/MS (e.g., acetonitrile with 0.1% formic acid) and dry down in a vacuum concentrator. Reconstitute in a small volume of 0.1% formic acid for MS analysis.

LC-SRM/MRM Analysis:

- Chromatography: Separate the peptides using a reverse-phase C18 nano-flow or high-performance liquid chromatography (HPLC) column with a gradient of water and acetonitrile (both with 0.1% formic acid).

- Mass Spectrometry: Analyze the eluting peptides using a triple quadrupole (QQQ) mass spectrometer.

- The first quadrupole (Q1) is set to filter the specific precursor ion (m/z) of the proteotypic peptide.

- The selected ion is fragmented in the second quadrupole (Q2) via collision-induced dissociation (CID).

- The third quadrupole (Q3) is set to filter 3-5 specific fragment ions (transitions) unique to that peptide.

- Scheduling: Transitions are monitored only during a predefined retention time window to maximize the number of data points acquired per peak and improve sensitivity.

Quantification:

- Quantify the target allergen by integrating the peak areas of the fragment ion transitions.

- Use internal standards, ideally stable isotope-labeled (SIL) versions of the proteotypic peptides, spiked into the sample at a known concentration. This corrects for losses during sample preparation and ion suppression during MS analysis, enabling absolute quantification [6] [5].

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Research Reagent Solutions for Proteotypic Peptide-Based Assays

| Item | Function | Example |

|---|---|---|

| Trypsin (Sequencing Grade) | Proteolytic enzyme that cleaves C-terminal to Lys and Arg residues, generating peptides ideal for MS analysis. | Trypsin Gold, Mass Spectrometry Grade [8]. |

| Reducing & Alkylating Reagents | Break disulfide bonds (reduction) and cap cysteine residues (alkylation) to ensure complete, reproducible digestion. | Dithiothreitol (DTT) / Tris(2-carboxyethyl)phosphine (TCEP) and Iodoacetamide (IAA) [8]. |

| Stable Isotope-Labeled (SIL) Peptides | Internal standards for absolute quantification; chemically identical to target peptides but with a mass shift. | Synthesized peptides with heavy (13C, 15N) Lys or Arg [7] [5]. |

| C18 Solid-Phase Extraction (SPE) | Desalting and purification of peptide mixtures after digestion, removing interfering salts and buffers. | Sep-Pak C18 cartridges [8]. |

| Triple Quadrupole (QQQ) Mass Spectrometer | The cornerstone instrument for targeted SRM/MRM assays, offering high sensitivity and specificity. | SCIEX QTRAP series, Agilent 6460/6490 series [6] [2]. |

Proteotypic peptides are indispensable tools in modern applied proteomics, serving as unique biomarkers that enable the precise identification and quantification of proteins in highly complex samples. Their defined selection criteria—centered on uniqueness and MS-detectability—ensure analytical specificity and robustness. This is powerfully demonstrated in the field of food safety, where MS-based methods targeting these peptides are overcoming the limitations of traditional immunoassays by providing multiplexed, specific, and reliable detection of allergens even in challenging processed food matrices like bakery products. The continued refinement of peptide selection databases, experimental protocols, and instrumentation will further solidify the role of proteotypic peptides in transitioning protein biomarker discovery from the research bench to validated clinical and industrial applications.

In the field of proteomics, particularly for applications like detecting hazardous proteins in complex food matrices, the identification and quantification of signature peptides is a fundamental task for mass spectrometry (MS). Signature peptides are unique amino acid sequences that act as surrogates for specific proteins of interest. In complex mixtures, such as alternative protein-based foods, it is often impossible to analyze intact proteins directly. Instead, proteins are digested into peptides, and specific, uniquely identifying peptides are measured to confirm the presence and quantity of the parent protein. This approach is central to targeted proteomic assays, which can confirm the presence of hazardous proteins at high sensitivity, down to the femtomole level [9]. The process relies on core principles of mass spectrometry, including the accurate mass measurement of peptides, the specific fragmentation patterns that provide sequence information, and the quantitative comparison of peptide abundances.

Core Principles of Identification and Quantification

Principle 1: Identification via Accurate Mass and Fragmentation Signature

The identification of a signature peptide is a two-step process. First, the peptide's precursor ion is identified based on its mass-to-charge ratio (m/z) with high accuracy. Second, this precursor ion is isolated and fragmented, typically by collision-induced dissociation (CID), to generate a tandem mass spectrum (MS/MS). The fragmentation process primarily breaks the peptide bonds, creating a series of b-ions (from the N-terminus) and y-ions (from the C-terminus). The pattern of these fragment ions is a unique fingerprint that can be matched against theoretical fragmentation patterns derived from a protein sequence database using search engines like Mascot or MaxQuant [10] [9]. This match confirms the amino acid sequence of the signature peptide, thereby identifying the protein from which it originated.

Principle 2: Quantification via Isotope Labeling and Peak Amplitude Comparison

Quantitative proteomic mass spectrometry involves comparing the amplitudes of peaks resulting from different isotope labeling patterns [11]. In methods like Stable Isotope Labeling by Amino Acids in Cell Culture (SILAC), samples are labeled with "light" or "heavy" isotopic forms of amino acids. When these samples are mixed and analyzed by MS, the signature peptides appear as pairs of peaks with a known mass difference. The relative intensity of these peak pairs directly reflects the relative abundance of the peptide (and thus the protein) in the original samples. For situations where full metabolic labeling is not possible, fractional isotope labeling occurs, leading to complex isotopomer distributions. Quantitative analysis of these complex distributions can be performed using a least-squares Fourier transform convolution (LS-FTC) approach to determine both the extent of labeling and the relative abundance of the peptides [11].

Principle 3: Specificity in Complex Matrices

A signature peptide must be unique to the target protein to avoid misidentification in a complex sample such as a food matrix. Mass spectrometry's high mass accuracy and resolution are critical for this discrimination. Advanced techniques like multiplexed immunoassays and mass spectrometry can simultaneously quantify specific protein fragments responsible for allergic responses by targeting their unique signature peptides. This offers high sensitivity and specificity, even in challenging samples [12]. Furthermore, the development of a comprehensive hazardous protein database as part of a data analytics pipeline is essential for reliably identifying unknown or unexpected proteins in alternative protein-based foods [9].

Quantitative Data and Performance

The following table summarizes key quantitative performance metrics for mass spectrometry-based detection and quantification of signature peptides, as demonstrated in recent applications.

Table 1: Quantitative Performance of MS-Based Signature Peptide Analysis

| Performance Metric | Demonstrated Level | Context / Technique |

|---|---|---|

| Detection Sensitivity | Femtomole (fmol) level | Targeted assay for validation of hazardous proteins [9] |

| Detection Limits | As low as 0.01 ng/mL | Multiplexed immunoassays and mass spectrometry for specific allergens [12] |

| Quantitative Analysis | Comparison of complex isotopomer distributions | Least-squares Fourier transform convolution (LS-FTC) for fractional labeling [11] |

| Labeling Efficiency | ~95% fractional atom labeling | 15N-labeling of C. elegans and Drosophila [11] |

| Labeling Efficiency | ~35% fractional residue labeling | 2H8-valine labeling in chickens [11] |

Experimental Protocols

Protocol 1: Non-Targeted Screening for Hazardous Proteins in Food

This protocol outlines an effective non-targeted workflow for screening hazardous proteins in alternative protein-based foods (APBFs) [9].

- Protein Extraction Optimization: Efficiently extract proteins from the complex APBF matrix. This is a critical step and may require optimization for different food types. The use of glass beads for homogenization can improve extraction efficiency [9].

- Protein Digestion: Digest the extracted proteins into peptides using specific enzymes. A common approach is to use a combination of Lysyl Endopeptidase (Lys-C) and sequencing-grade modified trypsin [9].

- Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) Analysis:

- Separate the complex peptide mixture using reversed-phase liquid chromatography.

- Analyze the eluting peptides using a tandem mass spectrometer equipped with a high-resolution mass analyzer.

- Operate the mass spectrometer in data-dependent acquisition (DDA) mode, where the most intense precursor ions are automatically selected for fragmentation to generate MS/MS spectra.

- Data Analysis:

- Process the raw MS data using software (e.g., MaxQuant [10]) to search the MS/MS spectra against a comprehensive hazardous protein database.

- Identify proteins based on the detection of their signature peptides.

Protocol 2: Quantitative Analysis using Fractional Isotope Labeling

This protocol describes a general method for quantifying peptide abundances in experiments involving fractional isotope labeling, such as pulse-labeling experiments [11].

- Pulse-Labeling Experiment: Grow cells or an organism on a medium containing a stable isotope-labeled precursor (e.g., 15N-ammonium sulfate or 13C6-isoleucine).

- Sample Preparation and Mixing: Harvest the cells and prepare the protein extract. For SILAC-style experiments, mix the labeled sample with an unlabeled control sample in a known ratio.

- LC-MS/MS Analysis: Analyze the peptide mixture via LC-MS/MS as described in Protocol 1.

- Quantitative Data Analysis using LS-FTC:

- Use Fourier transform convolution to calculate the theoretical isotope distributions for the unlabeled and fractionally labeled signature peptides. This method provides an exact calculation without approximations [11].

- Apply a non-linear least-squares fitting routine to compare the theoretical isotope distributions with the experimental mass spectrum.

- The fitting algorithm simultaneously determines the relative abundance of the peptide from the different samples and the extent of fractional isotope labeling [11].

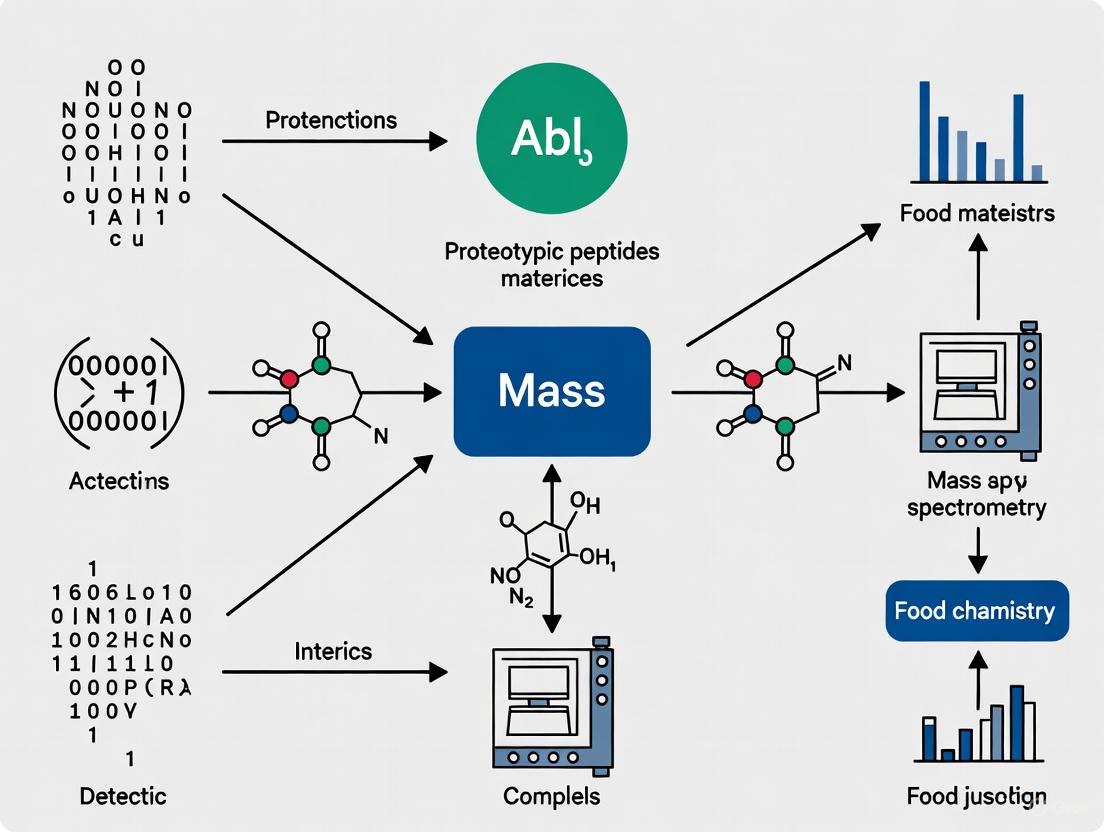

Workflow Visualization

Diagram 1: Overall MS workflow for signature peptide analysis.

Diagram 2: Peptide identification via MS/MS fragmentation.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Signature Peptide Analysis

| Reagent / Material | Function / Application |

|---|---|

| Trypsin (Sequencing Grade) | Proteolytic enzyme for specific digestion of proteins into peptides for LC-MS/MS analysis [9]. |

| Lysyl Endopeptidase (Lys-C) | Proteolytic enzyme often used in combination with trypsin for efficient protein digestion [9]. |

| SILAC Amino Acids (e.g., 13C6-Lysine, 13C6-Arginine) | Stable isotope-labeled amino acids for metabolic labeling and quantitative comparison of protein abundance between samples [11]. |

| 15N-Ammonium Sulfate | Nitrogen source for fractional atomic labeling of cells/organisms for quantitative proteomic studies [11]. |

| Urea, Thiourea | Chaotropes for efficient protein extraction and solubilization from complex sample matrices [9]. |

| RC DC Protein Assay Kit | A detergent-compatible assay for accurate protein quantification after extraction [9]. |

| C18 Solid-Phase Extraction (SPE) Cartridges | For desalting and cleaning up peptide mixtures prior to LC-MS/MS analysis [9]. |

| High-pH Reversed-Phase Chromatography Kits | For peptide fractionation to reduce sample complexity and increase proteomic coverage [13]. |

| TMTpro Reagents | Tandem Mass Tag reagents for multiplexing, allowing simultaneous quantification of peptides from multiple samples [13]. |

The detection and quantification of specific proteins or DNA sequences in complex food matrices present significant analytical challenges. While traditional methods like Enzyme-Linked Immunosorbent Assay (ELISA) and Polymerase Chain Reaction (PCR) have been workhorse technologies for decades, they exhibit critical limitations in specificity, multiplexing capability, and robustness to food processing effects. This application note details how mass spectrometry (MS)-based proteomics, particularly through the detection of proteotypic peptides, overcomes these limitations. We present experimental protocols and data demonstrating how liquid chromatography-tandem mass spectrometry (LC-MS/MS) provides superior solutions for biomarker verification, allergen detection, and food authenticity services in complex matrices.

Traditional bioanalytical methods have served as fundamental tools for detecting proteins and nucleic acids in food products. However, their application to complex, processed food matrices reveals significant analytical challenges that can compromise result accuracy and reliability.

ELISA Limitations: The ELISA platform relies on antibody-antigen interactions, making it vulnerable to antibody cross-reactivity with non-target proteins, particularly in complex matrices containing homologous proteins [14]. Furthermore, thermal processing of foods can denature or degrade the conformational epitopes recognized by ELISA antibodies, leading to potentially false-negative results [6]. The technique also suffers from an inherent inability to multiplex effectively, requiring separate assays for different analytes and increasing sample volume requirements, analysis time, and cost [15] [6].

PCR Limitations: While PCR excels at detecting specific DNA sequences, it cannot directly quantify protein content or activity, creating a critical disconnect for applications where protein presence and quantity are clinically or regulatory relevant [6]. PCR results may also indicate the presence of a species' DNA without correlating to the actual protein concentration, especially problematic for allergenic proteins where threshold levels are based on protein content, not DNA [12].

Mass Spectrometry: A Paradigm Shift in Detection Specificity

Mass spectrometry, particularly LC-MS/MS using targeted approaches like Selected Reaction Monitoring (SRM) or Multiple Reaction Monitoring (MRM), fundamentally addresses the specificity limitations of traditional methods. Instead of relying on antibody binding or DNA amplification, MS directly detects and quantifies analytes based on their intrinsic molecular properties—mass-to-charge ratio and fragmentation patterns [16] [17].

The core innovation in MS-based protein detection involves targeting proteotypic peptides—unique peptide sequences that are specific to a parent protein and serve as reliable surrogates for its quantification [6]. This approach provides unparalleled specificity, as it can differentiate between highly homologous protein isoforms and detect specific post-translational modifications that are often invisible to immunoassays [16] [14]. MS-based methods have demonstrated detection limits as low as 0.1-5 mg kg⁻¹ (parts per million), rivaling the sensitivity of ELISA while offering significantly improved reliability in complex matrices [6].

Table 1: Comparative Analysis of Detection Technologies

| Feature | ELISA | PCR | Mass Spectrometry (LC-MS/MS) |

|---|---|---|---|

| Detection Principle | Antibody-antigen interaction [15] | DNA amplification [18] | Mass-to-charge ratio of ions [15] |

| Target Analyte | Protein (epitopes) | DNA sequences | Proteotypic peptides [6] |

| Multiplexing Capacity | Low (typically single-plex) [15] | Moderate (multiplex panels available) [18] | High (dozens to hundreds of targets) [6] [17] |

| Specificity Issues | Cross-reactivity, matrix effects [14] | Does not detect protein | High specificity via proteotypic peptides [6] |

| Effect of Food Processing | High (epitope denaturation) [6] | Low (DNA may persist) | Moderate (targets stable peptides) [6] |

| Sensitivity | 0.1-5 mg kg⁻¹ [6] | Varies by target | 0.1-5 mg kg⁻¹ (can reach femtomole) [6] [9] |

| Sample Throughput | Medium to High [15] | High | Medium (increasing with automation) [15] [17] |

Experimental Protocol: Targeted MS for Allergen Detection in Processed Foods

The following detailed protocol describes a validated workflow for multiplexed detection of allergenic proteins (e.g., from peanut, milk, and egg) in a baked goods matrix using LC-SRM/MS.

Materials and Reagents

Table 2: Research Reagent Solutions for MS-Based Allergen Detection

| Reagent / Material | Function / Application | Specifications / Notes |

|---|---|---|

| Extraction Buffer | Protein solubilization from complex food matrix | Typically contains chaotropic agents (e.g., urea), detergents, and reducing agents [9]. |

| Trypsin / Lys-C Mix | Protein digestion into peptides | Sequencing-grade enzymes for specific cleavage C-terminal to Lys and Arg [9]. |

| Stable Isotope-Labeled Peptide Standards (SIS) | Absolute quantification internal standards | Synthetic peptides identical to proteotypic peptides but with heavy isotopes (e.g., ¹³C, ¹⁵N) [6]. |

| C18 Solid-Phase Extraction (SPE) Plates | Sample clean-up and desalting | Removes interfering salts and lipids prior to LC-MS/MS analysis. |

| LC-MS/MS System | Peptide separation and detection | Nanoflow or microflow LC system coupled to triple quadrupole mass spectrometer [6] [17]. |

Step-by-Step Workflow

Step 1: Protein Extraction from Food Matrix

- Homogenize 1 g of the baked good sample with 10 mL of extraction buffer (e.g., 6 M Guanidine-HCl, 50 mM Tris-HCl, 10 mM DTT, pH 8.0) [9].

- Agitate the mixture for 2 hours at room temperature to ensure complete solubilization and reduction of disulfide bonds.

- Clarify the extract by centrifugation at 15,000 × g for 20 minutes. Transfer the supernatant containing the solubilized proteins to a new tube.

Step 2: Enzymatic Digestion into Peptides

- Determine protein concentration using a compatible assay (e.g., bicinchoninic acid assay).

- Alkylate thiol groups by adding iodoacetamide to a final concentration of 20 mM and incubating in the dark for 30 minutes.

- Dilute the sample to reduce denaturant concentration. Add trypsin/Lys-C mixture at a 1:50 (w/w) enzyme-to-protein ratio.

- Incubate at 37°C for 12-16 hours to achieve complete digestion [6] [9].

- Stop the digestion by acidifying with formic acid (final concentration 1%).

Step 3: Peptide Clean-up and Addition of Internal Standards

- Desalt the digested peptides using C18 SPE plates according to manufacturer's instructions.

- Elute peptides in a solution of 50% acetonitrile, 0.1% formic acid.

- Dry the eluents under vacuum and reconstitute in 0.1% formic acid.

- Add a known amount of stable isotope-labeled internal standard (SIS) peptides for each target proteotypic peptide to enable absolute quantification [6].

Step 4: LC-SRM/MS Analysis

- Separate peptides using a reversed-phase nanoLC system with a C18 column (75 µm × 150 mm, 2 µm particle size) and a 30-minute linear gradient of 5-35% acetonitrile in 0.1% formic acid at a flow rate of 300 nL/min.

- Introduce eluting peptides into the triple quadrupole mass spectrometer via electrospray ionization.

- Monitor 3-5 predefined precursor-product ion transitions (SRM transitions) for each proteotypic peptide and its corresponding SIS peptide. The selection of proteotypic peptides is critical and should be empirically verified for specificity and stability [6]. Example transitions for a peanut allergen (Ara h 1) peptide might be:

- Precursor ion (m/z 567.3²⁺) → Product ion (m/z 756.4)

- Precursor ion (m/z 567.3²⁺) → Product ion (m/z 863.5)

- Precursor ion (m/z 567.3²⁺) → Product ion (m/z 975.5)

Step 5: Data Analysis and Quantification

- Integrate the peak areas for both the native and SIS peptide transitions.

- Calculate the native-to-SIS peak area ratio for each target peptide.

- Interpolate the absolute amount of the native peptide (and thus the parent protein) from a calibration curve generated using synthetic peptide standards [6].

Figure 1: MS-Based Allergen Detection Workflow. The process involves protein extraction, digestion into peptides, LC separation, and highly specific MS detection.

Key Advantages of MS in Practical Applications

Unparalleled Specificity via Proteotypic Peptides

MS-based methods transcend the cross-reactivity issues of ELISA by targeting proteotypic peptides. For example, in detecting milk allergens, ELISA may struggle to distinguish between whey and casein proteins, especially when one fraction is preferentially lost during processing. In contrast, an SRM assay can independently and simultaneously quantify specific caseins (e.g., α-S1-casein) and whey proteins (e.g., β-lactoglobulin) by targeting unique peptide sequences for each, providing a more accurate and informative result [6].

Robustness to Food Processing Effects

Thermal processing can alter protein structure, masking antibody epitopes and leading to underestimation of allergen content by ELISA. MS methods that target stable, proteotypic peptides are generally more resilient to these changes. While some peptides may be modified or lost, careful selection of stable peptide targets during method development ensures reliable detection even in extensively processed foods [6].

High-Level Multiplexing for Comprehensive Analysis

The ability to monitor dozens to hundreds of peptides in a single LC-MS/MS run is a transformative advantage. A single analysis can screen for multiple allergens from different sources (e.g., peanut, milk, egg, soy), verify food authenticity by detecting species-specific peptide markers and assess the presence of protein-based toxins simultaneously [19] [9]. This multiplexing capability drastically improves analysis efficiency, reduces sample consumption, and provides a more comprehensive safety and authenticity profile compared to sequential single-plex ELISAs.

Table 3: Quantitative Performance Data of LC-MS/MS vs. ELISA

| Performance Metric | ELISA | LC-MS/MS (SRM) |

|---|---|---|

| Dynamic Range | 2-3 orders of magnitude [14] | 4-5 orders of magnitude [14] |

| Sample Volume Required | ~100 µL [15] | ~1 µL (post-digestion) [15] |

| Multiplexing Capacity | 1 protein per assay [15] | Dozens of proteins per assay [6] [17] |

| Quantitation of Specific Protein Isoforms | Limited (depends on antibody) | High (via unique peptides) [16] |

| Detection of Processed Foods | Variable; often underestimates [6] | More robust with optimized peptides [6] |

Mass spectrometry-based proteomics represents a significant technological advancement over traditional ELISA and PCR methods for the detection of proteins in complex food matrices. By directly targeting proteotypic peptides, LC-MS/MS provides superior specificity, the capacity for high-level multiplexing, and enhanced robustness to food processing effects. The experimental protocol outlined herein provides a reliable framework for researchers to implement this powerful technology for applications ranging from allergen compliance and food authenticity testing to the discovery and validation of novel protein biomarkers. As MS instrumentation and methodologies continue to evolve and become more accessible, their role in ensuring food safety and quality is poised for substantial growth.

Mass spectrometry (MS) has emerged as a powerful analytical platform for addressing critical challenges in food safety and authenticity. Its ability to detect and quantify specific protein biomarkers, known as proteotypic peptides, within complex food matrices provides researchers and food development professionals with unprecedented analytical capabilities. These peptides are uniquely representative of their parent proteins, exhibiting robust detection regardless of variations in food matrix, sample preparation protocol, and MS instrumentation [20]. The application of MS-based methods is particularly valuable for analyzing processed foods where proteins may be denatured or otherwise altered, rendering traditional antibody-based detection methods less effective [21] [22]. This application note details established protocols and key applications of MS-based detection of proteotypic peptides within the framework of food safety compliance and authenticity verification.

Key Application Areas

Allergen Detection and Quantification

Food allergen detection represents one of the most critical applications of targeted MS in food safety. With the rising prevalence of food allergies worldwide, sensitive and reliable detection of trace allergens in manufactured food is essential for consumer protection and regulatory compliance [20].

- Multiplexed Detection: Unlike enzyme-linked immunosorbent assays (ELISAs), which typically target a single allergen, MS enables simultaneous quantification of multiple allergenic proteins from different sources in a single run [21] [22]. This is particularly valuable for products manufactured in facilities handling multiple allergens.

- Robustness to Processing: MS methods target specific peptide sequences rather than conformational protein epitopes, making them more robust for detecting allergens in thermally processed foods where proteins may be denatured [21].

- Sensitivity and Standardization: Selected reaction monitoring (SRM) and multiple reaction monitoring (MRM) on triple quadrupole systems provide detection limits comparable to ELISAs (0.1–5 mg kg⁻¹) while avoiding issues of antibody cross-reactivity [21]. Ongoing work focuses on standardizing proteotypic peptide targets through resources like the Allergen Peptide Browser [20].

Food Authenticity and Fraud Detection

Food authenticity verification ensures that products match their label declarations regarding origin, composition, and processing methods. MS-based foodomics approaches provide powerful tools for detecting economically motivated adulteration.

- Geographical Origin Verification: Multi-omics strategies combining proteomics, metabolomics, and lipidomics can create unique fingerprints that authenticate the geographical origin of high-value products like olive oil, honey, and wine [23].

- Species Authentication: Proteotypic peptides enable sensitive detection of species substitution in meat and seafood products, combating fraudulent labeling practices [23]. For example, LC-MS/MS methods have been developed for detecting horse and pork in halal beef [24].

- Composition Verification: MS methods can verify premium ingredients and detect substitution with inferior alternatives, such as identifying adulteration in saffron or authenticating extra virgin olive oil [25] [23].

Safety Compliance and Regulatory Monitoring

MS technologies provide robust solutions for ensuring compliance with food safety regulations through sensitive detection of contaminants and verification of label claims.

- Regulatory Compliance: MS workflows support compliance with regulations from bodies like the FDA and European Commission regarding allergen labeling and contaminant levels [26] [22]. The US FASTER Act and EU FIC No. 1169/2011 define specific allergens requiring declaration.

- Contaminant Screening: Beyond allergens, MS platforms enable comprehensive screening for pesticides, persistent organic pollutants (POPs), and other chemical contaminants in complex food matrices [26].

- Standardized Workflows: Automated solutions like the AllergenScreener standardize sample preparation and analysis across food types, delivering consistent, reliable results for regulatory decision-making [26].

Table 1: Key Mass Spectrometry Platforms for Food Analysis Applications

| Instrument Type | Key Applications | Strengths | Example Systems |

|---|---|---|---|

| Triple Quadrupole (TQ-MS) | Targeted allergen quantification, contaminant screening | High sensitivity and specificity for SRM/MRM; Excellent quantification | SCIEX Triple Quad 4500, EVOQ LC-TQ [26] [22] |

| Q-TOF (Quadrupole Time-of-Flight) | Untargeted allergen screening, food authenticity | High resolution mass accuracy; Retrospective data analysis | impact II VIP, compact QTOF [26] |

| TIMS-TOF (Trapped Ion Mobility) | Complex authenticity profiling, contaminant ID | Additional separation dimension; High confidence compound ID | timsTOF Pro 2 [26] |

| MALDI-TOF | Food fraud detection, protein profiling | Rapid analysis; Minimal sample preparation | autoflex maX [26] |

| DART-MS | Rapid screening, quality control | Chromatography-free workflows; High throughput | EVOQ DART-TQ+ [26] |

Experimental Protocols

Sample Preparation for Allergen Detection in Processed Foods

Principle: Efficient extraction and digestion of proteins into measurable peptides is crucial for reliable allergen detection, particularly in challenging matrices like baked goods or chocolate [22].

Materials:

- Protein extraction buffer (compatible with food matrix)

- Reduction and alkylation reagents: Tris(2-carboxyethyl)phosphine (TCEP) or dithiothreitol (DTT) and iodoacetamide

- Sequencing-grade modified trypsin

- Solid-phase extraction (SPE) cartridges for clean-up (C18 or mixed-mode)

- Internal standards (stable isotope-labeled peptide standards when available)

Procedure:

- Protein Extraction: Homogenize 1 g of food sample with 10 mL of appropriate extraction buffer. The buffer composition may vary based on the food matrix (e.g., consideration of fat, carbohydrate, or polyphenol content) [22].

- Reduction and Alkylation: Denature extracted proteins with 8 M urea. Reduce with 5-10 mM TCEP or DTT at 37°C for 30-60 minutes. Alkylate with 15-20 mM iodoacetamide at room temperature for 30 minutes in the dark [5].

- Digestion: Dilute urea concentration to <1.5 M. Add trypsin at 1:20-1:50 (enzyme-to-protein ratio). Incubate at 37°C for 4-16 hours with gentle agitation [21] [5].

- Clean-up: Acidify digest with formic or trifluoroacetic acid to pH <3. Desalt using C18 SPE cartridges. Elute peptides with acetonitrile/water mixture (typically 50-80% ACN). Dry under vacuum and reconstitute in MS-compatible solvent (e.g., 0.1% formic acid) [5].

- Quality Control: Monitor digestion efficiency by SDS-PAGE or using control peptides if internal standards are available.

LC-MS/MS Analysis for Multiplexed Allergen Detection

Principle: This method uses liquid chromatography coupled to tandem mass spectrometry (LC-MS/MS) with targeted scanning (SRM/MRM) to simultaneously detect and quantify multiple allergens based on proteotypic peptides [20] [24].

Materials:

- Nano or ultra-high performance liquid chromatography (UHPLC) system

- Triple quadrupole mass spectrometer

- LC column: C18 reversed-phase (75 μm-2.1 mm ID, 1.7-3 μm particle size)

- Mobile phases: A) 0.1% formic acid in water; B) 0.1% formic acid in acetonitrile

Procedure:

- Chromatographic Separation:

MS Analysis with SRM/MRM:

- Use electrospray ionization in positive mode.

- Monitor predefined transitions (precursor ion → product ion) for proteotypic peptides of target allergens.

- Optimize instrument parameters for each transition: collision energy, declustering potential, and collision cell exit potential.

- Implement retention time scheduling to maximize the number of monitored peptides without compromising sensitivity [21].

Data Analysis:

- Integrate peak areas for all transitions for each peptide.

- Verify detection based on co-elution of multiple transitions and their relative intensity ratios matching those of standard peptides.

- Quantify using calibration curves generated with heavy isotope-labeled internal standards or matrix-matched external standards [21] [5].

Food Authenticity Verification via Non-Targeted Profiling

Principle: High-resolution mass spectrometry (HRMS) enables untargeted profiling for food authenticity assessment by detecting compositional patterns and markers indicative of origin, variety, or adulteration [23].

Materials:

- UHPLC system coupled to Q-TOF or Orbitrap mass spectrometer

- Appropriate columns for targeted compounds (e.g., C18 for metabolites, HILIC for polar compounds)

- Chemical standards for method validation

Procedure:

- Sample Preparation: Prepare samples using standardized extraction protocols suitable for the food matrix and analytes of interest (e.g., metabolites, lipids).

- LC-HRMS Analysis:

- Analyze samples using UHPLC coupled to HRMS in data-dependent acquisition (DDA) or data-independent acquisition (DIA) mode.

- Use both positive and negative electrospray ionization modes for comprehensive coverage.

- Include quality control samples (pooled quality controls) throughout the sequence [23].

- Data Processing:

- Marker Verification:

- Confirm identity of potential marker compounds using authentic standards when available.

- Validate markers across multiple samples and batches to ensure robustness.

Table 2: Performance Characteristics of MS-Based Allergen Detection Methods

| Allergen Category | Reported LOD in Food | Key Proteotypic Peptides | Noteworthy Challenges |

|---|---|---|---|

| Peanut | <10 μg/g [24] | Multiple peptides from Ara h 1, Ara h 2, Ara h 3/4 [24] | High lipid content in matrices [22] |

| Tree Nuts (Hazelnut, Almond, Walnut, etc.) | <10 μg/g for several nuts [24] | 44 identified tryptic marker peptides across 6 nut species [24] | Cross-reactivity potential in antibody-based methods avoided with MS [21] |

| Milk | Comparable to ELISA (0.1-5 mg kg⁻¹) [21] | Peptides from caseins and whey proteins [20] | Differential quantification of whey vs. casein [21] |

| Egg | Comparable to ELISA (0.1-5 mg kg⁻¹) [21] | Peptides from ovalbumin and ovomucoid [20] | Robustness to thermal processing [21] |

| Soy & Wheat | Guidance available for peptide selection [20] | Limited consensus peptides identified [20] | More research needed for standardized peptides [20] |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for MS-Based Food Analysis

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Sequencing-Grade Trypsin | Proteolytic digestion of proteins into measurable peptides | Selective cleavage C-terminal to lysine and arginine; most commonly used enzyme [21] [5] |

| Stable Isotope-Labeled Peptide Standards (SIL) | Absolute quantification internal standards | Chemically synthesized with heavy isotopes (13C, 15N); identical chemical properties to native peptides [5] |

| PNGase F | Glycoprotein analysis; deglycosylation enzyme | Releases N-linked glycans from glycoproteins/glycopeptides; important for glycoprotein allergen analysis [5] |

| Hydrazide Resin | Glycopeptide enrichment | Solid-phase capture of glycopeptides for enrichment; reduces sample complexity [5] |

| C18 Solid-Phase Extraction Cartridges | Sample clean-up and desalting | Removes interfering compounds and salts prior to LC-MS analysis; improves sensitivity [5] |

| UHPLC Columns (C18, 1.7-2 μm) | Chromatographic separation of peptides | Provides high-resolution separation of complex peptide mixtures; essential for multiplexed analysis [24] [5] |

| Allergen Peptide Browser Database | Proteotypic peptide selection | Online resource (AllergenPeptideBrowser.org) for verified peptide markers [20] |

Workflow Visualization

Allergen Detection Workflow

This workflow illustrates the comprehensive process for MS-based allergen detection, encompassing three critical phases: sample preparation, LC-MS/MS analysis, and data processing, culminating in multiplexed allergen reporting.

Food Authentication Strategy

This diagram outlines the integrated multi-omics approach for food authentication, demonstrating how different analytical dimensions combine through chemometric analysis to verify origin, detect adulteration, and assess label compliance.

Mass spectrometry-based detection of proteotypic peptides provides researchers and food safety professionals with powerful tools for addressing complex challenges in allergen detection, food authenticity, and regulatory compliance. The protocols and applications detailed in this document highlight the versatility, sensitivity, and specificity of MS methodologies across diverse food matrices. As MS instrumentation, analysis software, and standardized workflows continue to advance, the role of this technology in ensuring food safety and authenticity will expand, offering increasingly robust solutions for protecting consumers and maintaining integrity in the global food supply chain. The ongoing development of verified proteotypic peptide databases and standardized methods will further enhance the reliability and adoption of MS-based approaches throughout the food industry.

From Theory to Practice: Methodological Workflows for Complex Food Matrices

Mass spectrometry (MS)-based proteomics is a powerful technique for identifying and quantifying proteins in complex biological samples [27]. Within food science, its application is crucial for detecting proteotypic peptides—unique peptide sequences that reliably represent a specific parent protein—in complex food matrices [28] [29]. This process is fundamental for food authentication, allergen profiling, and safety surveillance, such as screening for hazardous proteins in alternative protein-based foods (APBFs) [29] [9]. The workflow is multi-stage, requiring careful attention at each step, from sample preparation to data interpretation, to ensure valid and reproducible results [30]. This article provides a detailed protocol for a complete MS-based proteomics workflow, framed within the context of food analysis.

Experimental Workflow

The following diagram illustrates the comprehensive workflow for a mass spectrometry-based proteomics experiment, from sample preparation through to data analysis.

Protocols and Methodologies

Sample Preparation and Protein Extraction

Efficient protein extraction from complex food matrices is a critical first step. The complexity of APBFs, for example, poses a greater challenge than traditional meat products, requiring optimized protocols [9].

Detailed Protocol for Protein Extraction from a Polyacrylamide Gel (Applicable to Pre-separated Samples) [31]:

- Materials: Polyacrylamide gel stained with an MS-compatible stain (e.g., glutaraldehyde-free silver or Coomassie), gel destain solution, 100% acetonitrile, 10 mM dithiothreitol (DTT), 55 mM iodoacetamide (freshly prepared, light-protected), gel wash solution, gel enzyme solution (e.g., trypsin), 25 mM ammonium bicarbonate, gel extraction solution, formic acid, low-binding microcentrifuge tubes.

- Procedure:

- Excise and Destain: Wearing gloves, excise the protein band/spot of interest and place it in a low-binding microcentrifuge tube. Destain with 100 µL of appropriate destain solution for 30 minutes with vigorous shaking. Remove the destain solution and wash with 400 µL of water, repeating until the gel piece is colorless [31].

- Dehydrate: Add 400 µL of 100% acetonitrile to dehydrate the gel piece for 10 minutes. Remove the supernatant and dry the gel piece in a vacuum centrifuge [31].

- Reduce and Alkylate: Add 100 µL of 10 mM DTT and incubate for 45 minutes at 55°C to reduce disulfide bonds. Remove the DTT solution, add 100 µL of 55 mM iodoacetamide, and incubate for 30 minutes at room temperature in the dark to alkylate free cysteines. Remove the iodoacetamide solution and wash the gel piece twice with 400 µL of gel wash solution for 15 minutes per wash [31].

- Dehydrate Again: Dehydrate with 100% acetonitrile as before and dry in a vacuum centrifuge [31].

For total protein extraction from complex food matrices like APBFs, optimization is key. This often involves evaluating different extraction buffers and mechanical disruption methods (e.g., using glass beads) to maximize protein yield [9].

Proteolytic Digestion

In bottom-up proteomics, proteins are enzymatically digested into peptides for MS analysis [31] [32].

Detailed Protocol for In-Gel Digestion [31]:

- Materials: Gel enzyme working solution (e.g., sequencing-grade modified trypsin at 10-20 µg/mL in 25 mM ammonium bicarbonate).

- Procedure:

- Rehydrate the dried gel piece with a sufficient volume (e.g., 10-20 µL) of the gel enzyme working solution to cover it. Incubate on ice for 1 hour.

- After rehydration, add enough 25 mM ammonium bicarbonate to cover the gel piece again to prevent drying during digestion. Incubate at 37°C for a minimum of 4 hours or overnight.

It is worth noting that digestibility is a key criterion in selecting optimal proteotypic peptides, as incomplete digestion leads to inaccurate quantification [28]. The cleavage kinetics of trypsin can vary depending on neighboring residues [28].

Peptide Cleanup and Enrichment

Prior to MS analysis, peptides require cleanup and potential enrichment to remove salts, detergents, and other interfering compounds [31].

Detailed Protocol for Peptide Desalting using Reversed-Phase Chromatography [31]:

- Materials: C18 solid-phase extraction tips or stage tips, peptide extraction solution (e.g., 5% formic acid, 50% acetonitrile), acidified solvent (e.g., 0.1% Trifluoroacetic acid - TFA).

- Procedure (using C18 tips):

- Condition the C18 material by washing with acetonitrile.

- Equilibrate the tip with an acidified solvent like 0.1% TFA.

- Bind the peptide sample by slowly passing the acidified peptide solution through the C18 material.

- Wash with 0.1% TFA to remove salts and impurities.

- Elute the purified peptides with a solution of 50-70% acetonitrile containing 0.1% formic acid.

For specific applications like phosphoproteomics, enrichment at the peptide level using affinity capture (e.g., TiO2 beads) is performed at this stage [31].

Liquid Chromatography-Mass Spectrometry (LC-MS) Analysis

Peptides are separated by liquid chromatography and analyzed by mass spectrometry.

1. Liquid Chromatography: Peptides are loaded onto a reverse-phase C18 column and separated via a gradient of increasing organic solvent (acetonitrile). This reduces sample complexity and reduces ion suppression [27] [30]. Monitoring the stability of chromatographic parameters (peak width, shape, and retention time) is critical for reproducible and quantitative results [30].

2. Mass Spectrometry: Electrospray Ionization (ESI) is the most common ion source, transferring peptides from the liquid phase to the gas phase as ions [27]. Two primary data acquisition strategies are used:

- Data-Dependent Acquisition (DDA): The mass spectrometer automatically selects the most abundant precursor ions for fragmentation (MS/MS). This is a well-proven, sensitive method [32].

- Data-Independent Acquisition (DIA): All precursor ions within a specific m/z window are fragmented simultaneously, providing highly reproducible data [32].

3. System Suitability and Calibration: To ensure validity of results, the LC-MS system must be calibrated and monitored. The mass spectrometer should be calibrated with a suitable calibration mixture that covers the full m/z measurement window and is compatible with ESI [30]. Furthermore, the stability of the chromatographic system should be checked using a simple calibration mixture of peptides before and during the analysis [30].

Data Analysis

The raw data from the mass spectrometer is processed to identify and quantify peptides and proteins. A modern approach involves workflow-based analysis for scalability and reproducibility [32].

1. Peptide Identification: Tandem mass spectra are matched against a protein sequence database using search engines (e.g., Sequest) [28] [32]. Parameters include precursor and fragment mass tolerances, and specified static (e.g., carbamidomethylation) and dynamic (e.g., oxidation) modifications [28].

2. Protein Inference and Quantification: Identified peptides are assembled into protein identifications. For quantification, label-free methods like MaxQuant [32] or isobaric labeling strategies (e.g., TMT, iTRAQ) can be used. In targeted proteomics, quantification relies on optimal proteotypic peptides [28]. The quantitative data is then aggregated to the protein level [32].

3. Downstream Statistical Analysis: Tools like MSstats perform more elaborate normalization, imputation, and statistical significance testing for differential expression [32].

4. Quality Control: Quality control metrics are gathered throughout the process, and tools like MultiQC provide summary statistics and plots to ensure the data is fit for purpose [32].

Key Data and Reagents

The following table summarizes the quantitative performance of a targeted proteomics method for Bovine Serum Albumin (BSA) in a food matrix, demonstrating key parameters for a valid assay [28].

Table 1: Quantitative Performance of a Targeted Proteomics Assay for BSA in Milk [28]

| Parameter | Value | Description |

|---|---|---|

| Linear Range | 1 - 100 ppm | The concentration range over which quantification is linear. |

| Coefficient of Determination (R²) | > 0.9990 | Indicates excellent linearity of the calibration curve. |

| Limit of Detection (LOD) in Milk | 0.78 mg/kg | The lowest concentration of BSA that can be reliably detected. |

| Optimal Proteotypic Peptide | LVNELTEFAK | The selected peptide representing BSA, chosen for its specificity, digestibility, recovery, and stability. |

A successful proteomics experiment relies on a suite of essential reagents and materials. The table below lists key components for the workflow.

Table 2: Research Reagent Solutions for Mass Spectrometry Proteomics

| Reagent/Material | Function / Purpose | Examples / Notes |

|---|---|---|

| Sequencing Grade Modified Trypsin | Proteolytic enzyme that specifically cleaves proteins at lysine and arginine residues. | Crucial for reproducible digestion [28]. |

| Dithiothreitol (DTT) | Reducing agent that breaks disulfide bonds between cysteine residues. | Used in sample preparation [31]. |

| Iodoacetamide (IAA) | Alkylating agent that modifies free cysteine sulfhydryl groups to prevent reformation of disulfides. | Must be prepared fresh and protected from light [31]. |

| C18 Solid Phase | Reversed-phase material for peptide desalting and cleanup prior to MS. | Packed in tips or columns [31]. |

| Ammonium Bicarbonate | Volatile buffer used in digestion protocols; easily removed during lyophilization. | Common buffer for in-solution and in-gel digestion [31]. |

| Mass Spec Calibrants | Solution of ions with known m/z for accurate mass calibration of the instrument. | Must be compatible with ESI and cover the required m/z range [30]. |

| LC-MS/MS System | Instrumentation for peptide separation (LC) and mass analysis/fragmentation (MS/MS). | High-resolution mass spectrometers (e.g., Orbitrap) are preferred [28] [30]. |

| Protein/Peptide Standards | Isotopically labeled internal standards for absolute quantification (e.g., AQUA peptides). | Allows for precise quantification in complex matrices [28]. |

This workflow overview provides a detailed guide for applying mass spectrometry from protein extraction to data analysis, with a specific focus on detecting proteotypic peptides in complex food matrices. The robustness of the results hinges on rigorous optimization at every stage, particularly sample preparation for challenging foods [9], and the implementation of a quality control system to ensure data validity [30]. By adhering to standardized protocols, using high-quality reagents, and employing reproducible data analysis workflows, researchers can reliably utilize MS-based proteomics for critical applications in food safety, authentication, and allergen research.

In the application of mass spectrometry for detecting proteotypic peptides in complex food matrices, the selection of optimal peptide biomarkers is a pivotal step that fundamentally determines the sensitivity, specificity, and reliability of the entire analytical method. Proteotypic peptides are uniquely representative of a specific protein within a proteome and exhibit consistent detectability by mass spectrometry [3]. Within food safety and allergen detection, this selection process becomes particularly critical, as regulatory compliance and consumer health depend on the accurate quantification of trace allergenic proteins in processed food products [33] [6]. This protocol details evidence-based selection criteria and methodologies for identifying robust proteotypic peptides, with particular emphasis on overcoming challenges posed by complex food matrices, food processing-induced modifications, and genetic variations in allergenic proteins.

Core Selection Criteria for Proteotypic Peptides

The selection of proteotypic peptides must balance multiple, sometimes competing, criteria to ensure analytical robustness. The following table synthesizes the essential parameters for evaluation:

Table 1: Comprehensive Criteria for Selecting Robust Proteotypic Peptides

| Criterion | Description | Rationale & Impact |

|---|---|---|

| Sequence Uniqueness | Peptide sequence must be unique to the target protein(s) within the relevant proteome(s) [3]. | Precludes false positives from homologous proteins; essential for specificity in complex food matrices [6]. |

| Absence of Polymorphisms & Modifications | Should lack high-frequency single nucleotide polymorphisms (SNPs), known post-translational modification (PTM) sites, and chemically modifiable residues (e.g., Cys, Met) unless specifically targeted [34] [3]. | Ensures consistent quantitation across samples and populations; avoids variability from incomplete alkylation or oxidation [3]. |

| Favorable Physicochemical Properties | Typically 7-25 amino acids; appropriate hydrophobicity for chromatography; predictable charge states [34]. | Ensures efficient ionization, separation, and detection; peptides outside these ranges may have poor MS response [34] [35]. |

| Stable & Efficient Generation | High predicted cleavage efficiency by trypsin; avoidance of missed cleavage sites and chemically unstable sequences [3]. | Maximizes yield and reproducibility of peptide generation from the protein digest, critical for quantitative accuracy [3]. |

| Robustness to Processing | Resistance to degradation or modification from thermal and chemical processing of foods [36]. | For food analysis, peptides must remain detectable and representative after cooking or other manufacturing processes [36]. |

| Optimal MS Detectability | Consistent production of high-intensity, predictable fragment ions (e.g., b- and y-ions) under collision-induced dissociation (CID) [34] [37]. | Directly impacts the sensitivity and limit of detection of the final MS assay. |

Experimental Protocol for Peptide Selection and Verification

This section provides a detailed workflow for the empirical identification and verification of proteotypic peptides, particularly for allergenic ingredients in food.

Stage 1: In Silico Selection and Prioritization

- Define the Target Proteome: Compile a list of canonical protein sequences for the allergen of interest (e.g., peanut, milk, egg) from reliable databases such as UniProt.

- In Silico Digestion: Perform a theoretical digestion of the target proteins using trypsin (cleaving C-terminal to Lys and Arg), with tools like the PeptideCutter web-tool on ExPASy [3].

- Apply Initial Filters: Filter the resulting peptide list based on length (e.g., 7-25 residues) and exclude peptides containing:

- Cysteine (to avoid variability from incomplete alkylation) and Methionine (susceptible to oxidation) [3].

- Known non-synonymous SNPs or sequence conflicts between databases.

- Potential sites for common PTMs (unless studied intentionally).

- Specificity BLAST: Perform a BLAST search of the candidate peptide sequences against the proteomes of all expected ingredients in the food matrix to ensure uniqueness [6] [3]. For xenograft models or complex matrices with multiple species, use tools like PeptideManager to select species-specific peptides [3].

- Check for Isoform Coverage: Determine if the candidate peptide is unique to a specific protein isoform or shared across all relevant isoforms, depending on the analytical goal [33] [36].

Stage 2: Empirical Validation Using Incurred Food Matrices

Theoretical selection must be followed by empirical validation in relevant matrices to account for real-world complexities [33] [36].

- Prepare Incurred Food Materials: Create model food systems by spiking the allergenic ingredient (e.g., peanut flour) into a non-allergenic base matrix (e.g., cookie dough, chocolate) at defined concentrations. Subject these materials to relevant processing (e.g., baking, extrusion) to mimic industrial conditions [33] [36].

- Protein Extraction and Digestion: Extract proteins from the incurred materials using a validated, buffered solution. Reduce (e.g., with DTT) and alkylate (e.g., with iodoacetamide) the extracted proteins. Digest the proteins into peptides using sequencing-grade trypsin under controlled conditions [6].

- Untargeted LC-HRMS Analysis: Analyze the resulting complex peptide digests using high-resolution, discovery-grade Liquid Chromatography-Mass Spectrometry (LC-MS/MS). Data-Dependent Acquisition (DDA) is typically employed to identify as many peptides as possible [36].

- Data Processing and Peptide Filtering: Process the raw HRMS data against a protein sequence database. Filter the resulting peptide identifications with high confidence. Then, cross-reference this empirical observation list with the in silico candidate list from Stage 1.

- Rank Final Candidate Peptides: Rank the empirically verified peptides based on:

- Signal Intensity and Consistency: Peptides consistently detected with high intensity across replicates and processing conditions are preferred [36].

- Robustness: Peptides that remain detectable across different food matrices and varying degrees of processing [36].

- Specificity: Confirmation that the peptide is only present in samples containing the target allergen.

The following workflow diagram summarizes this multi-stage protocol:

The Scientist's Toolkit: Key Reagents and Materials

Successful implementation of the selection protocol requires specific reagents and tools. The following table lists essential items and their functions.

Table 2: Essential Research Reagents and Materials for Peptide Selection Workflows

| Category | Item | Function / Application |

|---|---|---|

| Sample Preparation | Sequencing-grade modified trypsin | Specific enzymatic digestion of proteins C-terminal to Lys and Arg for reproducible peptide generation [6]. |

| Reduction & alkylation reagents (e.g., DTT, Iodoacetamide) | Breaks disulfide bonds and alkylates cysteine residues to prevent reformation, ensuring complete digestion [6]. | |

| Buffered protein extraction solutions | Efficient and consistent extraction of proteins from complex, often challenging, food matrices [6]. | |

| Mass Spectrometry | High-resolution mass spectrometer (e.g., Orbitrap) | Untargeted discovery analysis for high-confidence peptide identification in complex digests [36]. |

| Triple quadrupole mass spectrometer | Development and execution of highly sensitive targeted MS (SRM/MRM) assays using the finalized peptides [38] [6]. | |

| Stable isotope-labeled (SIL) synthetic peptides | Internal standards for precise and accurate quantification in targeted MS assays; corrects for matrix effects and losses [38] [6]. | |

| Bioinformatics & Databases | Protein sequence databases (e.g., UniProt, RefSeq) | Source of canonical protein sequences for in silico digestion and peptide identification [3]. |

| Peptide selection software (e.g., PeptideManager, SRMAtlas) | Facilitates and expedites the selection of proteotypic and species-specific peptides, checking for uniqueness [3] [39]. | |

| Spectral libraries (e.g., SRMAtlas, GPM) | Repository of validated peptide spectra for comparing and confirming experimental fragmentation patterns [37] [39]. |

Concluding Remarks

The rigorous, multi-stage process of proteotypic peptide selection outlined here—combining stringent in silico criteria with empirical validation in relevant, processed food matrices—is foundational to developing mass spectrometric methods for allergen detection that are both robust and reliable. Adherence to these protocols ensures that the selected peptide biomarkers are specific, sensitive, and stable, thereby enabling accurate quantification that protects allergic consumers and supports regulatory compliance. As mass spectrometry continues to evolve, the standardization of these selection criteria will be crucial for improving inter-laboratory reproducibility and advancing the field of food allergen analysis.

The accuracy of mass spectrometric analysis, particularly in the detection of proteotypic peptides within complex food matrices, is fundamentally dependent on the efficacy of the initial sample preparation. Inefficient protein extraction and purification can introduce biases, suppress ionization, and obscure low-abundance peptides, thereby compromising data quality and reliability. This application note provides a critical evaluation of several advanced protein precipitation techniques, including acetone, methanol-chloroform (M/C), and trichloroacetic acid (TCA)-acetone protocols. Framed within the context of proteomic analysis of complex biological samples, we present standardized protocols, quantitative performance data, and structured workflows to guide researchers in selecting and optimizing sample preparation methods for robust and reproducible mass spectrometry results.

Comparative Evaluation of Precipitation Methods

A comparative study of three common precipitation methods—acetone, methanol-chloroform (M/C), and TCA-acetone—applied to mammalian cell homogenates revealed significant differences in performance, which are critical for downstream mass spectrometry analysis [40].

Table 1: Quantitative Comparison of Protein Precipitation Methods [40]

| Precipitation Method | Key Procedural Variations | Protein Recovery (%) | Key Characteristics and Challenges |

|---|---|---|---|

| Acetone | With ultrasonic bath cycles | 104.18 ± 2.67 | Highest recovery; similar band profile to crude homogenate on SDS-PAGE. |

| Acetone | With NaOH addition | 103.12 ± 5.74 | High recovery; minimal protein loss. |

| Methanol-Chloroform (M/C) | With ultrasonic homogenization | 94.22 ± 4.86 | Intermediate recovery; does not adversely affect protein pattern on SDS-PAGE. |

| TCA-Acetone | Standard protocol | 77.91 ± 8.79 | Difficulties in pellet solubilization; negatively impacts recovery and band presence. |

| All Methods | -- | -- | Affected recovery of low molecular weight proteins (< 15 kDa). |

The data indicates that the acetone-based method, especially when augmented with an ultrasonic bath or NaOH, provides superior protein recovery and is recommended for proteomic workflows where capturing the full complexity of the cellular proteome is paramount [40]. The TCA-acetone protocol, while effective for some applications, presents significant challenges in solubilizing the resulting protein pellet, leading to lower recovery.

Detailed Experimental Protocols

Acetone Precipitation with Ultrasonication

This protocol is optimized for maximum protein recovery from cell homogenates [40].

- Sample Preparation: Start with a volume of cell homogenate containing 50-100 µg of protein in a microcentrifuge tube.

- Precipitation: Add four times the sample volume of ice-cold acetone. Vortex immediately to ensure thorough mixing.

- Ultrasonication: Place the tube in an ice-cooled ultrasonic bath for 3 cycles of 1 minute each, with 30-second intervals on ice.

- Incubation: Incubate the mixture at -20°C for a minimum of 1 hour to overnight for complete precipitation.

- Pelletting: Centrifuge at 15,000 × g for 15 minutes at 4°C. A visible protein pellet should form at the bottom of the tube.

- Washing: Carefully decant the supernatant without disturbing the pellet. Wash the pellet with 1 mL of ice-cold 80% acetone solution and vortex.

- Final Pelletting: Centrifuge again at 15,000 × g for 5 minutes at 4°C and carefully remove the entire wash supernatant.

- Drying and Solubilization: Air-dry the pellet for 5-10 minutes to evaporate residual acetone. Do not over-dry, as this will make resolubilization difficult. Solubilize the protein pellet in an appropriate buffer for downstream analysis.

Methanol-Chloroform (M/C) Precipitation

This method is effective for removing interfering substances and is suitable for lipid-rich samples [40].

- Sample Preparation: Use a volume of sample containing 50-100 µg of protein.

- Methanol Addition: Add 4 volumes of ice-cold methanol to the sample and vortex vigorously.

- Chloroform Addition: Add 1 volume of ice-cold chloroform, vortex thoroughly.

- Water Addition: Add 3 volumes of ultrapure water to create a phase separation. Vortex again until the mixture is cloudy.

- Centrifugation: Centrifuge at 14,000 × g for 15 minutes at room temperature. Proteins will form a fluffy white disc at the interface between the upper (aqueous) and lower (organic) phases.

- Aqueous Phase Removal: Carefully aspirate and discard the upper aqueous phase without disturbing the protein disc.

- Reprecipitation: Add 4 volumes of ice-cold methanol to the remaining lower phase and interphase. Vortex to mix.

- Final Pelletting: Centrifuge at 14,000 × g for 15 minutes at room temperature. The protein will now form a pellet at the bottom of the tube.

- Washing and Solubilization: Decant the supernatant and air-dry the pellet briefly. Solubilize the protein pellet in a suitable buffer.

TCA-Acetone Precipitation

This method is known for its stringency but can lead to lower recovery [40].

- Precipitation: Add an equal volume of ice-cold 20% (w/v) Trichloroacetic Acid (TCA) in acetone to the protein sample. Mix thoroughly.

- Incubation: Precipitate at -20°C for a minimum of 1 hour or overnight.

- Pelletting: Centrifuge at 15,000 × g for 15 minutes at 4°C.

- Washing: Wash the pellet twice with ice-cold acetone containing 0.07% (v/v) β-mercaptoethanol to remove residual TCA and salts.

- Drying: Air-dry the pellet to remove all traces of acetone.

- Solubilization: Solubilize the pellet in a strong denaturing buffer. This step often requires vigorous vortexing and may necessitate the use of ultrasonication to fully resuspend the difficult-to-solubilize pellet.

Workflow Visualization for Mass Spectrometry Analysis

The following diagram illustrates a generalized workflow for sample preparation in a bottom-up proteomics analysis, integrating the precipitation methods discussed.

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagent Solutions for Protein Precipitation

| Reagent / Material | Function in Sample Preparation |

|---|---|

| Acetone (HPLC grade) | Organic solvent for protein dehydration, precipitation, and washing; effectively removes water and soluble contaminants. |

| Methanol & Chloroform | Used in combination for phase separation; efficiently precipitates proteins and removes lipids and other non-polar contaminants. |

| Trichloroacetic Acid (TCA) | Strong denaturing acid that efficiently precipitates proteins; often used in an acetone mixture. |

| Ultrasonic Homogenizer / Bath | Applies ultrasonic energy to disrupt cells, fragment macromolecules, and aid in pellet resolubilization. |

| β-Mercaptoethanol / DTT | Reducing agent added to wash buffers to break disulfide bonds and prevent protein oxidation. |

| QuEChERS Kits | Ready-to-use kits for Quick, Easy, Cheap, Effective, Rugged, and Safe extraction, particularly useful for multi-residue analysis in food matrices [41]. |

| Solid-Phase Extraction (SPE) | A versatile and selective technique for purifying and concentrating analytes from complex samples, minimizing matrix effects [41]. |

The application of mass spectrometry for detecting proteotypic peptides in complex food matrices, such as spices, edible insects, and processed foods, presents significant analytical challenges. These matrices are rich in interfering compounds—including pigments, lipids, proteins, and carbohydrates—that can co-extract with target analytes, leading to ion suppression or enhancement, increased background noise, and reduced chromatographic performance. For instance, chili powder's complex matrix, rich in pigments, oils, and capsinoids, poses major challenges for accurate pesticide residue analysis by compromising sensitivity, reproducibility, and instrument longevity [42]. Similarly, edible insects contain high levels of fat and protein that complicate the extraction and analysis of pesticide residues [43]. Overcoming these matrix effects is paramount for achieving reliable quantification, particularly when employing liquid chromatography-tandem mass spectrometry (LC-MS/MS) for the precise identification and measurement of proteotypic peptides in food authentication, allergen profiling, and safety monitoring [29]. This application note details optimized protocols and strategies to mitigate these challenges, ensuring robust and reproducible results.

Optimized Sample Preparation Protocols

Effective sample preparation is the most critical step in managing complex food matrices. The following protocols are optimized to minimize matrix effects while maximizing the recovery of target peptides and analytes.

Optimized Extraction and Cleanup for Chili Powder and Spices

The following method, validated for the analysis of 135 pesticides in chili powder, can be adapted for peptide analysis from similar challenging matrices [42].

- Sample Size and Homogenization: Use a carefully optimized sample size. Smaller sizes may lack precision, while larger sizes amplify matrix effects. Pre-homogenize the sample to ensure uniformity [42].

- Extraction Solvent: Employ acetonitrile as the primary extraction solvent. It provides effective miscibility with a broad range of analytes while minimizing the co-extraction of non-polar matrix components [42] [43].

- d-SPE Cleanup: Implement a dispersive solid-phase extraction (d-SPE) cleanup. Optimize the combination of sorbents to target specific interferences [42]:

- Primary Secondary Amine (PSA): Removes organic acids and sugars.

- C18: Targets non-polar compounds like lipids and oils.

- Graphitized Carbon Black (GCB): Effective for removing pigments. Use with caution, as it can also adsorb planar molecules, potentially leading to analyte loss.

- Key Consideration: Avoid "over-cleaning" by systematically varying sorbent types and amounts to balance effective cleanup with high analyte recovery [42].

QuEChERS-Based Method for High-Fat Protein Matrices

For complex, high-fat matrices like edible insects, a modified QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) method is highly effective. The protocol below, used for pesticide analysis in insects, can be modified for protein and peptide extraction [43].

- Sample Preparation: Lyophilize (freeze-dry) samples to remove water without applying heat, thus preserving the integrity of heat-labile analytes. This also allows for better control over sample weight and solvent ratios [43].

- Extraction:

- Weigh 2.5–5.0 g of homogenized, dry sample into a 50 mL centrifuge tube.

- Add 15 mL of acetonitrile and 5 mL of water. Agitate for 5 minutes.

- Add a salt mixture (e.g., 6 g MgSO₄ and 1.5 g sodium citrate) to induce phase separation. Shake vigorously.

- Centrifuge to separate the phases [43].

- Cleanup: Transfer the supernatant to a d-SPE tube containing a combination of MgSO₄, PSA, and C18. Vortex and centrifuge. The purified extract can then be concentrated and reconstituted for LC-MS analysis [43].

General Proteomics Sample Preparation for LC-MS/MS