Overcoming Matrix Effects in Highly Processed Foods: Advanced Strategies for Reliable Allergen Detection

This article addresses the critical challenge of matrix effects that compromise the accuracy of allergen detection in complex, processed foods.

Overcoming Matrix Effects in Highly Processed Foods: Advanced Strategies for Reliable Allergen Detection

Abstract

This article addresses the critical challenge of matrix effects that compromise the accuracy of allergen detection in complex, processed foods. It provides a comprehensive resource for researchers and scientists, covering the foundational science of how food matrices interfere with analysis, evaluating advanced methodological approaches like LC-MS/MS and optimized immunoassays, detailing practical troubleshooting and extraction optimization protocols, and establishing rigorous validation frameworks. By synthesizing current research and emerging techniques, the content aims to enhance the reliability of allergen data, thereby improving food safety and supporting robust risk assessment for allergic consumers.

Understanding the Matrix Challenge: How Food Components and Processing Obscure Allergen Detection

In the critical field of food allergen detection, matrix effects represent a significant analytical challenge, particularly in highly processed foods. These effects cause a food sample's non-allergen components to interfere with the accurate detection and quantification of allergenic proteins. For researchers and drug development professionals, understanding and overcoming these interferences is paramount for ensuring food safety, regulatory compliance, and protecting public health. This guide details the common matrix-related issues encountered in the lab and provides targeted troubleshooting strategies to enhance the reliability of your experimental results.

FAQ: Understanding Matrix Effects in Allergen Detection

1. What are matrix effects and why are they problematic in allergen detection?

Matrix effects refer to the phenomenon where components in a food sample, other than the target analyte, alter the analytical signal. This can lead to either signal suppression (underestimation) or signal enhancement (overestimation) of the true allergen concentration [1]. The problem arises because food is a complex, heterogeneous system where allergenic proteins are not present in isolation but are part of a intricate microstructure containing fats, sugars, salts, and other proteins [1]. These components can interfere with the detection process, compromising the accuracy that is essential for protecting allergic consumers.

2. How does food processing influence matrix effects and allergen detection?

Processing operations (e.g., heating, fermentation, high-pressure treatment) induce physicochemical interactions between allergens and the surrounding matrix [2] [1]. For instance, thermal processing can cause allergenic proteins to denature, aggregate, or bind to other food components like carbohydrates or lipids [1]. This can "mask" the protein, making its epitopes less recognizable to antibodies in ELISA kits or altering its digestibility for LC-MS/MS analysis, ultimately leading to false negatives [3] [1]. Conversely, processing can sometimes expose new epitopes, potentially leading to false positives.

3. What are the practical consequences of protein masking?

Protein masking directly impacts the effectiveness of the most common allergen detection methods. In immunoassays like ELISA, structural changes to the protein can inhibit the antibody-protein interaction, causing the test to fail to detect an allergen that is present [3] [4]. In mass spectrometry-based methods, protein aggregation or embedding within the matrix can reduce the efficiency of enzymatic digestion into peptides and subsequent ionization, suppressing the signal [5]. This increases the risk of unsafe food reaching consumers who rely on accurate labeling.

4. Which detection methods are most susceptible to matrix effects?

All major detection methods are susceptible, but in different ways. The following table summarizes the primary susceptibility of each common method:

Table 1: Susceptibility of Allergen Detection Methods to Matrix Effects

| Detection Method | Primary Mechanism | Common Matrix Interferences |

|---|---|---|

| ELISA (Immunoassay) | Antibody-protein binding [3] | Fat content, pH, heat-induced protein denaturation, cross-reacting proteins [3] [1]. |

| PCR (DNA-based) | DNA amplification [3] | PCR inhibitors in the food matrix, degradation of DNA during processing [4]. |

| LC-MS/MS (Mass Spectrometry) | Peptide ionization and detection [6] | Ion suppression from co-eluting compounds (e.g., lipids, salts), inefficient protein extraction/digestion [6] [4]. |

Troubleshooting Guide: Overcoming Matrix Effects

Problem: Inconsistent or Erratic Results with ELISA

- Potential Cause: Signal suppression from protein masking due to thermal processing [1].

- Solution: Optimize the protein extraction buffer. Use buffers containing surfactants, reducing agents (e.g., dithiothreitol), or chaotropes (e.g., urea) to help solubilize denatured proteins and break protein-matrix interactions [7].

- Validation Step: Always use an incurred control material (a food sample with a known, added amount of allergen) that has undergone similar processing as your test samples to validate the extraction efficiency [7].

Problem: Low Signal Intensity in LC-MS/MS Analysis

- Potential Cause 1: Signal suppression from co-eluting matrix components.

- Solution 1: Incorporate a robust solid-phase extraction (SPE) cleanup step prior to LC-MS/MS analysis. This removes many interfering lipids, sugars, and salts, concentrating the target allergenic peptides [6] [4].

- Potential Cause 2: Inefficient enzymatic digestion of allergenic proteins into peptides due to aggregation or masking.

- Solution 2: Use an improved MALDI-TOF MS matrix, such as Sinapinic acid salt (SAS), which has been shown to inhibit protein aggregation and fragmentation, allowing for more reliable analysis of intact proteins [5]. Ensure proteins are fully reduced and alkylated before digestion to improve trypsin access [4].

Problem: High Background or False Positives

- Potential Cause: Non-specific binding or cross-reactivity in immunoassays, or signal enhancement from matrix components in MS.

- Solution: For ELISA, ensure proper dilution of the sample to minimize non-specific interactions. For LC-MS/MS, use tandem mass spectrometry (MS/MS) for confirmatory analysis, as the unique fragmentation patterns of target peptides provide a higher level of specificity than immunoassays or single-stage MS [6] [4].

Experimental Protocols for Mitigating Matrix Effects

Detailed Protocol: LC-MS/MS Allergen Detection with SPE Cleanup

This protocol is adapted from methodologies developed for detecting allergens in complex matrices like chocolate, cereals, and sauces [6] [4].

1. Sample Homogenization and Protein Extraction:

- Homogenize the food sample using a laboratory food processor.

- Weigh 1 g of sample into a centrifuge tube and add 10 mL of extraction buffer (e.g., 50 mM ammonium bicarbonate, 8 M urea, 10 mM dithiothreitol) [4].

- Mix thoroughly on a roller mixer for 1 hour at room temperature to reduce disulfide bonds and extract proteins.

- Centrifuge at 15,000 × g for 15 minutes. Collect the supernatant.

2. Protein Alkylation and Digestion:

- Add iodoacetamide to the extract to a final concentration of 20 mM. Incubate in the dark for 30 minutes to alkylate cysteine residues and prevent reformation of disulfide bonds [4].

- Add a digestion buffer containing trypsin (enzyme-to-substrate ratio of 1:50) and incubate overnight at 37°C to digest proteins into peptides.

3. Solid-Phase Extraction (SPE) Cleanup:

- Condition a reversed-phase SPE cartridge (e.g., Strata-X, 200 mg/6 mL) with 6 mL of acetonitrile (with 0.1% formic acid), then equilibrate with 6 mL of water (with 0.5% trifluoroacetic acid) [4].

- Load the digested sample onto the cartridge.

- Wash with 3 mL of 0.5% trifluoroacetic acid in water to remove impurities.

- Elute the allergenic peptides with 6 mL of acetonitrile.

- Evaporate the eluent to dryness under a gentle stream of nitrogen and reconstitute the residue in 300 µL of reconstitution solution (95:5:0.5 water-acetonitrile-formic acid) for LC-MS/MS analysis.

4. LC-MS/MS Analysis:

- Perform chromatographic separation using a C18 column with a gradient of water and acetonitrile, both containing 0.1% formic acid.

- Utilize Multiple Reaction Monitoring (MRM) on a triple quadrupole mass spectrometer to detect and quantify specific marker peptides for the target allergens (e.g., for pistachio and cashew) [6].

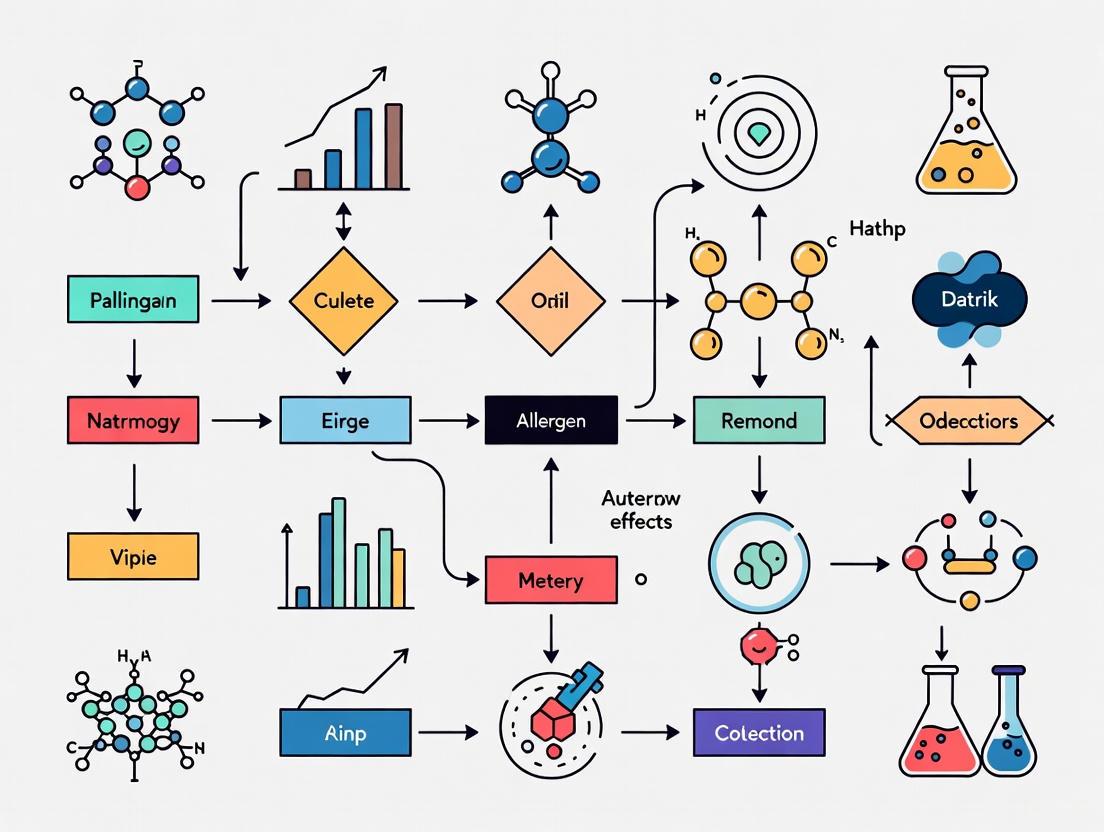

Workflow Diagram: Decision Pathway for Method Selection

This diagram outlines a logical workflow for selecting an appropriate allergen detection method based on the food matrix and processing conditions, helping to proactively manage matrix effects.

The Scientist's Toolkit: Key Research Reagent Solutions

The following reagents and materials are essential for developing robust allergen detection methods that counteract matrix effects.

Table 2: Essential Reagents for Overcoming Matrix Effects in Allergen Detection

| Reagent / Material | Function & Rationale | Application Example |

|---|---|---|

| Urea & Dithiothreitol (DTT) | Chaotropic agent and reducing agent. Disrupts hydrogen bonds and breaks disulfide bonds to solubilize denatured, aggregated proteins from processed foods [4]. | Protein extraction buffer for baked goods [4] [7]. |

| Iodoacetamide | Alkylating agent. Prevents reformation of disulfide bonds after reduction, "locking" proteins in an unfolded state for efficient enzymatic digestion [4]. | Sample preparation for LC-MS/MS to ensure complete tryptic digestion [4]. |

| Trypsin | Proteolytic enzyme. Digests intact proteins into smaller peptide fragments that are analyzable by LC-MS/MS. Efficiency is critical for accurate quantification [6] [4]. | Generation of marker peptides for targeted MS analysis of allergens like pistachio and cashew [6]. |

| Sinapinic Acid Salt (SAS) | Ionic liquid matrix for MALDI-TOF MS. Inhibits protein aggregation and prevents fragmentation during ionization, yielding more reliable molecular mass data for intact proteins [5]. | Direct analysis of intact milk allergens (e.g., α-lactalbumin, β-casein) in dairy products [5]. |

| Solid-Phase Extraction (SPE) Cartridges | Sample cleanup. Removes interfering lipids, pigments, and salts from complex food digests, reducing ion suppression and improving LC-MS/MS sensitivity [6] [4]. | Purification of allergenic peptide extracts from chocolate or meat products prior to LC-MS/MS [6]. |

Frequently Asked Questions (FAQs)

1. How do polyphenols in chocolate and fruit-based products interfere with allergen detection? Polyphenols, such as those found in dark chocolate or fruit spreads, can bind covalently and non-covalently to allergenic proteins. These interactions can mask the protein epitopes recognized by antibodies, leading to significantly reduced antibody binding and false-negative results in immunoassays. For instance, the tempering process in chocolate manufacturing has been shown to decrease antibody binding to peanut, egg, and milk proteins, regardless of the extraction buffer used [8]. Furthermore, protein-polyphenol interactions can alter protein solubility and structure, directly impacting the efficiency with which allergens can be extracted from the complex food matrix [9] [10].

2. Why is protein extraction particularly challenging from plant-based meats and other alternative proteins? Alternative protein matrices are often developed using novel processing technologies that create complex structures to mimic the texture and functionality of meat. This dense, structured matrix can trap and tightly bind proteins, making them difficult to solubilize with standard extraction buffers. One study on plant-based and fungi-derived meats found that common extraction buffers resulted in generally low protein extraction efficiencies. The development of an optimized method, which included pulverization, extended heating, and a buffer containing 5% SDS (sodium dodecyl sulfate), was required to achieve over 80% protein extraction efficiency, which is crucial for reliable allergen detection [11].

3. What role do carbohydrates play in the bioavailability and detection of other food components? Carbohydrates can interact with polyphenols and proteins, creating larger associations that affect their analysis and nutritional properties. Non-covalent interactions, such as hydrogen bonding, can occur between polyphenols and carbohydrates. In cereals, ferulic acid forms covalent cross-links with arabinoxylans, stabilizing the plant cell wall. These interactions can trap polyphenols and proteins within the carbohydrate matrix, reducing their bioaccessibility and making them more difficult to extract for analysis. This phenomenon is often observed in rye bread, contributing to what is known as "dry-baking" [12].

4. How do lipids affect the analysis of other components in a food matrix? Lipids can interact with polyphenols, potentially decreasing fat absorption but also complicating analysis. These interactions are often hydrophobic. In highly processed foods, the lipid phase can encapsulate or bind to proteins and polyphenols, creating a barrier that makes them less accessible to extraction buffers. Furthermore, the presence of fat has been shown to affect the bioaccessibility of certain polyphenols, like those in cocoa, during in vitro digestion. This encapsulating effect means that efficient disruption of the lipid phase is a critical first step in any extraction protocol for fatty matrices [10].

Troubleshooting Guides

Problem: Low Allergen Recovery from Chocolate

Background: Chocolate is a notoriously difficult matrix for allergen testing due to the presence of polyphenols, lipids, and a complex structure formed during tempering.

Investigation and Solution: A study on a model dark chocolate matrix found that tempering alone decreased antibody binding to allergenic proteins. The key to improving recovery lies in the extraction buffer composition [8].

- Step 1: Evaluate Buffer Composition. Standard phosphate-buffered saline (PBS) is often insufficient. Test buffers that include detergents or reducing agents.

- Step 2: Incorporate Detergents. The addition of a detergent like SDS can improve extraction efficiency by denaturing proteins and disrupting hydrophobic interactions with polyphenols and lipids.

- Step 3: Consider Reducing Agents. For proteins with disulfide bonds, adding a reducing agent like β-mercaptoethanol or dithiothreitol (DTT) can break these bonds and improve solubility.

Table 1: Impact of Extraction Buffer Additives on Peanut Protein Recovery from a Chocolate Matrix [8]

| Extraction Buffer Type | Key Component | Impact on Peanut Protein Recovery |

|---|---|---|

| PBS | None (Control) | Low |

| PBS + Detergent | SDS | Improved |

| PBS + Reducing Agent | DTT | Improved |

Problem: Inconsistent Allergen Test Results in Plant-Based Meats

Background: The structured, fibrous matrix of plant-based meats can physically entrap proteins and is rich in interfering compounds like polyphenols.

Investigation and Solution: Research has shown that a multi-pronged approach to sample preparation is required to achieve reproducible and accurate results [11].

- Step 1: Intensive Mechanical Disruption. Begin with thorough pulverization of the sample using a mortar and pestle under liquid nitrogen or a high-speed homogenizer. This physically breaks apart the dense matrix.

- Step 2: Optimized Chemical Lysis. Use an extraction buffer containing 5% SDS to solubilize proteins and disrupt non-covalent bonds. The high detergent concentration is key for these matrices.

- Step 3: Extended Heating. Subject the sample-buffer mixture to extended heating (e.g., 95°C for 10-15 minutes) to further denature proteins and enhance solubility.

Diagram 1: Optimized protein extraction workflow for plant-based meats.

Problem: Polyphenol-Induced Protein Precipitation and Epitope Masking

Background: In fruit-based products, cereals, and other plant foods, polyphenols can spontaneously bind to proteins, causing precipitation or conformational changes that hide antibody-binding sites.

Investigation and Solution: The binding is driven by hydrophobic interactions and hydrogen bonds, and can become covalent under oxidative conditions [9] [12].

- Step 1: Add Competitive Binding Agents. Including compounds like polyvinylpolypyrrolidone (PVPP) or skim milk in the extraction buffer can compete for polyphenol binding sites, reducing their interaction with the target proteins.

- Step 2: Use Blocking Agents in Immunoassays. Ensure the blotting or assay membrane is blocked with an effective agent (e.g., protein-based blockers) to prevent non-specific binding of polyphenols or polyphenol-protein complexes.

- Step 3: Adjust pH. Non-covalent polyphenol-protein interactions are strongest in acidic to neutral environments. Where possible, a slightly alkaline extraction pH may weaken these bonds.

Table 2: Reagent Solutions for Mitigating Polyphenol Interference

| Research Reagent | Function | Example Application |

|---|---|---|

| SDS (Sodium Dodecyl Sulfate) | Ionic detergent that denatures proteins, disrupts hydrophobic interactions, and improves solubility. | Key component (5%) in optimized extraction buffer for plant-based meats [11]. |

| PVPP (Polyvinylpolypyrrolidone) | Insoluble polymer that binds and precipitates polyphenols via hydrogen bonding, removing them from solution. | Added to extraction buffers for polyphenol-rich samples like fruit purees or cereal extracts. |

| β-Mercaptoethanol (BME) | Reducing agent that breaks disulfide bonds within and between proteins, aiding in solubilization. | Used in extraction buffers for proteins with high disulfide bond content [8]. |

Diagram 2: Polyphenol interference mechanism and mitigation strategies.

This technical support center provides troubleshooting guides and FAQs for researchers encountering matrix effects in food allergen detection. The following sections address specific experimental challenges and solutions, supported by case studies and detailed protocols.

Troubleshooting Guides

Guide: Overcoming Matrix Interference in Chocolate for Elemental Analysis

Issue: High-fat matrices like chocolate cause poor analytical precision and high background signals in techniques like Laser-Induced Breakdown Spectroscopy (LIBS) due to thermal instability and sample splashing [13].

Solution: Implement a solid-phase matrix modification using L-menthol to form a deep eutectic solvent (DES) in situ [13].

Experimental Protocol:

- Sample Preparation: Mix chocolate with L-menthol in a 1:1 (w/w) ratio.

- Heating: Heat the mixture at 65°C for 30 minutes to form a homogeneous liquid.

- Solidification: Pour the liquid into silicone molds and solidify at 4°C to create stable discs for analysis.

- Calibration: Use a matrix-matched external standard calibration prepared with L-menthol and stearic acid DES to mitigate matrix effects.

Expected Outcome: This method reduces background signals from 2-fold (for Cu) to 14-fold (for Ca) and improves coefficients of variation to 0.7–7.8% for macroelements and 4.2–4.9% for toxic metals compared to direct chocolate analysis [13].

Guide: Managing Allergen Detection in Complex Alternative Protein Matrices

Issue: Novel ingredients and intense processing in alternative proteins (plant-based meats, fungi-based proteins) create complex matrices that trap allergens, leading to low protein extraction efficiency and unreliable detection [14] [11].

Solution: Employ an optimized, high-efficiency protein extraction protocol to ensure accurate allergen quantification [14].

- Experimental Protocol:

- Pulverization: Mechanically pulverize the sample to disrupt the matrix.

- Chemical Lysis: Use an optimized extraction buffer containing 5% Sodium Dodecyl Sulfate (SDS).

- Heated Extraction: Extend the duration of heating during the extraction process to enhance protein solubility.

- Expected Outcome: This protocol achieves consistent protein extraction efficiency of at least 80% across diverse food matrices, which is vital for accurate allergen quantification and risk assessment [14].

Guide: Addressing Matrix-Induced Variations in Baked Egg Allergenicity

Issue: Minor modifications to a baked goods recipe (e.g., adding fruits like banana) can disrupt the food matrix, altering protein denaturation and increasing allergenicity, leading to false negatives in risk assessment [15].

Solution: Maintain strict adherence to standardized recipes and challenge protocols during clinical and laboratory studies [15].

- Experimental Considerations:

- Recipe Adherence: Do not alter prescribed parameters such as baking temperature, time, or ingredient proportions (see Table 1).

- Matrix Vehicle: Use only the specified flour types (e.g., wheat) and avoid incorporating unapproved additives like fruits or chocolate chips, which can displace the allergen from the matrix.

- Serving Size: Prepare individual portions (e.g., muffins) to ensure consistent heat penetration, as undercooked sections in larger items (e.g., a whole cake) can contain more allergenic protein.

- Expected Outcome: Strict protocol adherence ensures consistent protein denaturation and matrix binding, leading to reproducible allergenicity results and reliable safety recommendations [15].

Frequently Asked Questions (FAQs)

Q1: What is the "matrix effect" in food allergen analysis?

A1: The matrix effect refers to the combined influence of all components in a food sample, other than the target allergen, on the accuracy of its measurement. Components like fats, proteins, carbohydrates, and fiber can physically trap allergens, chemically interact with them, or interfere with detection methods, leading to both false-positive and false-negative results [1] [16] [17].

Q2: Why are alternative protein matrices particularly challenging for allergen testing?

A2: Alternative proteins (plant-based, insect-based, cultured meat) are often structured using novel processing technologies to mimic animal products. These processes create complex microstructures that bind proteins tightly, making them difficult to extract. Furthermore, these products contain diverse and novel ingredients, each contributing to a complex background matrix that can interfere with analytical detection methods [18] [14] [11].

Q3: How does food processing influence the matrix effect?

A3: Processing (e.g., heating, drying, fermentation) induces physicochemical interactions between food components. It can cause allergens to aggregate with other proteins or fats, hide epitopes, or create new ones. This alters how allergens are released during digestion and how they are recognized by antibodies in immunoassays or by the immune system itself [1].

Q4: What are common reagents used to overcome matrix effects in protein extraction?

A4: The table below lists key reagents used to improve protein extraction and detection from complex matrices.

Table 1: Key Research Reagent Solutions for Matrix Challenges

| Reagent | Function | Example Application |

|---|---|---|

| Sodium Dodecyl Sulfate (SDS) | Surfactant that disrupts hydrophobic interactions and solubilizes proteins. | General protein extraction; critical in optimized buffer for alternative proteins [14] [17]. |

| β-Mercaptoethanol | Reducing agent that breaks disulfide bonds within and between proteins. | Releasing allergens trapped in aggregated matrices in fish muscle [17]. |

| Ethylenediaminetetraacetic acid (EDTA) | Chelating agent that binds metal ions. Prevents metal-mediated protein aggregation. | Improving parvalbumin extractability; note: can interfere with Ca²⁺-dependent antibodies [17]. |

| L-Menthol | Matrix modifier that forms a deep eutectic solvent with fatty acids. | Solidifying high-fat chocolate samples for stable LIBS analysis [13]. |

Experimental Workflow & Signaling Pathways

The following diagram illustrates the core concept of how the food matrix influences allergen detection and clinical outcomes, integrating the case studies discussed.

Advanced Detection and Extraction Methodologies for Complex Matrices

Technical Support Center

Frequently Asked Questions (FAQs)

What are the primary advantages of transitioning from ELISA to LC-MS/MS for allergen detection?

LC-MS/MS offers several critical advantages over traditional ELISA methods, particularly for complex, processed foods. Key benefits include:

- High Precision and Specificity: LC-MS/MS differentiates between molecular isoforms, modifications, and structurally similar compounds, far exceeding ELISA's capabilities. It directly analyzes signature peptides, avoiding antibody cross-reactivity. [19] [20]

- Multiplexing Capability: Unlike ELISA, which requires a separate kit for each allergen, LC-MS/MS can detect and quantify multiple allergens simultaneously in a single analysis. [21] [20]

- Robustness to Food Processing: Antibodies used in ELISA can lose sensitivity to allergens that have been denatured or degraded during thermal processing. LC-MS/MS, which targets peptide sequences, is generally more robust to these changes. [21] [20]

- Mitigation of Matrix Effects: While both techniques can suffer from matrix interference, the use of internal standards and sophisticated sample cleanup in LC-MS/MS provides more robust and reproducible results in complex matrices. [19]

Why is my LC-MS/MS method failing to detect allergens in certain processed foods, like meat replacers?

Certain matrices, such as meat/meat replacers, are notoriously challenging due to high matrix effects that can suppress ionization or co-elute with target peptides. [22] This issue is often rooted in the sample preparation and extraction steps. To overcome this:

- Optimize the Extraction Buffer: Use a standardized, validated extraction solution. Recent studies show that using an extraction solution validated for ELISA, combined with a dedicated MS sample prep kit, can significantly improve reliability and correlation between LC-MS/MS and ELISA results. [23]

- Enhance Sample Cleanup: Implement a robust solid-phase extraction (SPE) step to remove interfering lipids, sugars, and pigments that are abundant in these matrices. This concentrates the target peptides and reduces background noise. [21]

- Verify Peptide Stability: Ensure your target "signature peptides" are not themselves degraded during the processing of the specific food matrix. [20]

My LC-MS/MS results show poor reproducibility. What steps can I take to improve this?

Poor reproducibility often stems from inconsistencies in sample preparation or instrument performance.

- Standardize Digestion: The enzymatic digestion of proteins into peptides is a critical source of variability. Use high-purity trypsin, control incubation time and temperature precisely, and consider using a digestion standard to monitor efficiency. [20]

- Use Internal Standards: Incorporate stable isotope-labeled (SIL) peptide analogues as internal standards. These correct for variations in sample preparation, ionization efficiency, and instrument performance. [20]

- Check Instrument Calibration: Recalibrate your mass spectrometry instrument using a commercial calibration solution to ensure mass accuracy and sensitivity. [24]

- Validate with a Control Standard: Regularly run a known standard, such as a HeLa protein digest, to verify overall system performance and distinguish between sample preparation and LC-MS system issues. [24]

How do I select the best "signature peptides" for LC-MS/MS allergen quantification?

Selecting the right peptides is fundamental to a successful method. Ideal signature peptides should be: [20]

- Proteotypic: Uniquely representative of the target allergenic protein and robustly generated regardless of matrix or sample preparation.

- Stable: Not prone to chemical modifications (e.g., deamidation, oxidation) during food processing or sample preparation.

- Specific: Unique to the target allergen and not present in any other proteins in the sample matrix.

- Responsive: Exhibit good ionization efficiency and produce strong, predictable fragment ions in MS/MS. Resources like the Allergen Peptide Browser (http://www.AllergenPeptideBrowser.org) can provide guidance for peptide selection. [20]

Troubleshooting Guides

Problem: Low Recovery of Allergens from Complex Matrices

Symptoms: Low signal for target peptides, failure to achieve desired detection limits, inconsistent quantitation.

| Possible Cause | Solution | Reference |

|---|---|---|

| Inefficient protein extraction | Use a reducing extraction buffer containing ammonium bicarbonate, urea, and dithiothreitol to effectively extract and denature allergen proteins from the food. | [21] |

| Matrix interference | Implement a solid-phase extraction (SPE) cleanup step after digestion to remove interfering compounds and concentrate the target peptides. | [21] |

| Inefficient enzymatic digestion | Alkylate proteins with iodoacetamide post-reduction to prevent reformation of disulfide bonds. Ensure optimal trypsin-to-protein ratio and overnight incubation for complete digestion. | [21] |

| Challenging matrix (e.g., meat) | A 2024 study recommends using an ELISA-validated extraction solution combined with an MS sample prep kit to improve recovery and correlate with established methods. | [23] |

Problem: Inaccurate Quantification Due to Matrix Effects

Symptoms: Signal suppression or enhancement, standard curve in pure solvent does not match response in sample.

| Possible Cause | Solution | Reference |

|---|---|---|

| Ion suppression | Improve chromatographic separation to separate target peptides from co-eluting matrix components. | [19] |

| Lack of correction for losses | Use stable isotope-labeled (SIL) internal standard peptides. They experience the same matrix effects and preparation losses as the native peptides, enabling accurate correction. | [20] |

| High-abundance proteins | For matrices with a dominant protein (e.g., wheat in bread), consider immunoaffinity depletion of the high-abundance protein to improve sensitivity for trace allergens. | [20] |

Experimental Protocols

Detailed Workflow: Multi-Allergen Analysis in Processed Foods using HRAM-LC-MS/MS

This protocol is adapted from a 2024 study that achieved strong correlation with ELISA values. [23]

1. Sample Homogenization:

- Process the food sample into a fine, homogeneous powder using a laboratory food processor or mill.

2. Protein Extraction:

- Mix the homogenized sample with a commercial, ELISA-validated extraction buffer. The exact composition is often proprietary but is designed to efficiently extract allergens from processed foods.

- Incubate the mixture with continuous agitation on a roller mixer for a defined period (e.g., 60 minutes).

- Centrifuge the extract to pellet insoluble debris and collect the supernatant containing the solubilized proteins.

3. Protein Denaturation, Reduction, and Alkylation:

- Add a denaturant (e.g., urea) and a reducing agent (e.g., dithiothreitol, DTT) to the extract. Incubate to break disulfide bonds.

- Alkylate the reduced thiol groups by adding iodoacetamide to prevent reformation of disulfide bonds.

4. Enzymatic Digestion:

- Add a digestion buffer (e.g., ammonium bicarbonate) and acetonitrile to the alkylated extract.

- Add a high-purity trypsin solution at an optimized enzyme-to-protein ratio.

- Incubate overnight at 37°C to allow for complete digestion of proteins into peptides.

5. Sample Cleanup and Concentration:

- Use a commercial MS sample preparation kit, which typically involves a solid-phase extraction (SPE) step.

- Condition the SPE cartridge with an organic solvent (e.g., acetonitrile with 0.1% formic acid) and equilibrate with an aqueous solution (e.g., water with 0.5% TFA).

- Load the digested sample onto the cartridge, wash with a mild acid to remove impurities, and elute the peptides with an organic solvent.

- Evaporate the eluent to dryness under a stream of nitrogen and reconstitute the peptides in a mobile-phase compatible solvent (e.g., water-acetonitrile-formic acid).

6. HRAM-LC-MS/MS Analysis:

- Inject the reconstituted sample onto a UHPLC system coupled to a high-resolution accurate mass tandem mass spectrometer.

- Use a reversed-phase C18 column for peptide separation with a gradient of water and acetonitrile, both modified with 0.1% formic acid.

- Operate the mass spectrometer in positive ion mode with data-dependent acquisition (DDA) or parallel reaction monitoring (PRM).

- Identify and quantify allergens based on the accurate mass and fragmentation spectra of their signature peptides.

Workflow and Relationship Diagrams

Allergen Detection Method Evolution

LC-MS/MS Allergen Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Example (from search results) |

|---|---|---|

| ELISA-validated Extraction Solution | Optimized for efficient extraction of allergenic proteins from difficult, processed food matrices, enabling better correlation between LC-MS/MS and ELISA data. | Used in Oyama et al. 2024 for multi-allergen analysis. [23] |

| Stable Isotope-Labeled (SIL) Peptides | Internal standards that correct for sample preparation losses and matrix-induced ionization suppression, ensuring accurate quantification. | Critical for precise allergen quantitation by MS. [20] |

| Pierce HeLa Protein Digest Standard | A complex protein digest standard used to check overall LC-MS/MS system performance and troubleshoot issues related to sample preparation or the instrument. | Cat. No. 88328 [24] |

| Pierce Peptide Retention Time Calibration Mixture | A mixture of synthetic peptides used to diagnose and troubleshoot the liquid chromatography (LC) system and gradient performance. | Cat. No. 88321 [24] |

| Trypsin (Proteomics Grade) | High-purity enzyme for specific and complete digestion of extracted proteins into peptides for MS analysis. | Used in sample preparation workflows. [21] [20] |

| Solid-Phase Extraction (SPE) Kits | Used for post-digestion sample cleanup to remove matrix interferents and concentrate target peptides, improving sensitivity and reliability. | e.g., Strata-X cartridges. [21] |

Technical Troubleshooting Guides

FAQ 1: How can I stabilize fish gelatin to prevent denaturation at higher temperatures during allergen analysis?

The Problem: Fish gelatin (a product of fish collagen hydrolysis) has poor thermal stability, with a low denaturation temperature (often 25–35°C) that is below human body temperature. This makes it unsuitable for applications requiring stability at 37°C, limiting its use in research simulating human physiological conditions [25].

The Solution: Non-covalent Stabilization with Hsp47 A highly effective strategy is the co-application of the chaperone protein Hsp47. This method stabilizes the triple-helix structure of fish collagen without covalent modification, which helps preserve its native biological functionality [25].

- Experimental Protocol:

- Materials: Fish collagen (isolated from fish skin), recombinant Hsp47 (from zebrafish or human sources).

- Complex Formation: Mix fish collagen with Hsp47 in a suitable buffer. The specific protein composite ratios should be optimized for your system.

- Stability Assessment: Use Circular Dichroism (CD) spectroscopy to determine the thermal denaturation temperature (Tm). The characteristic sigmoidal thermal transition is fitted to a two-state model to determine the Tm.

- Validation: Confirm complex formation and increased stability using techniques like Optical Nanoscopy Electron Microscopy (OpNS-EM) and FTIR spectra [25].

Expected Outcome: This method has been shown to dramatically increase the denaturation temperature of fish collagen from 31.7 °C to 37.7 °C, making it viable for in vitro applications [25].

FAQ 2: What buffer additives can enhance the separation of monomeric proteins from aggregates during purification?

The Problem: Purification of proteins, especially bispecific antibody fragments like tandem scFv, is often challenging due to co-elution of monomeric forms with high molecular weight (HMW) aggregates during affinity chromatography. This leads to low purity and can affect downstream applications [26].

The Solution: Salt Additives in Elution Buffers Incorporating specific salts into the elution buffer of Protein L affinity chromatography can create a preferential strengthening effect on the interaction between the resin and HMW species, thereby enhancing monomer-aggregate separation [26].

- Experimental Protocol:

- Chromatography Setup: Use a Protein L affinity resin (e.g., TOYOPEARL AF-rProtein L-650F).

- Elution Buffer Screening: Prepare elution buffers (e.g., 100 mM acetate, pH 3.0) with different additives:

- L-arginine monohydrochloride (Arg·HCl): 50-100 mM

- Sodium Chloride (NaCl): 50-500 mM

- Calcium Chloride (CaCl₂): 50-500 mM

- Elution and Analysis: Perform a two-step elution process. The first elution is with the salt-additive buffer, and the second is with the additive-free buffer. Analyze the fractions using HPLC-SEC to determine monomer and HMW content [26].

Expected Outcome: Among the tested salts, Arg·HCl has been identified as the most effective, yielding optimal product purity and recovery. A two-step purification process using this strategy can achieve a final product with <1% HMW species and an overall yield of 65% [26].

FAQ 3: How do salt matrices in complex food samples interfere with the accurate detection of protein allergens?

The Problem: The complex matrix of highly processed foods, including various salts and other components, can significantly interfere with the accurate detection and quantification of allergens. This interference can occur by altering the structure of allergens, affecting enzymatic digestion, or directly interfering with analytical detection methods like immunoassays or LC-FLD [1] [27].

The Solution: Matrix-Matched Calibration The most reliable method to correct for salt-matrix effects is to use calibration curves prepared in a solution that matches the salinity and composition of the sample matrix [27].

- Experimental Protocol for LC-FLD Analysis:

- Sample Preparation: Extract the target analytes (e.g., proteins or other compounds) from the food matrix.

- Derivatization: Perform fluorescence derivatization (e.g., with FMOC-Cl for phosphonates).

- Calibration: Prepare a set of standard solutions with known concentrations of the target analyte. The solvent for these standards must have the same salt concentration and composition as the test samples. For example, if analyzing a sample with 3.5% salinity, all standards should be dissolved in a 3.5% saline solution.

- Quantification: Use the matrix-matched calibration curve to quantify the analytes in the unknown samples. This corrects for variations in derivatization efficiency and LC behavior caused by the salt matrix [27].

Expected Outcome: This method has been validated for analyzing compounds in seawater media, achieving excellent accuracy and precision with recoveries in the 75-125% range, despite significant salt-induced effects on the derivatization process [27].

Research Reagent Solutions

This table details key reagents and their roles in optimizing buffer systems for protein recovery and analysis.

| Research Reagent | Primary Function | Application Context |

|---|---|---|

| Hsp47 (Heat Shock Protein) | Non-covalent stabilizer of collagen triple helix; increases thermal denaturation temperature. | Stabilizing fish gelatin/collagen for applications at physiological temperatures [25]. |

| L-Arginine Monohydrochloride | Elution buffer additive; enhances separation of monomeric proteins from aggregates in affinity chromatography. | Purification of bispecific antibodies (e.g., tandem scFv) and other sensitive proteins [26]. |

| Gellan Gum (GG) | Polysaccharide used to improve gel strength, elasticity, and thermal stability of fish gelatin hydrogels. | Creating stable composite hydrogels for biomaterial applications [28]. |

| Fe₂(SO₄)₃ (Ferric Sulfate) | Cross-linking agent that forms metal-ligand coordination bonds with carboxyl groups in gelatin. | Imparting flexibility and self-healing properties to fish gelatin-based hydrogels [28]. |

| FMOC-Cl | Fluorescent derivatization agent for compounds lacking a chromophore/fluorophore. | Enabling sensitive detection of analytes like glyphosate and phosphonates via LC-FLD in complex matrices [27]. |

Table 1: Quantitative Effects of Hsp47 on Fish Collagen Stability [25]

| Parameter | Fish Collagen Alone | Fish Collagen + Hsp47 Complex |

|---|---|---|

| Denaturation Temperature (Tₘ) | 31.7 °C | 37.7 °C |

| ΔTₘ | - | +6.0 °C |

| Key Characterization Techniques | CD Spectroscopy, SDS-PAGE, FTIR | CD Spectroscopy, OpNS-EM, FTIR, Cytotoxicity Assays |

Table 2: Performance of Salt Additives in Protein L Chromatography [26]

| Salt Additive | Effectiveness (Monomer Purity / Recovery) | Key Mechanism / Note |

|---|---|---|

| L-Arginine HCl | Most effective (Optimal purity & recovery) | Preferential strengthening of HMW-Protein L interaction; salting-in mechanism. |

| CaCl₂ | Effective at reducing HMW in 1st elution peak | Strong suppression of monomer elution; can lead to co-elution in 2nd peak. |

| NaCl | Moderate effect | Tunes elution profile based on concentration. |

Experimental Workflow and Pathway Diagrams

Diagram 1: Hsp47 Collagen Stabilization Workflow

Diagram 2: Strategy for Overcoming Matrix Effects

How do complex food matrices interfere with allergen detection, and what is the core challenge?

Complex food matrices present three primary challenges that interfere with the accurate detection of allergenic proteins. First, during processing, allergenic proteins can undergo structural changes, such as unfolding, aggregation, or fragmentation, and form complexes with other matrix components like fats, polyphenols, or tannins. This can mask the protein epitopes that antibodies rely on for detection [1] [29]. Second, matrix components can directly interfere with analytical instruments. In techniques like Liquid Chromatography-Mass Spectrometry (LC-MS), co-extracted compounds can cause ion suppression or enhancement, altering the signal of the target analyte and leading to inaccurate quantification [30] [31]. Finally, the extraction process itself can be inefficient. Proteins may be physically trapped within the complex structure of the food, such as the fibrous network of plant-based meats or the fat crystals in tempered chocolate, preventing their complete release into the extraction solution [11] [29].

The core challenge, therefore, is that an allergenic protein must be fully extracted from the complex food matrix in its detectable form to provide an accurate result. Without robust sample preparation, even the most advanced detection methods will fail [32] [11].

What is a proven, efficient protein extraction method for complex alternative proteins?

Researchers have developed an optimized protocol specifically for challenging matrices like plant-based and fungi-derived meat alternatives. This method significantly enhances protein solubility and extraction reproducibility, achieving over 80% efficiency across various food types [11].

Detailed Experimental Protocol:

- Sample Preparation (Pulverization): Begin by pulverizing the sample using a mortar and pestle under liquid nitrogen, or a similar mechanical grinding method. This critical step increases the surface area of the sample, breaking down the food's physical structure and making proteins more accessible to the extraction buffer [11].

- Chemical Lysis: Use an optimized extraction buffer containing 5% Sodium Dodecyl Sulfate (SDS). SDS is a strong ionic detergent that denatures proteins and breaks apart protein-lipid and protein-protein interactions, helping to solubilize allergens that are tightly bound within the matrix [11].

- Extended Heating: Incubate the sample-buffer mixture with extended heating. The specific study validating this method used a heating step, which further promotes protein denaturation and solubilization [11].

- Clarification: Centrifuge the extracted mixture to pellet insoluble debris. The resulting supernatant, which contains the solubilized proteins, can then be used for downstream allergen detection via ELISA, LC-MS, or other immunoassays [11].

How does the choice of extraction buffer impact allergen recovery from processed foods?

The composition of the extraction buffer is critical for overcoming matrix effects. Different buffers vary in their ability to disrupt protein-matrix interactions and maintain protein solubility and immunoreactivity. The table below summarizes findings from a study on recovering allergens from a model dark chocolate matrix [29].

Table 1: Impact of Extraction Buffer on Allergen Recovery from a Chocolate Matrix

| Extraction Buffer | Key Components | Impact on Total Protein Recovery | Key Considerations |

|---|---|---|---|

| PBS / Tris Buffer | Salt, buffer agents | Low recovery | Mild buffers are often insufficient for processed matrices, leading to poor protein yield. |

| HSB (Highly Substituted Buffer) | Urea, detergents | Moderate recovery | More effective than simple buffers, but may not fully extract aggregated proteins. |

| HSB/SDS/2-ME | SDS, 2-Mercaptoethanol | Highest recovery | The combination of a detergent (SDS) and a reducing agent (2-ME) is most effective for breaking interactions and solubilizing proteins. |

The study concluded that the addition of a detergent like SDS or a reducing agent was essential for improving the extraction efficiency of peanut proteins from chocolate. It also noted that tempering (a chocolate-specific processing step) decreased antibody binding regardless of the extractant, highlighting that processing can make epitopes inaccessible even if the protein is solubilized [29].

What strategies can minimize matrix effects in LC-MS analysis for allergens?

While the previous questions focus on extraction for immunoassays, LC-MS is another powerful detection technique that is highly susceptible to matrix effects. The following strategies are employed to minimize these interferences.

Table 2: Strategies to Minimize Matrix Effects in LC-MS Analysis

| Strategy | Description | Application Example |

|---|---|---|

| Sample Dilution | Diluting the final extract reduces the concentration of interfering compounds co-eluting with the analyte. | A dilution factor of 15 markedly reduced matrix effects for pesticide analysis in food matrices [31]. |

| Reduced Injection Volume | Lowering the volume of sample injected into the LC-MS system decreases the absolute amount of interferents entering the mass spectrometer. | An effective method to mitigate ion suppression without compromising method ruggedness [31]. |

| Internal Standards | Using isotope-labeled internal standards for each analyte. These standards co-elute with the native analyte and experience the same matrix effects, allowing for accurate correction. | Considered the most effective way to compensate for matrix effects; essential for high-quality quantitative data [30] [31]. |

| Optimized Clean-up | Employing selective solid-phase extraction (SPE) or other clean-up procedures to remove specific interferents like phospholipids or salts before LC-MS analysis. | Using specific clarification cartridges during pretreatment can significantly reduce matrix effects [30] [31]. |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents for Overcoming Matrix Effects in Allergen Detection

| Reagent / Material | Function in Sample Preparation |

|---|---|

| Sodium Dodecyl Sulfate (SDS) | Ionic detergent that disrupts hydrophobic and electrostatic interactions, denatures proteins, and aids in solubilizing allergens from complex matrices [11] [29]. |

| 2-Mercaptoethanol (2-ME) | Reducing agent that breaks disulfide bonds within and between protein molecules, helping to dissociate protein aggregates [29]. |

| Urea | Chaotropic agent that disrupts hydrogen bonding, leading to protein denaturation and increased solubility [29]. |

| Isotope-Labeled Internal Standards | Synthetic versions of target allergenic peptides containing stable isotopes; added to the sample at the start of preparation to correct for analyte loss and matrix effects during LC-MS quantification [30] [31]. |

Experimental Workflow for Allergen Extraction from Complex Matrices

The following diagram illustrates the logical workflow for developing and executing an effective allergen extraction protocol, integrating the key concepts from this guide.

FAQs: Addressing Key Challenges in Allergen Extraction and Detection

1. Why is my multiplex assay showing low allergen recovery from chocolate or baked goods? Chocolate and thermally processed matrices like biscuits are particularly challenging. Components in cocoa (polyphenols) and processing-induced interactions can bind allergens, preventing their efficient release into the solution. One study found that even with optimized buffers, maximum recovery from chocolate was only around 20%, and 60% from baked muffins [33]. To overcome this, ensure you are using an extraction buffer designed to disrupt these interactions.

2. What is the best extraction buffer for simultaneously detecting multiple allergens? A single "universal" buffer is elusive, but research has identified shared extraction methods that work for many allergens. Two buffers have shown optimized recovery (50-150%) for 14 food allergens from complex matrices [33]:

- Buffer D: 0.05 M sodium carbonate/sodium bicarbonate with 10% fish gelatine, pH 9.6

- Buffer J: PBS with 2% Tween-20, 1 M NaCl, 10% fish gelatine, and 1% PVP, pH 7.4 These buffers use additives like fish gelatine to block non-specific interactions and PVP to bind polyphenols.

3. My negative control shows high background signal. What could be the cause? This pattern is indicative of a sample matrix effect [34]. You can take the following steps:

- Confirm the sample has been clarified and is free of debris and lipids by centrifuging for 5-10 minutes.

- Ensure at least a 1:1 ratio of sample to assay diluent is used for serum or plasma. For tissue homogenates, dilute appropriately to reduce detergent concentration to ≤0.01%.

- For food samples, ensure the extraction buffer contains components like fish gelatine or PVP to suppress interfering substances [33].

4. How does food processing affect my ability to detect allergens? Thermal processing (e.g., baking) can significantly alter protein structure, mask antibody-binding sites (epitopes), and promote the formation of complex bonds between allergens and other matrix components like fats or carbohydrates [1]. This can make allergens "hidden" and less extractable, leading to underestimation of their true concentration. The specific matrix matters; for instance, an egg allergen might be detectable in a standard wheat muffin but not in a banana-chocolate chip muffin due to matrix disruption [15].

Troubleshooting Guide: Low Allergen Recovery

| Observed Problem | Potential Cause | Recommended Solution |

|---|---|---|

| Low recovery across all matrices | Inefficient extraction buffer; insufficient ionic strength or disrupting agents. | Switch to a high-performance buffer, such as PBS with 2% Tween-20, 1 M NaCl, and 10% fish gelatine [33]. |

| Severely low recovery from chocolate | Polyphenols and tannins in cocoa binding to allergenic proteins. | Add 1% Polyvinylpyrrolidone (PVP) to your extraction buffer to bind and neutralize polyphenols [33]. |

| Low recovery from baked goods | Thermal processing creating cross-links between allergens and the food matrix (e.g., wheat). | Increase extraction stringency by using a buffer with a higher pH (e.g., carbonate-bicarbonate, pH 9.6) and include a surfactant like Tween-20 [33]. |

| High variability between replicates | Inconsistent sample homogenization or extraction procedure. | Standardize the extraction protocol: use a fixed sample-to-buffer ratio (e.g., 1:10), vortex mix for 30 seconds, and incubate with orbital shaking (175 rpm) at 60°C for 15 minutes [33]. |

| Clogged instrument lines or high background | Incomplete clarification of sample extracts; lipids or particulate matter. | Centrifuge clarified supernatant at 1250 rcf for 20 minutes at 4°C and carefully sample from the middle, avoiding insoluble material [33] [34]. |

Optimized Experimental Protocol: Allergen Extraction from Processed Foods

This protocol is optimized for the simultaneous extraction of multiple allergens from challenging, processed food matrices for subsequent analysis by multiplex immunoassay [33].

Materials and Reagents

Research Reagent Solutions

| Item | Function in the Protocol |

|---|---|

| Sodium Carbonate/Bicarbonate Buffer | High-pH base buffer that helps disrupt matrix-protein interactions. |

| PBS with Tween-20 & NaCl | Neutral-pH buffer with detergent (Tween-20) and high salt to solubilize proteins. |

| Fish Gelatine (FG) | A protein-blocking additive that minimizes non-specific binding of allergens to matrix components and plasticware. |

| Polyvinylpyrrolidone (PVP) | Binds and neutralizes interfering polyphenols and tannins present in matrices like chocolate. |

| Non-Fat Dry Milk (NFDM) | Alternative protein-blocking agent used in some buffer formulations. |

Step-by-Step Extraction Procedure

- Preparation: Weigh 1 g of homogenized incurred food sample into a suitable tube.

- Buffer Addition: Add 10 mL of pre-warmed extraction buffer (e.g., Buffer D or J from the table above) to achieve a 1:10 sample-to-buffer ratio.

- Extraction: Vortex mix the sample for 30 seconds to ensure thorough suspension.

- Incubation: Incubate the mixture for 15 minutes in an orbital incubator set to 60°C and shaking at 175 rpm.

- Clarification: Centrifuge at 1250 rcf for 20 minutes at 4°C.

- Collection: Carefully collect the clarified supernatant from the middle of the tube, avoiding the pellet and any floating lipid layer.

Buffer Formulations for Testing

The table below details the composition of various extraction buffers cited in research. Buffers D and J are recommended as starting points for multiplex analysis [33].

| Buffer ID | Formulation | pH |

|---|---|---|

| A | PBS, 2% Tween-20, 1 M NaCl | 7.4 |

| B | PBS, 2% Tween-20, 1 M NaCl, 10% fish gelatine | 7.4 |

| C | 0.1 M Tris, 1% SDS, 0.1 M sodium sulphite | 8.5 |

| D | 0.05 M sodium carbonate/sodium bicarbonate, 10% fish gelatine | 9.6 |

| E | 0.05 M Tris, 0.2 M NaCl, 10% fish gelatine | 8.3 |

| F | 0.1 M ammonium carbonate | 9.0 |

| G | 0.1 M ammonium carbonate, 10% fish gelatine | 9.0 |

| I | PBS, 2% Tween-20, 1 M NaCl, 0.25% BSA, 1% PVP | 7.4 |

| J | PBS, 2% Tween-20, 1 M NaCl, 10% fish gelatine, 1% PVP | 7.4 |

| K | PBS, 2% Tween-20, 1 M NaCl, 2.5% NFDM, 1% PVP | 7.4 |

Workflow and Buffer Selection Diagrams

Allergen Extraction Buffer Selection

Optimized Extraction Workflow

Practical Strategies for Mitigating Interference and Optimizing Assay Performance

Accurate allergen detection in highly processed foods is critical for public health and regulatory compliance. However, analytical methods are frequently compromised by matrix effects and specific assay limitations. Three of the most pervasive challenges are antibody cross-reactivity, the high-dose hook effect, and polyphenol interference. These pitfalls can lead to both false-positive and false-negative results, creating significant risks for allergic consumers and presenting substantial analytical hurdles for researchers and food manufacturers. This technical guide provides targeted troubleshooting methodologies to identify, understand, and overcome these issues within the context of complex food matrices, enabling the development of more robust and reliable allergen detection protocols.

Understanding and Troubleshooting Common Pitfalls

Cross-Reactivity

Root Cause: Cross-reactivity occurs when antibodies bind to non-target proteins that share structural similarities with the target allergen. This is particularly common with polyclonal antibody assays, which recognize multiple epitopes and may exhibit reactivity with related species (e.g., mustard and rapeseed) [35]. This lack of specificity is a relevant source of errors in immunological methods [36].

Troubleshooting Strategies:

- Review Validation Data: Always consult the kit manufacturer's data for detailed cross-reactivity profiles of the antibodies in use [35].

- Utilize Monoclonal Antibodies: Where possible, employ monoclonal antibody assays, which are designed for recognition of a single, specific epitope, thereby reducing the potential for cross-reactivity [36] [35].

- Conduct Matrix Validation: If an unexpected positive result occurs and the specific matrix has not been tested by the kit manufacturer, perform a comprehensive matrix validation to rule out cross-reactivity [35].

The Hook Effect

Root Cause: The hook effect, or high-dose hook effect, is a phenomenon primarily affecting immunometric assays (e.g., sandwich ELISA and Lateral Flow Devices - LFDs) where an extremely high concentration of the analyte saturates both the capture and detection antibodies. This prevents the formation of the characteristic "sandwich" complex, leading to a false-negative or artificially low signal [35].

Troubleshooting Strategies:

- Perform Dilutions: If a very high allergen concentration is suspected, dilute the sample (e.g., 1:10) and re-analyze. This simple step is often enough to restore a linear response and reveal the true analyte concentration [35].

- Interpret Lines Carefully: For LFDs, trust the control line. A missing or weak control line indicates an invalid test, not a negative result [35].

- Know the Thresholds: Be aware that the hook effect typically occurs at concentrations far exceeding regulatory thresholds, often greater than 1000 ppm, depending on the assay [35].

Polyphenol Interference

Root Cause: Complex matrices like dark chocolate, wine, and buckwheat are rich in polyphenols and tannins. These compounds can form covalent, ionic, and hydrogen bonds or hydrophobic interactions with target allergenic proteins, reducing protein solubility and extractability. Furthermore, they can directly interfere with the detection antibodies, leading to signal suppression or false negatives [35] [29].

Troubleshooting Strategies:

- Use Specialized Extraction Buffers: Mitigate interference by incorporating fish gelatin or another protein-based binding agent into the extraction buffer to bind polyphenols [35].

- Modify Buffer Composition: Improve extraction efficiency by adding detergents (e.g., SDS) or reducing agents (e.g., 2-mercaptoethanol) to the extraction buffer. These components can help disrupt protein-polyphenol complexes [29].

- Adjust Extraction pH: Optimize the extraction pH to the optimal range for the target protein, typically between pH 6.5 and 7.5, to enhance solubility and recovery [35].

Table 1: Summary of Common Pitfalls and Mitigation Strategies

| Pitfall | Root Cause | Impact on Results | Key Mitigation Strategies |

|---|---|---|---|

| Cross-Reactivity [35] | Antibodies binding to non-target proteins with similar epitopes. | False Positives | Use monoclonal antibodies; review kit cross-reactivity profiles; perform matrix validation [35]. |

| Hook Effect [35] | Analyte saturation in sandwich-style assays preventing complex formation. | False Negatives | Dilute sample (1:10); ensure control line is present and strong on LFDs [35]. |

| Polyphenol Interference [35] [29] | Polyphenols binding to proteins or antibodies, masking detection. | False Negatives / Reduced Recovery | Use extraction buffers with additives (fish gelatin, SDS, 2-ME); optimize pH [35] [29]. |

Advanced Strategy: Using Incurred Samples for Validation

A critical step in validating that a method can overcome these pitfalls, especially in processed foods, is the use of incurred samples. Unlike spiked samples (where the allergen is added after processing), incurred samples are created by adding the allergen to the food before it undergoes all processing steps (e.g., heating, tempering) [37]. This process more accurately replicates real-world scenarios where processing can denature proteins, alter epitopes, and create interactions with the matrix that dramatically affect detectability [29] [37]. Validating methods with incurred samples is increasingly recognized as a best practice by organizations like AOAC International [37].

Figure 1: Workflow comparing spiked versus incurred sample validation for detecting allergens in processed foods.

Detailed Experimental Protocols

Protocol for Overcoming Polyphenol Interference in Chocolate

This protocol is adapted from research investigating the recovery of allergens from a model dark chocolate matrix [29].

1. Sample Preparation:

- Homogenize the chocolate sample to a fine powder using a mortar and pestle.

- Weigh 1 g of the homogenized sample.

2. Buffer Selection and Extraction:

- Prepare multiple extraction buffers with different compositions. For comparison, include:

- Standard Buffers: Phosphate-buffered saline (PBS), Tris buffer.

- Enhanced Buffers: Buffers containing a surfactant like Sodium Dodecyl Sulfate (SDS) and/or a reducing agent like 2-Mercaptoethanol (2-ME) [29].

- Mix the 1 g sample with 10 mL of each buffer solution.

- Stir the mixture for a defined period (e.g., 15 minutes) to aid extraction.

3. Analysis:

- Centrifuge the extracts to remove insoluble debris.

- Analyze the supernatants using your chosen detection method (e.g., ELISA, LC-MS).

- Compare the total protein yield and the specific allergenic protein signal obtained with the different extraction buffers. The buffers containing SDS and 2-ME have been shown to significantly improve the extraction efficiency of peanut proteins from a tempered chocolate matrix [29].

Protocol for Detecting and Compensating for Matrix Effects in LC-MS

Liquid Chromatography-Mass Spectrometry (LC-MS) is highly susceptible to matrix effects, where co-eluting compounds suppress or enhance the ionization of the target analyte [38] [30]. The following method provides a quantitative assessment.

1. Post-Extraction Spike Method for Quantitative ME Assessment [30]:

- Prepare a set of blank matrix samples (e.g., allergen-free food matrix) and extract them according to your standard procedure.

- Prepare a set of pure solvent standards (e.g., in mobile phase) at the same concentrations.

- Spike a known amount of the target analyte into both the extracted blank samples and the pure solvent standards.

- Analyze all samples by LC-MS/MS.

2. Calculation:

- Compare the peak areas of the analyte in the matrix sample (Amatrix) to the peak area in the pure solvent (Asolvent).

- Calculate the Matrix Effect (ME) as a percentage: ME (%) = (Amatrix / Asolvent) × 100% [30]

- An ME < 100% indicates ion suppression, ME > 100% indicates ion enhancement, and ME = 100% indicates no matrix effect.

3. Mitigation:

- If a significant ME is observed, the use of a stable isotope-labeled internal standard (SIL-IS) is the most effective way to compensate, as it co-elutes with the analyte and experiences the same ionization effects [38] [30].

Figure 2: Strategy for mitigating matrix effects in LC-MS/MS analysis using internal standards.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents for Overcoming Allergen Detection Challenges

| Reagent / Material | Function / Application | Key Consideration |

|---|---|---|

| Monoclonal Antibodies [35] | High-specificity binding to a single epitope of a target allergen; reduces cross-reactivity. | Preferred over polyclonal antibodies for target-specific assays. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) [38] [30] | Co-elutes with analyte in LC-MS; corrects for matrix effects and variability in sample preparation. | The gold standard for compensating for matrix effects in quantitative LC-MS. |

| Specialized Extraction Buffers [35] [29] [37] | Contains additives (SDS, 2-ME, fish gelatin) to disrupt protein-matrix interactions and improve recovery. | Composition must be optimized for the specific food matrix and target allergen. |

| Incurred Reference Materials [37] | Validates method performance under realistic processing conditions where proteins are denatured and matrix-bound. | Superior to post-processing spiked samples for assessing true method efficacy. |

| Molecularly Imprinted Polymers (MIPs) [39] | Synthetic polymers with tailor-made recognition sites for specific allergens; used in novel sensor platforms. | Offers an alternative to antibodies with potential for greater stability [39]. |

Frequently Asked Questions (FAQs)

Q1: My ELISA kit for soy shows a positive result in a product that should not contain soy. What should I do? A: First, suspect cross-reactivity. Review the kit's documentation for known cross-reactive substances. To confirm, you can run a complementary method, such as a DNA-based PCR test or LC-MS, if available. If the specific food matrix is new or complex, perform a matrix validation with the kit [35].

Q2: I ran an LFD test on a sample expected to have high allergen contamination, but the test line is very faint or absent, even though the control line is visible. What does this mean? A: This is a classic sign of the hook effect. The analyte concentration is likely so high that it is saturating the assay. Dilute your sample extract 1:10 or 1:100 and re-run the test. The test line should appear strongly, confirming a high positive result [35].

Q4: Why is LC-MS/MS sometimes considered superior to ELISA for allergen detection in processed foods? A: While ELISA is a powerful and widely used tool, LC-MS/MS offers key advantages for complex matrices. It is less susceptible to issues caused by antibody cross-reactivity and can detect proteins that have been denatured or modified during processing, as it typically detects signature peptides rather than conformational epitopes. Furthermore, LC-MS/MS can screen for multiple allergens simultaneously and is highly specific and accurate when properly validated [36] [40].

FAQs: Allergen Detection in Complex Food Matrices

What are the most significant challenges when detecting allergens in high-fat matrices? High-fat foods, like chocolate or certain dairy products, are a primary source of matrix interference in allergen detection. Lipids can co-extract with target proteins, leading to issues in immunoassays such as false-negative results by obscuring antigenic sites, or false positives through non-specific binding. Furthermore, fats can foul instrumentation, particularly in LC-MS/MS systems, reducing sensitivity and reliability [41]. Effective defatting steps and the use of robust internal standards are critical for accurate analysis.

How do high-sugar matrices interfere with allergen detection methods? High-sugar foods, such as syrups or date pastes, create a challenging viscous environment that hinders the efficient extraction of allergenic proteins. The high osmolarity can also denature proteins, altering their immunoreactivity and leading to underestimated allergen levels. Additionally, sugars can cause spectral interference in mass spectrometry-based methods. Dilution and extensive sample cleanup are often required, which can impact the final detection limit of the assay [2] [42].

Why is allergen detection in fermented products particularly complex? Fermentation processes (e.g., in yogurt, cheese, or soy sauce) use microorganisms that extensively break down and modify the original food proteins. This can destroy the IgE-binding epitopes that immunoassays are designed to detect, resulting in false negatives. However, the allergenic potential for a sensitized individual may remain. Detection therefore requires methods capable of identifying stable peptide markers or residual intact protein that survive the fermentation process [2].

What are the key differences between ELISA and LC-MS/MS for detecting allergens in processed foods? The choice between ELISA (Enzyme-Linked Immunosorbent Assay) and LC-MS/MS (Liquid Chromatography Tandem Mass Spectrometry) is crucial and depends on the project's goals.

- ELISA: This immunoassay is highly sensitive and specific to the conformational structure (epitopes) of allergenic proteins. It is ideal for high-throughput screening. However, food processing can denature proteins, destroying the epitopes that ELISA antibodies recognize, which leads to false-negative results. It is also susceptible to matrix interference [2] [43].

- LC-MS/MS: This method detects signature peptides from the allergenic protein, which are more stable during processing. It is highly specific, can multiplex (detect multiple allergens simultaneously), and is less susceptible to antibody-based cross-reactivity. However, it requires more sophisticated equipment and expertise, and can be affected by matrix suppression in mass spectrometry [2] [41].

What does "Limit of Detection (LOD)" and "Limit of Quantification (LOQ)" mean in the context of allergen analysis? These parameters are critical for validating any allergen detection method.

- LOD (Limit of Detection): The lowest amount of an allergen that can be reliably detected in a specific matrix, but not necessarily quantified as an exact value. It answers the question, "Is the allergen present?" [43]

- LOQ (Limit of Quantification): The lowest amount of an allergen that can be measured with acceptable precision and accuracy. It answers the question, "How much of the allergen is present?" [43] Establishing these values for each food matrix type is essential for reporting compliant and meaningful data.

Troubleshooting Guide for Matrix Effects

This guide addresses common issues, their likely causes, and evidence-based solutions.

Table 1: Troubleshooting High-Fat Matrices

| Problem | Potential Cause | Recommended Solution |

|---|---|---|

| False negatives in immunoassays | Lipids coating or obscuring protein epitopes. | Incorporate a defatting step using hexane or petroleum ether prior to protein extraction. |

| High background noise in LC-MS/MS | Ion suppression from co-eluting lipids. | Use a more extensive sample clean-up (e.g., SPE cartridges). Employ stable isotope labelled (SIL) internal standards to correct for suppression [41]. |

| Low protein recovery | Inefficient protein extraction from fatty environment. | Optimize the extraction buffer (e.g., increase salt concentration, use detergents like CHAPS). |

Table 2: Troubleshooting High-Sugar Matrices

| Problem | Potential Cause | Recommended Solution |

|---|---|---|

| Low analytical sensitivity | Viscosity preventing efficient protein extraction. | Increase buffer-to-sample ratio; use mechanical homogenization or ultrasonic-assisted extraction to break down the matrix [42]. |

| Protein denaturation | High osmolarity from sugars. | Ensure extraction buffers are properly isotonic and contain stabilizing agents. |

| Clogged columns (LC-MS/MS) | Sugars precipitating in the system. | Implement a rigorous sample cleanup involving precipitation/digestion of sugars and filtration before injection. |

Table 3: Troubleshooting Fermented & Highly Processed Matrices

| Problem | Potential Cause | Recommended Solution |

|---|---|---|

| False negatives in ELISA | Protein hydrolysis destroying antibody-binding epitopes [2]. | Switch to an LC-MS/MS method that targets stable peptide markers which survive fermentation. |

| Inconsistent results | Variable degree of protein hydrolysis between batches. | Implement a method that quantifies multiple signature peptides to ensure a representative result. |

| Difficulty detecting markers | Complex background of peptide fragments from fermentation. | Use immuno-enrichment prior to LC-MS/MS to isolate target peptides from the complex background. |

Detailed Experimental Protocols

Protocol 1: Ultrasound-Assisted Extraction for Complex Matrices

This protocol is adapted from methods used to extract sugars from date paste [42] and can be optimized for allergen protein extraction from viscous or hard-to-disrupt matrices.

1. Principle: Ultrasound waves create cavitation bubbles in a liquid medium, which implode and generate intense local shear forces and turbulence. This phenomenon disrupts the food matrix, enhancing solvent penetration and the release of intracellular proteins, thereby improving extraction efficiency and yield.

2. Reagents:

- Extraction Buffer (e.g., Phosphate Buffered Saline, PBS)

- Food sample (ground to a fine, homogeneous powder)

- n-Hexane (for defatting, if required)

3. Equipment:

- Ultrasonic bath or probe sonicator

- Thermostatic water bath

- Laboratory balance

- Centrifuge and centrifuge tubes

- Vacuum filtration system

4. Procedure:

- Sample Preparation: Weigh 5 g of homogenized sample into a centrifuge tube.

- Defatting (for high-fat matrices): Add 20 mL of n-hexane, vortex vigorously for 2 minutes, and centrifuge at 3000 x g for 10 minutes. Carefully decant and discard the organic (top) layer. Allow the residual solvent to evaporate under a fume hood.

- Extraction: Add a predetermined volume of extraction buffer (e.g., 10 mL/g sample) to the tube.

- Sonication: Place the tube in the ultrasonic bath, ensuring the water level is above the sample mixture. Extract at a stable frequency of 35 kHz for 20 minutes, maintaining the temperature at 40°C using the thermostatic bath [42].

- Separation: Centrifuge the sample at 8000 x g for 20 minutes to pellet insoluble debris.

- Clarification: Carefully collect the supernatant and vacuum-filter it through a 0.45 µm filter.

- Analysis: The clarified extract is now ready for downstream allergen detection via ELISA, LC-MS/MS, or other methods.

Protocol 2: LC-MS/MS Allergen Detection with Interference Correction

This protocol outlines a targeted LC-MS/MS approach designed to overcome matrix interference, leveraging concepts from recent research [41].

1. Principle: Allergenic proteins are extracted, enzymatically digested into peptides, and separated by liquid chromatography. The tandem mass spectrometer detects and quantifies specific signature peptides for each allergen using Multiple Reaction Monitoring (MRM). The use of Stable Isotope Labelled (SIL) peptide analogues as internal standards corrects for variable ionization efficiency and matrix effects.

2. Reagents:

- Trypsin (sequencing grade)

- Ammonium Bicarbonate

- Dithiothreitol (DTT)

- Iodoacetamide (IAA)

- Stable Isotope Labelled (SIL) peptide analogues

- Formic Acid

- Acetonitrile (HPLC grade)

3. Equipment:

- LC-MS/MS system with triple quadrupole mass spectrometer

- C18 Reverse-Phase UHPLC column

- Thermonixer

- SpeedVac concentrator

4. Procedure:

- Protein Extraction: Obtain a protein extract using a method like the ultrasound-assisted extraction above.

- Protein Digestion:

- Denature and reduce the extract using DTT.

- Alkylate with IAA to cysteine residues.

- Digest the proteins with trypsin overnight at 37°C.

- Internal Standard Addition: Add a known amount of the corresponding SIL peptides to the digested sample. This occurs post-digestion to account for sample loss and matrix effects during the LC-MS/MS analysis [41].

- LC-MS/MS Analysis:

- Inject the peptide mixture onto the UHPLC system.

- Separate peptides on the C18 column using a water/acetonitrile gradient with 0.1% formic acid.

- Analyze eluting peptides using the mass spectrometer in positive MRM mode, monitoring specific transitions for both the native and SIL peptides.

- Data Analysis: Quantify the native allergen peptides by comparing their peak areas to the peak areas of the added SIL internal standards. Software like the open-source MADIC (Matrix-Dependent Interference Correction) can be employed to identify and correct for specific matrix interference [41].

Workflow and Pathway Diagrams

Diagram Title: Allergen Detection Workflow for Complex Matrices

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Reagents and Materials for Allergen Detection Research

| Item | Function / Application |

|---|---|

| Stable Isotope Labelled (SIL) Peptides | Internal standards for LC-MS/MS that correct for matrix effects and quantify analyte loss; critical for achieving high-quality, reproducible data [41]. |

| Specific Antibodies (for ELISA/LFD) | Immunoaffinity reagents used in ELISA test kits and Lateral Flow Devices (LFDs) for the sensitive and specific capture of intact allergenic proteins [43]. |

| Trypsin (Sequencing Grade) | Proteolytic enzyme used in sample preparation for LC-MS/MS to digest complex proteins into predictable peptides for analysis. |