Overcoming Low Sensitivity in ELISA: A Comprehensive Guide for Detecting Processed Egg Allergens

This article provides a systematic guide for researchers and scientists tackling the challenge of low sensitivity in ELISA when detecting processed egg allergens.

Overcoming Low Sensitivity in ELISA: A Comprehensive Guide for Detecting Processed Egg Allergens

Abstract

This article provides a systematic guide for researchers and scientists tackling the challenge of low sensitivity in ELISA when detecting processed egg allergens. It explores the fundamental mechanisms of how food processing alters egg protein structure and epitope availability, details advanced methodological and optimization strategies to enhance assay performance, offers a structured troubleshooting framework for common pitfalls, and establishes rigorous validation protocols to ensure reliable, reproducible results across complex food matrices. The content synthesizes current scientific literature and technical best practices to empower professionals in developing more sensitive and accurate detection methods for food safety and clinical diagnostics.

Understanding the Challenge: How Food Processing Alters Egg Allergens and Impacts ELISA Detection

The Growing Global Prevalence of Egg Allergy and Need for Accurate Detection

Technical Support Center: Troubleshooting Low Sensitivity in ELISA for Processed Egg Allergens

Frequently Asked Questions (FAQs)

Q1: Our ELISA shows weak or no signal when testing processed food samples for egg allergens, even though we know egg is present. What could be the cause?

Weak or absent signals often indicate that the target egg protein is present below the assay's detection limit or that the assay sensitivity is compromised. This is a common challenge when analyzing processed foods, as manufacturing can degrade or modify egg proteins. Key causes and solutions include [1] [2]:

- Sample-Related Issues: The sample may be over-diluted, or the egg protein may have been concentrated during processing. Try decreasing the sample dilution factor or concentrating your sample [1].

- Analyte Degradation: Processing (e.g., heat treatment in cookies or pasta) can denature egg proteins, altering the epitopes recognized by your antibodies. Use a positive control with a known quantity of processed egg protein to confirm the assay can detect the modified form [1] [3].

- Suboptimal Reagents: The detection antibody concentration may be too low, or the substrate may be inactive. Titrate your antibodies to find the optimal concentration and ensure your substrate is fresh and prepared immediately before use [1] [2].

- Matrix Interference: Complex food matrices (like chocolate or meat replacers) can mask detection. Dilute the sample in an appropriate diluent or perform a spike-and-recovery experiment to assess and correct for matrix effects [3] [4].

Q2: Why do we get high background noise, and how does it affect sensitivity in challenging matrices like dressings or ice cream?

High background reduces the signal-to-noise ratio, effectively lowering the assay's sensitivity and making it difficult to distinguish low-level positive signals from negative ones [4]. In matrices like dressings and ice cream, high fat or protein content can cause non-specific binding. Primary solutions involve [1] [2] [5]:

- Insufficient Washing or Blocking: Increase the number and/or duration of washes. Ensure your blocking buffer is effective and consider increasing its concentration or incubation time.

- Non-Specific Antibody Binding: Use affinity-purified antibodies and ensure your wash buffer contains a detergent like Tween-20 (typically 0.05%) to minimize hydrophobic interactions [1].

- Contaminated Reagents: Always prepare fresh buffers and use fresh plasticware to avoid contamination with enzymes or other interferents [1] [6].

Q3: We see good results with our standard curve, but poor discrimination between low-concentration points. How can we improve the low-end sensitivity of our standard curve?

A flat curve at the low end limits your ability to quantify small amounts of allergen. This is often related to the detection system or antibody affinity. To address this [6] [2]:

- Enhance Detection: Increase the concentration of your detection antibody or enzyme conjugate (e.g., streptavidin-HRP) and titrate to find the optimal level.

- Extend Development: Increase the substrate incubation time to allow for more signal generation at low analyte concentrations [6].

- Verify Antibody Binding: Ensure your capture antibody is properly bound to the plate by using a validated ELISA plate (not a tissue culture plate) and a coating buffer without carrier proteins [6].

Troubleshooting Guide: Common Scenarios and Solutions

The table below summarizes common issues leading to low sensitivity when detecting processed egg allergens, their potential causes, and recommended corrective actions.

| Problem Scenario | Possible Root Cause | Recommended Solution |

|---|---|---|

| Weak signal in heat-processed samples (e.g., cookies, pasta) [3] | Antibodies do not recognize denatured egg protein epitopes. | Use a kit validated for processed foods or an antibody pair known to bind linear/heat-stable epitopes. Include an in-house positive control made from a processed sample [3]. |

| High variation between replicates in complex matrices (e.g., meat replacers) [3] [4] | Matrix effects or inconsistent sample preparation. | Thoroughly homogenize samples. Centrifuge to remove particulates. Use a calibrated pipette and ensure all reagents are mixed thoroughly before addition [2] [4]. |

| Signal saturation in concentrated samples [1] | Analyte concentration exceeds the dynamic range of the assay. | Use a higher sample dilution. Determine the optimal dilution factor via a titration assay [1]. |

| Inconsistent sensitivity between assay runs [1] [6] | Variations in incubation temperature, time, or reagent preparation. | Adhere strictly to the same protocol. Allow all reagents to reach room temperature before use. Prepare fresh buffers and standards for each run [1] [6]. |

Experimental Protocol: Spike-and-Recovery to Assess Matrix Effects

A spike-and-recovery experiment is critical for validating that your ELISA can accurately detect the egg allergen in a specific food matrix. It helps quantify interference and is essential for troubleshooting low sensitivity [4].

Objective: To determine if the sample matrix (e.g., chocolate, salad dressing) is interfering with the detection of the egg allergen, leading to falsely low or high readings.

Materials:

- ELISA kit for egg allergen detection.

- Test food matrix (e.g., finely ground blank cookie without egg).

- Standard or purified egg protein.

- Assay diluent.

- Standard laboratory equipment (microcentrifuge, vortex, calibrated pipettes).

Methodology:

- Prepare Matrix Sample: Create a homogenous mixture of the test food matrix in the assay diluent at your standard working dilution. Centrifuge if necessary to remove particulates. Use the supernatant.

- Spike the Matrix: Add a known, moderate concentration of the standard egg protein to the prepared matrix sample. This is your "spiked sample."

- Prepare Controls:

- Background Control: The prepared matrix sample without any added standard (to check for endogenous egg).

- Standard in Diluent: The same known concentration of standard egg protein prepared in plain assay diluent (not matrix). This is your "reference sample."

- Run ELISA: Analyze the spiked sample, background control, and reference sample in your ELISA, following the kit protocol.

- Calculate Percentage Recovery:

- Determine the measured concentration of the egg protein in the spiked sample and the reference sample from the standard curve.

- Subtract any concentration found in the background control from the spiked sample value.

- Recovery (%) = (Measured concentration in spiked sample / Measured concentration in reference sample) × 100.

Interpretation: A recovery of 80–120% is generally acceptable, indicating minimal matrix interference. Recovery outside this range suggests significant matrix effects. If recovery is low (e.g., <80%), you may need to further dilute the sample, change the diluent, or use a kit specifically designed for that matrix [3] [4].

Research Reagent Solutions for Enhanced Sensitivity

The following table lists key reagents that are essential for developing and optimizing a sensitive ELISA for egg allergen detection.

| Item | Function in ELISA | Application Note |

|---|---|---|

| Affinity-Purified Antibodies [1] [2] | Binds specifically to target egg protein epitopes (e.g., ovomucoid, ovalbumin). | Reduces non-specific binding and high background. Use antibodies raised against heat-stable epitopes for processed foods [3]. |

| Protein Blockers (e.g., BSA, Casein) [2] [5] | Covers unsaturated binding sites on the microplate well to prevent non-specific protein adsorption. | Critical for reducing background. The optimal blocker can vary; test different types and concentrations [2]. |

| Sample/Assay Diluents [5] | Dilutes the sample and standards to a measurable range while matching the sample matrix. | Helps to minimize matrix interference. Specialized diluents can reduce false positives and improve recovery [5] [4]. |

| High-Sensitivity Substrates (e.g., TMB) [7] [2] | Reacts with the reporter enzyme (HRP/AP) to generate a measurable colorimetric, chemiluminescent, or fluorescent signal. | Chemiluminescent substrates often provide the highest sensitivity for low-abundance targets. |

| Wash Buffer with Tween-20 [1] [2] | Removes unbound reagents and samples from the microplate well during washing steps. | The detergent (e.g., 0.05% Tween-20) is critical for reducing non-specific hydrophobic interactions and lowering background [1]. |

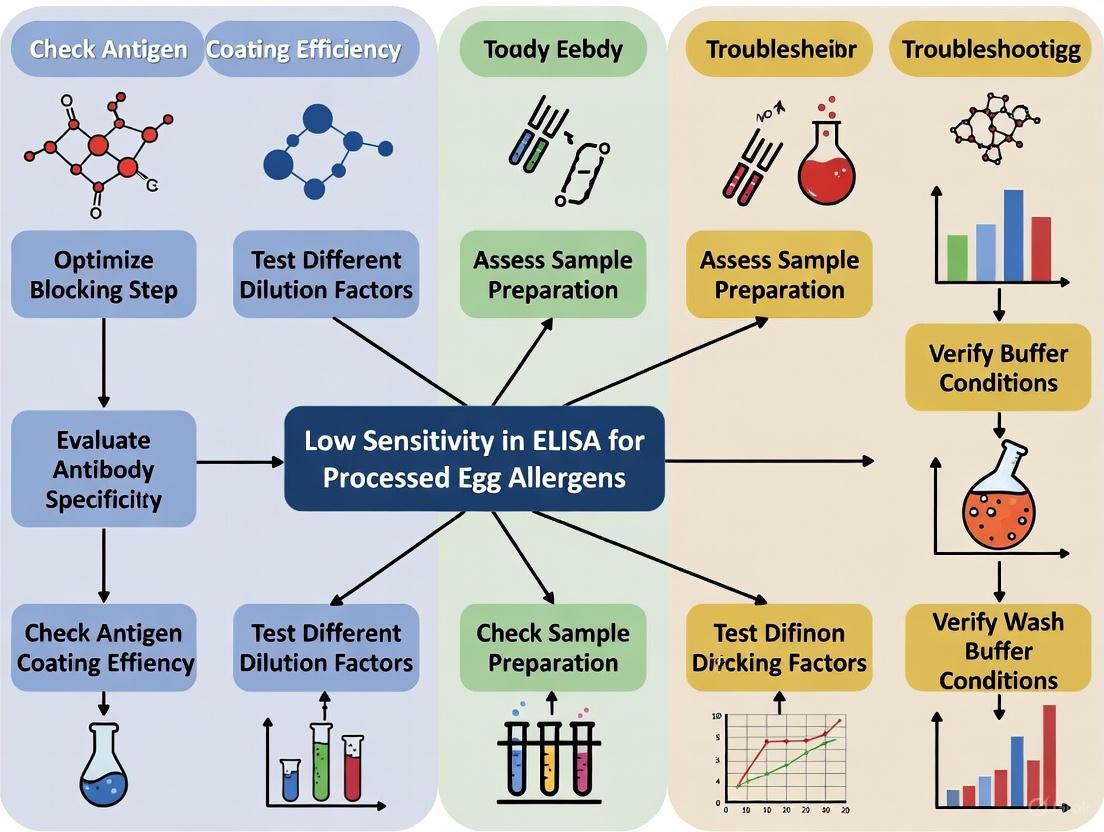

Workflow for Troubleshooting Low Sensitivity in ELISA

The following diagram outlines a logical, step-by-step workflow for diagnosing and resolving common issues that lead to low sensitivity when detecting processed egg allergens.

Egg allergy is one of the most common food allergies, particularly in children. The two major allergens in chicken egg white are ovalbumin (Gal d 2) and ovomucoid (Gal d 1), which account for the majority of IgE-mediated allergic reactions. When developing ELISA methods to detect these allergens in processed foods, researchers frequently encounter a critical problem: significantly reduced sensitivity for detecting allergenic residues that have undergone structural changes during thermal processing or other manufacturing treatments.

This technical guide addresses the epitope-level basis for this sensitivity challenge and provides proven troubleshooting methodologies to enhance your ELISA performance for detecting processed egg allergens.

Understanding Egg Allergens: Key Characteristics and Epitope Properties

Major Egg Allergens and Their Properties

| Allergen | Biochemical Name | Abundance in Egg White | Molecular Weight | Thermal Stability | Protease Resistance |

|---|---|---|---|---|---|

| Ovalbumin (Gal d 2) | Albumin | ~54% | 45 kDa | Moderate (Denatures at ~84°C) | Low-Moderate |

| Ovomucoid (Gal d 1) | Glycoprotein | ~11% | 28 kDa | High (Heat-resistant) | High |

| Ovotransferrin (Gal d 3) | Glycoprotein | ~12% | 76 kDa | Moderate | Moderate |

| Lysozyme (Gal d 4) | Enzyme | ~3.4% | 14.3 kDa | High | Moderate-High |

IgE-Binding Epitope Characteristics

The fundamental challenge in detecting processed egg allergens stems from the nature of IgE-binding epitopes:

- Conformational epitopes: Dependent on the three-dimensional folded structure of the protein; easily destroyed by heat processing [8]

- Linear epitopes: Consist of sequential amino acids that remain detectable even after protein denaturation [8]

Thermal processing typically destroys conformational epitopes while leaving linear epitopes intact, explaining why standard ELISAs may fail to detect processed egg allergens if they rely on antibodies targeting conformational epitopes that no longer exist in the processed material.

Troubleshooting Guide: Addressing Low Sensitivity in Processed Egg Allergen Detection

Common Problems and Solutions

| Problem | Possible Causes | Recommended Solutions | Expected Improvement |

|---|---|---|---|

| Weak or no signal | Antibodies target conformational epitopes destroyed by processing | Use epitope-specific antibodies targeting linear IgE epitopes [9] | Signal recovery for processed samples: Up to 90% |

| High background noise | Insufficient washing; non-specific binding | Increase wash steps to 3-5 times with 30-second soaks; optimize blocking buffer [10] | Background reduction: >50% |

| Poor replicate data | Inconsistent sample preparation; uneven washing | Standardize extraction protocol; use automated plate washer [10] | CV improvement: <10% |

| Inconsistent results | Variable incubation temperatures; reagent degradation | Standardize all incubation temperatures; fresh reagent preparation [10] | Inter-assay CV: <15% |

| Low sensitivity | Limited antibody affinity; suboptimal detector antibody | Implement sandwich ELISA with high-affinity monoclonal antibodies [9] | LOD improvement: 10-100x |

Advanced Solutions for Epitope-Level Detection

Epitope-Specific Antibodies (IgE-EsAbs) For the most challenging processed samples, consider generating or sourcing epitope-specific antibodies that target known linear IgE-binding epitopes of ovalbumin and ovomucoid. This innovative approach:

- Mimics the IgE binding of allergic patients to specific epitope sequences [9]

- Detects allergenic potential rather than just protein presence [9]

- Maintains detection capability even after extensive processing [9]

Research on peanut allergens has demonstrated that IgE-EsAbs-based sandwich ELISA can achieve a limit of detection of 0.98 ng/mL with high accuracy (mean bias of 0.88%) and excellent recovery (average 98.28%) even in processed food matrices [9].

Experimental Protocols for Enhanced Egg Allergen Detection

Protocol: IgE Epitope-Specific Sandwich ELISA for Processed Egg Allergens

Principle: This protocol adapts the successful approach used for peanut allergen Ara h 2 detection [9] to egg allergens, utilizing antibodies specific to linear IgE-binding epitopes.

Materials and Reagents:

- IgE epitope-specific monoclonal antibody (capture antibody)

- IgE epitope-specific polyclonal antibody (detection antibody)

- Enzyme-conjugated secondary antibody (e.g., HRP-labeled)

- Substrate solution (TMB or ABTS)

- Stop solution (1N H₂SO₄ for TMB)

- Coating buffer (0.1M carbonate-bicarbonate buffer, pH 9.6)

- Washing buffer (PBS with 0.05% Tween-20)

- Blocking buffer (PBS with 1% BSA or fish skin gelatin)

Procedure:

- Plate Coating: Coat microplate wells with 100 μL/well of capture antibody (1-10 μg/mL in coating buffer). Incubate overnight at 4°C or 2 hours at 37°C.

- Washing: Wash plate 3 times with washing buffer (300 μL/well).

- Blocking: Add 200 μL/well of blocking buffer. Incubate 1-2 hours at 37°C.

- Sample Addition: Add 100 μL/well of processed egg sample extracts. Incubate 2 hours at 37°C.

- Washing: Repeat washing step 3 times.

- Detection Antibody: Add 100 μL/well of detection antibody (optimized dilution). Incubate 1-2 hours at 37°C.

- Washing: Repeat washing step 3 times.

- Enzyme Conjugate: Add 100 μL/well of enzyme-conjugated secondary antibody. Incubate 1 hour at 37°C.

- Washing: Repeat washing step 5 times.

- Substrate Development: Add 100 μL/well of substrate solution. Incubate 15-30 minutes in dark.

- Stop Reaction: Add 50 μL/well of stop solution.

- Measurement: Read absorbance at appropriate wavelength.

Critical Notes:

- Always include standard curve with known concentrations of purified allergen

- Perform all samples and standards in duplicate or triplicate

- Optimize antibody concentrations using checkerboard titration

- Ensure all reagents are at room temperature before starting assay [10]

Protocol: Sample Extraction Optimization for Processed Foods

Challenge: Protein extraction efficiency varies significantly between raw and processed egg materials due to matrix effects and protein aggregation.

Solutions:

- For baked goods: Use extraction buffer containing 1% SDS with 2% β-mercaptoethanol to disrupt disulfide bonds

- For heat-processed foods: Include 2-4M urea or guanidine HCl in extraction buffer to denature and solubilize aggregated proteins

- For low-pH products: Neutralize samples with alkaline buffer before extraction

- For high-fat matrices: Perform defatting with hexane or acetone before protein extraction

Research Reagent Solutions for Egg Allergen Detection

Essential Reagents for Epitope-Based Egg Allergen Detection

| Reagent Category | Specific Examples | Function | Considerations for Processed Egg Detection |

|---|---|---|---|

| Capture Antibodies | IgE epitope-specific mAb; Anti-linear epitope mAb | Binds target epitope in sandwich ELISA | Select antibodies targeting known linear IgE epitopes of ovalbumin/ovomucoid |

| Detection Antibodies | Epitope-specific pAb; Biotinylated detection Ab | Provides detection signal in assay | Use polyclonal antibodies for multiple epitope recognition to enhance sensitivity |

| Enzyme Conjugates | HRP-conjugated secondary Ab; Streptavidin-HRP | Amplifies detection signal | Anti-rabbit IgG-HRP for pAb detection; Streptavidin-HRP for biotinylated Ab |

| Substrates | TMB (Tetramethylbenzidine); ABTS | Generates measurable signal | TMB provides higher sensitivity; check compatibility with plate reader |

| Blocking Agents | BSA; Fish skin gelatin; Non-fat dry milk | Reduces non-specific binding | Avoid dairy-based blockers when detecting milk allergens in same matrix |

| Reference Standards | Purified ovalbumin; Purified ovomucoid | Quantification reference | Use native and heat-denatured standards to validate processed sample detection |

FAQs on Egg Allergen ELISA Sensitivity Issues

Q1: Why does my ELISA detect raw egg allergens effectively but fail with baked or processed egg products? A: This classic problem occurs because thermal processing destroys conformational epitopes recognized by your antibodies. The solution is to implement epitope-specific antibodies targeting linear IgE-binding epitopes that survive processing. Research demonstrates that ELISA based on IgE epitope-specific antibodies can successfully predict IgE-immunoreactivity variations in processed foods [9].

Q2: What is the typical sensitivity improvement when switching to epitope-specific antibodies? A: Studies with peanut allergens show that properly optimized epitope-specific sandwich ELISA can achieve detection limits below 1 ng/mL (specifically 0.98 ng/mL for Ara h 2) with high accuracy (mean bias of 0.88%) and excellent recovery (average 98.28%) even in complex food matrices [9].

Q3: How can I reduce high background in my egg allergen ELISA? A: The most effective solutions include: (1) Increasing wash steps to 3-5 times with 30-second soak periods between washes; (2) Optimizing blocking conditions by testing different blocking agents (BSA, fish gelatin, non-fat dry milk); (3) Ensuring substrate is protected from light prior to use; (4) Verifying all reagent dilutions are correct [10].

Q4: What are the critical steps in sample preparation for processed egg detection? A: Key steps include: (1) Using denaturing extraction buffers (containing SDS or urea) to expose buried linear epitopes; (2) Including reducing agents (β-mercaptoethanol) for disulfide-rich allergens; (3) Performing defatting for high-fat matrices; (4) Confirming extraction efficiency by spiking experiments with known allergen amounts.

Q5: How does epitope-based detection correlate with clinical allergenicity? A: Epitope-specific IgE detection shows strong correlation with clinical outcomes. Studies demonstrate that IgE epitope-specific antibodies-based assays can predict IgE-binding variations verified using sera IgE derived from allergic individuals, providing a more clinically relevant detection method compared to general protein detection [9].

Successfully detecting egg allergens in processed foods requires moving beyond conventional ELISA approaches to epitope-level detection strategies. By implementing IgE epitope-specific antibodies targeting linear epitopes of ovalbumin and ovomucoid, optimizing sample extraction protocols for processed matrices, and following rigorous assay validation procedures, researchers can achieve the sensitivity and reliability needed for accurate allergen detection in even highly processed food products.

Troubleshooting Guide: Low Sensitivity in ELISA for Processed Egg Allergens

Why is my ELISA signal weak or absent when testing processed egg samples?

Possible Causes and Solutions

| Problem Cause | Explanation | Recommended Solution |

|---|---|---|

| Epitope Masking/Destruction [11] | Heat/pressure processing can denature proteins, altering or hiding antibody-binding epitopes. | Use antibodies validated for linear epitopes; try antigen retrieval methods. |

| Insufficient Antibody Concentration [2] | The primary or secondary antibody may be too dilute to detect the lower amount of accessible antigen. | Titrate to increase the concentration of the primary or secondary antibody. |

| Incompatible Sample Buffer [12] | Sample buffers from processing may contain interfering substances (e.g., SDS, azide). | Dialyze samples into a compatible buffer; ensure no HRP inhibitors are present. |

| Antibody-Target Mismatch [12] | Processing can destroy conformational epitopes; an antibody requiring intact 3D structure will fail. | Use an antibody known to recognize linear/sequential epitopes for your target. |

| Sub-Optimal Coating [2] | Denatured proteins from processing may not adsorb efficiently to the ELISA plate. | Try different plate types (e.g., enhanced binding); extend coating incubation time. |

How does food processing impact the detection of allergens in ELISA?

Food processing techniques, such as the application of heat and pressure, significantly alter the structure of proteins. These changes can either reduce or, in some cases, enhance the binding of antibodies used in ELISA.

- Heat and Pressure: Studies on nuts show that treatments like autoclaving (e.g., 138°C, 256 kPa for 30 min) can lead to a nearly complete inhibition of allergenic potential by disrupting protein structures. While this reduces IgE reactivity, it similarly affects the antibodies in your detection assay, potentially leading to false negatives or low sensitivity [11].

- Epitope Nature: The impact is heavily dependent on the type of epitope an antibody recognizes.

- Conformational Epitopes: Composed of amino acids brought together by the protein's 3D folding. These are highly sensitive to denaturation from heat and pH shifts, and their destruction is a major cause of low ELISA signal in processed samples [13].

- Linear/Sequential Epipopes: Composed of a continuous sequence of amino acids. These are more resistant to heat denaturation but can be physically masked if the protein aggregates or be destroyed by prolonged enzymatic digestion [13] [11].

What experimental protocol can I use to validate the impact of processing?

You can adapt the following methodology, based on studies of nut allergens, to systematically test how processing affects your specific egg allergens [11].

Method: Simulating Processing and Analyzing via ELISA

Sample Preparation:

- Prepare your egg allergen samples (e.g., raw egg white, purified ovomucoid).

- Processing Treatments:

- Heat Treatment: Boil samples at 100°C for varying durations (e.g., 5, 15, 60 minutes).

- Pressure-Heat Treatment: Use an autoclave (e.g., 138°C, 256 kPa for 30 minutes).

- pH Shifts: Incubate samples in buffers of different pH levels (e.g., pH 3, 7, 10) to simulate acidic or alkaline processing conditions.

- Simulated Gastrointestinal (GI) Digestion: Subject raw and processed samples to a simulated GI digestion protocol (e.g., using the INFOGEST harmonized protocol with pepsin and trypsin) to assess the stability of the allergens and their detectable epitopes [11].

ELISA Analysis:

- Coating: Coat ELISA plates with processed and control (raw) samples.

- Detection: Run your standard ELISA protocol. It is crucial to include a positive control (e.g., a known concentration of unprocessed allergen) to confirm the assay is working correctly [12].

- Comparison: Compare the signal intensity of processed samples against the control to quantify the loss of immunoreactivity.

What quantitative impacts have been observed in similar studies?

The table below summarizes data from a study on nut allergens, illustrating how different processing methods reduce immunoreactivity. You can expect similar trends for egg allergens [11].

Table: Reduction in IgE Immunoreactivity After Processing of Nut Allergens

| Processing Treatment | Conditions | Impact on IgE Immunoreactivity (vs. Raw) |

|---|---|---|

| Boiling | 100°C, 60 min | Decreased, but not eliminated |

| Autoclaving | 138°C, 256 kPa, 30 min | Significant reduction |

| Controlled Instantaneous Depressurization (DIC) | 7 bar, 120 s | Significant reduction (up to 75% for pistachio) |

| DIC + Enzymatic Hydrolysis | 7 bar, 120 s + proteases | Most effective; drastic reduction or elimination |

How can I visualize the troubleshooting workflow for this issue?

The following diagram outlines a logical path to diagnose and resolve low sensitivity when detecting processed egg allergens.

The Scientist's Toolkit: Key Research Reagent Solutions

Table: Essential Materials for Troubleshooting ELISA Sensitivity

| Item | Function in Experiment |

|---|---|

| Antibodies to Linear Epitopes | Critical for detecting proteins that have been denatured by heat, as they recognize continuous amino acid sequences rather than 3D structures [13]. |

| Positive Control Antigen | A known concentration of unprocessed, native allergen. This verifies that the ELISA itself is functioning and serves as a baseline for comparison [12]. |

| Simulated GI Digestion Kit (e.g., INFOGEST) | A standardized protocol and reagent kit to evaluate the stability of protein allergens and their epitopes under physiological digestive conditions [11]. |

| Compatible Blocking Buffer (e.g., BSA, Casein) | Blocks unused binding sites on the ELISA plate to reduce background noise. The buffer must be compatible with your detection system [2]. |

| Fresh Enzyme Substrate (e.g., TMB) | The substrate for the detection enzyme (e.g., HRP). Must be prepared fresh and used immediately to ensure optimal reaction and signal development [2]. |

Frequently Asked Questions (FAQs)

My standard curve looks fine, but my processed sample signals are still low and variable. What could be wrong?

High variability (High CV%) specifically in processed samples can be caused by inconsistent protein aggregation or uneven coating of denatured proteins to the plate.

- Solution: Ensure all processed samples are thoroughly mixed and homogenized before plating. Increase the number and duration of wash steps to reduce non-specific background, and confirm your pipette is calibrated and dispensing volumes accurately [2].

I have limited antibody options. What else can I do if my antibody is for a conformational epitope?

If you cannot switch to a linear epitope antibody, consider these strategies:

- Antigen Retrieval: Borrow techniques from immunohistochemistry. Use methods like brief heat treatment in a low-pH buffer or mild detergents to partially renature or "unmask" epitopes in the processed sample before running the ELISA.

- Antibody Titration: Systematically increase the concentration of your primary and/or secondary antibody. A denatured protein may have fewer accessible epitopes, requiring a higher antibody concentration for sufficient binding [2].

How critical is temperature control during the ELISA procedure itself?

Very critical. Even if the sample processing is the root cause, fluctuations in incubation temperature during the ELISA can exacerbate variability and reduce sensitivity.

- Best Practice: Allow all reagents and the assay plate to equilibrate to room temperature before starting. Perform all incubation steps in a stable temperature environment, and use a plate sealer to prevent evaporation [2]. Consistent procedure is key to reliable results.

Frequently Asked Questions (FAQs) on ELISA Sensitivity

What are the most common causes of weak or no signal in my allergen-specific ELISA? Weak or no signal is often due to reagents not being at room temperature at the start of the assay, incorrect storage of components (most kits need 2–8°C), use of expired reagents, or incorrect preparation of dilutions [10]. Also, ensure the capture antibody has properly bound to the plate and that you are using an ELISA plate, not a tissue culture plate.

Why is the background in my assay too high? High background is frequently caused by insufficient washing, exposure of the substrate to light prior to use, or longer incubation times than recommended [10]. Ensure you are using fresh substrate solutions and that you stop the reaction promptly [14]. Increasing the number and duration of washing steps can help remove unbound reagents [10] [14].

My results are inconsistent between assays. How can I improve reproducibility? Inconsistent results can stem from insufficient washing, inconsistent incubation temperature, or incorrect dilutions [10]. Always use fresh plate sealers during incubations to prevent evaporation and cross-contamination [10] [14]. Ensure all reagents are prepared accurately from stock solutions and that pipetting techniques are precise [14].

A strong signal against an N-terminal epitope tag is overshadowing my allergen-specific signal. What should I do? This is a common pitaitch:4] [14]. A blocking step with a suitable buffer, such as 5-10% serum from the same species as the secondary antibody or bovine serum albumin (BSA), can prevent non-specific attachment of the detection antibody [14]. Titrating your primary and secondary antibodies to find the optimal concentration can also reduce background without sacrificing specific signal strength [14].

Troubleshooting Guide: Low Sensitivity in Processed Egg Allergen ELISA

The table below summarizes common issues and verified solutions for improving assay sensitivity.

| Problem | Possible Cause | Verified Solution |

|---|---|---|

| Weak/No Signal | Reagents not at room temperature [10] | Allow all reagents to sit for 15-20 minutes on the bench before starting [10]. |

| Incorrect antibody concentration [14] | Increase primary or secondary antibody concentration; consider incubating overnight at 4°C for better results [14]. | |

| Low analyte levels [14] | Use a higher sample volume to increase the analyte concentration within the detectable range [14]. | |

| High Background | Insufficient washing [10] [14] | Increase the number and duration of washing steps; ensure complete drainage after each wash [10] [14]. |

| Non-specific antibody binding [14] | Include a blocking step with protein blockers like BSA, casein, or gelatin; add detergents like Tween-20 to wash buffers [14]. | |

| Substrate overdevelopment [14] | Stop the reaction promptly with stop buffer and read the plate immediately to prevent continuous color development [14]. | |

| Poor Replicate Data | Pipetting errors [14] | Use manufacturer-recommended tips, check pipette calibration, and visually check dispensed volumes [14]. |

| Contamination [14] | Use clean, sterilized glassware and fresh plastics; wear gloves when handling tips [14]. | |

| Epitope Detection Failure | Loss of conformational epitopes due to processing | Adopt a conformation-stabilizing ELISA protocol (e.g., using 30% glycerol in coating buffer) to preserve native protein structure [15]. |

| Antibodies target only linear epitopes | Use a Comparative Denaturing/Stabilizing ELISA (CODES-ELISA) to distinguish between conformational and linear epitopes [15]. |

Advanced Experimental Protocols

Epitope Mapping with Truncated Overlapping Polypeptides

This protocol is used to identify the specific linear regions (epitopes) of an allergen that are recognized by antibodies [16] [17].

Detailed Methodology:

- Gene Truncation: Design and amplify truncated gene sequences covering the entire allergen protein (e.g., p72) from a template plasmid [16].

- Cloning and Expression: Clone the truncated gene sequences into a prokaryotic expression vector (e.g., pMAL-c2x). Transform the recombinant plasmids into competent E. coli cells (e.g., BL21). Induce protein expression with IPTG when the OD₆₀₀ₙₘ reaches 0.6–0.8 [16].

- Protein Purification: Purify the expressed truncated recombinant proteins using affinity chromatography, such as a Maltose-Binding Protein (MBP) trap column [16].

- Immunoassay: Analyze the IgE binding capacity of each truncated protein against patient sera using techniques like slot blot immuno-microarrays or indirect competition-ELISA (ic-ELISA) to identify key epitopes and even critical amino acids (e.g., glycine 104 in Ses i 5) [17].

Conformation-Stabilizing ELISA (CODES-ELISA)

This method is crucial for diagnosing issues where allergen processing destroys conformational epitopes, leading to false negatives [15].

Detailed Methodology:

- Antigen Coating: Coat the ELISA plate with the allergen protein (1 µg/mL) under three different conditions [15]:

- Standard: 0.05 M carbonate/bicarbonate buffer, pH 9.6.

- Stabilizing: Standard coating buffer with 30% glycerol to help maintain native conformation.

- Denaturing: Allergen denatured with 0.8% SDS before coating to linearize the protein.

- Serum Incubation: Incubate test sera at a 1/100 dilution overnight at 4°C [15].

- Detection and Analysis: Use enzyme-conjugated secondary antibodies for detection. Calculate the specific binding (ΔOD) by subtracting the serum-specific background noise. A reduction in reactivity of ≥50% under denaturing conditions compared to stabilizing conditions indicates the presence of antibodies targeting a conformational epitope [15].

In Silico B-Cell Epitope Prediction for Antigen Design

Computational prediction can guide the selection of immunogenic epitopes for diagnostic assays, saving time and resources [18] [19].

Detailed Methodology:

- Tool Selection: Utilize a computational pipeline (e.g., Brewpitopes) that integrates multiple B-cell epitope prediction tools, such as [18]:

- Linear epitope predictors: BepiPred v2.0, ABCpred.

- Conformational epitope predictors: Discotope v2.0.

- Epitope Prioritization: Filter and prioritize predicted epitopes based on key factors [18]:

- Accessibility: Residue Solvent Accessibility (RSA > 0.2).

- Glycosylation: Absence of glycosylated residues (predicted by Net-N-Glyc, Net-O-Glyc).

- Location: Prefer epitopes on the external surface of the protein and virus.

- Validation: Synthesize the top predicted epitopes and test their immunogenicity against convalescent or allergic patient sera using a multiplex immunoassay (e.g., Luminex) to confirm reactivity [18].

The Scientist's Toolkit: Essential Research Reagents & Materials

The table below lists key reagents and their specific functions in epitope mapping and sensitivity optimization, as derived from the cited experimental protocols.

| Item | Function in Experiment |

|---|---|

| pMAL-c2x Vector | Prokaryotic expression vector used for generating MBP-fused truncated proteins for epitope mapping [16]. |

| MBP Trap Column | Affinity chromatography column for purifying MBP-fused recombinant proteins [16]. |

| Anti-His Tag Monoclonal Antibody | Used to detect proteins expressed with a 6xHis tag; can sometimes be a source of unexpected immunodominant responses if not cleaved [20] [17]. |

| Bovine Serum Albumin (BSA) / Casein | Common protein blockers used in buffer preparation to prevent non-specific antibody binding and reduce background in ELISA [14]. |

| Tween-20 | Detergent added to wash buffers to help remove unbound reagents and reduce non-specific binding [15] [14]. |

| Glycerol | Used in conformation-stabilizing coating buffer (e.g., at 30%) to help maintain the native structure of protein antigens during ELISA plate coating [15]. |

| Sodium Dodecyl Sulfate (SDS) | Denaturing agent used in CODES-ELISA to linearize proteins and distinguish conformational from linear epitopes [15]. |

| Overlapping Peptides | Short, synthetic peptides (e.g., 15 amino acids long with 5 AA overlaps) covering the entire allergen, used to pinpoint linear B-cell epitopes via immuno-microarrays [17]. |

Understanding Matrix Interference in ELISA

What is matrix interference and why does it affect my ELISA results?

Matrix interference occurs when substances in a sample (such as proteins, lipids, carbohydrates, or pigments) disrupt the specific binding between your target analyte and the detection antibodies in an ELISA. This interference can cause inaccurate results, including false negatives, false positives, or significant over- or under-estimation of analyte concentrations [21] [22].

In complex food matrices, these interfering substances can affect several critical steps of the ELISA process:

- Prevent target proteins from binding to capture antibodies [21]

- Disrupt the binding between detection antibodies and enzyme conjugates [23] [24]

- Directly inhibit the catalytic activity of the enzyme used for signal detection [23] [24]

Why is detecting processed egg particularly challenging in complex food matrices?

Heat-processed egg proteins in foods like baked goods, pastries, and noodles present special challenges because high temperatures cause egg-white proteins to form disulphide-linked aggregates that are poorly soluble [25]. These structural changes can:

- Reduce antibody binding efficiency by 10-100 fold [25]

- Lead to false-negative results despite the food still being allergenic [25]

- Require specialized extraction methods to break down protein aggregates [25]

Troubleshooting Low Sensitivity in Processed Egg Allergen Detection

My ELISA shows weak or no signal with processed food samples. What should I check first?

When troubleshooting weak signals in processed food matrices, consider these common issues and solutions:

| Possible Cause | Recommended Solution |

|---|---|

| Poor protein extraction from heat-processed samples | Use extraction buffers with reducing agents and surfactants to break down disulphide-linked aggregates [25] |

| Insufficient sample preparation | Employ techniques like dilution, filtration, or centrifugation to reduce matrix effects [21] [22] |

| Incompatible ELISA kit | Verify your kit is validated for processed matrices; consider switching to kits specifically designed for processed egg detection [25] |

| Suboptimal sample pH | Neutralize samples to pH 7.0-7.5, as extremes can disrupt antibody binding [21] [22] |

How can I confirm that matrix interference is causing my sensitivity issues?

The spike-and-recovery assay is the standard method to evaluate matrix interference [21]. This protocol involves:

- Prepare spiked samples: Add a known concentration of purified egg protein standard to your food matrix sample

- Prepare controls: Include the same concentration of standard in dilution buffer alone

- Run ELISA: Process all samples and controls using your standard ELISA protocol

Calculate recovery: Determine the percentage of recovered analyte using this formula:

Recovery % = (Concentration in spiked sample / Concentration in control) × 100

Interpretation guidelines:

- 80-120% recovery: Minimal matrix interference - your method is suitable [21]

- <80% recovery: Matrix interference is suppressing detection - requires mitigation strategies

- >120% recovery: Matrix components are enhancing signal - also requires investigation [26]

Which food matrices typically cause the most significant interference with egg allergen detection?

Research comparing seven commercial egg ELISA kits across nine food matrices revealed substantial variation in performance [3]. The table below summarizes recovery rates across different matrices:

| Food Matrix | Number of Kits with Acceptable Recovery (80-120%) | Performance Notes |

|---|---|---|

| Cookie, Chocolate, Stock Cube, Wine | 7/7 kits | Least problematic matrices |

| Pasta, Vegetable Drink, Ice Cream, Salad Dressing | ≥4/7 kits | Moderate matrix effects |

| Meat/Meat Replacers | 1/7 kits | Most challenging matrix with high interference |

What specific components in food matrices cause interference?

Research on vegetable matrices identified these common interfering components and their effects:

| Matrix Component | Primary Interference Mechanism | Effect on ELISA |

|---|---|---|

| Chlorophyll | Disrupts antibody-IgG-HRP binding | Most pronounced interference [23] [24] |

| Vegetable Proteins | Competes with target binding | Reduces specificity [23] [24] |

| Sugars (glucose, fructose, sucrose) | Alters protein structure & binding | Variable effects based on concentration [23] [24] |

| Inorganic Salts | Modifies ionic strength & protein structure | Can improve or worsen detection [26] |

| Lipids | Non-covalent interactions with proteins | Alters antibody recognition [26] |

Methodologies for Overcoming Matrix Interference

What specialized extraction methods improve detection of processed egg allergens?

For heat-processed egg proteins, standard extraction buffers often fail to efficiently recover target proteins. The ELISA Systems Processed Egg assay demonstrates an effective approach:

Protocol for Enhanced Protein Extraction:

- Use specialized extraction buffer containing reducing agents (e.g., DTT) to break disulphide bonds in aggregated proteins [25]

- Include surfactants to improve solubility of denatured proteins [25]

- Optimize extraction temperature and time - typically 15-60 minutes at 50-60°C with agitation [25]

- Centrifuge to remove particulate matter before analysis [25]

This approach can significantly improve detection sensitivity compared to conventional extraction methods, potentially reducing false-negative results [25].

How can I modify my ELISA protocol to minimize matrix effects?

Consider these protocol adjustments when working with challenging matrices:

| Modification | Application | Implementation |

|---|---|---|

| Sample Dilution | Reduces concentration of interfering substances | Establish Minimum Required Dilution; use kit standard buffer as diluent [21] [22] |

| Simultaneous Incubation | Decreases exposure time to matrix | Incubate sample and enzyme-labeled antibody together in coated wells [21] |

| Extended Washes | Removes loosely-bound interferents | Increase wash cycle duration; add 30-second soak steps [27] |

| Matrix-Matched Standards | Compensates for matrix effects | Prepare standard curve in blank matrix extract [21] |

Are some ELISA formats more resistant to matrix interference?

Yes, different ELISA formats show varying susceptibility to matrix effects. Research on sarcoplasmic calcium binding protein (SCP) detection found:

Comparative Performance in Challenging Conditions:

- Indirect Competitive ELISA (icELISA): Maintained stable recovery until 100°C heating, better resistance to structural changes [26]

- Sandwich ELISA (sELISA): Significantly declined above 80°C, more affected by protein aggregation [26]

This suggests that icELISA may be preferable for detecting processed allergens where heat treatment causes protein structural changes [26].

Researcher's Toolkit: Essential Reagents & Methods

Key Research Reagent Solutions for Matrix Challenges

| Reagent/Method | Function in Mitigating Matrix Effects |

|---|---|

| Reducing Agents (DTT, β-mercaptoethanol) | Break disulphide bonds in heat-aggregated proteins [25] |

| Surfactants (Tween-20, Triton X-100) | Improve solubility of denatured proteins [25] |

| Blocking Agents (BSA, non-fat milk) | Reduce nonspecific binding from matrix components [21] |

| Acetic Acid Treatment | Effectively reduces interference from chlorophyll and plant proteins [23] [24] |

| Buffer Exchange Columns | Remove interfering components through matrix exchange [22] |

| Specialized Assay Diluents | Formulated specifically for complex matrices like serum, plasma [21] |

Workflow Diagram: Systematic Approach to Troubleshooting Matrix Interference

Matrix Interference Mechanisms in Food ELISA

Frequently Asked Questions

Can I use the same ELISA kit for both raw and highly processed egg detection?

Not necessarily. Research shows that kits specifically validated for processed egg detection perform significantly better with heat-treated samples. Standard kits may underestimate egg content by 10-100 fold in heat-processed foods due to protein aggregation that reduces antibody binding [25]. Always check manufacturer claims for matrix compatibility.

How does heat processing specifically affect egg protein detection?

Heat processing causes egg-white proteins to form disulphide-linked aggregates that are poorly soluble and hinder antibody binding [25]. This structural change is particularly problematic in sandwich ELISA formats that require two distinct antibody binding sites to remain accessible [26].

What alternative methods should I consider when ELISA shows persistent matrix interference?

When ELISA continues to show significant matrix effects despite optimization, consider:

- PCR (Polymerase Chain Reaction): Detects allergen-specific DNA, often more stable in processed foods where proteins may be denatured [28]

- LC-MS/MS (Liquid Chromatography-Mass Spectrometry): Provides superior specificity and can better distinguish target analytes from matrix components [28]

- Specialized ELISA kits designed specifically for your challenging matrix [25] [3]

How important is sample dilution in managing matrix effects?

Sample dilution is one of the simplest and most effective approaches to reduce matrix interference [21] [22]. By diluting the sample, you reduce the concentration of interfering components while maintaining detectable levels of your target analyte. The key is establishing the Minimum Required Dilution that maintains analytical sensitivity while minimizing interference [21].

Advanced ELISA Techniques and Assay Design for Maximum Sensitivity

Troubleshooting Guide: Resolving Low Sensitivity in ELISA for Processed Egg Allergens

This guide addresses common issues and solutions for researchers experiencing low sensitivity when using ELISAs to detect processed egg allergens.

Problem: Weak or No Signal When Detecting Processed Egg Allergens

You follow the protocol, but the signal is faint or absent, even though you know the allergen is present in the sample. This is a common challenge when epitopes are damaged or masked during food processing.

| Possible Cause | Explanation & Solution | Supporting Experimental Evidence |

|---|---|---|

| Epitope Damage from Processing | Thermal processing (e.g., baking) can denature proteins, destroying the epitope recognized by your antibody. | A 2023 study comparing ELISA kits for egg detection found that thermal processing and complex matrices like chocolate can significantly reduce allergen recovery, leading to false negatives or low signals [3]. |

| Solution: Use an antibody validated for robust, linear epitopes. Linear epitopes (short, continuous amino acid sequences) are more likely to survive heat denaturation than conformational epitopes (dependent on 3D structure) [29]. | ||

| Inefficient Allergen Extraction | The buffer may not effectively release the allergenic protein from the food matrix, making it unavailable for detection. | A 2025 optimization study demonstrated that standard PBS buffers often fail to recover allergens from challenging matrices. The use of specialized extraction buffers with additives like fish gelatine and PVP was critical, improving recovery to 50-150% for most incurred matrices [30]. |

| Solution: Optimize your extraction buffer. A validated buffer for egg in processed foods is 50 mM carbonate-bicarbonate with 10% fish gelatine (pH 9.6) or PBS with 2% Tween-20, 1 M NaCl, 10% fish gelatine, and 1% PVP (pH 7.4) [30]. | ||

| Matrix Interference | Components in the food sample (e.g., fats, polyphenols, tannins) can bind to the allergen or the antibody, inhibiting the assay. | The same 2023 study identified that matrices like meat replacers showed high interference, with only one of seven commercial ELISA kits performing adequately. Diluting the sample or using buffers with blocking additives can mitigate this [3]. |

| Solution: Dilute your sample to reduce interference or use a buffer containing additives like Polyvinylpyrrolidone (PVP), which binds and removes polyphenols commonly found in chocolate matrices [30]. | ||

| Insufficient Antibody Concentration | The antibody may be too dilute to effectively bind the low levels of target allergen remaining after processing. | General ELISA troubleshooting guides consistently list "not enough antibody" as a primary cause of weak signal. The solution is to increase the concentration of your primary or detection antibody and consider titration to find the optimal concentration [6] [2]. |

| Solution: Titrate your capture and detection antibodies to determine the optimal concentration for detecting the processed allergen, as the effective target concentration may be lower than in native proteins. |

Problem: High Background Signal

A high background can mask a weak specific signal, reducing the assay's sensitivity and reliability.

| Possible Cause | Explanation & Solution |

|---|---|

| Insufficient Washing or Blocking | Unbound antibodies or enzymes remain in the well, or non-specific binding sites are not adequately blocked. |

| Solution: Increase the number and/or duration of washes. Add a 30-second soak step between washes. Ensure your blocking buffer is appropriate; consider increasing the concentration of your blocker (e.g., BSA, casein) or the blocking time [6] [10] [2]. | |

| Antibody Concentration Too High | An excessively high antibody concentration can lead to non-specific binding. |

| Solution: Titrate the antibody to find the concentration that gives the best signal-to-noise ratio. Decrease the concentration if background is too high [2]. |

Experimental Protocol: Optimized Extraction for Processed Egg Allergens

The following methodology, adapted from recent research, is designed to maximize the recovery of egg proteins from challenging processed food matrices [30].

Objective: To efficiently extract egg allergens from a baked biscuit matrix for quantitative analysis by ELISA.

Materials:

- Optimized Extraction Buffer D: 50 mM sodium carbonate / sodium bicarbonate, 10% fish gelatine, pH 9.6 [30].

- Incurred Baked Biscuit Sample: Biscuit dough incurred with defined levels of egg protein and baked at 185°C for 15 minutes.

- Centrifuge capable of 1,250 rcf.

- Orbital Shaker Incubator.

Procedure:

- Sample Preparation: Homogenize the baked biscuit sample into a fine powder.

- Weigh and Add Buffer: Weigh 1 g of sample into a suitable tube and add 10 mL of pre-warmed Optimized Extraction Buffer D (1:10 sample-to-buffer ratio).

- Extract: Vortex the mixture for 30 seconds to ensure thorough mixing.

- Incubate: Place the tube in an orbital incubator at 60°C for 15 minutes, shaking at 175 rpm. This elevated temperature and agitation help disrupt matrix interactions.

- Clarify: Centrifuge at 1,250 rcf for 20 minutes at 4°C.

- Recover Supernatant: Carefully collect the clarified supernatant from the middle of the tube, avoiding any insoluble pellet or floating fat.

- Analyze: Proceed with your specific ELISA protocol, using the extracted supernatant as your sample.

FAQs on Antibody and Epitope Selection

Q1: What is the key difference between an epitope that is "robust" versus "labile" in the context of processed foods?

A robust epitope is typically a linear epitope, composed of a short, continuous sequence of amino acids. Because its identity is based on the primary protein structure, it is more likely to survive the denaturing effects of heat, pressure, and chemical changes during food processing. In contrast, a labile epitope is often a conformational epitope, formed by amino acids that are brought together in the protein's three-dimensional native structure. This 3D structure is easily disrupted (denatured) by processing, destroying the epitope and making it undetectable by antibodies that recognize it [29].

Q2: My ELISA works well for native egg protein but fails with baked samples. What should I do?

This is a classic sign that your antibody is likely targeting a labile, conformational epitope. Your course of action should be:

- Switch Antibodies: Seek out an antibody that has been specifically validated for detecting processed or denatured egg allergens. These are more likely to target robust, linear epitopes.

- Optimize Extraction: Immediately implement the optimized extraction protocol detailed above. A standard PBS buffer is often insufficient to recover allergens from a baked matrix [30].

- Validate with a Positive Control: Use an incurred sample (one you have spiked with a known amount of egg before baking) to confirm that your new method can accurately recover the allergen post-processing [3].

Q3: Why is the choice of extraction buffer so critical for detecting allergens in chocolate or baked goods?

Complex matrices like chocolate and baked goods contain interfering substances. Chocolate has polyphenols and fats that can bind to proteins and antibodies, while baking can incorporate allergens into a cross-linked food network. A specialized buffer does more than just solubilize proteins; its specific pH, salt concentration, and additives work to:

- Disrupt Interactions: Break bonds between the allergen and the matrix (e.g., starch, fibers).

- Solubilize Proteins: Keep the extracted allergen in solution.

- Neutralize Interferents: Additives like PVP bind polyphenols, and fish gelatine blocks non-specific binding, preventing these substances from interfering with the antibody-antigen reaction [30].

Visualizing the Core Concepts

Epitope Integrity After Processing

This diagram illustrates why antibody choice is critical for detecting processed allergens.

Workflow for Enhanced Detection

This workflow chart outlines the key steps to improve ELISA sensitivity for processed egg allergens.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Antibodies to Linear Epitopes | These are essential for detecting processed allergens, as they bind to continuous amino acid sequences that survive protein denaturation caused by heat [29]. |

| Carbonate-Bicarbonate Buffer (pH 9.6) | A common coating buffer that also serves as an effective extraction base. The alkaline pH enhances protein solubility and release from the matrix [30] [31]. |

| Fish Gelatine | A blocking agent added to extraction buffers. It saturates non-specific binding sites on both the plasticware and the sample matrix, reducing background and interference [30]. |

| Polyvinylpyrrolidone (PVP) | A key additive for challenging matrices like chocolate. It binds to and neutralizes polyphenols and tannins that would otherwise sequester the target protein or antibodies [30]. |

| Tween-20 | A non-ionic detergent included in wash buffers and some extraction buffers. It reduces non-specific hydrophobic interactions, thereby lowering background signal [10] [2]. |

| High-Binding ELISA Plates | Specially treated polystyrene microplates designed to passively adsorb proteins (antibodies or antigens) efficiently, ensuring a solid assay foundation. Not to be confused with tissue culture plates [6] [7]. |

Troubleshooting Guides

Guide 1: Troubleshooting Low Antigen-Binding Capacity

Problem: Your ELISA for processed egg allergens is showing unexpectedly low signal, suggesting poor antigen binding.

| Possible Cause | Diagnostic Steps | Recommended Solution |

|---|---|---|

| Random Antibody Orientation | Compare signal with a pre-adsorbed Protein G surface. | Use Fc-specific immobilization via Protein A/G or biotin-streptavidin for oriented binding [32] [33]. |

| Antibody Denaturation on Polystyrene | Test antibody activity in solution via a different assay. | Use a secondary antibody-coated surface to prevent direct adsorption to polystyrene, preserving integrity [32]. |

| Inefficient Biotin-Streptavidin Binding | Verify the biotinylation ratio of your antibody. | Use site-specific biotinylation strategies (e.g., enzymatic via microbial transglutaminase) to label the Fc region; this can improve antigen-binding capacity by 3-fold compared to random lysine biotinylation [34]. |

Guide 2: Troubleshooting High Background Signal

Problem: Your assay has high background noise, obscuring the detection of low-abundance egg allergens.

| Possible Cause | Diagnostic Steps | Recommended Solution |

|---|---|---|

| Non-specific Binding | Run the assay without primary capture antibody. | Improve blocking; use non-fouling surface coatings like polyethylene glycol (PEG) or polysaccharides [35]. |

| Non-specific Binding to Capture Protein | Use a control with a non-specific antibody from the same host species. | Choose Protein A/G or secondary antibodies with minimal cross-reactivity to human serum proteins [32]. |

| Streptavidin Leakage | Check for desorption of streptavidin from the surface. | Ensure covalent coupling of streptavidin to the solid support [36]. |

Frequently Asked Questions (FAQs)

FAQ 1: Why should I use oriented immobilization (e.g., Protein G or biotin-streptavidin) instead of passively adsorbing my antibody directly to the plate?

Passive adsorption leads to random antibody orientation and can cause denaturation, with studies showing only 10-25% of adsorbed antibodies remain functional [34]. Oriented immobilization via the Fc region ensures the antigen-binding sites are exposed to the solution. This can result in a 3-fold improvement in antigen-binding capacity and sensitivity [34], which is crucial for detecting low levels of processed egg allergens.

FAQ 2: The food matrix in my egg allergen samples (e.g., chocolate, meat) is causing interference. How can surface engineering help?

Complex matrices like chocolate, pasta, and meat are known to cause significant interference in ELISAs [3]. Surface engineering can mitigate this by:

- Reducing Non-specific Binding: Employ advanced blocking agents or non-fouling polymer brushes (e.g., PEG) on the surface to prevent matrix proteins from adhering where they don't belong [35].

- Improving Specific Signal: By ensuring proper antibody orientation, you increase the number of functional capture antibodies, which amplifies the specific signal relative to the background matrix noise [33].

FAQ 3: For biotin-streptavidin immobilization, what is the difference between random and site-specific biotinylation, and why does it matter?

- Random Biotinylation: Uses NHS-ester chemistry to biotinylate lysine residues across the entire antibody (heavy and light chains). This can block antigen-binding sites and lead to heterogeneous, poorly oriented immobilization [34].

- Site-Specific Biotinylation: Uses enzymes like microbial transglutaminase (mTG) to attach biotin specifically to a conserved glutamine (Q295) in the antibody's Fc region [34]. This guarantees uniform orientation away from the binding sites, maximizing assay performance.

FAQ 4: My Protein G-coated plates are expensive. Are there any cost-effective alternatives for oriented immobilization?

Yes. As an alternative to purified Protein G, one strategy is to coat surfaces with engineered cells that express Protein G on their surface [35]. This method provides a high-surface-area, Fc-specific substrate without the cost of protein purification and can enhance antibody-coating capacity.

Data Presentation

Table 1: Performance Comparison of Antibody Immobilization Strategies

| Immobilization Method | Key Feature | Binding Capacity / Performance | Best Use Case |

|---|---|---|---|

| Passive Adsorption | Simple, low-cost; random orientation [34] | Low (10-25% functional antibodies) [34] | Robust antibodies, cost-sensitive screening |

| Protein A/G Coating | Fc-specific, oriented; commercial plates available [32] [33] | High, species/subclass-dependent affinity [32] | General oriented immobilization for mouse/rabbit IgG |

| Random Biotin-Streptavidin | Strong binding; requires biotinylation [35] | Moderate (risk of binding site occlusion) [34] | When covalent attachment is needed |

| Site-Specific Biotin-Streptavidin | Uniform orientation via Fc-biotinylation [34] | High (~3x improvement vs. random) [34] | Maximal sensitivity assays, low-abundance targets |

| Secondary Antibody Coating | Prevents denaturation, captures specific species IgG [32] | ~0.625 pmol/well of mouse IgG [32] | When primary antibodies are prone to denaturation |

Table 2: Egg Allergen Recovery in Challenging Food Matrices

This table summarizes the performance of different commercial egg allergen ELISA kits in various matrices, highlighting the challenge of matrix effects [3].

| Food Matrix | Number of Kits with Satisfactory Recovery (out of 7) | Notes on Matrix Interference |

|---|---|---|

| Cookie, Chocolate, Wine | 7 | Low interference; most kits perform well. |

| Pasta, Salad Dressing, Ice Cream | 4 | Moderate interference; kit selection is critical. |

| Meat/Meat Replacers | 1 | High interference; the most challenging matrix. |

Experimental Protocols

Protocol: Evaluating Immobilization Strategies for Egg Allergen Capture

Objective: To compare the performance of passive adsorption versus oriented immobilization for capturing processed egg allergens in a complex matrix.

Materials:

- Surfaces: Polystyrene ELISA plate (for passive adsorption), Protein G-coated plate, Streptavidin-coated plate.

- Antibodies: Specific mouse anti-egg allergen IgG, Biotinylated version of the same antibody (both random and site-specific if available).

- Reagents: Blocking buffer (e.g., BSA or casein), processed egg allergen standard, food sample extracts, standard ELISA detection reagents.

Procedure:

- Coating: Immobilize the capture antibody on the different surfaces.

- Passive Adsorption: Dilute anti-egg allergen IgG in coating buffer and add to the polystyrene plate. Incubate overnight at 4°C.

- Protein G Orientation: Dilute the same IgG and add to the Protein G plate. Incubate 1-2 hours at room temperature.

- Biotin-Streptavidin Orientation: Dilute the biotinylated anti-egg allergen IgG and add to the Streptavidin plate. Incubate 1 hour at room temperature.

- Blocking: Wash all plates and block with an appropriate blocking agent for 1-2 hours.

- Antigen Binding: Add a dilution series of the egg allergen standard and your food sample extracts to the plates. Incubate for the required time.

- Detection and Analysis: Complete the ELISA with your chosen detection antibody and substrate. Compare the sensitivity, signal-to-noise ratio, and recovery of the egg allergen from the food matrix across the different surfaces.

Workflow: Comparing Antibody Immobilization Strategies

The Scientist's Toolkit

Research Reagent Solutions

| Item | Function in Surface Engineering | Example Application |

|---|---|---|

| Protein G-coated Plates | Oriented immobilization of antibodies from many species via Fc region binding [32]. | General capture antibody coating for sandwich ELISA. |

| Secondary Antibody-coated Surfaces | Pre-adsorbed surface that binds a specific antibody isotype, preventing its denaturation on polystyrene [32]. | Ideal when primary antibodies are limited in quantity or prone to denaturation. |

| Streptavidin-Coated Plates | Provides a surface for immobilizing any biotinylated molecule with high affinity and stability [34] [35]. | Versatile platform for oriented immobilization of biotinylated capture antibodies. |

| Microbial Transglutaminase (mTG) | Enzyme for site-specific biotinylation of antibodies at a conserved glutamine in the Fc region (Q295) [34]. | Creating optimally oriented biotinylated antibodies for maximum assay sensitivity. |

| Non-fouling Polymers (e.g., PEG) | Synthetic polymers used to modify surfaces to minimize non-specific protein adsorption [35]. | Reducing background noise in complex matrices like food samples. |

Frequently Asked Questions (FAQs) on ELISA Blocking

1. What is the primary purpose of a blocking step in an ELISA? The blocking step is critical to prevent non-specific binding of detection antibodies or other assay components to the multi-well plate surface itself. When a plate is fully blocked, assay sensitivity is enhanced because non-specific background signal is significantly reduced [37].

2. Why might my ELISA have a high background despite using a blocking buffer? High background is commonly caused by an ineffective blocking strategy. Potential reasons include:

- Insufficient Blocking: The blocking time may be too short, the concentration of the blocking agent too low, or the blocking buffer itself may be incompatible with your antibody-sample pair [37] [2].

- Cross-Reactivity: The detection antibody may be cross-reacting with the blocking agent itself. For instance, if you are using a secondary antibody raised in goat, a blocking buffer containing normal goat serum could cause high background [38].

- Insufficient Washing: Inadequate washing after the blocking step can leave unbound proteins that contribute to background [10].

3. How do I choose the right blocking agent for my experiment? The optimal blocking agent depends on your specific assay components and sample type. Common agents include proteins like BSA, casein, gelatin, or serum [2]. The key is to select a blocking protein that is immunologically inert to your antibodies and sample. A checkerboard titration is the best method to compare different blocking solutions and identify the one that delivers the highest signal-to-noise ratio for your assay [39].

4. Can the sample matrix affect my blocking strategy? Yes. The sample matrix (e.g., serum, cell lysate) can introduce its own proteins and factors that lead to non-specific binding. It is recommended to use a standard diluent that matches your sample matrix as closely as possible. If the sample shows poor linearity, spike-and-recovery experiments should be performed to ensure the matrix is not interfering with detection [37].

Troubleshooting Guide: High Background and Non-Specific Binding

| Problem Phenomenon | Potential Root Cause | Recommended Troubleshooting Action |

|---|---|---|

| High Uniform Background | Ineffective blocking buffer or insufficient blocking time [37] [2]. | Increase blocking time and/or concentration of the blocker. Try a different blocking reagent (e.g., switch from BSA to casein) [38] [2]. |

| Antibody concentration is too high [2]. | Titrate the primary and secondary antibodies to find the optimal working concentration that minimizes background. | |

| Insufficient washing after blocking or between antibody steps [10] [6]. | Increase the number and/or duration of washes. Add a 30-second soak step between washes to ensure unbound components are fully removed [10]. | |

| High Spotty Background | Non-specific binding of antibodies [38]. | Ensure a block step is included. Use an affinity-purified antibody, and consider using a serum-based blocker from the same species as the secondary antibody [38]. |

| Contaminated buffers or reusable plastics introducing HRP [38] [6]. | Always prepare fresh buffers. Use fresh plate sealers and reagent reservoirs for each step to avoid residual enzyme contamination [10]. | |

| Poor Sensitivity with Background | Blocking agent interfering with antigen-antibody binding. | Test different types of blocking agents (e.g., non-fat dry milk, BSA, fish gelatin) to find one that does not mask the epitope of your target allergen. |

Experimental Protocol: Systematic Optimization of Blocking Conditions

A checkerboard titration is the most effective method for optimizing multiple ELISA parameters simultaneously, including the blocking buffer [37] [39]. The following protocol outlines this process.

Objective: To identify the blocking agent and concentration that minimizes background while maximizing specific signal in an ELISA for detecting processed egg allergens.

Materials:

- ELISA plates

- Coating antibody (specific to your target allergen)

- Target allergen standard

- Detection antibody (specific to your target allergen)

- Enzyme-conjugated secondary antibody (if using indirect detection)

- Candidate blocking buffers (e.g., 1%, 3%, and 5% BSA in PBS; 1%, 3%, and 5% Casein in PBS; 5% non-fat dry milk in PBS)

- Wash buffer (e.g., PBS with 0.05% Tween-20)

- Substrate solution

- Stop solution

- Plate reader

Methodology:

- Plate Coating: Coat the plate with a fixed, optimal concentration of the capture antibody. Incubate overnight, then wash.

- Checkerboard Blocking: Apply different blocking buffers to the plate in a grid pattern. For example, use different columns for different blocking agents (BSA, Casein, Milk) and different rows for different concentrations (1%, 3%, 5%). Incubate for 1-2 hours at room temperature.

- Allergen and Detection: After washing, add your target allergen standard at a known concentration, followed by the detection antibody and enzyme conjugate as per your standard protocol.

- Signal Detection: Add substrate, stop the reaction, and read the absorbance.

Data Analysis: Calculate the signal-to-noise ratio for each well: Signal-to-Noise Ratio = (Mean Absorbance of Test Well) / (Mean Absorbance of Negative Control Well) The blocking condition that yields the highest signal for the positive control and the lowest signal for the negative control (highest signal-to-noise ratio) is the optimal condition.

Workflow for Blocking Strategy Optimization

Research Reagent Solutions for Blocking Optimization

The following table lists key reagents essential for developing and optimizing an effective ELISA blocking strategy.

| Reagent | Function in Blocking Optimization |

|---|---|

| Bovine Serum Albumin (BSA) | A common protein blocker that binds to unsaturated binding sites on the polystyrene plate. It is defined and pure, but may not be suitable for all assay systems due to potential cross-reactivity [2]. |

| Casein | A protein derived from milk. Its non-immunogenic nature often makes it a highly effective blocking agent, especially for immunoassays, as it is less likely to interact with antibodies. |

| Non-Fat Dry Milk | A complex and inexpensive blocking agent containing caseins and other proteins. However, it can contain biotin and immunoglobulins that may cause interference in some assays [38]. |

| Normal Sera (e.g., Goat, Horse) | Serum from a non-immune animal is used to block against non-specific binding, particularly when it matches the species of the secondary antibody. It is complex and can be highly effective. |

| Fish Skin Gelatin | A alternative blocking protein that is immunologically distant from mammalian proteins, reducing the chance of cross-reactivity in assays detecting mammalian allergens or analytes. |

| Tween-20 | A non-ionic detergent added to wash buffers. It helps reduce non-specific hydrophobic interactions, thereby lowering background. Typical concentrations range from 0.01% to 0.1% [2]. |

Detecting egg allergens in processed foods presents a significant analytical challenge. During thermal processing, egg proteins can denature, aggregate, and undergo structural changes that mask antibody-binding epitopes, dramatically reducing detection sensitivity in conventional Enzyme-Linked Immunosorbent Assays (ELISAs) [40] [28]. This limitation is particularly critical given that for egg-allergic individuals, the eliciting dose (ED01) for an objective reaction can be as low as 0.2 mg of total egg protein [40]. Bridging this sensitivity gap requires moving beyond traditional ELISA formats to advanced signal amplification strategies that can detect trace amounts of altered allergens. This technical guide explores cutting-edge enzymatic and synthetic biology approaches—including CRISPR-linked immunoassays (CLISA) and T7 RNA polymerase–linked immunosensing assays (TLISA)—to overcome these limitations, providing researchers with practical troubleshooting advice and optimized protocols for enhanced egg allergen detection.

Advanced Signal Amplification Technologies

Traditional Enzymatic Amplification Systems

Traditional ELISA relies on enzyme conjugates such as Horseradish Peroxidase (HRP) and Alkaline Phosphatase (AP) to generate a detectable signal [7]. While these systems remain fundamental, their sensitivity is often insufficient for detecting low-abundance allergens in complex matrices. The biotin-streptavidin system provides a significant amplification advantage by exploiting the high-affinity interaction between biotin and streptavidin. Since each streptavidin molecule contains four biotin-binding sites and multiple biotins can be conjugated to a single secondary antibody, this system allows for the incorporation of more enzyme molecules per detection event, substantially enhancing signal intensity [41].

Synthetic Biology-Enhanced Immunoassays

CRISPR-Linked Immunoassays (CLISA) and T7 RNA Polymerase–Linked Immunosensing Assays (TLISA) represent a paradigm shift in immunoassay sensitivity. These approaches marry the specificity of antibody-antigen recognition with the powerful amplification capabilities of nucleic acid detection.

In CLISA, the traditional enzyme label is replaced with a CRISPR-Cas system. Once the antibody-antigen binding occurs, a triggered Cas enzyme (such as Cas12a or Cas13a) cleaves reporter molecules, creating an amplified, detectable signal [42]. Similarly, TLISA employs a T7 RNA polymerase system linked to the detection antibody, enabling programmed synthesis of numerous RNA reporters following antigen recognition [42]. These cell-free synthetic biology approaches can achieve detection limits in the atto- to femtomolar range, bridging the sensitivity gap that has traditionally separated protein detection from nucleic acid-based tests like PCR [42].

Table 1: Comparison of Signal Amplification Approaches for Allergen Detection

| Amplification Method | Mechanism | Approximate Detection Limit | Suitability for Processed Egg Allergens |

|---|---|---|---|

| Traditional ELISA | HRP/AP enzyme-substrate reaction | Pico- to nanomolar [42] | Limited - epitopes may be denatured [28] |

| Biotin-Streptavidin | Multi-enzyme loading via high-affinity binding | Low picomolar [41] | Moderate - improved but still epitope-dependent |

| CLISA | CRISPR-Cas mediated nucleic acid amplification | Atto- to femtomolar [42] | High - detects trace amounts despite denaturation |

| TLISA | T7 RNA polymerase-driven RNA reporter synthesis | Atto- to femtomolar [42] | High - exceptional for low-abundance targets |

Troubleshooting Guide: Low Sensitivity in Egg Allergen Detection

Frequently Asked Questions

Q1: My ELISA shows weak or no signal when testing processed food samples for egg allergens, despite using a high-quality commercial kit. What are the primary causes?

- Epitope Denaturation: Thermal processing can alter egg protein structures, hiding the antibody-binding sites recognized by your ELISA [28]. Consider using kits specifically validated for processed foods or switching to synthetic biology approaches less dependent on native protein structure.

- Matrix Effects: Complex food matrices (especially meat replacers, chocolate, and dressings) can interfere with antibody binding [40]. Only 1 of 7 commercial egg ELISA kits performed satisfactorily in meat/meat replacer matrices in a recent study.

- Insufficient Signal Amplification: Traditional enzymatic detection may be inadequate for trace allergen levels. Implement biotin-streptavidin amplification or transition to CLISA/TLISA formats [41] [42].

- Suboptimal Reagent Conditions: Ensure all reagents are at room temperature before use, use fresh substrates protected from light, and verify expiration dates [10].

Q2: How can I improve the sensitivity of my current ELISA without completely changing platforms?

- Optimize Antibody Orientation: Use Protein A, Protein G, or biotin-streptavidin systems to ensure uniform antibody orientation, enhancing binding efficiency [42].

- Enhance Washing Efficiency: Improve signal-to-noise ratio by increasing wash buffer soak time (add 30-second increments) and ensure complete drainage after each wash step [10].

- Extend Incubation Times: Gradually increase incubation times with the detection antibody, but be consistent across assays to maintain reproducibility [10].