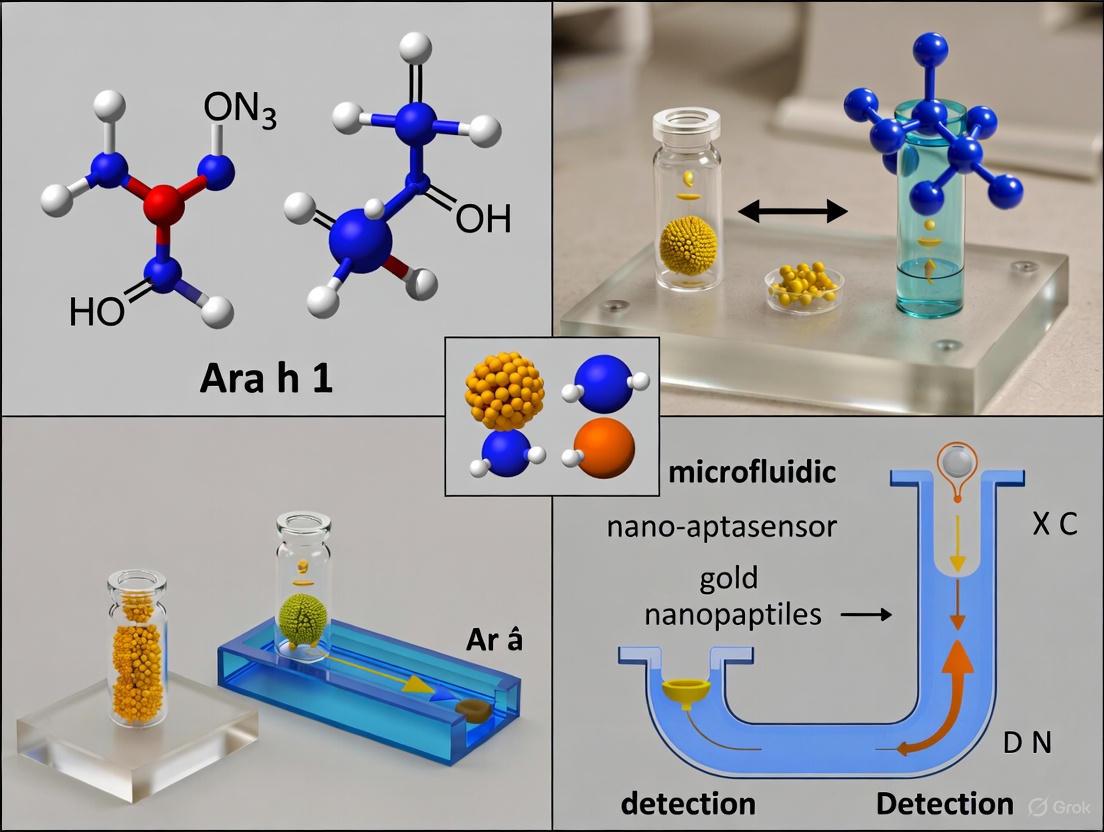

Microfluidic Origami Nano-aptasensors for Peanut Allergen Detection: A Comprehensive Guide for Researchers

This article provides a detailed exploration of microfluidic origami nano-aptasensors, an emerging technology for rapid, sensitive, and on-site detection of peanut allergens.

Microfluidic Origami Nano-aptasensors for Peanut Allergen Detection: A Comprehensive Guide for Researchers

Abstract

This article provides a detailed exploration of microfluidic origami nano-aptasensors, an emerging technology for rapid, sensitive, and on-site detection of peanut allergens. Aimed at researchers, scientists, and drug development professionals, it covers the foundational principles of using paper-based microfluidics and aptamer bioreceptors, the methodology for fabricating and operating these devices, critical optimization parameters for enhancing performance, and the validation of these sensors against complex food matrices and established techniques. The content synthesizes recent advancements, including the application of novel nanomaterials like black phosphorus for signal amplification, to present a complete picture of the current state and future potential of this transformative point-of-need diagnostic tool.

The Foundation of Microfluidic Origami Aptasensors: Principles, Components, and Significance

What are μPADs?

Microfluidic Paper-Based Analytical Devices (μPADs) are a class of analytical devices that use paper as a substrate to create microfluidic structures, such as channels and reaction zones, by patterning hydrophobic materials onto the hydrophilic paper [1] [2]. The field was notably advanced by the work of Whitesides and colleagues in 2007 [1]. These devices leverage the natural capillary action of paper to wick fluids without the need for external pumps or power sources, making them particularly suited for developing low-cost, portable, and disposable diagnostic tools [1] [2]. The most common application of paper-based microfluidic devices is in the development of point-of-care (POC) diagnostic devices, which could eliminate the need for costly and time-consuming laboratory-based analytical procedures [2].

Key Advantages of μPADs

The appeal of μPADs stems from a combination of physicochemical and practical benefits.

- Affordability and Accessibility: Paper is a low-cost, readily available, and lightweight material, making μPADs inexpensive to produce [1]. This enables their deployment in resource-limited and remote areas [3].

- Power-Free Operation: The cellulose fiber network of paper wicks fluids by capillary action, enforcing complete mixing and reaction at the micro-level without requiring external power [3] [1].

- Miniaturization and Portability: μPADs are miniaturized systems that consume small volumes of samples and reagents [3] [1]. Their small size and simplicity contribute to excellent portability.

- Ease of Use and Disposal: The design of μPADs is often simple and user-friendly, requiring minimal training to operate [1]. Being made primarily of paper, they are also easy to dispose of, often by incineration [1].

- Versatility and Biocompatibility: Paper is an excellent substrate for immobilizing various biological recognition elements (e.g., antibodies, aptamers, enzymes) [4]. Its inherent biocompatibility makes it suitable for a wide range of chemical and biochemical analyses [1].

Fabrication and Detection Techniques

Fabrication Methods

A variety of techniques exist for creating hydrophobic barriers on paper to define the microfluidic pathways.

- Wax Printing: A low-cost and simple method where a wax pattern is printed onto paper and then heated to allow the wax to penetrate through the paper, creating a hydrophobic barrier [1].

- Photolithography: This was the first method used to create μPADs. It involves using UV light to pattern a photoresist on paper, resulting in high-resolution structures [1].

- Inkjet Etching/Printing: This technique can be used to modify the surface properties of paper to create hydrophilic channels [1].

- Plasma Etching and Flexographic Printing: Other methods that can define hydrophobic and hydrophilic regions on paper substrates [1].

- PDMS Plotting: A computer-controlled plotter is used to deposit polydimethylsiloxane (PDMS) onto the paper to form the fluidic channels [1].

Detection Methods

Detection of analytes on μPADs can be achieved through several means, each with its own advantages.

- Colorimetric Detection: This is a cost-effective and simple method where a color change indicates the presence or concentration of an analyte. It is easily read by the naked eye or with a simple scanner [1].

- Electrochemical Detection: This method offers high sensitivity and selectivity. It involves measuring electrical signals (e.g., current, potential) resulting from a biochemical reaction and is well-suited for portable instrumentation [1] [5].

- Chemiluminescence (CL) Detection: CL detection involves measuring light emitted from a chemical reaction. It provides high sensitivity and a wide dynamic range and is highly amenable to miniaturization [1] [4].

- Fluorescence Detection: This method relies on measuring the light emitted by a fluorescent molecule and can offer very high sensitivity [1].

Application in Allergen Detection: A Model Protocol

The following section details a specific application of a μPAD for detecting the peanut allergen Ara h1, demonstrating the integration of the principles discussed above. This protocol is adapted from recent research and serves as an excellent model for point-of-care food safety analysis [5].

Workflow for an Electrochemical μ-PAD for Ara h1 Detection

The overall process, from device preparation to final detection, is visualized in the following workflow. This particular approach utilizes an electrochemical detection method with signal amplification via nanocomposites.

Detailed Experimental Protocol

Objective: To quantitatively detect the peanut allergen Ara h1 in food products using a portable microfluidic paper-based analysis device (μ-PAD) with electrochemical detection.

Principle: The device operates based on the variation in the differential pulse voltammetry (DPV) response current induced by the specific capture of the target Ara h1 allergen. Black phosphorus–Au nanocomposites (BP–Au) are used to enhance the electron transfer rate at the electrode interface for signal amplification. A specific sulfhydryl-terminated aptamer is immobilized on the nanocomposite via Au–S bonding. When the target Ara h1 is present, it binds to the aptamer, causing steric hindrance that reduces the DPV current. The decrease in current is proportional to the concentration of Ara h1 [5].

Materials:

- Black phosphorus crystals: Served as the starting material for synthesizing black phosphorus nanosheets (BPNSs) [5].

- Chloroauric acid (HAuCl₄·3H₂O): Used for the in-situ growth of AuNPs on BPNSs to form BP-Au nanocomposites [5].

- Ara h1 aptamer: A single-stranded DNA oligonucleotide with a 5' sulfhydryl modification (-SH). Its sequence is: 5'-SH-C6-TCG CAC ATT CCG CTT CTA CCG GGG GGG TCG AGC GAG TGA GCG AAT CTG TGG GTG GGC CGT AAG TCC GTG TGT GCG AA-3' [5].

- Phosphate Buffered Saline (PBS): Used as a buffer solution.

- Food samples: e.g., cookies, bread, milk.

- Whatman chromatographic paper: Used as the substrate for the μ-PAD.

- Electrochemical workstation: For performing DPV measurements.

Procedure:

- Device Fabrication: Create the μ-PAD using a patterning method such as wax printing on Whatman chromatographic paper. The design should include a working electrode, a counter electrode, and a reference electrode [5].

- Nanocomposite Synthesis and Electrode Modification:

- Exfoliate black phosphorus crystals to obtain BPNSs.

- Synthesize BP-Au nanocomposites by immersing BPNSs in a HAuCl₄ solution, leading to the in-situ growth and anchoring of AuNPs on the BPNSs.

- Drop-cast the prepared BP-Au nanocomposite suspension onto the surface of the working electrode and allow it to dry.

- Aptamer Immobilization: Incubate the modified working electrode with the sulfhydryl-modified Ara h1 aptamer solution. The AuNPs on the nanocomposite will form stable Au–S bonds with the aptamer, fixing it to the electrode surface. Wash with PBS to remove unbound aptamers.

- Sample Analysis:

- Sample Extraction: Extract proteins from the homogenized food sample using an appropriate buffer.

- Detection: Apply the extracted sample solution to the detection zone of the μ-PAD. Incubate for a specific time (e.g., 20 minutes) to allow the Ara h1 allergen to bind to the immobilized aptamer.

- Measurement: Perform DPV measurements on the device. Record the peak current response.

- Quantification: Compare the DPV current response of the sample to a calibration curve obtained from standards with known concentrations of purified Ara h1 to determine the concentration in the sample.

Performance Data of the Ara h1 μ-PAD

The analytical performance of the described μ-PAD for detecting Ara h1 is summarized in the table below.

Table 1: Analytical performance of the electrochemical μ-PAD for Ara h1 detection [5].

| Parameter | Result |

|---|---|

| Detection Principle | Electrochemical (Differential Pulse Voltammetry) |

| Linear Range | 25 – 800 ng mL⁻¹ |

| Limit of Detection (LOD) | 11.8 ng mL⁻¹ |

| Total Analysis Time | < 20 minutes |

| Specificity | Good (tested against Ara h2) |

| Recovery in Spiked Food | 93.50% – 101.86% |

| Correlation with ELISA (R²) | 0.9956 |

Research Reagent Solutions for μ-PADs

The table below lists key reagents and materials commonly used in the development and operation of μ-PADs, particularly for biosensing applications like allergen detection.

Table 2: Essential research reagents and materials for μ-PAD-based biosensing.

| Reagent/Material | Function and Role in μ-PADs |

|---|---|

| Chromatography Paper (e.g., Whatman) | Serves as the hydrophilic, porous substrate that drives fluid flow via capillary action and provides a surface for reactions [5] [4]. |

| Aptamers | Single-stranded DNA or RNA oligonucleotides that act as synthetic recognition elements; they bind targets with high specificity and offer advantages in cost and stability over antibodies [5]. |

| Magnetic Microbeads (MBs) | Functionalized particles used for easy and efficient immobilization of biomolecules (e.g., antigens, antibodies) on paper, increasing the surface area for immunoreactions [4]. |

| Black Phosphorus-Au Nanocomposite | A nanomaterial used to modify electrodes; it improves electrical conductivity for signal amplification and provides a substrate for immobilizing biomolecules via bonding with gold [5]. |

| Electrochemical Probes (e.g., in DPV) | The measurement technique for quantitative detection; it offers high sensitivity, portability, and is compatible with miniaturized systems [5]. |

| Chemiluminescence Substrates (e.g., Luminol) | A highly sensitive detection method where light emission from a chemical reaction is measured, eliminating the need for an external light source [4]. |

The Evolution: μPAEDs and 3D Origami Devices

The field of paper-based microfluidics continues to evolve. A significant advancement is the development of microfluidic paper-based analytical extraction devices (μPAEDs). These are all-in-one devices that integrate an extraction system (e.g., solid-phase extraction) directly with the detection system on a single paper platform. This integration minimizes sample preparation steps, reduces the time between extraction and detection, and further enhances the device's suitability for on-site analysis [3].

Another major innovation is the creation of 3D μPADs using origami (folding) and kirigami (cutting) techniques. This approach allows for the construction of devices that can conduct complex, multi-step analytical procedures, such as full immunoassays, by controlling fluid flow vertically between layers. Reagents can be pre-loaded and stored in different layers, making the device a ready-to-use, self-contained analytical platform [4]. The following diagram illustrates the concept of an origami-based device for a multi-step assay.

In conclusion, μPADs represent a powerful and versatile analytical platform whose advantages—cost-effectiveness, portability, and ease of use—make them ideally suited for point-of-care applications. Their continued development, including integration with extraction methods and complex 3D designs, is poised to have a significant impact on fields ranging from clinical diagnostics to food safety and environmental monitoring.

In the realm of biosensing and diagnostic development, the selection of an appropriate biorecognition element is paramount. For decades, antibodies have been the cornerstone reagent for molecular detection in applications from research to clinical diagnostics. However, aptamers, which are short, single-stranded DNA or RNA oligonucleotides selected for specific target binding, have emerged as a powerful alternative [6]. For researchers developing advanced sensors, such as a microfluidic origami nano-aptasensor for peanut allergen detection, understanding the fundamental distinctions between these two molecular tools is critical for making an informed choice that aligns with the performance needs and practical constraints of the project [7].

This article provides a objective comparison, structured within the context of food allergen research, to equip scientists with the information needed to strategically select bioreceptors. We will compare the intrinsic properties of aptamers and antibodies, summarize quantitative data for easy comparison, and provide detailed experimental protocols that highlight the integration of aptamers into state-of-the-art sensing platforms.

Molecular Characteristics: A Head-to-Head Comparison

Aptamers and antibodies differ fundamentally in their origin, structure, and production, which gives rise to unique performance characteristics.

Origin and Production: Aptamers are discovered entirely in vitro through a process called SELEX (Systematic Evolution of Ligands by EXponential enrichment), which selectively enriches oligonucleotide sequences from a vast random library for their ability to bind a specific target [6]. In contrast, antibodies are large protein immunoglobulins generated in vivo by the immune system of animal models or by recombinant expression [6]. This difference in production has a direct impact on batch-to-batch consistency, with aptamers exhibiting near non-existent variability due to their chemical synthesis [6] [8].

Size and Structure: Aptamers are significantly smaller, typically 5–10 times smaller (1–3 nm) and 10 times lighter (~15 kDa) than antibodies (~150 kDa, 10–15 nm) [6]. This compact size allows for high packing density on sensor surfaces, which can enhance sensitivity.

Stability and Renaturation: A key operational advantage of aptamers is their robust stability. They can tolerate a wide range of pH and temperature, be dried and rehydrated, and can often be heat-denatured and refolded to restore function. Antibodies, once denatured, typically aggregate irreversibly and lose function [6]. The table below provides a detailed breakdown of these properties.

Table 1: Comparative Properties of Bioreceptors

| Feature | Aptamers | Antibodies |

|---|---|---|

| Molecule Type | Single-stranded DNA or RNA | Protein (Immunoglobulin) |

| Size / Molecular Weight | 1–3 nm / ~15 kDa [6] | 10–15 nm / ~150 kDa [6] |

| Production Process | Chemical synthesis (in vitro SELEX) [6] | Biological production (in vivo or cell culture) [6] |

| Batch-to-Batch Variability | Very low [6] [8] | Can be significant [6] |

| Thermal Denaturation | Can often renature after cooling [6] | Typically irreversible [6] |

| Storage Requirements | Lyophilized at room temperature; no cold chain needed [6] | Often requires refrigerated cold chain (2–8°C) [6] |

| Target Range | Virtually any molecule (ions, small molecules, proteins, cells) [6] | Limited by immunogenicity [6] |

| Modification | Easy, site-specific chemical modification [6] [7] | More challenging and unpredictable [6] |

Biosensing Applications and Experimental Protocols

The distinct properties of aptamers translate into tangible benefits in various biosensing formats, particularly in microfluidic and point-of-care devices where stability, cost, and miniaturization are critical.

Lateral Flow Assays (LFAs) and Microfluidic Platforms

Traditional LFAs and emerging microfluidic devices heavily rely on the stability and cost-effectiveness of their biorecognition elements.

Advantages of Aptamers: Aptamers remain functional after heat exposure and drying, making them ideal for settings without refrigeration [6]. Their synthetic nature also makes them about 5–6 times cheaper to manufacture at scale than antibodies [6]. Substituting aptamers can significantly reduce per-test reagent costs.

Protocol: Microfluidic Origami Nano-Aptasensor for Peanut Allergen (Ara h1) Detection [7]

- Objective: To construct a low-cost, rapid, and sensitive 3D microfluidic electrochemical sensor for detecting the major peanut allergen, Ara h1.

- Materials:

- Aptamer Probe: Ara h1-specific aptamer (sequence: 5́-TCG CAC ATT CCG CTT CTA CCG GGG GGG TCG AGC GAG TGA GCG AAT CTG TGG GTG GGC CGT AAG TCC GTG TGT GCG AA-3́) [7].

- Substrate: Chromatography paper patterned with PDMS microchannels and screen-printed electrodes (working, counter, reference).

- Nanomaterial: Black phosphorus nanosheets (BPNSs) to enhance electrochemical signal.

- Apparatus: Electrochemical workstation.

- Method:

- Probe Preparation: Decorate BPNSs with the Ara h1-specific aptamer via electrodeposition onto the paper-based working electrode.

- Chip Fabrication: Create the 3D sensor by sequentially folding the patterned paper substrate into an origami structure.

- Sample Incubation: Apply the extracted food sample to the sensor and allow it to react with the aptamer-decorated BPNSs for up to 20 minutes.

- Electrochemical Detection: Measure the current output. The specific binding of Ara h1 to the aptamer causes a variation in charge transfer on the electrode, resulting in a measurable change in current.

- Performance: This aptasensor achieved a detection limit of 21.6 ng/mL for Ara h1 in a linear range of 50–1000 ng/mL, demonstrating the potential for point-of-need testing [7].

Electrochemical Biosensors

Aptamers are exceptionally well-suited for electrochemical biosensing due to their ability to be engineered into reagentless, signal-on platforms.

E-AB Sensor Principle: In a typical electrochemical aptamer-based (E-AB) sensor, the aptamer is end-labelled with a redox molecule (e.g., methylene blue) and attached to an electrode surface. In the absence of the target, the aptamer is flexible, keeping the tag far from the electrode and limiting electron transfer. Upon target binding, the aptamer undergoes a conformational change that swings the redox tag closer to the electrode surface, resulting in a measurable increase in current [6]. This mechanism is rapid, real-time, and requires no wash steps or secondary reagents.

Protocol: HOF-Based Ultrasensitive Aptasensor for Ara h1 [9]

- Objective: To develop a highly sensitive electrochemical aptasensor using a conductive hydrogen-bonded organic framework (HOF) for signal amplification.

- Materials:

- Conductive HOF: Nickel-anchored PFC-73-Ni, serving as an excellent electrocatalyst.

- Electrode: Gold-electrodeposited glassy carbon electrode (DpAu@GCE).

- Aptamer: Thiol-modified Ara h1 aptamer immobilized on the electrode.

- Complementary DNA (cDNA): Sequence modified on the PFC-73-Ni for connection to the aptamer.

- Redox Mediator: Hydroquinone (HQ).

- Method:

- Electrode Functionalization: Immobilize the thiolated Ara h1 aptamer on the DpAu@GCE via Au-S bonding.

- Probe Assembly: Hybridize the PFC-73-Ni@cDNA conjugate with the aptamer on the electrode surface.

- Detection Mechanism: In the absence of Ara h1, the assembled structure catalyzes the oxidation of HQ, generating a strong electrochemical signal. When Ara h1 is present, it binds to the aptamer with higher affinity, displacing the PFC-73-Ni@cDNA and causing a signal decrease.

- Measurement: Record the differential pulse voltammetry (DPV) signal corresponding to the concentration of Ara h1.

- Performance: This sensor demonstrated an exceptionally low detection limit of 0.26 nM and a wide linear range of 1–120 nM, successfully detecting Ara h1 in spiked food samples [9].

The workflow below illustrates the core signaling mechanism of an electrochemical aptasensor.

Diagram 1: E-AB Sensor Signaling Mechanism

The Scientist's Toolkit: Key Research Reagent Solutions

For scientists embarking on the development of an aptamer-based sensor, the following reagents and materials are essential components of the experimental workflow.

Table 2: Essential Research Reagents for Aptasensor Development

| Reagent / Material | Function / Role in Development | Example from Context |

|---|---|---|

| Target-Specific Aptamer | The core biorecognition element that binds the analyte with high specificity and affinity. | Ara h1 aptamer (e.g., sequence P1-16 with Kd ~54 nM) [10]. |

| Chemical Modification Kits | Enable functionalization of aptamers (e.g., with thiol, biotin, or fluorescent tags) for immobilization and signaling. | Thiol modification for gold surface attachment [9]; Texas Red or Alexa Fluor 647 for optical assays [10]. |

| Nanomaterial Enhancers | Used to increase surface area, improve electron transfer, and amplify the detection signal. | Black Phosphorus Nanosheets (BPNSs) [7]; Conductive Hydrogen-Bonded Organic Frameworks (HOFs) like PFC-73-Ni [9]. |

| Microfluidic Chip Substrates | Provide a low-cost, portable platform for fluidic handling and sensor assembly. | Chromatography paper for origami devices [7]; PDMS or glass for conventional microfluidics [11]. |

| SELEX Kit Components | For the in vitro selection of new aptamers, including initial random oligonucleotide libraries and reagents for partitioning and amplification. | Used in the discovery of aptamers like P1-16 for peanut allergens [10] [12]. |

The choice between aptamers and antibodies is not merely a substitution of one reagent for another, but a strategic decision that influences sensor design, performance, and commercial viability. For applications demanding high stability, low-cost production, minimal batch variability, and ease of chemical modification—such as in point-of-care food allergen detection—aptamers present a compelling case [6] [13].

The ongoing development of sophisticated platforms like microfluidic origami aptasensors and HOF-enhanced electrochemical sensors underscores the growing synergy between novel materials and the unique properties of oligonucleotide bioreceptors [7] [9]. As the library of validated aptamers continues to expand, their role in empowering researchers to create next-generation diagnostic tools is set to increase significantly, potentially bridging critical gaps between complex laboratory testing and real-world analytical needs.

The peanut allergen Ara h1 is a major allergenic protein, constituting approximately 12–16% of the total peanut protein and being responsible for 35–95% of all peanut-induced allergic reactions [5]. Its reliable detection is crucial for public health. Microfluidic origami nano-aptasensors represent a cutting-edge analytical platform that combines the portability and low cost of paper-based microfluidics with the high specificity of nucleic acid aptamers. These devices are designed to bridge the gap between complex laboratory testing and rapid food allergen analysis at the point of need, offering detection times as short as 20 minutes [14] [5].

Performance Data and Analytical Figures of Merit

The analytical performance of different configurations of microfluidic aptasensors for Ara h1 detection is summarized in Table 1. The data demonstrate that these devices achieve clinically relevant detection limits and wide linear ranges suitable for monitoring allergen contamination in food products.

Table 1: Performance Comparison of Microfluidic Aptasensors for Ara h1 Detection

| Sensor Type / Key Material | Detection Method | Linear Range (ng/mL) | Limit of Detection (LOD) (ng/mL) | Total Analysis Time | Reference |

|---|---|---|---|---|---|

| Origami Nano-aptasensor / Black Phosphorus Nanosheets (BPNSs) | Electrochemical | 50 – 1,000 | 21.6 | ≤ 20 min | [14] |

| Paper-Based μ-PAD / BP–Au Nanocomposites | Electrochemical (DPV*) | 25 – 800 | 11.8 | ≤ 20 min | [5] |

*DPV: Differential Pulse Voltammetry

Experimental Protocol: Fabrication and Assay of a Microfluidic Origami Nano-Aptasensor

The following protocol details the fabrication of an origami microfluidic electrochemical nano-aptasensor and the procedure for the detection of Ara h1, based on optimized parameters from recent research [14] [5].

Materials Fabrication and Sensor Preparation

- Device Fabrication: Pattern a piece of chromatography paper with hydrophobic materials (e.g., wax or PDMS) to create microfluidic channels and screen-printed electrodes [14] [15].

- Synthesis of Black Phosphorus Nanosheets (BPNSs): Exfoliate black phosphorus crystals to obtain BPNSs. Characterize the resulting nanosheets using Transmission Electron Microscopy (TEM) to confirm a multi-layer structure with surface folds [5].

- Preparation of Sensing Probe: Decorate the synthesized BPNSs with Ara h1-specific aptamers. The aptamer sequence (5′-SH-C6-TCG CAC ATT CCG CTT CTA CCG GGG GGG TCG AGC GAG TGA GCG AAT CTG TGG GTG GGC CGT AAG TCC GTG TGT GCG AA-3′) should be used, with the thiol (-SH) modification allowing for binding to nanomaterials [5].

- Probe Immobilization: Electrodeposit the aptamer-decorated BPNSs onto the surface of the paper-based working electrode. This creates the core sensing interface.

Assay Procedure for Ara h1 Detection

- Sample Introduction: Apply the prepared food extract (approximately 20-50 µL) directly to the sample inlet zone of the folded origami device.

- Immunoreaction: Allow the sample to wick through the device for a defined incubation period (optimized to be within 20 minutes). During this time, the target Ara h1 protein in the sample binds specifically to the immobilized aptamers on the electrode surface.

- Washing: Unfold and refold the origami device to align the reaction zone with pre-loaded washing buffers. This step removes unbound substances. The use of multiple washing layers in the 3D origami design ensures efficient cleaning [15].

- Signal Measurement: After washing, the electrochemical signal is measured directly on the paper-based electrode. The common technique used is Differential Pulse Voltammetry (DPV). The binding of the target protein hinders electron transfer at the electrode surface, resulting in a measurable decrease in the DPV current response, which is proportional to the Ara h1 concentration [5].

- Quantification: Quantify the Ara h1 concentration in the unknown sample by interpolating the measured signal against a standard calibration curve prepared with known concentrations of purified Ara h1.

Critical Optimization Parameters

For optimal sensor performance, the following parameters should be optimized:

- Aptamer Probe Concentration: The density of aptamers on the nanosheets affects sensitivity.

- Aptamer Self-Assembly Time: The duration allowed for the aptamers to correctly fold and assemble on the nanomaterial surface.

- Antigen-Aptamer Reaction Time: The incubation time for the target allergen to bind to the aptamer probe [14].

Workflow and Signaling Pathway Visualization

The following diagrams, generated using Graphviz and adhering to the specified color palette, illustrate the experimental workflow and the signaling mechanism of the aptasensor.

Aptasensor Assay Workflow

Signaling Mechanism

This diagram illustrates the electrochemical signaling mechanism based on electron transfer hindrance upon target binding.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagent Solutions for Aptasensor Development

| Item | Function/Description | Application in Ara h1 Detection |

|---|---|---|

| Black Phosphorus Nanosheets (BPNSs) | A two-dimensional nanomaterial with high carrier mobility and large surface area for probe immobilization; serves as an excellent signal amplification platform [14] [5]. | Used as the core sensing substrate. Often decorated with aptamers and electrodeposited on the electrode. |

| BP-Au Nanocomposites | Formed by in-situ growth of AuNPs on BPNSs; enhances electrical conductivity and stability of the sensing platform, and provides a surface for aptamer attachment via Au-S bonds [5]. | Improves electron transfer rate and serves as a stable substrate for immobilizing thiol-modified aptamers. |

| Ara h1 Specific Aptamer | A single-stranded DNA oligonucleotide selected for high affinity and specificity to the Ara h1 protein; serves as the biological recognition element [14] [5]. | The primary bioreceptor that specifically captures the target Ara h1 allergen from complex sample matrices. |

| Magnetic Microbeads (MBs) | Micron-sized particles used for easy and efficient immobilization of biomolecules (e.g., antigens) on paper substrates within defined reaction zones [15]. | Can be used in competitive assay formats to immobilize a reference antigen, facilitating separation and washing steps. |

Application Notes: BPNSs in Microfluidic Aptasensors

The integration of Black Phosphorus Nanosheets (BPNSs) into microfluidic origami aptasensors represents a significant advancement in the development of rapid, sensitive, and portable platforms for peanut allergen detection. These nanomaterials enhance biosensor performance through their unique physicochemical properties.

Key Properties and Functional Advantages

BPNSs contribute critical functionalities to the nano-aptasensor system. Their two-dimensional, layered structure provides an exceptionally large surface area for the immobilization of high-density aptamer probes, which are the biological recognition elements for the peanut allergen Ara h 1 [7]. Furthermore, BPNSs exhibit high carrier mobility and considerable catalytic activity, which directly enhances the electrochemical signal transduction, leading to improved detection sensitivity [7]. The functionalization of BPNSs is a crucial step; in the referenced microfluidic origami aptasensor, BPNSs were decorated with a specific Ara h 1 aptamer and poly-L-lysine (PLL) to form stable BPNSs-PLL-Apt bioconjugates on the paper-based working electrode [7].

Performance in Allergen Detection

The application of this BPNS-enhanced aptasensor for detecting the peanut allergen Ara h 1 has demonstrated high performance, as summarized in the table below.

Table 1: Analytical Performance of the BPNSs-based Microfluidic Origami Nano-aptasensor

| Performance Parameter | Result |

|---|---|

| Detection Principle | Electrochemical, Label-free [7] |

| Target Allergen | Peanut Ara h 1 [7] |

| Linear Detection Range | 50 – 1000 ng/mL [7] |

| Sensitivity | 0.05 µA·ng/mL [7] |

| Limit of Detection (LOD) | 21.6 ng/mL [7] |

| Total Assay Time | < 20 minutes [7] |

| Sensor Cost | ~USD $0.8 [7] |

This sensor has been successfully validated with real food samples, such as cookie dough spiked with Ara h 1, confirming its practicality for food allergen analysis at the point of need [7].

Experimental Protocols

Protocol 1: Fabrication of the Microfluidic Origami Nano-aptasensor

This protocol details the construction of the paper-based electrochemical sensor platform.

2.1.1 Materials and Reagents

- Chromatography paper substrate [7]

- Conductive carbon ink (for screen-printing electrodes) [7]

- Ag/AgCl ink (for reference electrode) [7]

- Polydimethylsiloxane (PDMS) for microchannel patterning [7]

2.1.2 Procedure

- Microchannel Patterning: Create an array of microfluidic channels on the chromatography paper by patterning with PDMS. The paper's inherent capillary action enables fluid flow without external pumps [7].

- Electrode Screen-Printing: Pattern the working electrode (WE), counter electrode (CE), and reference electrode (RE) onto the paper substrate using conductive carbon and Ag/AgCl inks [7].

- Origami Assembly: Design the chip in a two-dimensional flat geometry that can be sequentially folded to create a 3D structure with a separate layer for the working electrode [7].

Protocol 2: Synthesis of Aptamer-Decorated BPNSs (BPNSs-PLL-Apt)

This protocol covers the preparation and functionalization of the BPNS-based sensing probe.

2.2.1 Materials and Reagents

- Bulk black phosphorus crystals [7]

- N-methyl-2-pyrrolidone (NMP) solvent [7]

- Ara h 1-specific aptamer (sequence: 5́-TCG CAC ATT CCG CTT CTA CCG GGG GGG TCG AGC GAG TGA GCG AAT CTG TGG GTG GGC CGT AAG TCC GTG TGT GCG AA-3́) [7]

- Poly-L-lysine (PLL) [7]

2.2.2 Procedure

- Liquid-phase Exfoliation of BPNSs: Exfoliate bulk black phosphorus in NMP solvent under a nitrogen atmosphere to produce few-layer BPNSs [7].

- Characterization: Verify the successful exfoliation using Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM). The resulting BPNSs should exhibit a typical sheet-like and layered structure [7].

- Bioconjugation: Immobilize the Ara h 1-specific aptamer onto the BPNSs using poly-L-lysine (PLL) as a linking polymer to form the BPNSs-PLL-Apt bioconjugates [7].

- Electrodeposition: Electrodeposit the prepared BPNSs-PLL-Apt bioconjugates onto the surface of the paper-based working electrode [7].

Protocol 3: Allergen Detection and Measurement

This protocol describes the operational steps for detecting Ara h 1 in a food sample.

2.3.1 Procedure

- Sample Preparation: Homogenize a 0.1 g food sample in a capsule containing extraction buffer. Filter the homogenate to remove large particulates [10].

- Sample Introduction: Apply the filtered sample homogenate to the microfluidic aptasensor.

- Incubation and Binding: Allow the sample to flow through the fluidic channels and incubate for a defined period (optimized to 20 minutes). During this time, the Ara h 1 allergen binds specifically to the aptamer on the BPNSs [7].

- Electrochemical Measurement: Use a ferro/ferricyanide redox probe in a label-free electrochemical detection. The specific binding event causes a variation in charge transfer on the electrode, leading to a measurable change in current output [7].

- Data Analysis: Quantify the Ara h 1 concentration based on the measured current, using the established calibration curve (linear range: 50–1000 ng/mL) [7].

The following workflow diagram illustrates the key experimental steps from sensor fabrication to result analysis.

The Scientist's Toolkit: Key Research Reagent Solutions

The development and operation of a BPNS-based microfluidic aptasensor rely on several critical reagents and materials. The table below lists these essential components and their functions.

Table 2: Essential Research Reagents and Materials for BPNS-based Aptasensor

| Reagent/Material | Function/Description | Key Characteristics |

|---|---|---|

| Black Phosphorus Nanosheets (BPNSs) | Two-dimensional nanomaterial serving as the sensing platform [7]. | High surface area, excellent electroconductivity, direct bandgap [7]. |

| Ara h 1-specific DNA Aptamer | Biological recognition element that binds specifically to the target allergen [7]. | High affinity and specificity; alternative to antibodies; selected via SELEX [16]. |

| Poly-L-lysine (PLL) | A cationic polymer used as a linker for aptamer immobilization on BPNSs [7]. | Facilitates stable bioconjugate formation (BPNSs-PLL-Apt) [7]. |

| Chromatography Paper | Substrate for the microfluidic origami chip [7]. | Enables capillary-driven fluid flow; low-cost; portable [7]. |

| Ferro/Ferricyanide Redox Probe | Mediator for electrochemical signal transduction in label-free detection [7]. | Change in electron transfer efficiency upon allergen-aptamer binding is measured [7]. |

| N-methyl-2-pyrrolidone (NMP) | Solvent used for the liquid-phase exfoliation of bulk BP into BPNSs [7]. | Provides appropriate surface energy for efficient exfoliation [7]. |

The Concept of Origami Folding for 3D Microfluidic Architecture

The integration of origami folding principles with microfluidic technology represents a transformative approach for creating sophisticated three-dimensional (3D) analytical devices from two-dimensional (2D) precursors. This paradigm shift enables the development of compact, multi-functional lab-on-a-chip systems that facilitate complex fluid manipulation and multi-step analytical processes through simple folding techniques. Origami microfluidic devices leverage the inherent capillary action of porous substrates like paper, eliminating the need for external pumping systems and making them particularly valuable for point-of-need testing applications [7] [11]. The folding architecture allows for the creation of separate functional layers that can be brought into precise alignment, enabling sequential reagent delivery, washing steps, and detection protocols in a self-contained format [17]. This technical note details the application of origami 3D microfluidic architecture within the specific context of developing a nano-aptasensor for peanut allergen detection, providing comprehensive protocols and analytical performance data for researchers in food safety and biosensor development.

Fundamental Principles and Design Considerations

Core Architectural Concepts

Origami-inspired microfluidic devices operate on the principle of transforming 2D patterned substrates into 3D functional networks through strategic folding. This design methodology offers several distinct advantages over traditional 2D microfluidic systems, including reduced footprint, vertical fluidic connectivity, and the ability to perform multi-step assays in a predetermined sequence [17]. The 3D configuration enables complex fluid handling that would otherwise require extensive tubing and connectors in conventional microfluidic systems.

The typical origami microfluidic architecture consists of multiple layers connected via folding joints:

- Sample introduction layer: Contains predefined zones for sample application

- Reagent storage layers: House pre-loaded reagents in isolated compartments

- Reaction layers: Feature modified surfaces for specific binding events

- Detection layers: Enable signal transduction and readout

Fluid transport between these layers occurs through capillary action when layers are folded into contact, with timing controlled by the geometry of the channels and the absorbency of the substrate material [7].

Material Selection and Properties

The choice of substrate material critically influences device performance, fabrication methodology, and application suitability. The following table summarizes key material options and their characteristics:

Table 1: Material Options for Origami Microfluidic Devices

| Material | Advantages | Limitations | Suitability for Allergen Detection |

|---|---|---|---|

| Chromatography Paper | High porosity, excellent capillary action, low cost, biocompatible | Limited structural integrity, susceptible to humidity | Ideal for disposable allergen sensors; used in Ara h1 detection [7] |

| Polyvinylidene Fluoride (PVDF) | High protein binding capacity, tunable wettability | Requires surface treatment for optimal wettability | Excellent for antibody/aptamer immobilization; used in E. coli detection [17] |

| Polydimethylsiloxane (PDMS) | Transparent, gas permeable, easy molding | Hydrophobic, requires surface treatment | Suitable for hybrid designs requiring oxygen permeability [11] |

| Glass/Silicon | High stability, excellent optical properties | High cost, complex fabrication | Less common for origami applications due to rigidity |

For allergen detection applications, chromatography paper offers an optimal balance of performance and cost-effectiveness, with a typical device cost of approximately $0.80 per unit [7]. PVDF membranes provide superior protein binding capacity but require pretreatment with solvents such as ethanol, Tween-20, or Triton X-100 to achieve appropriate wettability [17].

Fabrication Protocols

Laser Ablation Fabrication Method

Laser ablation enables precise patterning of microfluidic channels and reservoirs with high resolution. The following protocol details the fabrication process for an origami microfluidic device suitable for allergen detection:

Materials and Equipment:

- PVDF or cellulose membranes (0.45 μm pore size recommended)

- Laser ablation system (e.g., Epilog Zing series)

- Double-sided adhesive (100 μm thickness recommended)

- Design software (Adobe Illustrator or similar)

- Solvents for membrane treatment (ethanol, acetate, Tween-20, Triton X-100, citrate)

Step-by-Step Procedure:

Membrane Pretreatment:

- Cut PVDF membranes to desired dimensions (typically 1.8 × 6.5 cm²)

- Treat membranes with ethanol and sonicate for 10 minutes at 37°C to remove organic residues

- Rinse with ultrapure water and dry at 74°C for 15 minutes

- Evaluate wettability via contact angle measurements (target <90° for spontaneous capillary action)

Laser Parameter Optimization:

- Optimize laser power and cutting speed to minimize structural deterioration

- Typical parameters for PVDF: Laser power 10-30%, cutting speed 40-80%

- Create circular reservoirs (4 mm diameter recommended) and connecting microchannels

Device Assembly:

- Attach one layer of the PVDF rectangles to double-sided adhesive prior to ablation

- Adhere functionalized cellulose or PVDF membranes to designated reservoirs

- Align and adhere multiple PVDF layers to create the complete device architecture

- Validate channel connectivity using dye solutions [17]

Wax Patterning Method

For paper-based devices, wax patterning offers a low-cost alternative to laser ablation:

Materials and Equipment:

- Chromatography paper (Whatman Grade 1 recommended)

- Solid wax printer or wax screen-printing setup

- Hot plate or oven (100-120°C)

- Hydrophobic barrier materials (optional)

Procedure:

- Design the microfluidic pattern using appropriate software

- Print or deposit wax onto the paper substrate in the desired pattern

- Heat the paper to 100-120°C for 1-2 minutes to allow wax penetration

- Cool to room temperature to form hydrophobic barriers

- Functionalize specific zones with biological recognition elements [7]

Application to Peanut Allergen Detection: Nano-Aptasensor Development

Sensing Mechanism and Probe Design

The origami microfluidic nano-aptasensor for peanut allergen Ara h1 employs an electrochemical detection mechanism based on aptamer-functionalized black phosphorus nanosheets (BPNSs). The detection principle relies on the specific binding between the immobilized aptamer and the target allergen, which induces a measurable change in electrochemical signal [7].

Aptamer Sequence for Ara h1:

This specific aptamer, selected through Systematic Evolution of Ligands by Exponential Enrichment (SELEX), demonstrates high affinity and specificity for the Ara h1 protein [7].

BPNSs-Aptamer Bioconjugate Preparation:

- Prepare BPNSs through mechanical exfoliation or chemical synthesis

- Functionalize BPNSs with poly-L-lysine (PLL) to enhance biocompatibility and surface area

- Incubate PLL-modified BPNSs with thiol-modified aptamers (10 μM concentration) for 12 hours at 4°C

- Purify the BPNSs-PLL-Apt bioconjugates through centrifugation at 10,000 rpm for 10 minutes

- Resuspend in appropriate buffer (e.g., 10 mM Tris-HCl, pH 7.4) for electrode modification [7]

Device Functionalization Protocol

Materials:

- Fabricated origami microfluidic device

- BPNSs-PLL-Apt bioconjugates

- Carbon ink (for screen-printed electrodes)

- Ag/AgCl ink (for reference electrode)

- Ferro-ferricyanide redox probe ([Fe(CN)₆]³⁻/⁴⁻)

- Phosphate buffered saline (PBS, pH 7.4)

Functionalization Steps:

- Electrode Preparation:

- Pattern working electrode (WE), counter electrode (CE), and reference electrode (RE) on paper substrate using screen printing

- Cure electrodes according to manufacturer specifications (typically 60°C for 2 hours)

Probe Immobilization:

- Deposit 5 μL of BPNSs-PLL-Apt bioconjugate solution onto the working electrode

- Allow to dry at room temperature for 30 minutes

- Rinse gently with PBS to remove unbound aptamers

Device Assembly:

- Fold the device according to predetermined configuration to align sample introduction zone with detection zone

- Secure layers with adhesive or magnetic fasteners

- Pre-load necessary reagents in designated reservoirs [7]

Detection Protocol and Performance

Sample Analysis Procedure:

- Sample Introduction:

- Apply 50-100 μL of extracted food sample to the sample introduction zone

- Allow capillary action to transport sample to reaction zone (approximately 3-5 minutes)

Incubation and Reaction:

- Fold device to bring sample in contact with detection zone

- Incubate for 15 minutes to allow aptamer-allergen binding

- Fold additional layers to introduce washing buffer if necessary

Electrochemical Measurement:

- Add ferro-ferricyanide redox probe to the detection zone

- Perform square wave voltammetry or electrochemical impedance spectroscopy

- Measure current output at predetermined potential [7]

Analytical Performance: Table 2: Performance Metrics of Origami Microfluidic Nano-Aptasensor for Ara h1 Detection

| Parameter | Value | Conditions |

|---|---|---|

| Detection Limit | 21.6 ng/mL | In cookie dough samples |

| Linear Range | 50-1000 ng/mL | R² > 0.99 |

| Sensitivity | 0.05 μA·ng/mL | - |

| Total Assay Time | <20 minutes | Including sample preparation |

| Reproducibility | 3.19% RSD | n=15 devices |

| Recovery in Food Samples | 90.1-104.0% | Spiked cookie dough samples |

The sensor demonstrates excellent specificity for Ara h1 with minimal cross-reactivity to other peanut proteins or common food matrix components [7].

Research Reagent Solutions

Successful implementation of origami microfluidic allergen detection requires specific reagents and materials with defined functions:

Table 3: Essential Research Reagents for Origami Microfluidic Allergen Detection

| Reagent/Material | Function | Specifications/Alternatives |

|---|---|---|

| Black Phosphorus Nanosheets (BPNSs) | Signal amplification platform; high surface area for aptamer immobilization | Layer-dependent bandgap; high carrier mobility; alternative: graphene oxide |

| Poly-L-Lysine (PLL) | Coupling agent for aptamer immobilization on BPNSs | Enhances biocompatibility; provides amine groups for conjugation |

| Anti-Ara h1 Aptamer | Biological recognition element; specific binding to target allergen | Thiol-modified for surface attachment; SELEX-selected sequence |

| Ferro-ferricyanide Redox Probe | Electrochemical signal generation | [Fe(CN)₆]³⁻/⁴⁻ in PBS buffer; concentration: 5 mM |

| PVDF Membrane | Substrate for fluid transport and reagent immobilization | 0.45 μm pore size; high protein binding capacity |

| TMB Substrate Solution | Colorimetric detection (for colorimetric variants) | Contains H₂O₂ as oxidizing agent; produces blue color upon oxidation |

| Screen-Printed Electrodes | Electrochemical transduction platform | Carbon working electrode; Ag/AgCl reference electrode |

Comparative Analysis with Alternative Detection Platforms

Origami microfluidic platforms offer distinct advantages compared to conventional allergen detection methods:

Table 4: Comparison of Allergen Detection Platforms

| Platform | Detection Limit | Assay Time | Cost per Test | Equipment Needs | Suitability for POC |

|---|---|---|---|---|---|

| Origami Microfluidic Aptasensor | 21.6 ng/mL [7] | 20 minutes | ~$0.80 [7] | Portable potentiostat | Excellent |

| Traditional ELISA | 1-10 ng/mL [11] | 4-6 hours | $5-15 | Plate reader, washer | Poor |

| Colorimetric LAMP Microfluidic | 0.4 ng/μL (DNA) [18] | 60 minutes | $1-3 | Water bath, centrifuge | Good |

| LC-MS/MS | 0.1-1 ng/mL | 30-60 minutes | $50-100 | HPLC, mass spectrometer | Poor |

| Lateral Flow Immunoassay | 10-50 ng/mL | 10-15 minutes | $2-5 | None | Excellent |

The origami microfluidic approach balances sensitivity, cost-effectiveness, and operational simplicity, making it particularly suitable for resource-limited settings and point-of-need testing scenarios.

Troubleshooting and Optimization Guidelines

Successful implementation of origami microfluidic allergen detection requires attention to several critical parameters:

Key Optimization Parameters:

- Aptamer Concentration: Optimize between 1-20 μM for maximum surface coverage without steric hindrance

- Self-Assembly Time: Typically 12 hours at 4°C for complete aptamer orientation

- Antigen-Aptamer Reaction Time: 15 minutes provides optimal balance between sensitivity and assay speed

- Wettability Control: Ensure contact angle <90° for spontaneous capillary action through membrane pretreatment

Common Issues and Solutions:

- Incomplete fluid flow: Check membrane pretreatment; ensure proper folding alignment

- High background signal: Optimize washing steps; consider blocking agents (e.g., BSA)

- Poor reproducibility: Standardize fabrication parameters; control environmental humidity

- Signal drift: Ensure stable redox probe concentration; check electrode integrity

Visualizations

Origami μPAD Fabrication and Folding Sequence

Allergen Detection Signaling Workflow

The integration of origami folding principles with microfluidic technology creates a powerful platform for developing sophisticated biosensors for food allergen detection. The 3D architecture enables complex multi-step assays in a compact, inexpensive format suitable for point-of-need testing. The specific application to peanut allergen Ara h1 detection demonstrates excellent analytical performance with a detection limit of 21.6 ng/mL, sensitivity of 0.05 μA·ng/mL, and total assay time under 20 minutes. The protocols detailed in this application note provide researchers with comprehensive methodologies for fabricating, functionalizing, and implementing these devices, with potential applications extending to other food safety hazards, clinical diagnostics, and environmental monitoring.

Fabrication and Operational Workflow: Building and Using Your Aptasensor

This application note details the protocol for fabricating a three-dimensional microfluidic origami nano-aptasensor, a low-cost and rapid diagnostic platform designed for the detection of the peanut allergen Ara h 1. Origami paper-based analytical devices (µPADs) leverage the capillary action of paper to transport fluids without external equipment, integrating sample processing and electrochemical detection into a single, portable platform [7]. The fabrication process combines wax patterning to create microfluidic channels, screen-printing to fabricate electrodes, and a folding (origami) assembly to form a three-dimensional structure with functional layers. This guide provides a comprehensive, step-by-step protocol for researchers and scientists to replicate this biosensing platform.

Research Reagent Solutions

The following table lists the essential materials and reagents required for the fabrication of the microfluidic origami nano-aptasensor and its application in allergen detection.

| Item | Function/Application | Specification/Notes |

|---|---|---|

| Chromatography Paper | Microfluidic chip substrate | Whatman No. 1 paper is typically used for its superior porosity and hydrophilicity [7] [19]. |

| Conductive Carbon Ink | Screen-printing of working and counter electrodes | e.g., ED581ss ink [7] [19]. |

| Ag/AgCl Ink | Screen-printing of reference electrode | - |

| Black Phosphorus Nanosheets (BPNSs) | Nanomaterial to enhance electrode sensitivity | Provides a large surface area and more catalytic active sites [7]. |

| Anti-Ara h1 Aptamer | Biological recognition element | Synthesized oligonucleotide with high affinity and specificity for the Ara h1 target [7]. |

| Poly-L-lysine (PLL) | Bioconjugation agent | Used to form stable BPNSs-PLL-Apt bioconjugates for immobilization [7]. |

| PDMS | Material for patterning microchannels | Used to create hydrophobic barriers on the paper substrate [7]. |

| Ferro-ferricyanide Redox Probe | Electrochemical detection | Used as a mediator for label-free electrochemical detection [7]. |

Chip Fabrication Workflow

The following diagram illustrates the comprehensive fabrication process for the microfluidic origami nano-aptasensor.

Detailed Fabrication Protocol

Step 1: Microchannel Patterning

- Objective: To create hydrophobic barriers that define hydrophilic microfluidic channels on the paper substrate.

- Procedure:

- Design the microfluidic channel pattern and electrode layout using design software (e.g., Adobe Illustrator CS5) [19]. The typical design features a two-dimensional flat geometry that can be folded into a 3D device.

- Use a wax printer (e.g., Xerox ColorQube 8570) to print the designed pattern directly onto the surface of chromatography paper [19].

- Place the printed paper on a hotplate or in an oven at 120°C for 5 minutes [19]. This heating step allows the wax to melt and penetrate through the entire thickness of the paper, forming a complete hydrophobic barrier.

- Note: Alternatively, PDMS can be used to pattern the microchannel array on the paper substrate [7].

Step 2: Electrode Screen-Printing

- Objective: To fabricate the three-electrode system (Working Electrode, Counter Electrode, and Reference Electrode) integral to electrochemical detection.

- Procedure:

- Prepare screen stencils based on the electrode design.

- Use a screen-printing apparatus to apply conductive carbon ink onto the predefined areas for the Working Electrode (WE) and Counter Electrode (CE).

- Screen-print the Ag/AgCl ink to form the Reference Electrode (RE).

- Allow the printed electrodes to cure completely according to the ink manufacturer's specifications.

Step 3: Working Electrode Functionalization

- Objective: To modify the Working Electrode with a nano-composite and biorecognition element for specific and sensitive detection.

- Procedure:

- Electrodeposition of Black Phosphorus Nanosheets (BPNSs):

- Prepare a stable dispersion of BPNSs.

- Electrodeposit the BPNSs onto the surface of the carbon-based Working Electrode. This material provides a large surface area and enhances electrocatalytic activity, which is crucial for signal amplification [7].

- Aptamer Immobilization:

- Form a bioconjugate by decorating the BPNSs with poly-L-lysine (PLL) and the anti-Ara h1 aptamer.

- Immobilize this BPNSs-PLL-Apt bioconjugate onto the Working Electrode surface. The aptamer serves as the specific capture probe for the Ara h1 allergen [7].

- Electrodeposition of Black Phosphorus Nanosheets (BPNSs):

Step 4: Origami Folding and Assembly

- Objective: To assemble the 2D patterned paper into a functional 3D device that integrates sample introduction, fluidic control, and detection zones.

- Procedure:

- Fold the paper device along pre-defined creases. This design uses sequential folding to bring separate layers into contact, creating a vertical flow path [7].

- The final 3D structure positions the sample inlet, reaction zones, and electrode detection area for optimal performance. The folding act can also serve as a simple valve, controlling the flow of fluid between layers and reducing sample volume requirements [19].

Experimental Protocol & Performance

Allergen Detection Assay

The operational protocol for using the fabricated aptasensor to detect the peanut allergen Ara h1 is as follows [7]:

- Sample Introduction: Apply the liquid sample (e.g., extracted food sample) to the sample inlet of the folded device.

- Capillary Flow: Allow the sample to wick through the paper microchannels via capillary action until it reaches the detection chamber containing the functionalized Working Electrode.

- Incubation: The sample incubates with the aptamer-decorated electrode for a period of less than 20 minutes. During this time, the target Ara h1 allergen binds specifically to the immobilized aptamers.

- Electrochemical Measurement: Add a ferro-ferricyanide redox probe to the system. The specific binding event between the aptamer and the allergen inhibits electron transfer, resulting in a measurable decrease in current.

- Signal Readout: Use a portable potentiostat to perform electrochemical measurements (e.g., Differential Pulse Voltammetry). The change in current is quantitatively correlated to the concentration of Ara h1 in the sample.

Analytical Performance

The optimized microfluidic origami nano-aptasensor demonstrates the following performance characteristics for the detection of Ara h1 [7]:

| Analytical Parameter | Performance Value |

|---|---|

| Detection Limit | 21.6 ng/mL |

| Linear Detection Range | 50 - 1000 ng/mL |

| Sensitivity | 0.05 µA·ng/mL |

| Total Assay Time | < 20 minutes |

| Approximate Chip Cost | USD $0.80 |

The sensor has been successfully validated by detecting Ara h1 in spiked cookie dough samples, demonstrating its practicality for complex food matrices [7]. The use of aptamer-decorated BPNSs was critical to achieving this high sensitivity and low detection limit.

Synthesis and Functionalization of Signal-Amplifying Nanoprobes (e.g., BPNSs, BP-Au)

The development of highly sensitive and selective biosensors is crucial for the detection of food allergens, which pose a significant health risk to susceptible individuals. This document details the synthesis, functionalization, and application of signal-amplifying nanoprobes, specifically black phosphorus nanosheets (BPNSs) and gold-decorated black phosphorus (BP-Au), within the context of developing a microfluidic origami nano-aptasensor for the detection of the major peanut allergen Ara h1. These nanomaterials serve as the core sensing element, enhancing sensitivity and enabling rapid, low-cost detection at the point of need [20]. The protocols herein are designed for researchers and scientists engaged in biosensor development and nanomaterial functionalization.

Research Reagent Solutions

The following table lists the essential materials and reagents required for the synthesis, functionalization, and assembly of the nano-aptasensor.

Table 1: Key Research Reagents and Materials

| Reagent/Material | Function/Application in the Protocol |

|---|---|

| Black Phosphorus Crystals | Starting material for the synthesis of BPNSs via liquid exfoliation [20]. |

| N-Methyl-2-pyrrolidone (NMP) | Solvent used for the liquid exfoliation of bulk black phosphorus into nanosheets [20]. |

| Chloroauric Acid (HAuCl₄) | Gold precursor for the synthesis of gold nanoparticles (AuNPs) and the formation of BP-Au nanocomposites [20]. |

| Ara h1 Specific Aptamer | Single-stranded DNA molecule that acts as the biological recognition element for the specific capture of the Ara h1 allergen [20]. |

| Poly-L-lysine (PLL) | A cationic polymer used to functionalize BPNSs, providing amino groups for the subsequent immobilization of aptamers [20]. |

| Ferro/Ferricyanide Redox Probe | Electrochemical mediator used in the buffer solution to enable label-free electrochemical detection [20]. |

| Chromatography Paper | Porous and hydrophilic substrate used for fabricating the microfluidic origami device [20]. |

| Conductive Carbon Ink | Used for screen-printing the working, counter, and reference electrodes onto the paper substrate [20]. |

| Ag/AgCl Ink | Used to formulate the reference electrode on the screen-printed electrochemical cell [20]. |

Synthesis of Black Phosphorus Nanosheets (BPNSs)

Protocol: Liquid Exfoliation of BPNSs

Objective: To produce few-layer Black Phosphorus Nanosheets from bulk black phosphorus crystals.

Materials:

- Bulk black phosphorus crystals

- N-Methyl-2-pyrrolidone (NMP)

- Argon or Nitrogen gas

- Centrifuge and centrifuge tubes

- Probe sonicator

Procedure:

- Preparation: Place 20 mg of bulk black phosphorus crystals into a 20 mL glass vial. All procedures should be performed in an inert atmosphere (e.g., inside a glovebox filled with Argon gas) to prevent oxidation of phosphorus.

- Dispersion: Add 10 mL of NMP to the vial, ensuring the crystals are fully submerged.

- Exfoliation: Seal the vial and transfer it out of the glovebox. Immediately place it in an ice-water bath. Insert the probe sonicator and sonicate the mixture for 8 hours at a power of 300 W. The ice-water bath is critical to dissipate heat and minimize material degradation.

- Separation: Transfer the resulting dark dispersion into centrifuge tubes. Centrifuge at 4,000 rpm for 20 minutes to remove any unexfoliated, large aggregates.

- Collection: Carefully collect the supernatant, which contains the exfoliated BPNSs. The BPNSs can be further concentrated by a second centrifugation step of the supernatant at 12,000 rpm for 10 minutes, followed by decanting the excess solvent.

- Storage: Re-disperse the BPNS pellet in a desired solvent (e.g., deoxygenated water) under an inert atmosphere and store at 4°C for future use. Characterization via Scanning Electron Microscopy (SEM) should reveal a typical sheet-like pattern and layered structure [20].

Functionalization of Nanoprobes

Protocol: Immobilization of Aptamer on BPNSs (BPNSs-PLL-Apt)

Objective: To functionalize the surface of BPNSs with a specific aptamer for Ara h1 recognition.

Materials:

- As-synthesized BPNSs dispersion

- Poly-L-lysine (PLL)

- Ara h1 specific aptamer (sequence: 5́-TCG CAC ATT CCG CTT CTA CCG GGG GGG TCG AGC GAG TGA GCG AAT CTG TGG GTG GGC CGT AAG TCC GTG TGT GCG AA −3́)

- EDC/NHS crosslinking kit

- Phosphate Buffered Saline (PBS), pH 7.4

Procedure:

- PLL Coating: Add 1 mg/mL of PLL to the BPNSs dispersion. Allow the mixture to incubate for 2 hours at room temperature with gentle shaking. The PLL will electrostatically adsorb to the BPNSs, providing a surface rich in primary amine groups.

- Washing: Centrifuge the BPNSs-PLL mixture and re-disperse the pellet in PBS buffer to remove any unbound PLL.

- Aptamer Conjugation: Activate the carboxyl-terminated aptamers using a standard EDC/NHS protocol in MES buffer for 15 minutes. Then, mix the activated aptamers with the BPNSs-PLL dispersion.

- Self-Assembly: Incubate the mixture for 12 hours at room temperature to allow covalent amide bond formation between the activated aptamer and the amine groups on PLL.

- Purification: Centrifuge the final BPNSs-PLL-Apt bioconjugates and wash twice with PBS to remove any unbound aptamers. The bioconjugates are now ready for deposition onto the sensor electrode [20].

Protocol: Preparation of Aptamer-Functionalized BP-Au Nanocomposites

Objective: To synthesize gold nanoparticle-decorated BPNSs and functionalize them with aptamers for enhanced electrochemical signal amplification.

Materials:

- BPNSs dispersion

- Chloroauric acid (HAuCl₄)

- Trisodium citrate

- Thiol-modified Ara h1 aptamer

- 10 mM Tris(2-carboxyethyl)phosphine (TCEP)

Procedure:

- Synthesis of AuNPs: Prepare gold nanoparticles (AuNPs) via the classical citrate reduction method. Briefly, heat 100 mL of 1 mM HAuCl₄ to boiling while stirring. Rapidly add 2.5 mL of 38.8 mM trisodium citrate solution. Continue heating and stirring until the solution turns deep red. Allow it to cool to room temperature.

- Decoration of BPNSs: Mix the as-prepared BPNSs dispersion with the AuNP solution at a 1:4 volume ratio. Incubate for 2 hours to allow the AuNPs to adsorb onto the BPNSs surface via van der Waals forces or coordination interactions, forming BP-Au nanocomposites.

- Aptamer Reduction: Simultaneously, incubate the thiol-modified aptamer with 10 mM TCEP for 1 hour to reduce any disulfide bonds.

- Probe Assembly: Co-incubate the reduced, thiol-modified aptamer with the BP-Au nanocomposites for 12 hours at room temperature. The thiol groups will form strong covalent Au-S bonds with the gold nanoparticles on the composite surface.

- Blocking and Purification: Passivate the remaining surface of the AuNPs with 1 mM 6-mercapto-1-hexanol (MCH) for 1 hour to minimize non-specific adsorption. Purify the resulting BP-Au-Apt nanoprobes via centrifugation and re-suspend in PBS [20].

Sensor Fabrication and Experimental Data

Protocol: Microfluidic Origami Aptasensor Assembly

Objective: To fabricate a 3D origami electrochemical sensor integrated with the functionalized nanoprobes.

Materials:

- Chromatography paper substrate

- PDMS polymer

- Conductive carbon ink, Ag/AgCl ink

- Screen-printing apparatus

- Functionalized BPNSs-PLL-Apt or BP-Au-Apt nanoprobes

Procedure:

- Patterning: Create a microfluidic channel pattern on the paper substrate using PDMS as a hydrophobic barrier.

- Electrode Printing: Screen-print the three-electrode system (Working, Counter, and Reference electrodes) onto the paper substrate using carbon ink. Use Ag/AgCl ink to formulate the reference electrode.

- Probe Immobilization: Deposit 5 µL of the functionalized nanoprobes (BPNSs-PLL-Apt or BP-Au-Apt) onto the working electrode area and allow it to dry at room temperature.

- Origami Folding: The 2D flat chip is designed with predefined folding lines. The chip is sequentially folded to create a 3D vertical flow device, aligning the sample inlet and the electrode detection zone. This design allows for dual detection on a single chip [20].

Performance Data and Optimization

The performance of the aptasensor was evaluated by measuring the electrochemical current response upon exposure to varying concentrations of the Ara h1 allergen. Key experimental parameters were optimized to achieve maximum sensitivity.

Table 2: Optimized Experimental Parameters for the Nano-aptasensor

| Parameter | Optimized Condition | Function |

|---|---|---|

| Aptamer Concentration | 1.0 µM | Determines the density of recognition elements on the electrode surface. |

| Self-Assembly Time | 12 hours | Ensures sufficient time for the aptamer to immobilize on the nanoprobes. |

| Antigen-Aptamer Reaction Time | 20 minutes | Time required for the target allergen to bind to the immobilized aptamer. |

| Total Detection Time | Within 20 minutes | The complete assay time from sample introduction to result. |

Table 3: Analytical Performance of the BPNSs-based Aptasensor for Ara h1 Detection

| Performance Metric | Result |

|---|---|

| Detection Principle | Electrochemical (Current Output) |

| Linear Detection Range | 50 - 1000 ng/mL |

| Sensitivity | 0.05 µA·ng/mL |

| Limit of Detection (LOD) | 21.6 ng/mL |

| Assay Cost (per test) | ~ USD $0.8 |

The sensor demonstrated a wide linear range and high sensitivity, which was attributed to the excellent electroconductivity and large surface area of the BPNSs, providing more catalytic active sites [20].

Workflow and Signaling Diagrams

Sensor Assembly and Detection Workflow

Nanoprobe Signaling Mechanism

The development of reliable, sensitive, and specific biosensors is paramount in diagnostic and environmental monitoring applications. Aptamers, single-stranded DNA or RNA oligonucleotides selected via Systematic Evolution of Ligands by Exponential Enrichment (SELEX), have emerged as powerful molecular recognition elements, offering advantages over traditional antibodies including higher stability, lower production cost, and easier modification [21] [22]. Their effective integration into biosensing platforms, however, hinges on the immobilization strategy used to anchor them to the transducer surface [23]. This Application Note details two fundamental immobilization techniques—Au-S bonding and electrodeposition—within the context of developing a microfluidic origami nano-aptasensor for the detection of the peanut allergen Ara h1. We provide detailed protocols, a comparative analysis, and a structured reagent toolkit to facilitate robust sensor fabrication for researchers and scientists in the field of food safety and diagnostic development.

Au-S Bonding for Aptamer Immobilization

The covalent bond formed between gold (Au) and sulfur (S) is one of the most prevalent and reliable methods for immobilizing thiol-modified aptamers on gold electrodes or gold nanostructures.

Underlying Principles and Protocol

This method relies on the chemisorption of a thiol group (-SH), typically introduced at the 5' or 3' end of an aptamer, onto a gold surface, forming a stable Au-S bond [21] [23]. A critical subsequent step involves passivating the remaining gold surface with a short-chain alkanethiol like 6-mercapto-1-hexanol (MCH). This step serves two essential functions: it displaces non-specifically adsorbed aptamers, promoting a vertical orientation and reducing lateral interactions, and it creates a hydrophilic antifouling layer that minimizes the nonspecific adsorption of interfering compounds [23].

Detailed Step-by-Step Protocol:

- Surface Preparation: Clean the gold electrode surface thoroughly. A common method involves sequential polishing with alumina slurries of decreasing particle sizes (e.g., 1.0, 0.3, and 0.05 µm) on a microcloth, followed by sonication in ethanol and deionized water for 5 minutes each to remove residual polishing materials. Electrochemical cleaning via cyclic voltammetry in 0.5 M H₂SO₄ (typically 20-50 cycles between -0.2 and +1.5 V at a scan rate of 100 mV/s) is highly recommended to achieve a pristine, oxide-free gold surface [21].

- Aptamer Immobilization: Prepare a 1-10 µM solution of the thiolated aptamer (e.g., specific for Ara h1) in a suitable buffer, often phosphate-buffered saline (PBS) or Tris-EDTA (TE) buffer. Deposit a precise volume (e.g., 20-50 µL) onto the clean gold surface and incubate in a humidified chamber for a defined period, typically 12-16 hours (overnight) at room temperature, to allow for the formation of a self-assembled monolayer [23].

- Surface Passivation: Rinse the electrode gently with deionized water to remove unbound aptamers. Subsequently, incubate the functionalized surface with a 1-10 mM aqueous solution of 6-mercapto-1-hexanol (MCH) for 30-60 minutes. This step is crucial for achieving a well-ordered monolayer and maximizing target binding efficiency [23].

- Final Rinse and Storage: Rinse the prepared aptasensor thoroughly with deionized water and a clean assay buffer to remove any traces of MCH. If not used immediately, the sensor can be stored dry at 4°C.

Table 1: Key Reagents for Au-S Bonding Immobilization

| Reagent / Material | Function / Description |

|---|---|

| Thiol-modified Aptamer | The biorecognition element; the thiol group enables covalent attachment to gold surfaces. |

| Gold Electrode/Surface | The transducer platform for aptamer immobilization and electrochemical signal generation. |

| 6-Mercapto-1-Hexanol (MCH) | A short-chain alkanethiol used to backfill unoccupied gold sites, reducing non-specific binding. |

| Phosphate Buffered Saline (PBS) | A common buffer for preparing aptamer solutions and maintaining a stable pH during immobilization. |

Workflow Visualization

The following diagram illustrates the sequential steps involved in the Au-S bonding immobilization strategy.

Electrodeposition for Aptamer Immobilization

Electrodeposition is a potent technique for integrating aptamers with nanocomposite materials onto electrode surfaces, enhancing surface area and catalytic activity.

Underlying Principles and Protocol

This method involves the electrochemical deposition of metallic nanoparticles (e.g., Au-Pd) or conductive nanocomposites onto an electrode surface from a precursor solution, often followed by the immobilization of aptamers via Au-S bonding or physical adsorption. A notable application is the use of a TiO₂-Carbon Nanofiber (CNF) nanocomposite incorporated with Au-Pd bimetallic nanoparticles (Au-PdNPs) to create a highly sensitive platform [24]. The TiO₂-CNF matrix provides a large surface area and excellent electronic properties, while the electrodeposited Au-PdNPs further enhance the active surface area and facilitate subsequent aptamer attachment [24].

Detailed Step-by-Step Protocol:

- Nanocomposite Modification: Prepare a dispersion of the TiO₂-CNF nanocomposite (e.g., 1.0 mg/mL in a suitable solvent like dimethylformamide, DMF). Deposit a fixed volume (e.g., 5-10 µL) onto the surface of a screen-printed carbon electrode (SPCE) and allow it to dry at room temperature to form a stable layer (SPE/TiO₂-CNF) [24].

- Electrodeposition of Bimetallic Nanoparticles: Prepare an electrochemical cell containing a precursor solution for Au-PdNPs, such as 1.0 mM HAuCl₄ and 1.0 mM Na₂PdCl₄ in 0.5 M H₂SO₄. Immerse the modified SPCE/TiO₂-CNF as the working electrode. Perform electrodeposition using a constant potential technique (e.g., -0.4 V vs. Ag/AgCl) or cyclic voltammetry (e.g., 15 cycles between -0.8 V and +0.6 V) to form a uniform layer of Au-PdNPs on the nanocomposite surface [24].

- Aptamer Immobilization: Rinse the SPCE/TiO₂-CNF/Au-PdNPs electrode and incubate it with a solution of the thiolated aptamer (e.g., 1 µM in PBS) for a specified time (e.g., 2 hours) to allow the aptamers to bind to the deposited gold nanostructures via Au-S chemistry [24].

Table 2: Key Reagents for Electrodeposition-based Immobilization

| Reagent / Material | Function / Description |

|---|---|

| TiO₂-CNF Nanocomposite | Provides a high-surface-area, conductive scaffold to anchor metallic nanoparticles. |

| Chloroauric Acid (HAuCl₄) | Precursor for gold nanoparticles, providing sites for subsequent aptamer immobilization. |

| Sodium Tetrachloropalladate (Na₂PdCl₄) | Precursor for palladium nanoparticles; forms bimetallic Au-Pd with synergistic catalytic effects. |

| Screen-Printed Carbon Electrode (SPCE) | A low-cost, disposable, and miniaturizable platform ideal for point-of-care sensors. |

Workflow Visualization

The following diagram illustrates the fabrication workflow for an electrodeposition-based aptasensor.

Comparative Analysis and Application in Allergen Detection

The choice between Au-S bonding and electrodeposition is dictated by the requirements for sensitivity, simplicity, and the nature of the transducer platform.

Table 3: Comparative Analysis of Immobilization Strategies

| Feature | Au-S Bonding | Electrodeposition with Nanocomposites |

|---|---|---|

| Principle | Covalent chemisorption on gold | Electrochemical deposition & covalent/physical adsorption |

| Complexity | Moderate | High |

| Required Substrate | Primarily gold surfaces | Various conductors (e.g., carbon SPCE) |

| Typical Electrode | Gold disk or film electrode | Screen-printed carbon electrode (SPCE) |

| Active Surface Area | Standard (electrode geometry) | Significantly enhanced (nanocomposite & nanoparticles) |

| Best-Suited For | Fundamental studies, well-defined surfaces | High-sensitivity applications, disposable sensors |

| Reported LOD for Ara h1 | Not directly applicable in basic form | 0.035 pg/mL [24] |

In the context of peanut allergen detection, these strategies have been successfully implemented. A microfluidic origami aptasensor utilized aptamer-decorated black phosphorus nanosheets, likely immobilized via interactions similar to electrodeposition, achieving a detection limit of 21.6 ng/mL for Ara h1 in cookie dough samples [20]. In a more recent and sensitive approach, the electrodeposition-based platform (SPCE/TiO₂-CNF/Au-PdNPs) demonstrated a remarkably low detection limit of 0.035 pg/mL for Ara h1 in bread and peanut butter, showcasing the power of nanocomposite integration for real-sample analysis [24].

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for Aptasensor Development

| Category / Item | Specific Example | Function in Aptasensor Development |

|---|---|---|

| Aptamer | Anti-Ara h1 Aptamer (e.g., sequence from Sangon Biotechnology [20]) | The core biorecognition element that binds specifically to the target allergen. |

| Electrode Materials | Gold Disk Electrode; Screen-Printed Carbon Electrode (SPCE) | Serve as the solid support and transducer for signal measurement. |

| Nanocomposites | TiO₂-Carbon Nanofiber (CNF); Black Phosphorus Nanosheets (BPNS) [20] | Enhance electrical conductivity, provide a large surface area for aptamer loading, and improve catalytic activity. |

| Metal Precursors | HAuCl₄, Na₂PdCl₄ | Used in electrodeposition to form metallic nanoparticles that facilitate aptamer immobilization and signal amplification. |

| Surface Modifiers | 6-Mercapto-1-Hexanol (MCH) | Critical for creating a well-ordered, anti-fouling monolayer on gold surfaces in Au-S bonding protocols. |