Optimized Real-Time PCR Protocol for Sensitive Detection of Walnut Allergen Coding Sequences in Processed Foods

This article provides a comprehensive guide for developing and validating a real-time PCR (qPCR) method for the detection of walnut allergen coding sequences, specifically targeting Jug r 1, Jug r...

Optimized Real-Time PCR Protocol for Sensitive Detection of Walnut Allergen Coding Sequences in Processed Foods

Abstract

This article provides a comprehensive guide for developing and validating a real-time PCR (qPCR) method for the detection of walnut allergen coding sequences, specifically targeting Jug r 1, Jug r 3, and Jug r 4. Tailored for researchers and food safety professionals, the content covers foundational principles, a step-by-step optimized protocol, troubleshooting for processed food matrices, and rigorous validation against other methods like ELISA. It also synthesizes the latest findings on clinical threshold doses to bridge the gap between analytical detection and human health risk assessment, supporting accurate food labeling and allergen management.

The Critical Need for Walnut Allergen Detection: Principles and Public Health Impact

Walnut Allergy Prevalence and Global Labelling Regulations

Walnut allergy is one of the most common and severe tree nut allergies, representing a significant global health concern [1]. For affected individuals, strict avoidance of walnut and products containing it is the primary management strategy, making accurate food labeling a critical public safety issue [2] [3]. This has prompted regulatory bodies worldwide to establish stringent allergen labeling laws for prepackaged foods.

The need for reliable detection methods is paramount, as cross-contact during manufacturing can introduce walnut traces into other products [2]. Real-time PCR (polymerase chain reaction) has emerged as a highly sensitive and specific technique for detecting walnut allergen coding sequences, even in complex processed food matrices [4] [3]. This application note details the prevalence and regulatory landscape of walnut allergy and provides established protocols for its detection via real-time PCR, supporting both food safety programs and regulatory compliance.

Walnut Allergy Prevalence and Regulatory Landscape

Prevalence and Clinical Significance

Tree nut allergies, including walnut allergy, are among the most common food allergies in both children and adults [1]. Walnut is consistently ranked as one of the six tree nut allergies most commonly reported by children and adults, alongside almond, hazelnut, pecan, cashew, and pistachio [1]. Allergic reactions to walnut can be severe and are a frequent cause of life-threatening anaphylaxis [3]. Notably, approximately 50% of children allergic to one tree nut are allergic to another, and most children with tree nut allergy do not outgrow it [1].

Recent research indicates that the prevalence and sensitivity to walnut allergies are dynamic. A 2025 Japanese study reported a marked decline in the eliciting dose (ED05) for walnut over time, meaning that smaller amounts of walnut are now required to trigger a reaction in allergic populations. The ED05 for walnut was found to be 4.37 mg, which is higher than that for cashew nut (0.53 mg) but similar to peanut (4.88 mg) [5]. This trend underscores the necessity for periodic reassessment of allergen risk thresholds.

Global Labeling Regulations

Globally, regulations mandate the declaration of major food allergens on prepackaged food labels. The Codex Alimentarius, the international food standards guideline, requires the declaration of specific allergens, including tree nuts [6]. Most national regulations are aligned with this standard, though the specific nuts listed can vary.

Table 1: Global Labeling Requirements for Tree Nuts and Walnut

| Country/Region | Tree Nuts Listed as Major Allergens | Specific Mention of Walnut | Other Notable Allergens |

|---|---|---|---|

| USA [2] [7] | Mandatory for 6 key tree nuts (including walnut) | Yes | Soybeans, Peanuts, Milk, Egg, Fish, Crustacean Shellfish, Wheat, Sesame |

| Canada [8] | Mandatory | Yes | Sesame, Mustard, Molluscs |

| European Union (EU) [8] [3] | Mandatory | Yes | Celery, Lupin, Molluscs, Mustard |

| Australia/NZ [8] | Mandatory | Yes | Sesame, Lupin |

| Japan [8] | Mandatory (Walnut is on the mandatory list) | Yes | Buckwheat, Pork, Peach, Gelatin (and others recommended) |

| United Kingdom [8] | Mandatory (follows EU regulations) | Yes | Celery, Lupin, Molluscs, Mustard |

In the United States, the Food Allergen Labeling and Consumer Protection Act (FALCPA) identifies "tree nuts" as a major allergen. The U.S. Food and Drug Administration (FDA) maintains a specific "Tree Nut List" that delineates which nuts are considered major allergens. In the most recent 2025 guidance, walnut remains a mandated allergen, while several other nuts, such as coconut and chestnut, have been removed from the list [7]. As of January 1, 2023, sesame has been added as the 9th major food allergen in the U.S. [2].

Labeling can be accomplished in one of two ways:

- Including the food source name in parentheses following the ingredient (e.g., "natural flavor (walnut)").

- Using a "Contains" statement immediately after the ingredient list (e.g., "Contains walnut") [2].

It is important to note that advisory statements such as "may contain walnut" are voluntary and not regulated by law, though the FDA advises they must be truthful and not misleading [2] [7].

Real-Time PCR Detection of Walnut Allergens

Method Principle and Advantages

Real-time PCR (RT-PCR) is a DNA-based method for the direct, qualitative, and/or quantitative detection of specific walnut DNA sequences [9]. The technique targets unique genomic sequences, such as allergen-coding genes (e.g., Jug r 1, Jug r 3, Jug r 4), and amplifies them, with fluorescence-based detection enabling real-time monitoring of the amplification process [4] [3].

This method offers several advantages for allergen detection:

- High Specificity and Sensitivity: Capable of detecting trace amounts (as low as 2.5 pg) of walnut DNA [4] [3].

- Robustness in Processed Foods: DNA is generally more stable than proteins in heat-processed foods, though severe treatments like autoclaving can degrade DNA and reduce detection sensitivity [3].

- Reliability: Shows greater sensitivity and reliability in detecting hidden walnut in commercial foodstuffs compared to protein-based methods like ELISA [4] [3].

Experimental Protocol

DNA Extraction

Efficient DNA extraction is critical for assay sensitivity.

- Recommended Method: Use a CTAB-phenol-chloroform-based DNA extraction method, which has been demonstrated as most effective for walnut [4] [3].

- Commercial Kits: Validated commercial kits, such as the SureFood PREP Advanced (Art. No. S1053), can also be used to ensure consistent yield and purity [9].

- DNA Quality Check: Assess the concentration and purity of the extracted DNA using spectrophotometry (A260/A280 ratio ~1.8) and confirm integrity by agarose gel electrophoresis.

Real-Time PCR Assay

This protocol is adapted from published methodologies [4] [3] [9].

Table 2: Reaction Setup for Real-Time PCR

| Component | Volume per Reaction | Final Concentration |

|---|---|---|

| 2x SYBR Green Master Mix | 10.0 µL | 1x |

| Forward Primer (10 µM) | 0.8 µL | 400 nM |

| Reverse Primer (10 µM) | 0.8 µL | 400 nM |

| Template DNA | 2.0 µL | ~10-100 ng |

| Nuclease-free Water | 6.4 µL | - |

| Total Volume | 20.0 µL |

Primer Sequences: The following primer sets, designed against walnut allergen-coding sequences, provide high specificity.

- Jug r 1 (2S albumin): Forward: 5'-TCCATGGCTAAGTTCTTCAGC-3', Reverse: 5'-CACACCGCTTGTAGCTGTTC-3' [3]

- Jug r 3 (LTP): Forward: 5'-GGCTCTCAATGCTCTTGTCC-3', Reverse: 5'-TGAGCCACCTTTGTCATCAC-3' [3]

- Jug r 4 (11S legumin): Forward: 5'-AGATGCACACACACACACGA-3', Reverse: 5'-TGGTGTTGCTGCTGTGATAG-3' [3]

Thermocycling Conditions:

- Initial Denaturation: 95°C for 10 minutes

- Amplification (45 cycles):

- Denaturation: 95°C for 15 seconds

- Annealing/Extension: 60°C for 60 seconds (data acquisition in the SYBR Green/FAM channel)

- Melt Curve Analysis: 95°C for 10 seconds, followed by a continuous temperature increase from 65°C to 95°C at a rate of 0.1°C/second.

Data Analysis

- Quantification: For quantitative analysis, include a standard curve of known concentrations of walnut DNA (e.g., 0.1 pg/µL to 100 ng/µL) in each run. The cycle threshold (Ct) values of unknowns are plotted against the standard curve to determine the DNA concentration [9].

- Qualitative Detection: A sample is considered positive if its Ct value is less than or equal to the predetermined limit of detection (LOD) of the assay.

- Specificity Check: Perform melt curve analysis to confirm the amplification of a single, specific product. The presence of a single, distinct peak indicates specific amplification.

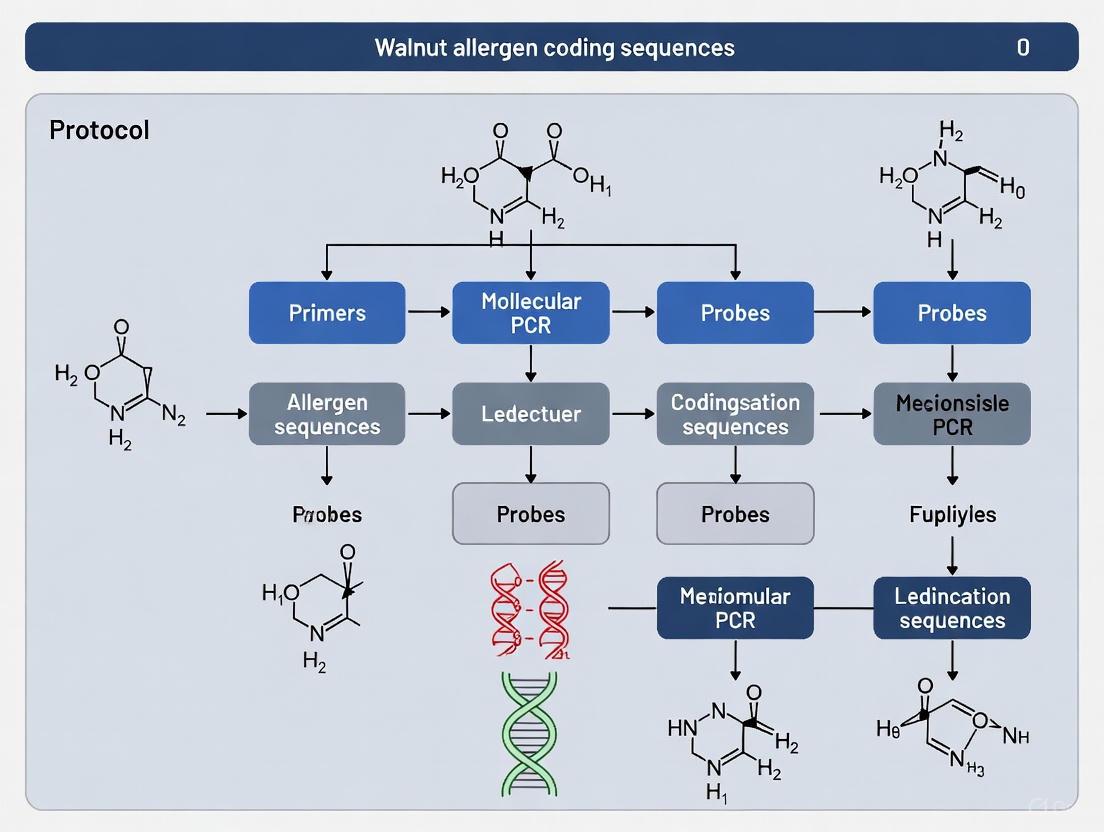

Workflow Visualization

The following diagram illustrates the complete experimental workflow for the detection of walnut allergens in food products:

Method Validation

- Specificity: The assay must not cross-react with DNA from other tree nuts (e.g., pecan, almond, hazelnut), peanuts, soy, or common cereal grains [10]. Test against a panel of non-target species.

- Sensitivity (LOD/LOQ): Determine the Limit of Detection (LOD) and Limit of Quantification (LOQ) using serially diluted walnut DNA in a blank food matrix. The described method can achieve an LOD of ≤ 0.4 mg walnut per kg of food sample and an LOQ of 1 mg/kg [9]. Another study reported an LOD of 2.5 pg of walnut DNA and a practical detection limit of 0.001% (w/w) walnut in wheat [3] [10].

- Effect of Processing: Note that thermal treatment combined with pressure (e.g., autoclaving) can fragment DNA, reducing amplification efficiency. In contrast, High Hydrostatic Pressure (HHP) processing has been shown to have no significant effect on DNA amplification [3].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Kits for Walnut Allergen Detection

| Product/Item | Function/Application | Example/Reference |

|---|---|---|

| CTAB-Phenol-Chloroform | High-quality genomic DNA extraction from complex food matrices. | In-house protocol [3] |

| SYBR Green Master Mix | Fluorescent dye for real-time PCR detection of amplified DNA. | Various commercial suppliers [3] |

| Jug r-specific Primers | Oligonucleotides for specific amplification of walnut allergen genes. | Jug r 1, Jug r 3, Jug r 4 primers [3] |

| Commercial Allergen Kit | Validated, ready-to-use system for standardized detection and quantification. | SureFood ALLERGEN Walnut (S3607) [9] |

| Reference Material | Certified material for creating a standard curve for quantitative PCR. | SureFood QUANTARD Allergen 40 (S3301) [9] |

| Real-time PCR Instrument | Thermocycler with fluorescence detection capabilities. | Roche LightCycler, Applied Biosystems 7500, Bio-Rad CFX96 [9] |

The combination of a dynamic regulatory environment and robust, sensitive detection methodologies is essential for protecting consumers with walnut allergies. Real-time PCR stands out as a highly specific and reliable technique for identifying the presence of walnut DNA in food products, thereby supporting manufacturers in their compliance efforts and risk assessment programs. The protocols and information provided here offer a framework for laboratories to implement or refine their walnut allergen testing strategies, contributing to greater food safety and informed consumer choice.

Limitations of Protein-Based Detection Methods (e.g., ELISA) in Processed Foods

For individuals with food allergies, the accurate detection of allergenic residues in processed foods is a critical public health issue. Protein-based detection methods, particularly the Enzyme-Linked Immunosorbent Assay (ELISA), have been the cornerstone of food allergen monitoring due to their direct targeting of allergenic proteins [11]. ELISA operates on the principle of antigen-antibody interaction, using enzyme-labelled conjugates and substrates to generate a measurable color change corresponding to the concentration of the target protein [12]. Its advantages include sensitivity, selectivity, and relatively straightforward operation [13].

However, the reliability of ELISA can be significantly compromised when analyzing processed foods. Food processing techniques—such as thermal treatment, changes in pH, and the presence of complex food ingredients—can alter protein structure, mask antibody recognition sites, and introduce matrix interferences [14]. These limitations pose substantial risks for both allergic consumers and food manufacturers, potentially leading to false-negative results and undetected allergen presence. This application note details the specific limitations of ELISA in processed food analysis and positions real-time PCR as a complementary DNA-based method for detecting walnut allergen coding sequences, enhancing the robustness of allergen control protocols.

Core Principles and Limitations of ELISA

Fundamental Principles of ELISA

ELISA is a plate-based biochemical assay that detects antigen-antibody interactions. The most common formats are direct, indirect, and sandwich ELISA (sELISA) [12]. In the context of food allergen detection, the target molecule is the allergenic protein. The assay uses antibodies specific to the protein of interest; a positive reaction is confirmed by an enzyme-mediated color change, the intensity of which is measured spectrophotometrically [12] [11]. This direct correlation between the signal and the protein concentration makes ELISA a powerful quantitative tool for specific protein detection.

Key Limitations in Processed Food Analysis

Despite its widespread use, ELISA faces several challenges that can affect its accuracy and reproducibility in processed foods, as summarized below.

Table 1: Key Limitations of ELISA in Processed Food Analysis

| Limitation | Impact on ELISA Performance | Underlying Mechanism |

|---|---|---|

| Structural Protein Alterations [14] | Reduced antibody binding, leading to false negatives. | High temperatures (e.g., >80°C) and extreme pH conditions cause protein unfolding (denaturation) or aggregation, obscuring epitopes recognized by antibodies. |

| Food Matrix Interference [14] | Inaccurate quantification (false positives or negatives); recovery rates can deviate significantly (e.g., 12%–411%) [14]. | Matrix components (e.g., inorganic salts, carbohydrates, lipids, tannins, detergents) can interact non-specifically with proteins or antibodies, or alter protein conformation. |

| Cross-Reactivity [13] | False positive results. | Antibodies may bind non-specifically to non-target proteins that share structural similarities with the target allergen, compromising assay specificity. |

| Non-Specific Binding (NSB) [13] | Elevated background signal, reducing sensitivity and accuracy. | Non-target substances in the sample adsorb to the solid phase (microplate) due to incomplete blocking, generating a false immunosignal. |

| Dependency on Antibody Quality [15] | Erroneous and irreproducible results. | The assay's performance is contingent on the affinity, specificity, and stability of the primary and secondary antibodies. Suboptimal antibodies are a major source of error. |

Experimental Insights into ELISA Limitations

Effects of Processing and Matrices on Sarcoplasmic Calcium Binding Protein (SCP)

A recent investigative study provides a mechanistic understanding of how processing and food matrices affect ELISA detection, using Sarcoplasmic Calcium Binding Protein (SCP) from crustaceans as a model allergen [14].

Experimental Protocol:

- Protein Treatment: SCP was subjected to various temperatures (4–100°C) and pH (3–11) conditions. It was also incubated with different matrix components, including inorganic salts (NaCl, KCl, CaCl₂), carbohydrates (glucose, arabinose, maltose), and peanut oil.

- Analysis: Treated SCP was analyzed using:

- sELISA and icELISA: To evaluate detection recoveries.

- Spectroscopy: Circular dichroism (CD) and fluorescence spectroscopy to assess secondary and tertiary structural changes.

- Molecular Dynamics Simulation: To model interactions between SCP and matrix molecules.

Key Findings:

- Temperature: Recoveries in sELISA significantly declined (12%–64%) at temperatures above 80°C, while icELISA remained stable until 100°C. This indicates that thermal processing can destroy conformational epitopes critical for sELISA [14].

- pH: Under acidic conditions (pH 3), SCP became more compact, which improved recovery in icELISA but reduced it in sELISA, demonstrating that the same structural change can affect different ELISA formats in opposing ways [14].

- Food Matrices: Inorganic salts, carbohydrates, and peanut oil impacted the tertiary structure and aggregation state of SCP via non-covalent interactions, leading to significant variations in ELISA results [14].

This study underscores that the structural integrity of the target protein is paramount for accurate ELISA detection, and any factor that disrupts this integrity can compromise the assay.

Comparative Performance: ELISA vs. Real-Time PCR

A direct comparison of ELISA and real-time PCR for detecting crustacean shellfish allergens highlighted critical methodological differences [16]. The study used identical split samples of Manhattan clam chowder and fish sauce. The real-time PCR assays demonstrated a broader dynamic range (0.1–10⁶ mg/kg) compared to ELISA (200–4000 mg/kg). Furthermore, the ELISA kits exhibited significant matrix interference, whereas the PCR assays did not, leading to more reliable detection in complex food systems [16].

The Case for Real-Time PCR in Walnut Allergen Detection

The limitations of ELISA are particularly relevant for walnut allergens. A 2025 study (Nut CRACKER Study) established that the estimated eliciting doses (ED01 and ED05) for walnut protein are as low as 0.8 mg and 3.8 mg, respectively [17] [18]. This extreme sensitivity required for protection demands detection methods that remain robust despite food processing.

Real-time PCR (qPCR) is a DNA-based technique that amplifies and detects specific DNA sequences. It is an excellent complementary tool to ELISA for allergen detection, as it relies on the stability of DNA, which is often more resistant to food processing than proteins [11] [19].

Table 2: Comparison of ELISA and Real-Time PCR for Allergen Detection

| Parameter | ELISA | Real-Time PCR |

|---|---|---|

| Target Molecule | Protein (allergen) | DNA (allergen-coding gene) |

| Effect of Heat Processing | Significant; can denature proteins and destroy antibody epitopes [14] | More resilient; DNA is thermally stable, though fragmentation can occur [11] |

| Effect of Food Matrix | Prone to interference (e.g., by polyphenols, lipids) [14] | Can be less susceptible with optimized DNA extraction [16] |

| Quantification | Direct quantification of the allergenic protein | Indirect quantification; correlates with the presence of the allergenic species |

| Specificity | High, but susceptible to cross-reactivity with related proteins [13] | High; achieved by targeting unique DNA sequences [19] |

| Throughput | High | High, with multiplexing potential [11] |

Recommended Protocol: Real-Time PCR for Detection of Walnut Allergen Coding Sequences

The following protocol is adapted for the detection of walnut DNA, providing a complementary approach to protein-based ELISA assays.

Workflow Overview:

Figure 1: Real-time PCR workflow for allergen detection.

1. Sample Preparation and DNA Extraction:

- Sample Commutation: Grind the food sample to a fine, homogeneous powder using a laboratory mill.

- DNA Extraction: Use a commercial kit designed for complex food matrices. The protocol should effectively remove PCR inhibitors (e.g., polyphenols, polysaccharides, fats). This typically involves:

- Lysis: Incubating the sample with a lysis buffer and proteinase K.

- Purification: Binding DNA to a silica membrane/column in the presence of a chaotropic salt.

- Washing: Removing contaminants with wash buffers.

- Elution: Dissolving the purified DNA in elution buffer or nuclease-free water.

- DNA Quantification & Quality Check: Measure DNA concentration and purity (A260/A280 ratio) using a spectrophotometer. Integrity can be checked by gel electrophoresis.

2. In Silico Analysis and Primer/Probe Design:

- Target Gene Selection: Identify a walnut-specific DNA sequence, preferably a single-copy allergen-encoding gene (e.g., Jug r 1, Jug r 2, Jug r 3) or a multi-copy gene from the chloroplast or mitochondrial genome for higher sensitivity [20].

- Sequence Specificity Verification: Use tools like BLAST to ensure the selected sequence is unique to walnut and does not align with non-target species (e.g., pecan, other tree nuts).

- Oligonucleotide Design:

- Amplicon Length: Keep it short (90-200 bp) to facilitate amplification from potentially degraded DNA in processed foods [19].

- Primers and Probe: Design primers and a hydrolysis probe (e.g., TaqMan) that meet standard qPCR design criteria (GC content, melting temperature, absence of secondary structures). The probe is labeled with a reporter dye (e.g., FAM) at the 5' end and a quencher (e.g., BHQ1) at the 3' end.

3. Real-Time PCR Amplification:

- Reaction Mix: Prepare a master mix containing:

- 1X qPCR master mix (Hot Start DNA Polymerase, dNTPs, MgCl₂)

- Forward and reverse primers (e.g., 300-500 nM each)

- Hydrolysis probe (e.g., 100-200 nM)

- DNA template (e.g., 5-100 ng of total DNA)

- Nuclease-free water to volume.

- Amplification Protocol: Run the plate on a real-time PCR instrument using a cycling program such as:

- Initial Denaturation: 95°C for 10 min.

- 40-45 cycles of:

- Denaturation: 95°C for 15 sec.

- Annealing/Extension: 60°C for 60 sec (acquire fluorescence).

- Controls: Include in each run:

- Negative Controls: No-template control (NTC) and non-allergenic food matrix control.

- Positive Control: DNA from a certified walnut standard.

- Internal Amplification Control (IAC): To detect PCR inhibitors.

4. Data Analysis and Interpretation:

- Threshold Cycle (Ct): Determine the Ct value for each sample.

- Standard Curve: For quantification, use a serial dilution of walnut DNA with known concentrations to generate a standard curve (Ct vs. log concentration).

- Result Interpretation: A sample is considered positive for walnut if it produces a fluorescence curve that crosses the threshold within the defined cycle range, and the negative controls are negative.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Materials for Allergen Detection Studies

| Item | Function/Benefit | Example Application |

|---|---|---|

| High-Binding Polystyrene Microplates | Optimal surface for adsorption of capture antibodies in ELISA. | Coating step in sandwich or indirect ELISA protocols [13]. |

| Monoclonal/Polyclonal Antibodies | High-affinity, specific antibodies are critical for assay sensitivity and specificity. | Target capture and detection in ELISA; must be validated to minimize cross-reactivity [13]. |

| Enzyme-Conjugates & Substrates | Generate the detectable signal in ELISA. | HRP-streptavidin conjugate with TMB substrate produces a colorimetric change [12] [13]. |

| Blocking Buffers (e.g., BSA, Casein) | Reduce non-specific binding (NSB) by saturating unused sites on the microplate. | Essential step after coating to minimize background noise and false positives [13]. |

| DNA Extraction Kits for Complex Matrices | Efficiently isolate high-quality, inhibitor-free DNA from processed foods. | Critical first step for reliable real-time PCR results [19] [20]. |

| TaqMan Probe-Based qPCR Master Mix | Provides all components for efficient, specific DNA amplification with hydrolysis probes. | Core reagent for real-time PCR detection of walnut allergen coding sequences [19]. |

Protein-based ELISA is a powerful but imperfect tool for allergen detection in processed foods. Its vulnerability to protein denaturation, matrix effects, and antibody-related issues necessitates a multi-faceted approach to food safety. For life-threatening allergens like walnut, where reaction thresholds are exceedingly low, relying solely on ELISA introduces significant risk.

Integrating real-time PCR into control protocols provides a robust, complementary method. By targeting stable DNA sequences, real-time PCR can overcome many of the limitations inherent to protein detection, offering greater resilience to food processing and complex matrices. For comprehensive allergen management and the protection of sensitive individuals, a combined strategy utilizing both ELISA and real-time PCR is highly recommended.

Food allergies represent a significant global health challenge, with walnut being a major trigger for severe reactions [21] [18]. Accurate detection of hidden walnut allergens in food products is crucial for consumer protection and regulatory compliance. While protein-based detection methods like ELISA (Enzyme-Linked Immunosorbent Assay) have been widely used, DNA-based detection techniques, particularly real-time PCR (Polymerase Chain Reaction), offer distinct advantages due to the superior stability of DNA molecules through various food processing conditions [21] [22].

This application note details the experimental protocols and advantages of utilizing real-time PCR for detecting walnut allergen coding sequences, framed within broader research on allergen detection methodologies. The stability of allergen-coding DNA sequences compared to protein epitopes makes DNA-based detection particularly valuable for analyzing processed foods where proteins may become denatured or structurally altered [22] [3].

Core Principles and Advantages of DNA-Based Detection

Fundamental Stability of DNA Molecules

DNA molecules demonstrate greater thermal stability and resistance to processing-induced denaturation compared to proteins. This fundamental characteristic is paramount for reliable allergen detection in processed foods [21]. Where protein epitopes may be destroyed or altered during thermal processing, masking them from antibody recognition in ELISA tests, DNA sequences remain amplifiable and detectable [22] [23].

The multi-copy nature of target genomic sequences (e.g., mitochondrial DNA, ribosomal DNA regions) further enhances detection sensitivity. Even when severe processing fragments the genome, the high copy number increases the probability that at least some target sequences remain intact for amplification [24]. Research confirms that real-time PCR can detect walnut DNA at levels as low as 0.1-1 mg kg⁻¹ (ppm) in complex food matrices, demonstrating remarkable sensitivity [21] [24].

Comparative Performance in Processed Foods

Table 1: Comparison of Allergen Detection Method Performance in Food Analysis

| Parameter | DNA-Based (Real-Time PCR) | Protein-Based (ELISA) |

|---|---|---|

| Target Molecule | Species-specific DNA sequences [25] | Allergenic proteins (e.g., Jug r 1, Jug r 3) [23] |

| Effect of Thermal Processing | DNA is more stable; remains detectable after mild to moderate heating [3] | Proteins can denature, aggregate, or undergo epitope modification; reduced detectability [22] [23] |

| Limit of Detection (Walnut) | As low as 0.1 mg kg⁻¹ (ppm) [21] | Varies; can be less sensitive than PCR in processed foods [23] |

| Specificity | High; depends on primer design [3] | High; can be affected by cross-reactive antibodies (e.g., with pecan) [23] |

| Quantification | Semi-quantitative or quantitative [24] | Quantitative [25] |

| Suitability for Processed Foods | Excellent [21] | Variable; may underestimate allergen content [22] |

Experimental Protocols for Real-Time PCR Detection

DNA Extraction and Purification

Efficient and pure DNA extraction is critical for sensitive PCR detection. The CTAB-phenol-chloroform method has been identified as particularly effective for walnut and other tree nuts [3].

Protocol: CTAB DNA Extraction from Food Samples

- Homogenization: Grind 200 mg of food sample to a fine powder using a laboratory mill under liquid nitrogen.

- Lysis: Incubate the sample with 1 mL of pre-warmed CTAB extraction buffer and Proteinase K for 60 minutes at 65°C with occasional gentle mixing.

- Purification: Add an equal volume of phenol:chloroform:isoamyl alcohol, mix thoroughly, and separate phases by centrifugation.

- Precipitation: Transfer the upper aqueous phase to a new tube. Add 0.7 volumes of isopropanol to precipitate nucleic acids.

- Washing: Pellet DNA by centrifugation, wash with 70% ethanol, and air-dry.

- Resuspension: Dissolve the purified DNA in 50 µL of TE buffer or nuclease-free water.

- Quality Control: Measure DNA concentration and purity using a spectrophotometer.

Real-Time PCR Assay Design and Workflow

Table 2: Key Research Reagent Solutions for Real-Time PCR Walnut Detection

| Reagent / Material | Function / Description | Specifications / Notes |

|---|---|---|

| Species-Specific Primers | Binds to and amplifies unique walnut DNA sequences. | Designed from allergen genes (e.g., Jug r 1, Jug r 3, Jug r 4) or multi-copy genomic regions [4] [3]. |

| Fluorescent Probes | Generates a quantifiable signal upon DNA amplification. | TaqMan probes are commonly used [21]. SYBR Green is an alternative [3]. |

| Real-Time PCR Master Mix | Contains enzymes, dNTPs, and buffer for efficient DNA amplification. | Commercial kits are available. Must be compatible with the probe chemistry [24]. |

| DNA Polymerase | Enzyme that synthesizes new DNA strands. | Thermostable (e.g., Taq polymerase) is essential for cycling at high temperatures. |

| Standard Reference DNA | Enables quantification of the target DNA in the sample. | Serial dilutions of purified, quantified walnut DNA. |

Figure 1: Real-time PCR workflow for walnut allergen detection.

Protocol: Real-Time PCR Amplification

Primer and Probe Design: Design oligonucleotides to target walnut-specific sequences.

- Target Genes: Allergen-coding sequences (e.g., Jug r 1, Jug r 3, Jug r 4) are excellent targets [4] [3]. Multi-copy non-coding regions like ITS1 are also used to enhance sensitivity [21].

- Specificity Check: Verify in silico that sequences are unique to walnut and do not cross-react with other species.

Reaction Setup:

- Prepare a reaction mix containing: 1x TaqMan Master Mix, forward and reverse primers, TaqMan probe, and template DNA.

- A standard curve using known concentrations of walnut DNA must be included for quantification.

Thermal Cycling:

- Initial Denaturation: 95°C for 10 minutes.

- Amplification (40-45 cycles):

- Denature: 95°C for 15 seconds.

- Anneal/Extend: 60°C for 60 seconds (acquire fluorescence).

- The cycle threshold (Cq) value is determined for each sample.

Critical Experimental Data and Validation

Sensitivity and Specificity Performance

Table 3: Quantitative Performance of DNA-Based Walnut Detection Methods

| Target Gene / Region | Limit of Detection (LOD) | Limit of Quantification (LOQ) | Specificity Notes | Source |

|---|---|---|---|---|

| ITS1 Region | 0.1 mg kg⁻¹ (walnut in flour) | Not specified | Specific for J. regia; no cross-reactivity with other nuts/animals. | [21] |

| Jug r 3 | 2.5 pg walnut DNA | 0.05% (500 mg kg⁻¹) in spiked samples | High specificity for walnut. | [4] [3] |

| Multiplex Nut Assay | 0.64 mg kg⁻¹ (in cookie) | Not specified; semi-quantitative | Simultaneously detects peanut, hazelnut, walnut, cashew. | [24] |

Validation studies on commercial food products demonstrate the practical reliability of these methods. One survey of 232 foodstuffs found several products with undeclared walnut or pecan, highlighting the method's utility for verifying labeling compliance [21]. Another study testing 100 commercial samples confirmed that real-time PCR was the most sensitive technique compared to two different ELISA formats [23].

Impact of Food Processing on Detection

Processing can degrade DNA, potentially affecting PCR efficiency. However, DNA is generally more resilient than proteins.

Figure 2: Comparative effects of food processing on detection targets.

- Thermal Processing: Severe heat treatment can fragment DNA. Studies show autoclaving reduces both DNA yield and amplification efficiency [3]. However, the use of short amplicons and multi-copy targets mitigates this issue, allowing detection even in baked cookies [24].

- Non-Thermal Processing: Methods like High Hydrostatic Pressure have minimal impact on DNA amplification, making PCR highly suitable for foods processed with these technologies [3].

The stability of allergen-coding DNA sequences establishes real-time PCR as a powerful and reliable tool for detecting walnut allergens in food products. Its advantages are particularly evident when analyzing processed foods, where protein integrity may be compromised. The protocols detailed herein provide a framework for implementing this sensitive and specific detection method, contributing significantly to food safety research and the protection of allergic consumers.

This application note provides a comprehensive framework for the molecular detection of walnut allergen coding sequences in food products. Walnut allergy is a significant health concern with a high prevalence of severe reactions, driven primarily by seed storage proteins. We detail the molecular characteristics of three key walnut allergens—Jug r 1 (2S albumin), Jug r 3 (non-specific lipid transfer protein), and Jug r 4 (11S globulin)—and present validated real-time PCR protocols for their specific detection. The methodologies outlined herein support food safety testing, allergen risk assessment, and clinical diagnostics by enabling sensitive and specific identification of walnut traces in complex matrices, even following food processing treatments that may compromise protein integrity.

Walnut allergy ranks among the most common and severe tree nut allergies globally, affecting both children and adults with a high rate of systemic reactions including anaphylaxis [26] [27]. The clinical relevance of walnut allergy is underscored by prevalence data from the EuroPrevall project, which indicates that approximately 3% of the adult European population is sensitized to walnut, with country-specific rates ranging from 0.1% in Iceland to 8% in Spain [26]. Component-resolved diagnostics have revealed that sensitization patterns to specific walnut proteins correlate with clinical outcomes, age of onset, and geographical distribution, making molecular characterization essential for accurate diagnosis and effective food safety controls [27].

The walnut allergens Jug r 1, Jug r 3, and Jug r 4 represent distinct protein families with varying biochemical properties and clinical significance. Jug r 1, a 2S albumin storage protein, is recognized as a major allergen associated with severe systemic reactions and persistent allergy [26]. This protein exhibits high stability due to its cysteine-rich structure and disulfide bridges, making it resistant to digestive processes and thermal treatments [26]. Jug r 3, a nonspecific lipid transfer protein (nsLTP), is more frequently associated with allergic reactions in Mediterranean regions and can cause symptoms ranging from oral allergy syndrome to severe anaphylaxis [27]. Jug r 4, an 11S globulin storage protein, contributes to the allergenicity of walnut with approximately 57% of walnut-allergic patients showing IgE reactivity to this component [28]. The complementary sensitization profiles of these three allergens make them ideal targets for comprehensive detection strategies in both clinical diagnostics and food safety testing protocols.

Molecular Characteristics of Key Walnut Allergens

Table 1: Biochemical and immunological characteristics of key walnut allergens

| Allergen | Protein Family | Biological Function | Molecular Weight | IgE Reactivity | Clinical Significance |

|---|---|---|---|---|---|

| Jug r 1 | 2S albumin | Seed storage protein | 12-15 kDa | 71.4%-96.9% [26] | Severe systemic reactions; primary walnut allergy; heat and digestion stable |

| Jug r 3 | Non-specific lipid transfer protein (nsLTP) | Pathogenesis-related protein | ~9 kDa [27] | Varies by region (higher in Mediterranean) [27] | Varies from oral allergy syndrome to anaphylaxis; heat stable |

| Jug r 4 | 11S globulin (Legumin) | Seed storage protein | ~58 kDa (precursor) [28] | 57% [28] | Systemic reactions; cross-reactive with hazelnut, cashew, and peanut [28] |

Jug r 1: The Major Walnut Allergen

Jug r 1 belongs to the 2S albumin superfamily, characterized by small, globular, water-soluble proteins with high contents of asparagine, glutamine, cysteine, and arginine residues [26]. The protein consists of two subunits (large and small) connected by disulfide bridges, contributing to its remarkable stability in the gastrointestinal tract's harsh acidic environment [26]. This structural robustness enables Jug r 1 to cross the gut mucosal barrier and present to the immune system, triggering allergic responses in sensitized individuals [26]. The DNA sequence of Jug r 1 consists of 663 base pairs encoding 142 amino acids, with identified linear IgE-binding epitopes located at AA28-35, AA42-49, AA55-62, AA65-73, AA97-104, and AA109-121 [26]. From a clinical perspective, sensitization to Jug r 1 is strongly associated with primary walnut allergy and systemic symptoms, with studies showing that 71.4% of children with walnut-induced anaphylaxis in Northern Italy were positive for Jug r 1 [26]. A Korean study further demonstrated that 96.9% of children with walnut allergy were sensitized to Jug r 1, and the concentration of Jug r 1-sIgE was higher than for other walnut components [26].

Jug r 3: The Lipid Transfer Protein

Jug r 3 represents a nonspecific lipid transfer protein (nsLTP) characterized by its compact structure stabilized by four disulfide bridges, conferring resistance to proteolysis and thermal processing [27]. This allergen is particularly significant in Mediterranean regions where nsLTP sensitization is common, often linked to peach allergy (Pru p 3) [27]. Unlike the seed storage proteins Jug r 1 and Jug r 4, Jug r 3 sensitization does not consistently correlate with severe systemic reactions to walnut, showing variable clinical manifestations from mild oral symptoms to anaphylaxis depending on individual sensitization patterns and co-factors [27].

Jug r 4: The Legumin Storage Protein

Jug r 4 is an 11S globulin (legumin group) allergen encoded by a cDNA that produces a precursor protein with a predicted molecular weight of 58.1 kDa [28]. This hexameric seed storage protein dissociates into acidic and basic subunits linked by disulfide bonds in its mature form. Serum IgE from 21 of 37 (57%) walnut-allergic patients demonstrated binding to recombinant Jug r 4, confirming its importance as a walnut allergen [28]. Significant in vitro cross-reactivity has been demonstrated between Jug r 4 and homologous legumin proteins in hazelnut, cashew, and peanut, explaining the frequent clinical co-allergy observed between these tree nuts and peanut [28]. Sensitization to Jug r 4, particularly in combination with Jug r 1, correlates with more severe allergic reactions and systemic symptoms [27].

Real-Time PCR Detection Methodology

Workflow for Walnut Allergen Detection

The following diagram illustrates the comprehensive workflow for detecting walnut allergen coding sequences in food products using real-time PCR methodology:

DNA Extraction and Quality Control

High-quality DNA extraction is fundamental for successful real-time PCR detection of walnut allergens. The CTAB-phenol-chloroform extraction method has been demonstrated as particularly effective for walnut and other tree nuts, providing superior DNA yield and quality compared to commercial kits [4]. This method effectively removes polysaccharides, polyphenols, and other PCR inhibitors that can compromise amplification efficiency. Following extraction, DNA quantity and quality should be assessed using spectrophotometric (A260/A280 ratio ~1.8-2.0) or fluorometric methods. For processed food samples, additional purification steps may be necessary to eliminate contaminants introduced during manufacturing. DNA integrity should be verified by conventional PCR amplification of a conserved housekeeping gene or by agarose gel electrophoresis to confirm the presence of high-molecular-weight DNA, particularly important for samples subjected to severe thermal processing which can cause DNA fragmentation [4] [29].

Primer and Probe Design for Walnut Allergen Targets

Table 2: Target sequences for real-time PCR detection of walnut allergens

| Target Allergen | Target Gene Type | Amplification Chemistry | Detection Limit | Key Considerations |

|---|---|---|---|---|

| Jug r 1 | Allergen-coding sequence | LNA probe / TaqMan | 2.5 pg walnut DNA [4] | High specificity; minimal cross-reactivity |

| Jug r 3 | Allergen-coding sequence | LNA probe / TaqMan | 0.01% walnut (100 mg/kg) [4] | Sensitive detection even in processed foods |

| Jug r 4 | Allergen-coding sequence | LNA probe / TaqMan | 2.5 pg walnut DNA [4] | Cross-reactivity assessment needed |

| Chloroplast markers (alternative) | Multi-copy genes | SYBR Green / TaqMan | 0.1 mg/kg [30] [31] | Higher sensitivity but less specific |

Primer and probe design should target unique regions within the coding sequences of Jug r 1, Jug r 3, and Jug r 4 to ensure specific amplification. Locked Nucleic Acid (LNA) probes have demonstrated superior sensitivity and specificity compared to SYBR Green chemistry for allergen detection, with enhanced capacity to discriminate between closely related species [29]. LNA nucleotides are bicyclic RNA analogues in which the 2'-oxygen and 4'-carbon atoms are connected by an extra methylene bridge, conferring increased thermal stability and greater mismatch discrimination compared to conventional DNA probes [29]. For each target allergen, primers should be 18-22 nucleotides in length with a Tm of 60±2°C, and amplicon sizes should be limited to 60-150 bp to ensure efficient amplification, particularly from processed food samples where DNA fragmentation may occur. For absolute quantification, standard curves should be generated using serial dilutions of plasmid DNA containing the target sequence or genomic DNA of known concentration.

Real-Time PCR Amplification Protocol

The following protocol has been validated for detection of walnut allergen coding sequences in processed foods [4]:

Reaction Setup:

- Prepare 25 μL reactions containing: 1X PCR buffer, 3-5 mM MgCl₂, 0.2 mM dNTPs, 0.3 μM each primer, 0.1-0.2 μM LNA or TaqMan probe, 1.25 U DNA polymerase, and 2-50 ng template DNA.

- Include appropriate negative controls (no-template) and positive controls (walnut DNA of known concentration).

- Perform reactions in triplicate to ensure reproducibility.

Thermal Cycling Conditions:

- Initial denaturation: 95°C for 10 minutes

- 40-45 cycles of:

- Denaturation: 95°C for 15 seconds

- Annealing/Extension: 60°C for 60 seconds (with fluorescence acquisition)

- Final hold: 4°C

Data Analysis:

- Set threshold fluorescence in the exponential phase of amplification above background but sufficiently low to provide high amplification efficiency.

- Determine cycle threshold (Ct) values for each reaction.

- For quantitative analysis, use standard curves to interpolate target DNA concentration.

- Confirm amplification specificity by melt curve analysis if using SYBR Green chemistry.

This protocol has demonstrated a limit of detection (LOD) of 2.5 pg of walnut DNA and can detect as little as 0.01% (100 mg/kg) of walnut in raw matrices using Jug r 3 primers [4]. The method has shown greater sensitivity and reliability in detecting walnut traces in commercial foodstuffs compared to ELISA assays, particularly in processed foods where protein epitopes may be denatured [4].

Research Reagent Solutions

Table 3: Essential research reagents for walnut allergen detection by real-time PCR

| Reagent Category | Specific Products/Examples | Function in Protocol |

|---|---|---|

| DNA Extraction Kits | DNeasy Plant Pro Kit (Qiagen), CTAB-phenol-chloroform method | High-quality DNA isolation from complex food matrices |

| PCR Master Mixes | TaqMan Environmental Master Mix, LightCycler 480 Probes Master | Provides optimized buffer, enzymes, dNTPs for efficient amplification |

| Fluorescent Probes | LNA probes, TaqMan probes (FAM/BHQ) | Target-specific detection with enhanced specificity and sensitivity |

| Positive Controls | Plasmid DNA containing Jug r 1, Jug r 3, Jug r 4 sequences | Standard curve generation and assay validation |

| Real-Time PCR Instruments | Applied Biosystems 7500, Roche LightCycler 480, Bio-Rad CFX96 | Automated thermal cycling with fluorescence detection capabilities |

Impact of Food Processing on Detection

Food processing methods significantly impact the detectability of walnut allergens through both protein-based and DNA-based detection methods. Thermal processing, particularly when combined with pressure (autoclaving), can reduce DNA yield, quality, and amplification efficiency due to fragmentation and degradation of DNA molecules [4] [29]. Studies have demonstrated that autoclaving (121-138°C under pressure) substantially reduces the amplifiability of walnut DNA, whereas high hydrostatic pressure (HHP) treatment alone does not produce significant effects on DNA amplification [4]. In contrast, boiling treatments typically have minimal impact on DNA detection sensitivity. These processing effects highlight the advantage of multi-target detection approaches for walnut allergens, as different sequences may exhibit varying resistance to degradation. For instance, shorter amplicons (≤100 bp) remain detectable even in severely processed samples where longer targets may be compromised [31]. When developing detection protocols for specific food products, it is essential to validate the method using processed materials that reflect the intended application, as processing-induced modifications to DNA can affect both the absolute limit of detection and the quantitative accuracy of real-time PCR assays.

Clinical Relevance and Threshold Doses

Understanding the clinical relevance of walnut allergens and their eliciting doses is crucial for contextualizing the importance of sensitive detection methods. Recent research has established that very small amounts of walnut protein can trigger allergic reactions in sensitized individuals. The Nut CRACKER study analyzed 626 walnut oral food challenges and determined that discrete doses of walnut protein eliciting symptoms in 1% (ED01) and 5% (ED05) of the allergic population were 0.8 mg and 3.8 mg, respectively [18]. These thresholds are remarkably low, equivalent to minute fractions of a single walnut kernel, underscoring the critical need for highly sensitive detection methods in food safety testing. A Japanese study further confirmed the potency of walnut allergens, establishing an ED05 of 4.37 mg for walnut in their population, with even lower thresholds observed in patients with high levels of Jug r 1-specific IgE [5]. These findings directly inform public health policies and food labeling requirements, highlighting the importance of detection methods capable of identifying walnut traces at levels relevant to clinical reactivity. Real-time PCR protocols targeting allergen coding sequences provide the necessary sensitivity to detect walnut contamination at or below these established threshold doses, thereby supporting effective allergen management and consumer protection.

The molecular detection of walnut allergen coding sequences via real-time PCR represents a robust, sensitive, and specific approach for identifying walnut contamination in food products. Targeting the major allergens Jug r 1, Jug r 3, and Jug r 4 provides comprehensive coverage of the principal allergenic components in walnut, accommodating varying sensitization patterns across different populations. The protocols outlined in this application note have been validated across multiple studies and demonstrate superior performance compared to protein-based detection methods, particularly in processed foods where allergen integrity may be compromised. As walnut allergy continues to represent a significant health concern with potentially severe outcomes, the implementation of reliable detection methods supports both clinical diagnostics and food safety initiatives, ultimately contributing to improved quality of life for walnut-allergic consumers through accurate food labeling and reduced risk of accidental exposure.

For individuals with walnut allergy, exposure to even trace amounts of walnut can trigger reactions ranging from mild symptoms to life-threatening anaphylaxis [32]. The prevalence of walnut allergy makes it a significant public health concern, affecting approximately 0.6% of children in the US and representing the most common tree nut allergy in the country [33] [32]. The management of walnut allergy relies entirely on the strict avoidance of walnuts and products containing them, making accurate detection and labeling of walnut in food products a critical safety issue [3] [23].

This article explores the vital link between the analytical sensitivity of walnut detection methods and the clinical thresholds that protect allergic consumers. Establishing this relationship ensures that detection methodologies are sufficiently sensitive to identify walnut concentrations that could provoke allergic reactions. Real-time PCR (RT-PCR) has emerged as a powerful technique for detecting walnut traces in complex food matrices, offering the specificity and sensitivity required to verify labeling compliance and protect consumer health [3] [23].

Walnut Allergy Prevalence and Clinical Relevance

Epidemiological Significance

Walnut allergy exhibits notable geographical variation in prevalence. In the United States, walnut is the most commonly reported tree nut allergy, affecting approximately one-third of tree nut-allergic individuals [33]. European studies report a range of walnut allergy prevalence, from 0.1% to 3.7% across different countries, with France showing the highest rate [32]. In Spain, the prevalence of IgE sensitization to Jug r 4 with clinical reaction has been reported between 0.1% and 0.35% [23].

Clinical Manifestations and Severity

Walnut allergy can provoke a spectrum of IgE-mediated symptoms including nausea, vomiting, pruritus, abdominal pain, urticaria, angioedema, diarrhea, asthma, and potentially fatal anaphylaxis [32]. The severity of reactions often correlates with sensitization to specific walnut storage proteins. Individuals with severe reactions to walnut have been shown to have higher levels of IgE to Jug r 1, Jug r 2, Jug r 6, and Jug r 4 compared to those with milder reactions [33].

Cross-Reactivity Considerations

A significant clinical concern is the cross-reactivity between walnut and other tree nuts, particularly pecan, as they belong to the same Juglandaceae family [32]. This cross-reactivity often necessitates the avoidance of both nuts by allergic individuals. Additionally, the homology between walnut Jug r 4 and peanut Ara h 3 (approximately 73% sequence identity) may contribute to cross-reactivity between these botanically distinct allergens [33] [34].

Eliciting Doses and Clinical Thresholds

Reference Doses for Allergen Risk Management

The establishment of reference doses for allergenic foods is a critical component of risk management. These doses represent the maximum amount of an allergen that can be safely consumed without triggering a reaction in the majority of sensitive individuals. While comprehensive population-based threshold data for walnut remains limited, similar allergens have established reference doses that inform detection sensitivity requirements.

For instance, a reference dose of 10 mg of shrimp protein (approximately 44 mg of shrimp) has been proposed to protect most shrimp-allergic individuals [35]. For milk allergens, a reference dose of 0.1 mg of milk proteins has been established, which translates to approximately 3.03 mg of liquid milk per kg of food [36]. These values provide important benchmarks for understanding the sensitivity required for walnut detection methodologies.

Minimum Eliciting Doses for Walnut

Research indicates that the minimum amount of walnut protein that elicits an allergic reaction in 5% of the sensitized population is estimated to be 3–4 mg [23]. This threshold underscores the exceptional sensitivity required for detection methods to effectively protect consumers. Individual variability in reaction thresholds is high, necessitating detection capabilities that can identify even trace amounts of walnut in food products.

Real-Time PCR Detection of Walnut Allergens

Methodological Principle and Advantages

Real-time PCR (RT-PCR) represents a sophisticated DNA-based approach for detecting walnut allergens in food products. This technique amplifies specific walnut allergen coding sequences using fluorescence-based detection, allowing for both qualitative identification and quantitative analysis [3]. Compared to protein-based immunoassays, RT-PCR offers several advantages for allergen detection in processed foods:

- Enhanced stability of DNA targets versus protein antigens in processed food matrices [37] [23]

- Superior sensitivity with detection limits reaching parts per million (ppm) levels [3] [23]

- High specificity through careful primer design targeting unique walnut sequences [3]

- Robust performance across various food processing conditions [3]

Target Genes and Analytical Performance

The selection of appropriate target sequences is crucial for developing sensitive and specific RT-PCR assays. Research has demonstrated that targeting walnut allergen coding sequences such as Jug r 1 (2S albumin), Jug r 3 (lipid transfer protein), and Jug r 4 (11S globulin) provides excellent specificity and sensitivity for walnut detection [3]. The performance of these targets is summarized in Table 1.

Table 1: Performance Characteristics of Real-Time PCR Methods for Walnut Detection

| Target Allergen | Gene/Sequence Target | Limit of Detection (DNA) | Limit of Detection (Walnut in Food) | Reference |

|---|---|---|---|---|

| Jug r 1, 3, 4 | Allergen coding sequences | 2.5 pg walnut DNA | 0.01% (100 mg/kg) | [3] |

| Jug r 3 | Allergen coding sequence | Not specified | 0.01% (100 mg/kg) | [3] |

| Walnut (unspecified) | Mitochondrial DNA | Not specified | 10 ppm (mg/kg) | [23] |

The exceptional sensitivity of these methods enables detection of walnut traces at levels that could potentially trigger reactions in highly sensitive individuals, thereby supporting food safety management.

Comparison with Immunoassay Methods

Studies have directly compared RT-PCR with enzyme-linked immunosorbent assay (ELISA) for walnut detection in commercial food products. In one comprehensive survey of 100 commercial samples, RT-PCR demonstrated superior sensitivity compared to both a commercial sandwich ELISA kit and a multimeric scFv ELISA [23]. While there was general agreement between methods for most samples, discrepancies were noted in heat-treated samples or products containing pecan, where the walnut ELISA kit showed cross-reactivity [23].

This comparative performance highlights the complementary nature of these techniques, with RT-PCR providing a highly sensitive and specific approach for detecting walnut DNA even in processed foods where proteins may be denatured.

Experimental Protocols for Real-Time PCR Detection

DNA Extraction and Purification

Proper DNA extraction is fundamental to successful RT-PCR detection. The following protocol has been validated for walnut detection in complex food matrices [3] [23]:

- Sample Homogenization: Finely grind food samples using an analytical mill to ensure representative sampling.

- CTAB–Phenol–Chloroform Extraction: Utilize cetyltrimethylammonium bromide (CTAB) buffer followed by phenol-chloroform extraction for optimal DNA yield from walnut-containing samples.

- DNA Purification: Employ commercial DNA clean-up systems (e.g., Wizard DNA Clean-up System, Promega) to remove potential PCR inhibitors.

- Quality Assessment: Measure DNA concentration and purity using UV spectrophotometry (e.g., NanoDrop ND-1000). Acceptable 260/280 ratios typically range from 1.8 to 2.0.

This extraction method has proven particularly effective for walnut, providing high-quality DNA suitable for amplification even from processed food matrices [3].

Primer Design and Validation

Effective RT-PCR detection requires carefully designed primers targeting walnut-specific sequences:

- Target Selection: Focus on allergen coding sequences (Jug r 1, Jug r 3, Jug r 4) or conserved mitochondrial genes (e.g., 12S rRNA, 16S rRNA) [3] [37].

- Specificity Validation: Test primer specificity against a panel of non-target species, including common ingredients and potentially cross-reactive nuts [3] [37].

- Sensitivity Determination: Establish limits of detection and quantification using serial dilutions of walnut DNA and spiked food samples [3].

For walnut detection, primer sets targeting Jug r 3 have demonstrated particularly high sensitivity, detecting as little as 0.01% (100 mg/kg) of raw walnut in spiked samples [3].

Real-Time PCR Amplification Protocol

The following amplification protocol has been successfully employed for walnut detection [3]:

Reaction Setup:

- Prepare reaction mixes containing SYBR Green master mix

- Add specific primers (typically 0.2-0.5 µM each)

- Include approximately 10-50 ng of template DNA

Amplification Parameters:

- Initial denaturation: 95°C for 10 minutes

- 40-45 cycles of:

- Denaturation: 95°C for 15 seconds

- Annealing: 60-65°C for 30-60 seconds

- Fluorescence acquisition at the end of each annealing step

Data Analysis:

- Determine cycle threshold (Ct) values

- Quantify using standard curves from known DNA concentrations

- Confirm amplification specificity through melt curve analysis

This protocol has been validated across various food matrices, demonstrating robust performance for walnut detection [3] [23].

Impact of Food Processing on Detection Sensitivity

Processing Effects on DNA Quality

Food processing methods can significantly impact the quality and amplifiability of DNA targets, consequently affecting detection sensitivity. Studies have investigated various processing techniques:

- Thermal Treatment Combined with Pressure (Autoclaving): This severe processing method reduces both yield and amplification efficiency of walnut DNA due to fragmentation and degradation [3].

- High Hydrostatic Pressure (HHP): This emerging processing technology does not produce significant effects on walnut DNA amplification, making detection equally effective in HHP-treated products [3].

- Oven Cooking and Autoclaving: Model studies with meat products have shown that while thermal processing may reduce DNA quality, well-designed RT-PCR assays still achieve sensitivities of 0.01% (w/w) or better in cooked hams and autoclaved sausages [36].

Optimization Strategies for Processed Foods

To maintain detection sensitivity across variously processed foods, several strategies prove effective:

- Target Shorter Amplicons: Designing primers to amplify shorter DNA fragments (100-150 bp) improves detection in highly processed foods where DNA fragmentation occurs [3].

- Normalized Quantification: Using the ∆Ct method with an endogenous control accounts for variations in DNA recovery and quality from processed samples [36].

- Matrix-Matched Standards: Preparing calibration curves using processed model mixtures that mimic the food matrix being analyzed improves quantification accuracy [36].

Research Reagent Solutions

Table 2: Essential Research Reagents for Walnut Allergen Detection by RT-PCR

| Reagent/Category | Specific Examples | Function/Application | Reference |

|---|---|---|---|

| DNA Extraction Kits | NucleoSpin Food Kit (Macherey-Nagel), Wizard DNA Clean-up System (Promega) | Isolation and purification of high-quality DNA from complex food matrices | [23] [36] |

| PCR Reagents | SYBR Green master mixes, hydrolysis probes (TaqMan) | Fluorescence-based detection and quantification of amplified DNA targets | [3] [35] |

| Target Primers | Jug r 1, Jug r 3, Jug r 4 specific primers; 12S/16S rRNA primers | Specific amplification of walnut DNA sequences | [3] [37] |

| Reference Materials | Raw and heat-processed walnut powders, spiked model mixtures | Method calibration, validation, and quantification | [3] [23] |

| Quality Control Tools | UV spectrophotometry (NanoDrop), endogenous control primers (18S rRNA) | Assessment of DNA quality/quantity and amplification efficiency | [23] [36] |

Workflow Diagram

Diagram Title: Workflow for Walnut Detection Linking Analytical Sensitivity to Clinical Thresholds

The critical relationship between detection sensitivity and clinical thresholds forms the foundation for effective protection of walnut-allergic consumers. Real-time PCR methodologies targeting walnut allergen coding sequences provide the necessary sensitivity and specificity to detect walnut traces at levels relevant to clinical response thresholds. The validated protocols outlined in this article enable reliable detection of walnut as low as 0.01% (100 mg/kg) in various food matrices, sufficient to identify potentially hazardous contamination.

As research continues to refine population threshold data for walnut allergy, detection methodologies must evolve accordingly. The integration of sensitive DNA-based detection with robust clinical threshold data creates a comprehensive framework for evidence-based allergen management. This approach supports accurate food labeling, enables risk-based decision-making, and ultimately enhances the safety and quality of life for individuals with walnut allergy.

A Step-by-Step Protocol: From DNA Extraction to qPCR Amplification

This application note provides a detailed protocol for the optimal extraction of genomic DNA from walnut (Juglans regia) and related species using the CTAB-phenol-chloroform method. The procedure is specifically optimized to overcome the biochemical challenges posed by walnut tissues, which are rich in polysaccharides, polyphenols, and other secondary metabolites that can co-purify with DNA and inhibit downstream molecular applications. The high-quality DNA obtained through this method is suitable for sensitive downstream applications, particularly the real-time PCR detection of walnut allergen coding sequences (Jug r 1, Jug r 3, and Jug r 4) in food products, with demonstrated limits of detection as low as 2.5 pg of walnut DNA [4]. This protocol ensures the reliable detection of walnut traces as low as 0.4 mg/kg in complex food matrices, providing an essential tool for food allergen testing and compliance with labeling regulations [9].

The accurate detection of food allergens is crucial for protecting sensitized individuals. For walnut allergens, DNA-based detection methods, especially real-time PCR, offer high specificity and sensitivity [4] [30]. The success of these molecular assays is fundamentally dependent on the quality and purity of the isolated DNA [38]. Walnut tissues present specific challenges for DNA extraction due to their high content of polyphenols, polysaccharides, and lipids, which can become potent inhibitors of PCR amplification if not effectively removed during extraction [39] [40].

The CTAB (cetyltrimethylammonium bromide) method, particularly when combined with phenol-chloroform extraction, is well-established for plant tissues and is the recommended approach for obtaining high-quality DNA from walnut. This method has been successfully employed in research settings for the specific detection of walnut allergen genes, demonstrating superior performance compared to protein-based methods like ELISA in processed foods [4]. The following sections detail the chemistry, reagents, and a step-by-step protocol optimized for walnut tissue, ensuring DNA of sufficient purity and integrity for real-time PCR analysis of allergen coding sequences.

Chemical Principles and Reagent Functions

Understanding the role of each component in the extraction buffer is key to troubleshooting and further optimizing the protocol for specific walnut varieties or sample conditions.

Table 1: Key Components of CTAB Extraction Buffer and Their Functions

| Component | Typical Concentration | Primary Function | Role in Walnut DNA Extraction |

|---|---|---|---|

| CTAB | 2% (w/v) | Cationic detergent | Lyses cells and membranes; complexes with polysaccharides and denatures proteins at high salt concentration [39] [40]. |

| NaCl | 1.4 M | Ionic strength modulator | Creates high-salt conditions necessary for CTAB to form complexes with polysaccharides, preventing their co-precipitation with DNA [39] [40]. |

| EDTA | 20 mM | Chelating agent | Chelates Mg²⁺ ions, which are cofactors for DNase enzymes, thereby protecting DNA from degradation [40]. |

| Tris-HCl | 100 mM | Buffer | Maintains a stable pH (typically 8.0) throughout the extraction to prevent DNA denaturation [40]. |

| PVP | 1% (w/v) | Polymer | Binds to polyphenols and tannins (abundant in walnut) through hydrogen bonding, preventing their oxidation and subsequent co-precipitation with DNA [39] [40]. |

| β-Mercaptoethanol | 0.2-1% (v/v) | Reducing agent | Reduces disulfide bonds in proteins and prevents the oxidation of polyphenols into quinones, minimizing browning of the extract [40]. |

The protocol exploits the differential solubility of CTAB complexes. At high salt concentrations (>0.5 M NaCl), CTAB binds to polysaccharides, which are removed during the subsequent chloroform extraction. The DNA, which remains in the aqueous phase, is then precipitated at a lower effective salt concentration using isopropanol [39] [40].

Materials and Equipment

Reagents and Solutions

- CTAB Extraction Buffer: 2% CTAB, 100 mM Tris-HCl (pH 8.0), 1.4 M NaCl, 20 mM EDTA, 1% PVP (Polyvinylpyrrolidone). Add 0.2-1% β-mercaptoethanol fresh before use [39] [40].

- Liquid nitrogen

- RNase A (10 mg/ml, DNase-free) [39]

- Phenol:Chloroform:Isoamyl Alcohol (25:24:1 ratio) [39]

- Chloroform:Isoamyl Alcohol (24:1) [39]

- Isopropanol (chilled at -20°C)

- Ethanol (70%, chilled at -20°C)

- TE Buffer: 10 mM Tris-HCl (pH 8.0), 1 mM EDTA [39]

- Sodium Acetate (3 M, pH 5.2) - Optional, for alternative precipitation [38]

Equipment and Consumables

- Mortar and pestle (chilled)

- Water bath or heating block (60°C and 37°C)

- Centrifuge (capable of at least 14,000 × g)

- Polypropylene centrifuge tubes (2 ml) - Do not use polycarbonate tubes with phenol and chloroform [39]

- Vortex mixer

- Vacuum concentrator (e.g., SpeedVac) or ability to air-dry pellets [39]

Step-by-Step Protocol

Sample Preparation and Lysis

Tissue Disruption: For fresh or frozen walnut tissue, chill a mortar and pestle with liquid nitrogen. Add up to 100 mg of tissue and grind thoroughly to a fine powder. Keep the tissue frozen throughout the process to prevent the activation of degrading enzymes [39] [41].

- Alternative for freeze-dried tissue: Grind at room temperature to a fine powder [39].

Cell Lysis:

- Transfer the ground powder to a polypropylene tube.

- Add 500-1000 µl of pre-warmed (60°C) CTAB buffer (with β-mercaptoethanol) per 100 mg of tissue [39].

- Mix thoroughly by vortexing.

- Incubate the tube in a 60°C water bath for 30-60 minutes, mixing by inversion every 10 minutes. The sample should appear homogeneous.

Deproteinization and Purification

Clarification: Centrifuge the homogenate for 5-10 minutes at 14,000 × g at room temperature. Carefully transfer the supernatant to a new polypropylene tube, avoiding the pellet of cellular debris [39].

RNase Treatment: Add 5 µl of RNase A solution (10 mg/ml) to the supernatant. Mix gently and incubate at 37°C for 20 minutes to digest RNA [39].

Organic Extraction:

- Add an equal volume of Phenol:Chloroform:Isoamyl Alcohol (25:24:1) to the sample.

- Vortex vigorously for 5-10 seconds to form an emulsion.

- Centrifuge for 5-10 minutes at 14,000 × g to separate the phases. Three distinct layers will form: a lower organic phase, an interphase (containing denatured proteins and contaminants), and an upper aqueous phase (containing DNA) [39] [41].

- Carefully transfer the upper aqueous phase to a new tube. For samples with high levels of contaminants, repeat this extraction until the interphase is clear.

- Perform a final extraction with an equal volume of Chloroform:Isoamyl Alcohol (24:1) to remove residual phenol. Transfer the final aqueous phase to a new tube [39].

DNA Precipitation and Washing

DNA Precipitation: Add 0.7 volumes of cold isopropanol to the aqueous phase. Mix gently by inversion. Incubate at -20°C for at least 30 minutes to precipitate the DNA. A stringy white precipitate should be visible [39].

DNA Pelleting: Centrifuge the sample at 14,000 × g for 10 minutes at 4°C. Carefully decant the supernatant without disturbing the pellet.

Wash: Wash the DNA pellet by adding 500 µl of ice-cold 70% ethanol. Centrifuge at 14,000 × g for 5 minutes. Carefully decant the ethanol completely [39].

Drying: Air-dry the pellet for 15-30 minutes at room temperature or use a vacuum concentrator for a few minutes. Avoid over-drying, as this will make the DNA difficult to resuspend [39].

Resuspension: Dissolve the DNA pellet in 50-100 µl of TE Buffer or molecular biology grade water. Gently flick the tube or incubate at 37-55°C for 10-20 minutes to aid dissolution [39].

DNA Quantification and Quality Assessment

Quantify the DNA using a spectrophotometer (e.g., Nanodrop). High-quality DNA should have an A260/A280 ratio of ~1.8 and an A260/A230 ratio >2.0. Assess integrity by agarose gel electrophoresis, which should show a high molecular weight band with minimal smearing.

Application for Real-Time PCR Detection of Walnut Allergens

The DNA extracted via this protocol is suitable for highly sensitive real-time PCR assays targeting walnut allergen genes.

Table 2: Real-Time PCR Targets for Walnut Allergen Detection

| Target Gene | Allergen | Protein Family | Reported Sensitivity (DNA) | Reported Sensitivity (in food) | Key Reference |

|---|---|---|---|---|---|

| Jug r 3 | Lipid Transfer Protein | nsLTP | 2.5 pg | 100 mg/kg (0.01%) | [4] |

| Jug r 1 | 2S Albumin | 2S Albumin | 2.5 pg | Not specified | [4] |

| Jug r 4 | 11S Globulin | Legumin | 2.5 pg | Not specified | [4] |

| Chloroplast Markers (e.g., mat K) | - | - | High (for peanut) | 10 mg/kg (after boiling/autoclaving) | [31] |

A study using this CTAB-phenol-chloroform DNA extraction method demonstrated specific and accurate amplification of walnut allergen sequences (Jug r 1, Jug r 3, Jug r 4) with a limit of detection of 2.5 pg of walnut DNA. The Jug r 3 primer set was particularly robust, detecting down to 100 mg/kg of raw walnut in spiked samples [4]. This highlights the method's applicability for ensuring compliance with food labeling regulations and protecting consumers with walnut allergies.

Troubleshooting Guide

Table 3: Common Issues and Proposed Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Low DNA Yield | Incomplete tissue grinding, insufficient lysis. | Ensure tissue is a fine powder; increase incubation time/temperature at lysis step. |

| Brown/Dirty DNA | Polyphenol oxidation. | Increase concentration of β-mercaptoethanol and PVP; grind tissue while frozen. |

| DNA Difficult to Resuspend | Over-drying the pellet; presence of polysaccharides. | Do not over-dry pellet; gently warm during resuspension; perform additional chloroform extraction. |

| Poor A260/A280 Ratio | Protein or phenol contamination. | Repeat phenol:chloroform extractions until interphase is clear; ensure careful phase separation. |

| PCR Inhibition | Co-precipitation of polysaccharides or polyphenols. | Dilute DNA template; use a PCR facilitator like BSA; or further purify DNA using a silica column [41]. |

| Degraded DNA | DNase activity; too vigorous mixing. | Ensure all equipment and solutions are sterile; use EDTA-containing buffer; avoid vortexing after lysis step. |

The CTAB-phenol-chloroform protocol remains a robust and effective method for extracting high-quality DNA from challenging plant tissues like walnut. Its ability to remove PCR inhibitors such as polysaccharides and polyphenols makes it particularly suitable for preparing DNA for the highly sensitive real-time PCR detection of walnut allergen coding sequences. By following this optimized protocol, researchers and food testing laboratories can reliably detect trace amounts of walnut in food products, thereby playing a critical role in food safety and allergen management.

Primer Design Strategies for Allergen Coding Sequences (Jug r 1, Jug r 3, Jug r 4)

Within the framework of a broader thesis on developing robust protocols for the real-time PCR (RT-PCR) detection of walnut allergens, the strategic design of primers targeting specific allergen coding sequences is paramount. Walnut allergy is among the most prevalent tree nut allergies and can trigger severe reactions, making reliable detection of hidden allergens in processed foods a critical public health and regulatory concern [4] [42]. While protein-based detection methods like ELISA exist, their reliability can be compromised in processed foods where proteins may be denatured or altered [3]. DNA-based detection, particularly RT-PCR, offers a highly sensitive and specific alternative, as DNA is generally more resilient to food processing conditions [4] [3]. This application note details comprehensive primer design strategies and optimized protocols for the quantitative RT-PCR detection of three major walnut allergens: Jug r 1 (2S albumin), Jug r 3 (non-specific lipid transfer protein), and Jug r 4 (11S globulin, legumin). The methodologies outlined herein are designed to provide researchers and food safety professionals with a validated, sensitive, and reliable system for detecting walnut traces, even in complex food matrices.

Strategic Selection of Allergen Targets

The selection of appropriate allergen coding sequences as PCR targets is the foundational step for ensuring a successful detection assay. For walnut, the major allergens belong to different protein families and exhibit varying prevalence and clinical significance.

- Jug r 1 (2S Albumin): This allergen is a seed storage protein recognized as a major walnut allergen, with sensitization particularly frequent in certain geographic regions like the Netherlands and Spain [42]. Research indicates that Jug r 1-specific IgE levels are a strong discriminator for clinical walnut allergy in young children and can help predict the severity of reactions [43]. Its significance makes it an essential target for a comprehensive detection assay.

- Jug r 3 (Lipid Transfer Protein - LTP): LTPs are stable proteins resistant to digestion and thermal processing. Sensitization to Jug r 3 is more common in Southern Europe and can be associated with more severe systemic reactions [42]. Its stability makes it an excellent marker for detection, especially in processed foods.

- Jug r 4 (11S Globulin - Legumin): This is another major seed storage protein and one of the most abundant in walnut [33]. It is homologous to the major peanut allergen Ara h 3, sharing about 73% sequence identity, which is a consideration for investigating cross-reactivity [33]. It is recognized by a significant proportion of walnut-allergic individuals.

Targeting multiple, independently inherited allergen genes simultaneously, as demonstrated in the development of a triplex RT-PCR assay [4], significantly enhances the reliability and comprehensiveness of detection, guarding against false negatives due to genetic variation in walnut cultivars.

Table 1: Major Walnut Allergen Targets for RT-PCR Detection

| Allergen | Protein Family | Clinical & Practical Significance for Detection |

|---|---|---|

| Jug r 1 | 2S Albumin | Major allergen; good predictor of clinical allergy and severity in children [43]. |

| Jug r 3 | Lipid Transfer Protein (LTP) | Stable protein; associated with severe reactions; common target for sensitive detection assays [4] [42]. |

| Jug r 4 | 11S Globulin (Legumin) | Abundant seed storage protein; homologous to peanut Ara h 3 [33]. |

Primer and Probe Design Guidelines

The design of oligonucleotides for RT-PCR must adhere to stringent bioinformatic and thermodynamic principles to ensure high specificity, sensitivity, and efficiency.

Core Design Parameters

The following parameters, consistent with industry best practices, should guide the design of primers and probes [44]:

- Primer Length and Melting Temperature (Tm): Design primers between 18–30 bases in length. The optimal Tm is 60–64°C, with the forward and reverse primer Tm not differing by more than 2°C. The annealing temperature (Ta) should be set no more than 5°C below the lowest Tm of the primer pair [44].