Gold Nanoparticle-Based Lateral Flow Immunoassay for Wheat Allergen Detection: A Comprehensive Guide from Development to Application

This article provides a comprehensive overview of the development, optimization, and application of gold nanoparticle-based lateral flow immunoassays (LFIA) for the rapid and sensitive detection of wheat allergens, with a...

Gold Nanoparticle-Based Lateral Flow Immunoassay for Wheat Allergen Detection: A Comprehensive Guide from Development to Application

Abstract

This article provides a comprehensive overview of the development, optimization, and application of gold nanoparticle-based lateral flow immunoassays (LFIA) for the rapid and sensitive detection of wheat allergens, with a specific focus on gliadin. Tailored for researchers, scientists, and drug development professionals, the content explores the foundational principles of LFIA, details the step-by-step methodological process for constructing a wheat allergen assay, addresses critical troubleshooting and optimization parameters to enhance performance, and validates the method through comparative analysis with other diagnostic techniques. The integration of advanced strategies, such as molecular dynamics for antibody optimization and novel nanoparticle labels, is also discussed to present a future-oriented perspective on point-of-care food safety diagnostics.

Understanding Wheat Allergens and the Principles of Lateral Flow Immunoassays

The Clinical and Public Health Significance of Wheat Allergy and Celiac Disease

Wheat allergy and celiac disease represent two distinct but clinically significant gluten-related disorders with substantial public health implications. Celiac disease, an autoimmune disorder triggered by gluten, damages the small intestine and affects approximately 1% of the population globally [1]. Meanwhile, non-celiac gluten sensitivity (NCGS) may affect up to 10-15% of the global population, though recent research from the University of Melbourne suggests its symptoms are often part of the gut-brain interaction spectrum rather than being directly caused by gluten [1]. The development of accurate, rapid diagnostic tools is crucial for proper disease management. Gold nanoparticle-based lateral flow immunoassays (LFIA) have emerged as promising platforms for detecting wheat allergens like gliadin, offering rapid on-site testing capabilities that can benefit both clinical diagnostics and food safety monitoring [2] [3].

Quantitative Analysis of Gluten-Related Disorders and Detection Methods

Epidemiology and Clinical Presentation

Table 1: Global Prevalence and Key Characteristics of Gluten-Related Disorders

| Disorder Type | Global Prevalence | Key Trigger | Primary Symptoms | Diagnostic Criteria |

|---|---|---|---|---|

| Celiac Disease | ~1% general population [1] | Gluten (wheat, barley, rye) | Diarrhea, weight loss, fatigue, malnutrition; 50% of pediatric celiac cases may lack GI symptoms [1] | Positive serology (tTG-IgA) & confirmatory intestinal biopsy [1] |

| Non-Celiac Gluten Sensitivity (NCGS) | 10-15% global population [1] | Often not gluten (gut-brain interaction) [1] | Bloating (71%), abdominal discomfort (46%), abdominal pain (36%), fatigue (32%) [1] | Exclusion of celiac disease/wheat allergy + symptom resolution on GF diet |

| Wheat Allergy | Varies by region | Wheat proteins | Urticaria, breathing difficulties, anaphylaxis | Clinical history + IgE testing/oral food challenge |

| Celiac in SLE Pediatric Patients | 3% (3x higher prevalence) [1] | Gluten | Only 50% present with GI symptoms [1] | Serological screening in high-risk groups |

Table 2: Gluten Detection Technologies: Performance Comparison

| Detection Method | Detection Limit | Time Required | Equipment Needs | Primary Application |

|---|---|---|---|---|

| Gold nanoparticle-based LFIA [2] | 6.56 ng/mL (calculated); 25 ng/mL (visual) [2] | 15 minutes [3] | Minimal; portable strips | Rapid on-site screening |

| Sandwich ELISA [2] | 60 ng/mL [2] | 2-4 hours | Plate reader | Laboratory quantification |

| HPLC/MS [3] | Variable; sub-ppm possible | 30-60 minutes + sample prep | Advanced laboratory equipment | Confirmatory testing |

| PCR [3] | Variable | 2-3 hours | Thermal cycler, electrophoresis | DNA-based gluten detection |

Public Health Burden and Food Safety Regulations

The public health impact of gluten-related disorders extends beyond clinical symptoms to include significant lifestyle and economic burdens. Research indicates that 26% of households with celiac disease children experience gluten-free food insecurity, which significantly delays antibody normalization and disease recovery due to cost, transportation barriers, and limited access to gluten-free foods [1]. Regulatory frameworks have been established globally, with the Codex Alimentarius standard mandating that gluten-free products must contain less than 20 parts per million (ppm) of gluten [3]. This threshold is recognized by both the U.S. Food and Drug Administration and European Commission Regulation [3]. Emerging legislation, such as California's Allergen Disclosure for Dining Experiences (ADDE) Act, will require major restaurants to list common food allergens including wheat on menus by July 2026, highlighting the increasing recognition of these disorders as public health priorities [1].

Gold Nanoparticle-Based Lateral Flow Immunoassay: Application Notes and Protocols

Principle and Advantages of LFIA for Wheat Allergen Detection

The gold nanoparticle-based lateral flow immunoassay operates on a sandwich immunoassay principle for the detection of wheat gliadin, a major allergen and the immunotoxic component of gluten [2] [3]. The assay utilizes two monoclonal antibodies that specifically target gliadin—one immobilized on the membrane as a capture reagent and another conjugated to gold nanoparticles as a detection reagent [3]. When a sample containing gliadin is applied, it forms a complex with the gold nanoparticle-conjugated antibodies, which then migrate along the strip via capillary action until captured at the test line, generating a visible signal [2]. This technology offers significant advantages over traditional methods like ELISA, PCR, and HPLC, particularly for field use, as it requires minimal equipment, provides results within 15 minutes, and can be performed by non-specialized personnel [3]. The visual limit of detection of 25 ng/mL with a calculated LOD of 6.56 ng/mL in milk samples demonstrates sufficient sensitivity for monitoring the 20 ppm gluten threshold established for gluten-free foods [2] [3].

Experimental Protocol: LFIA for Gliadin Detection

Gold Nanoparticle Synthesis and Characterization

Protocol: Gold nanoparticles (AuNPs) of approximately 20 nm diameter are synthesized using the citrate reduction method of HAuCl₄ [3].

- Step 1: Prepare 0.01% HAuCl₄ solution and heat to boiling with vigorous stirring.

- Step 2: Rapidly add 1% trisodium citrate solution (1:10 v/v ratio) and continue heating until color changes to deep red.

- Step 3: Cool to room temperature and characterize using UV-Vis spectrophotometry (peak absorption at 523 nm) and dynamic light scattering (hydrodynamic diameter ~23 nm) [3].

- Step 4: Adjust concentration to an optical density of 10 at 520 nm for conjugation.

Antibody Selection and Conjugation Optimization

Protocol: Monoclonal antibodies (mAbs) against gliadin are screened for optimal pairing [2].

- Step 1: Screen anti-gliadin mAbs using pairwise sandwich ELISA to identify optimal capture-detection pairs (mAb 7 as capture antibody and HRP-labeled mAb 6 as detection antibody shown optimal in studies) [2].

- Step 2: Adjust AuNP solution to pH 8.0 using 0.1M K₂CO₃, which is critical for stable conjugation [3].

- Step 3: Add gliadin mAb to AuNP solution at optimal concentration of 1 μg/mL and incubate for 1 hour at room temperature with gentle mixing [3].

- Step 4: Block remaining surfaces with 1% BSA for 30 minutes.

- Step 5: Centrifuge at 12,000 × g for 15 minutes and resuspend in preservation buffer containing sucrose and BSA.

- Step 6: Characterize conjugated AuNPs using FESEM and UV-Vis spectroscopy (peak shift to 526-529 nm indicates successful conjugation) [3].

LFTS Assembly and Testing Procedure

Protocol: Lateral flow test strips are assembled with conjugated AuNPs applied to conjugate pad [3].

- Step 1: Dispense anti-gliadin mAb (1 mg/mL) and species-specific anti-IgG antibody (1 mg/mL) on nitrocellulose membrane as test and control lines, respectively.

- Step 2: Dry membranes at 37°C for 12 hours.

- Step 3: Assemble components: sample pad, conjugate pad containing gold-labeled mAbs, nitrocellulose membrane with test/control lines, and absorbent pad.

- Step 4: Cut into 4-mm wide strips and store in desiccated packaging.

- Step 5: For testing, apply 40 μL of extracted food sample to the sample pad and allow to migrate for 15 minutes [3].

- Step 6: Interpret results: two red lines (test and control) indicate positive result (>20 ppm gluten); one control line only indicates negative result (<20 ppm gluten) [3].

LFIA Test Workflow and Interpretation

Research Reagent Solutions

Table 3: Essential Materials for Gold Nanoparticle-Based LFIA Development

| Reagent/Material | Function/Description | Specifications/Alternatives |

|---|---|---|

| Anti-gliadin mAbs [2] | Primary detection reagents; specifically target gliadin epitopes | mAb 6 (detection) and mAb 7 (capture) shown optimal; specificity for PQPQLPY epitope enhances accuracy [3] |

| Gold nanoparticles (AuNPs) [3] | Signal generation; colorimetric detection | 20 nm spherical particles; citrate reduction synthesis; peak absorption 523 nm |

| Nitrocellulose membrane [3] | Matrix for antibody immobilization | Pore size 8-15 μm; consistent flow characteristics critical |

| Sample pad [3] | Application point for food extracts | Glass fiber or cellulose; may require pre-treatment with buffers/surfactants |

| Gliadin standard [2] | Positive control and calibration | Sigma-Aldrich; prepare stock solutions in 60% ethanol |

| Phosphate buffered saline (PBS) [3] | Buffer system for extraction and dilution | 0.01M phosphate, 0.138M NaCl, 0.0027M KCl, pH 7.4 |

| Blocking agents (BSA, sucrose) [3] | Stabilize conjugated AuNPs; reduce non-specific binding | 1% BSA for blocking; sucrose (2-5%) in preservation buffer |

Gold nanoparticle-based lateral flow immunoassays represent a significant advancement in the detection of wheat allergens, particularly for gliadin, addressing crucial clinical and public health needs in managing celiac disease and wheat allergy. The protocol outlined herein provides researchers with a comprehensive framework for developing sensitive, specific, and rapid tests capable of detecting gluten at the regulatory threshold of 20 ppm. With the high global prevalence of gluten-related disorders and the documented challenges of gluten-free food insecurity, such accessible detection technologies play an essential role in protecting vulnerable populations. Further development and refinement of these assays will continue to enhance clinical diagnostics, food safety monitoring, and ultimately improve quality of life for individuals with gluten-related disorders.

IgE-mediated wheat allergy is an emerging global health concern, particularly prevalent in Northern Europe and parts of Asia [4]. This immunologic response can manifest with symptoms ranging from mild urticaria to life-threatening anaphylaxis. A unique and severe manifestation is wheat-dependent exercise-induced anaphylaxis (WDEIA), where symptoms occur only when wheat ingestion is followed by physical exertion or other co-factors like NSAIDs or alcohol [4]. Among the complex mixture of wheat proteins, gliadin has been identified as a major culprit in triggering these allergic responses. Understanding the specific gliadin proteins and their epitopes is therefore crucial for developing accurate diagnostic tools, including gold nanoparticle-based lateral flow immunoassays (LFIAs) for rapid detection [2].

Major Wheat Allergen Proteins and Epitopes

Wheat proteins are classified into two main categories based on their solubility: the water/salt-soluble proteins (albumins and globulins) and the alcohol/dilute acid-soluble proteins (gliadins and glutenins) [4]. The table below summarizes the major allergenic wheat proteins, with gliadins being particularly significant.

Table 1: Major Allergenic Wheat Proteins and Their Characteristics

| Protein Category | Specific Protein | Allergen Designation | Solubility | Primary Clinical Association |

|---|---|---|---|---|

| Gliadins | ω-5-gliadin | Tri a 19 | Alcohol/water-soluble | WDEIA, IgE-mediated allergy |

| α/β-gliadin | Tri a 21 | Alcohol/water-soluble | IgE-mediated allergy | |

| γ-gliadin | Tri a 20 | Alcohol/water-soluble | IgE-mediated allergy | |

| Glutenins | HMW Glutenin | Tri a 26 | Dilute acid-soluble | IgE-mediated allergy |

| LMW Glutenin | Tri a 36 | Dilute acid-soluble | IgE-mediated allergy | |

| Albumins/Globulins | Lipid Transfer Protein (LTP) | Tri a 14 | Water/salt-soluble | WDEIA |

| Alpha-amylase inhibitors | Tri a 15 | Water/salt-soluble | IgE-mediated allergy |

The most allergenic wheat proteins responsible for IgE-mediated wheat allergy are gliadins, particularly ω-5-gliadin, and glutenins [4]. In WDEIA, ω-5-gliadin and LTP are the major allergens involved [4]. Gliadins are monomeric proteins that can be further subdivided into α/β-, γ-, and ω-gliadins based on their primary structure and molecular weight. Omega-5-gliadin, a subset of ω-gliadins with higher molecular weight (∼55–65 kDa) and specific repetitive motifs (QQIPQQ), is especially notable for its strong association with WDEIA [5].

Table 2: Key Epitopes in Gliadin Families for Wheat Allergy and Celiac Disease

| Gliadin Family | Epitope Type | Example Epitope Sequences/Regions | Associated Condition |

|---|---|---|---|

| ω-5-gliadin | IgE | SRLL-, FPQQQ, QQIPQQ repetitive motifs | WDEIA [5] |

| α-gliadin | T-cell (CD) | Five known core sequences | Celiac Disease [5] |

| γ-gliadin | T-cell (CD) | Eight known core sequences | Celiac Disease [5] |

| ω-1,2-gliadin | T-cell (CD) | Two known core sequences | Celiac Disease [5] |

Proteomic Profiling and Epitope Analysis Protocol

A detailed understanding of the specific gliadin proteins and their epitopes in a wheat sample requires sophisticated proteomic analysis. The following protocol, adapted from Cho et al. (2018), outlines the key steps for gliadin extraction, separation, and epitope characterization [5].

Protocol: Proteomic Analysis of Gliadins from Wheat Flour

Principle: This method uses sequential extraction to isolate alcohol-soluble gliadins from wheat flour, followed by high-resolution 2-Dimensional Gel Electrophoresis (2-DE) to separate individual protein components. The separated proteins are then identified using Tandem Mass Spectrometry (MS/MS), and the resulting sequences are analyzed for known CD and WDEIA epitopes [5].

Materials and Reagents:

- Wheat flour (e.g., from Triticum aestivum L. cv. Keumkang)

- 150 mM NaCl solution

- 70% Ethanol (HPLC grade recommended)

- 2-DE reagents: Immobilized pH Gradient (IPG) strips (pI range 6-11 and/or 3-11), SDS-PAGE gels, electrophoresis buffer, staining solutions (e.g., Coomassie Brilliant Blue, Sypro Ruby)

- MS/MS reagents: Trypsin (sequencing grade), MALDI matrix (if using MALDI-TOF/TOF), LC-MS/MS solvents

Procedure:

- Extraction of Gliadin Proteins:

- Begin with 100 mg of wheat flour.

- Add 1 mL of 150 mM NaCl solution. Shake the mixture for 2 hours at room temperature to dissolve and remove water/salt-soluble albumins and globulins.

- Centrifuge at 15,000 g and 20°C for 10 minutes. Carefully discard the supernatant.

- To the pellet, add 1 mL of 70% ethanol. Shake the mixture overnight at room temperature to solubilize the gliadins.

- Centrifuge again at 15,000 g and 20°C for 10 minutes.

- Collect the supernatant, which contains the extracted gliadins. Aliquot (e.g., 500 μL) and immediately freeze in liquid nitrogen. Store at -80°C for long-term preservation. Perform three separate extractions for analytical reproducibility [5].

Protein Separation using Two-Dimensional Gel Electrophoresis (2-DE):

- Use an appropriate volume of the gliadin extract for isoelectric focusing (IEF). The Keumkang study used a pI range of 6-11 in the first dimension for initial separation, identifying α-, γ-, and ω-gliadins in 31, 28, and one 2-DE spot, respectively [5].

- For a more comprehensive profile, especially to capture more ω-gliadins, a second separation using a broader pI range (3-11) is recommended. This approach identified an additional six ω-gliadins in the Keumkang cultivar [5].

- Following IEF, perform the second dimension separation by SDS-PAGE on a suitable polyacrylamide gel (e.g., 12%).

- Visualize the separated protein spots by staining (e.g., Coomassie Brilliant Blue or fluorescent stains) [5].

Protein Identification via Tandem Mass Spectrometry (MS/MS):

- Excise the protein spots of interest from the 2-DE gels.

- Digest the proteins in-gel with trypsin.

- Analyze the resulting peptides using tandem mass spectrometry (MS/MS).

- Identify the proteins by searching the acquired MS/MS spectra against relevant protein databases (e.g., NCBInr) [5].

Epitope Analysis:

- Compile the identified protein sequences from the MS/MS data.

- Systematically analyze these sequences for known core epitope sequences relevant to CD and WDEIA, as summarized in Table 2 of this document [5].

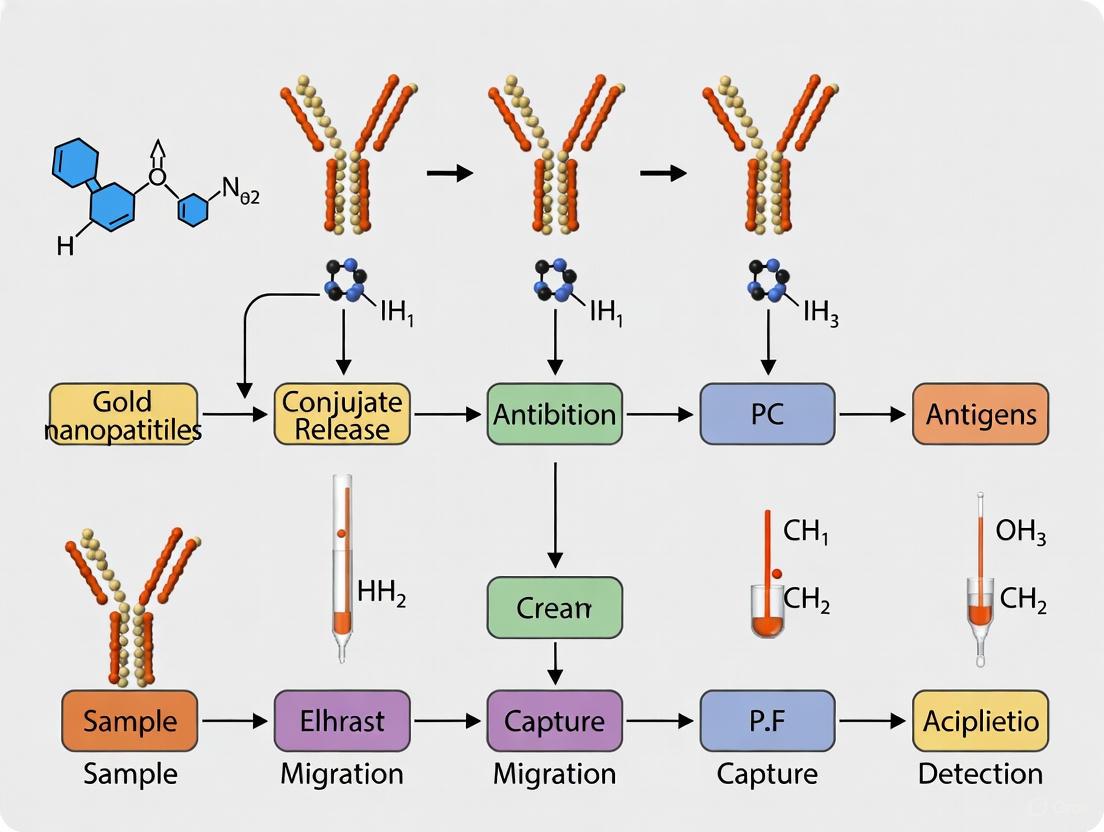

Diagram 1: Workflow for gliadin proteomic profiling.

Gold Nanoparticle-based Lateral Flow Immunoassay (LFIA) for Gliadin

For the rapid and on-site detection of the major wheat allergen gliadin in food products, a gold nanoparticle-based Lateral Flow Immunoassay (LFIA) presents a highly effective solution. The protocol below is based on the work of Hu et al. (2023), which developed a sensitive and specific LFIA for gliadin detection in milk, a common food matrix [2].

Protocol: Development of LFIA Strips for Gliadin Detection

Principle: This sandwich immunoassay uses two monoclonal antibodies (mAbs) that bind to distinct epitopes on the gliadin molecule. One mAb (capture antibody) is immobilized on a nitrocellulose membrane at the test line. The other mAb (detection antibody) is conjugated to gold nanoparticles (AuNPs). When a liquid sample containing gliadin is applied, it binds to the AuNP-conjugated mAb. This complex migrates along the strip via capillary action and is captured by the immobilized mAb at the test line, generating a visible red line due to the accumulation of AuNPs [2].

Materials and Reagents:

- Monoclonal Antibodies: A pair of high-affinity mAbs against gliadin (e.g., mAb 7 as capture antibody and mAb 6 as detection antibody, as identified by Hu et al.) [2].

- Gold Nanoparticles (AuNPs): Colloidal gold, ~20-40 nm in diameter.

- LFIA Components: Sample pad, conjugate pad, nitrocellulose membrane, absorbent pad, and backing card.

- Buffer Solutions: Phosphate Buffered Saline (PBS), blocking buffer (e.g., containing BSA or sucrose).

- Gliadin Standard: For calibration and quality control.

Procedure:

- Preparation of AuNP-mAb Conjugate:

- Adjust the pH of the colloidal gold solution to an optimal level (typically slightly above the isoelectric point of the antibody, often around pH 8.0-9.0).

- Add the detection mAb (e.g., mAb 6) to the pH-adjusted AuNP solution and incubate to allow adsorption of the antibody onto the AuNP surface.

- Block the remaining surfaces of the AuNPs with a suitable blocking agent (e.g., BSA) to prevent non-specific binding.

- Purify the conjugate by centrifugation and resuspend in a storage buffer containing stabilizers. Dispense the conjugate onto the conjugate pad and dry [2].

Assembly of LFIA Strips:

- Immobilize the capture mAb (e.g., mAb 7) at the test line (T-line) of the nitrocellulose membrane. Immobilize a control antibody (e.g., anti-mouse IgG) at the control line (C-line).

- Assemble the strip components in the following sequence on a backing card: sample pad, conjugate pad (overlapping the sample pad), nitrocellulose membrane (overlapping the conjugate pad), and absorbent pad (overlapping the end of the nitrocellulose membrane).

- Cut the assembled card into individual strips of the desired width (e.g., 4 mm) [2].

Detection and Analysis:

- Prepare the sample. For solid foods, an extraction with a suitable solvent (e.g., 60% ethanol) is necessary to solubilize gliadins.

- Apply the extracted sample (e.g., 80-100 μL) to the sample pad of the LFIA strip.

- Allow the sample to migrate up the strip for a specified time (e.g., 10-15 minutes).

- Visually inspect the strip for the appearance of lines. A visible T-line alongside a C-line indicates a positive result. The C-line must always appear for the test to be valid.

- The visual limit of detection (vLOD) reported for this assay was 25 ng/mL in milk, with a calculated LOD of 6.56 ng/mL [2].

Diagram 2: LFIA principle for gliadin detection.

The Scientist's Toolkit: Key Research Reagent Solutions

The following table details essential materials and reagents used in the featured experiments for gliadin analysis and detection.

Table 3: Research Reagent Solutions for Gliadin and Wheat Allergen Research

| Reagent / Material | Function / Application | Example & Key Characteristics |

|---|---|---|

| Anti-Gliadin mAbs | Core recognition elements in immunoassays (ELISA, LFIA). | mAb 6 (HRP-detection) & mAb 7 (capture); high specificity and affinity pair with minimal cross-reactivity [2]. |

| Colloidal Gold Nanoparticles | Signal generation in LFIA; conjugated to detection mAb. | ~20-40 nm diameter; conjugated to anti-gliadin mAb for visual detection [2]. |

| ω-5-gliadin Allergen | Positive control and assay standardization for specific IgE detection. | Purified native or recombinant ω-5-gliadin (Tri a 19); essential for WDEIA diagnostics [4]. |

| Ethanol (70%) | Solvent for extracting gliadins from food and flour matrices. | Effectively solubilizes monomeric gliadins while leaving other protein fractions insoluble [5]. |

| 2-DE & MS Consumables | High-resolution separation and identification of complex gliadin families. | IPG strips (pI 3-11, 6-11), SDS-PAGE gels, trypsin, MALDI/LC-MS/MS platforms [5]. |

Core Components and Working Principle of a Lateral Flow Immunoassay

Lateral Flow Immunoassays (LFIAs) are paper-based platforms for detecting and quantifying analytes in complex mixtures, where results are displayed within 5–30 minutes [6]. These assays are widely adopted in biomedicine, agriculture, food safety, and environmental sciences due to their simplicity, rapid results, and portability [6]. The COVID-19 pandemic demonstrated the feasibility of large-scale LFIA testing for clinical and public health purposes, highlighting their utility beyond traditional laboratory settings [7]. In the context of wheat allergen research, LFIAs provide a rapid, on-site method for detecting gluten proteins such as gliadin, which is crucial for food safety and managing celiac disease [3]. This application note details the core components, working principles, and experimental protocols for developing a gold nanoparticle-based LFIA for wheat allergen detection, framed within a broader thesis on method development for food allergen research.

Core Components of a Lateral Flow Immunoassay

A typical lateral flow test strip consists of overlapping membranes mounted on a backing card for stability and handling [6]. Each component plays a specific role in ensuring the proper flow, reaction, and detection of the target analyte. The table below summarizes the core components, their functions, and material considerations for developing an LFIA for wheat allergen detection.

Table 1: Core Components of a Lateral Flow Immunoassay Strip for Wheat Allergen Detection

| Component | Function | Common Materials | Considerations for Wheat Allergen (Gliadin) Detection |

|---|---|---|---|

| Sample Pad | Receives the liquid sample; distributes it evenly to the conjugate pad; may contain buffers and surfactants to treat the sample [6] [8]. | Cellulose, glass fiber [7] | Must effectively handle food extracts. Pre-treatment may be needed to solubilize gliadins [3]. |

| Conjugate Pad | Stores dried detector reagents (e.g., antibody-labeled nanoparticles); releases them upon contact with the sample [6]. | Glass fiber, polyester, rayon [6] | Conjugated anti-gliadin monoclonal antibodies must remain stable and functional when dried [3]. |

| Nitrocellulose Membrane | Critical platform where immunochemical reactions occur; contains immobilized capture reagents at the test and control lines [6] [9]. | Nitrocellulose with various capillary flow times [6] | Pore size and flow rate must be optimized for efficient capture of gliadin-antibody-gold complexes [6]. |

| Test Line | Contains immobilized capture antibodies (or antigens) specific to the target analyte; generates a positive signal [6] [8]. | Anti-target analyte antibodies bound to the membrane [3] | Striped with a monoclonal antibody specific for gliadin's immunodominant sequence (e.g., PQPQLPY) [3]. |

| Control Line | Verifies that the test has functioned correctly; captures unused conjugate particles [6] [10]. | Secondary antibodies specific to the conjugate antibody [9] | Confirms the flow and reactivity of the gold-labeled antibodies, ensuring test validity [8]. |

| Absorbent Pad | Acts as a waste reservoir; wicks the fluid through the strip to maintain continuous capillary flow [6] [10]. | High-density cellulose [6] | Must have sufficient capacity to handle the entire sample volume and prevent backflow. |

| Backing Card | Provides structural support for assembling and overlapping all strip components [6]. | Plastic, adhesive-coated vinyl or polyester [6] | Ensures mechanical stability during handling and storage. |

Working Principle and Assay Formats

The fundamental principle of an LFIA is that a liquid sample moves without external forces via capillary action through the various zones of the strip [6]. As the sample migrates, it interacts with reagents that lead to a visual response indicating the presence or absence of the target analyte. The two primary formats for LFIAs are the sandwich assay and the competitive assay.

The Direct (Sandwich) Format

The sandwich format is used for larger analytes with multiple antigenic sites, such as proteins or whole pathogens [6] [10]. This format is suitable for detecting gliadin, a protein complex.

Diagram 1: Sandwich assay workflow for gliadin detection

- Sample Application: The liquid food extract containing gliadin is applied to the sample pad.

- Conjugation: The sample migrates to the conjugate pad, dissolving the dried gold nanoparticle (GNP)-conjugated anti-gliadin antibodies. The gliadin antigens bind to these antibodies, forming an analyte-conjugate complex [3].

- Capture at Test Line: The complex continues to flow along the nitrocellulose membrane to the test line. This line is striped with a second, immobilized anti-gliadin antibody that captures the complex. The accumulation of GNPs results in a visible red line [3].

- Capture at Control Line: The remaining free GNP-conjugated antibodies continue to the control line, which is striped with a species-specific secondary antibody (e.g., anti-mouse IgG). This line captures the conjugate regardless of the presence of gliadin, validating the test functionality [9] [8].

- Result Interpretation: The appearance of both a test line and a control line indicates a positive result. The appearance of only the control line indicates a negative result. The absence of a control line indicates an invalid test [8].

The Competitive Format

The competitive format is used for small molecules with single antigenic determinants that cannot bind two antibodies simultaneously [6] [8]. While less common for large proteins like gliadin, it is the standard format for small allergens like certain mycotoxins.

Diagram 2: Competitive assay workflow for small molecules

- Sample Application: The sample containing the small analyte is applied.

- Conjugation: The analyte mixes with the GNP-conjugated antibodies in the conjugate pad.

- Competition at Test Line: The test line is coated with the target analyte (or an analogue). If the target is present in the sample, it binds to the conjugate antibodies, blocking them from binding to the test line. Therefore, no visible line appears at the test zone for a positive result. If the target is absent, the conjugate antibodies bind to the immobilized analyte on the test line, producing a visible line, indicating a negative result [6] [8].

- Control Line: The control line functions identically to the sandwich format, capturing excess conjugate to confirm proper flow.

Detailed Protocol: Gold Nanoparticle-Based LFIA for Gluten Detection

This protocol outlines the steps for developing a sandwich-format LFIA for detecting gluten in raw food materials, based on the method described by Hu et al. (2022) [3]. The target is gliadin, with a detection limit of 20 ppm, aligning with the Codex Alimentarius standard for "gluten-free" labeling [3].

Reagents and Materials

Table 2: Research Reagent Solutions for GNP-based Gliadin LFIA

| Item | Specification/Function | Source/Example |

|---|---|---|

| Anti-Gliadin mAb | Monoclonal antibody specific for the immunodominant 33-mer peptide (e.g., recognizes PQPQLPY); used for both conjugation and capture. | Commercial suppliers (e.g., RayBiotech [11]) |

| Gold Nanoparticles (GNPs) | ~20 nm spherical particles; serve as the colorimetric label due to localized surface plasmon resonance [3]. | TED PELLS, Inc. (citation:6) or Cytodiagnostics |

| Nitrocellulose Membrane | Porous membrane with optimized capillary flow time for protein immobilization and sample development. | EMD Millipore Hi-Flow Plus [11] [3] |

| Sample Pad | Glass fiber pad for sample application and filtration. | Ahlstrom-Munksjö [12] or EMD Millipore |

| Conjugate Pad | Glass fiber or polyester pad for storing dried antibody-GNP conjugates. | EMD Millipore [11] |

| Absorbent Pad | High-capacity cellulose pad to wick fluid and maintain flow. | EMD Millipore [11] or GE Healthcare |

| Backing Card | Adhesive-coated plastic card for assembling strip components. | DCNova or Kenosha |

| Buffer Salts & Blockers | PBS, Sucrose, Trehalose, BSA, Tween-20; used for conjugation, blocking, and sample pad treatment. | Sigma-Aldrich |

Step-by-Step Experimental Procedure

A. Synthesis and Conjugation of Gold Nanoparticles (GNPs)

- Synthesis of GNPs: Synthesize ~20 nm colloidal gold nanoparticles using the citrate reduction method of trisodium citrate with chloroauric acid (HAuCl₄) [3]. Confirm particle size and monodispersity via UV-Vis spectroscopy (peak at ~523 nm) and dynamic light scattering (DLS).

- pH Optimization: Adjust the pH of the GNP solution to 8.0 using a mild buffer like 2-10 mM potassium carbonate (K₂CO₃). This is the optimal pH for antibody adsorption to the GNP surface without causing aggregation [3].

- Antibody Conjugation: Determine the minimum amount of antibody required to stabilize the GNPs by adding varying concentrations of anti-gliadin monoclonal antibody (e.g., 0-8 µg/mL) to fixed volumes of GNPs. Incubate for 30-60 minutes. Add NaCl to a final concentration of 1.5 M to stress-test stability. The optimal antibody concentration is the lowest that prevents aggregation (solution remains red, not blue/purple) [3].

- Blocking and Stabilization: Add a blocking solution containing Bovine Serum Albumin (BSA) to a final concentration of 1% to cover any remaining bare GNP surfaces and minimize non-specific binding. Incubate for 30 minutes.

- Purification: Centrifuge the conjugate (e.g., at 14,000 x g for 30 minutes for 20 nm GNPs) to remove unbound antibodies and excess blockers. Resuspend the soft pellet in a storage buffer containing 10-20 mM Borax, 1% BSA, 5-10% sucrose, and 0.05-0.1% sodium azide [6].

- Characterization: Verify successful conjugation by a slight red-shift in the UV-Vis spectrum (e.g., from 523 nm to 529 nm) and a slight increase in hydrodynamic diameter as measured by DLS [3].

B. Strip Assembly and Coating

- Membrane Coating:

- Test Line: Dispense the capture anti-gliadin monoclonal antibody at a concentration of 1.0 mg/mL onto the nitrocellulose membrane using a striping dispenser. A typical volume is 0.5 µL per linear cm [11] [3].

- Control Line: Dispense a goat anti-mouse IgG secondary antibody at a concentration of 0.4 mg/mL approximately 3-5 mm downstream from the test line. A typical volume is 0.4 µL per linear cm [11].

- Conjugate Pad Preparation: Dilute the purified antibody-GNP conjugate to an optimal optical density (OD) and dispense it onto the glass fiber conjugate pad. Lyophilize or air-dry the pad, often in the presence of sugar stabilizers like sucrose or trehalose [6].

- Component Assembly: Mount the following components sequentially onto the adhesive backing card with ~1-2 mm overlaps to ensure capillary transfer [11]:

- Absorbent pad at the top.

- Nitrocellulose membrane in the center.

- Conjugate pad below the membrane.

- Sample pad at the bottom.

- Cutting: Cut the assembled card into individual strips of 4-5 mm width using a programmable shear cutter.

C. Test Procedure and Data Acquisition

- Sample Preparation: Homogenize the food sample (e.g., flour) and extract gliadin using a suitable extraction solution (e.g., 60% ethanol). Centrifuge to remove particulates.

- Assay Execution: Apply 40-100 µL of the extracted sample to the sample pad [3]. Follow with 80 µL of chase buffer if required by the strip design [11].

- Incubation and Visualization: Allow the strip to develop at room temperature for 15 minutes [3]. Observe the appearance of lines at the test and control zones.

- Result Interpretation:

- Positive: Both test (T) and control (C) lines are visible. The intensity of the test line is inversely proportional to the gliadin concentration.

- Negative: Only the control (C) line is visible.

- Invalid: The control line does not appear. The test should be repeated.

Table 3: Quantitative Performance of the Gluten LFIA

| Parameter | Specification/Value | Experimental Detail |

|---|---|---|

| Target Analyte | Gliadin (a component of gluten) | - |

| Assay Format | Sandwich immunoassay | Using identical mAbs for capture and detection [3] |

| Detection Limit | 20 ppm (ng/mL) | Meets Codex standard for "gluten-free" [3] |

| Assay Time | 15 minutes | Total development time [3] |

| Sample Volume | 40 µL | Volume of extracted sample applied [3] |

| Specificity | High for gliadin from wheat, rye, barley | Recognizes the immunodominant peptide sequence [3] |

| Quantitative Readout | Possible with a reader | Intensity can be measured with a colorimetric reader [12] |

Advanced Quantitative Readout Techniques

While visual readout is sufficient for qualitative assessment, quantitative data can be obtained using a dedicated reader device. These devices measure the intensity of the test line, which correlates with the analyte concentration [12]. For GNP-based LFIAs, the highest sensitivity in colorimetric readout is often achieved using the green channel of a color image sensor (center wavelength ~537 nm), as the signal-to-noise ratio for the red GNP signal is optimal in this band [12]. This approach can significantly improve the sensitivity and objectivity of the assay.

Advantages of Gold Nanoparticles as Optical Labels in LFIA

Lateral Flow Immunoassay (LFIA) has emerged as a predominant point-of-care diagnostic tool, characterized by its rapid analysis, cost efficiency, and user-friendly visual interpretation [13]. The core of its detection capability lies in the optical labels that generate the visible signal, and among these, gold nanoparticles (AuNPs) have established themselves as the leading label material. This document details the specific advantages of AuNPs as optical labels, framed within research on developing a gold nanoparticle-based LFIA for the detection of wheat allergens. The unique properties of AuNPs—from their strong optical characteristics to their superior biocompatibility—directly address the need for sensitive, rapid, and reliable detection of allergens like gliadin in complex food matrices [2] [3]. The following sections will quantify these advantages, provide detailed experimental protocols, and contextualize their application for researchers and scientists in food safety and drug development.

Core Advantages of Gold Nanoparticles in LFIA

The widespread adoption of AuNPs in LFIA is driven by a combination of optical, physical, and chemical properties that make them uniquely suited for this application.

Strong Optical Properties: AuNPs exhibit intense color due to Localized Surface Plasmon Resonance (LSPR), a phenomenon where conduction electrons oscillate in resonance with incident light [13]. This provides a high extinction coefficient, meaning they are intensely colored even at low concentrations, facilitating clear visual detection. The LSPR band and extinction coefficient are influenced by the nanoparticles' size, shape, and composition, allowing for tuning of their optical properties [13] [14]. For instance, larger spherical AuNPs and non-spherical variants like nanostars scatter light more effectively, further enhancing their visibility [15].

Excellent Biocompatibility and Simple Functionalization: AuNPs are known for their biocompatibility and chemical stability [13]. Their surface allows for straightforward conjugation with biomolecules, such as antibodies, through simple physical adsorption (physisorption) or more controlled covalent bonding methods [16]. This process is well-established, and the resulting conjugates are stable, ensuring the long-term shelf life of LFIA strips. The surface of AuNPs can be easily modified with antibodies via electrostatic interactions, typically by adjusting the pH of the colloidal solution to a value slightly above the isoelectric point of the antibody [3].

Enhanced Sensitivity through Morphology and Size Control: The sensitivity of an LFIA is critically dependent on the label's characteristics. Research demonstrates that moving beyond traditional spherical AuNPs to more complex morphologies can yield significant gains. For example, one study found that star-shaped gold nanoparticles (AuNSs) showed an 86% antibody binding efficiency due to their greater surface area, achieving a limit of detection (LOD) for aflatoxin B1 of 0.01 ng/mL, which surpassed the performance of both spherical nanoparticles and nano-flowers [13]. Similarly, the use of highly spherical gold nanoparticles (S-GNPs) can lead to an 8-fold decrease in LOD compared to conventional quasispherical nanoparticles, attributed to more effective antibody immobilization and superior optical properties [14].

Table 1: Comparative Performance of Different Gold Nanoparticle Morphologies in LFIA

| Nanoparticle Morphology | Key Feature | Reported Advantage | Limit of Detection (LOD) | Target Analyte |

|---|---|---|---|---|

| Spherical (C-GNPs) | Conventional, simple synthesis | Baseline for comparison | Varies with size (e.g., 9.9 ng/mL for 33.7 nm) [14] | Troponin I [14] |

| Gold Nano-Stars (AuNSs) | Branched structure, high surface area | Increased antibody binding efficiency (86%) [13] | 0.01 ng/mL [13] | Aflatoxin B1 [13] |

| Gold Nano-Popcorns (GNPNs) | Rough, hierarchical structure | Improved sensitivity vs. spheres [17] | 0.1 ng/mL [17] | Procalcitonin [17] |

| Superspherical (S-GNPs) | High uniformity, optimal optics | 8-fold lower LOD vs. C-GNPs [14] | 1.2 ng/mL [14] | Troponin I [14] |

Experimental Protocols for AuNP-Based LFIA

This section provides a detailed methodology for developing an LFIA for wheat allergen (gliadin) detection, from the synthesis of AuNPs to the assembly and testing of the strip.

Synthesis and Characterization of Spherical Gold Nanoparticles (Turkevich-Frens Method)

Objective: To synthesize ~20 nm spherical AuNPs for use as optical labels [3] [17].

Materials:

- Tetrachloroauric acid (HAuCl₄)

- Trisodium citrate dihydrate (Na₃C₆H₅O₇·2H₂O)

- Deionized water

Procedure:

- Add 100 mL of a 0.01% (w/v) HAuCl₄ solution to a clean, round-bottom flask equipped with a condenser.

- Heat the solution to boiling under continuous stirring.

- Rapidly add 2.7 mL of a 1% (w/v) trisodium citrate solution to the boiling gold solution.

- Continue heating and stirring for 15 minutes. The solution will change color from pale yellow to deep red.

- Remove the flask from the heat source and allow the colloidal suspension to cool to room temperature while stirring.

- Characterize the synthesized AuNPs by:

Antibody Conjugation and Probe Formation

Objective: To conjugate anti-gliadin monoclonal antibodies to the surface of the synthesized AuNPs to create stable detection probes [3].

Materials:

- Synthesized AuNP colloid

- Anti-gliadin monoclonal antibody (mAb)

- Bovine Serum Albumin (BSA)

- Phosphate Buffered Saline (PBS), pH 7.4

- Sucrose

- Tween 20

Procedure:

- pH Optimization: Determine the optimal pH for conjugation by adding AuNPs to solutions with different pH values (6.0-9.0). The ideal pH is the highest value that prevents aggregation upon salt addition, typically pH 8.0-9.0 [3].

- Antibody Concentration Optimization: At the optimal pH, add varying concentrations of antibody (e.g., 0-8 µg/mL) to separate aliquots of AuNPs. After incubation, add NaCl to a final concentration of 1.5 M. The minimal antibody concentration that prevents a color change from red to blue/purple (indicating aggregation) is the optimal amount for stable conjugation [3].

- Conjugation: For large-scale conjugation, adjust the pH of the AuNP colloid to the optimal value. Add the determined optimal concentration of anti-gliadin mAb dropwise under constant stirring. Incubate for 30-60 minutes at room temperature.

- Blocking: Add BSA to a final concentration of 0.25-1% to block any remaining bare gold surfaces and prevent non-specific binding. Incubate for another 30 minutes.

- Purification: Concentrate the conjugate by centrifugation (e.g., 15,000 × g for 30 min). Carefully discard the supernatant and resuspend the soft pellet in a storage buffer (e.g., PBS containing 0.1% BSA, 10% sucrose, and 0.05% Tween 20). Sucrose acts as a cryoprotectant during the drying of the conjugate pad.

- Storage: Store the purified antibody-AuNP conjugate at 4°C until use.

LFIA Strip Assembly and Test Procedure

Objective: To assemble the functional LFIA strip and perform the detection assay for gliadin.

Materials:

- Membrane components: Sample pad, conjugate pad, nitrocellulose (NC) membrane, absorbent pad.

- Immunoreagents: Captured anti-gliadin mAb (for test line), anti-species antibody or Protein A (for control line).

- Dispenser: BioDot XYZ3000 or equivalent.

Procedure:

- Strip Assembly:

- Test and Control Line Dispensing: Dispense the capture anti-gliadin mAb on the NC membrane to form the test line (T). Dispense an anti-mouse IgG antibody or Protein A at a separate location to form the control line (C). Dry the membrane overnight at room temperature [17].

- Pad Preparation: Saturate the conjugate pad with a buffer containing sugars and surfactants, then dry it. Apply the purified antibody-AuNP conjugate onto the treated conjugate pad and dry.

- Final Assembly: Laminate the sample pad, conjugate pad, NC membrane, and absorbent pad sequentially on a backing card with a 1-2 mm overlap between each component. Cut the assembled card into individual strips of the desired width (typically 4 mm).

- Test Execution:

- Apply 40-100 µL of the extracted food sample or standard to the sample pad [3] [18].

- As the sample migrates, it rehydrates the AuNP-antibody conjugate in the conjugate pad. If gliadin is present, it binds to the AuNP-mAb conjugate.

- The complex continues to flow across the NC membrane and is captured by the immobilized mAb at the test line, forming a visible red line.

- The unbound conjugate is captured at the control line, validating the test.

- Results can be read visually within 5-15 minutes [18].

The following diagram illustrates the workflow and principle of the sandwich LFIA for detecting wheat allergens.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Gold Nanoparticle-Based LFIA Development

| Item/Category | Specific Examples | Function in the Experiment |

|---|---|---|

| Gold Nanoparticles | Spherical AuNPs (20 nm, 40 nm), Gold Nano-Stars, Gold Nano-Popcorns [13] [17] | Optical label; generates the detectable signal based on LSPR. |

| Critical Antibodies | Anti-gliadin Monoclonal Antibodies (e.g., mAb 6, mAb 7) [2] | Provides specificity; detection antibody is conjugated to AuNPs, capture antibody is immobilized on the membrane. |

| Membrane & Pad System | Nitrocellulose Membrane (e.g., CNPC-SS12), Sample Pad (GFB-R4), Conjugate Pad (PT-R5), Absorbent Pad [17] | Paper-based platform that supports capillary flow and houses immunoreagents. |

| Conjugation Chemicals | Trisodium Citrate, HAuCl₄, BSA, Tween 20, Sucrose [3] [17] | Used for synthesizing, stabilizing, and functionalizing AuNPs, and for blocking non-specific sites. |

| Buffer Systems | Phosphate Buffered Saline (PBS), HEPES Buffer, Tris Buffer [13] [19] | Maintains optimal pH and ionic strength for antibody-antigen interactions and conjugate stability. |

Advanced LFIA Strategies and future trends

The field of AuNP-based LFIA continues to evolve with strategies aimed at pushing the limits of sensitivity.

Signal Amplification Techniques: The silver enhancement method is a powerful post-assay technique where silver ions are reduced onto the surface of captured AuNPs, depositing a metallic silver layer. This significantly increases the particle size and changes the color from red to black, leading to a dramatic enhancement of the signal [17]. Studies have reported up to a 10-fold improvement in sensitivity using this method [17].

Novel Detection Modalities: Moving beyond conventional colorimetric readouts, plasmonic scattering is an emerging modality. This involves using a transparent nitrocellulose membrane with a light-absorbing backing card to create a black background. This setup minimizes background reflection, allowing the strong scattering signal from AuNPs (especially larger ones around 100 nm) to be clearly visualized, significantly improving the signal-to-noise ratio and lowering the limit of detection [15].

Systematic Label Selection: The choice of nanoparticle label is a critical factor. A comparative study of colored labels (AuNPs, Au@Pt core-shell, latex, and magnetic nanoparticles) for detecting a bacterial pathogen concluded that the label's chemical nature and color directly impact the LOD. Au@Pt nanoparticles provided the best LOD in that study, underscoring the importance of screening different nanomaterials for a specific assay [19].

Comparing Sandwich vs. Competitive Assay Formats for Allergen Detection

The accurate detection of food allergens is a critical public health priority, with gluten-related disorders affecting a growing portion of the population. [20] Within this context, gold nanoparticle-based lateral flow immunoassays (LFIAs) have emerged as powerful tools for rapid, on-site screening of allergens such as wheat gliadin. [20] [3] The performance of these assays is fundamentally governed by their format, with sandwich and competitive assays representing two distinct approaches with specific applications. Sandwich immunoassays are predominantly used for larger antigens with multiple epitopes, while competitive formats are essential for detecting small molecules with single epitope sites. [21] This application note provides a detailed comparison of these two formats within the specific context of wheat allergen detection, offering structured protocols, performance data, and guidelines for format selection to assist researchers in developing optimal detection strategies.

Fundamental Principles and Format Selection

Sandwich Assay Format

The sandwich assay, also known as a non-competitive assay, requires two distinct antibodies that bind to different epitopes on the target antigen. [22] [21] In a lateral flow format, one antibody is typically conjugated to a reporter such as gold nanoparticles (AuNPs), while the other is immobilized on the nitrocellulose membrane as a capture antibody at the test line. [20] When the target antigen is present in the sample, it forms a complex "sandwiched" between the two antibodies, resulting in the accumulation of colored nanoparticles at the test line. The signal intensity is directly proportional to the antigen concentration, making the results intuitively interpretable—a visible test line indicates a positive result. [21] This format is ideal for larger protein allergens like wheat gliadin, which possesses multiple antibody-binding sites. [20]

Competitive Assay Format

Competitive assays are primarily employed for the detection of small molecules or single-epitope antigens that cannot accommodate two simultaneous antibodies. [21] This format operates on the principle of competition between the target analyte in the sample and a labeled competitor (antigen or analog) for a limited number of antibody binding sites. In the direct competitive format, the sample analyte competes with a labeled competitor for binding to antibodies immobilized at the test line. [21] Consequently, the signal intensity at the test line is inversely proportional to the analyte concentration—higher analyte concentrations lead to fainter test lines. [21] This counterintuitive signal response ("absence of line indicates positive") can present interpretation challenges but is necessary for detecting small allergenic peptides or hydrolyzed proteins. [21]

Decision Framework for Format Selection

The choice between sandwich and competitive formats should be guided by the molecular characteristics of the target allergen and the specific application requirements. The following table outlines the key selection criteria:

| Parameter | Sandwich Assay | Competitive Assay |

|---|---|---|

| Target Size | Larger proteins (>5 kDa) with multiple epitopes (e.g., native gliadin) [21] | Small molecules or single-epitope targets (e.g., hydrolyzed peptides, pesticide residues) [21] |

| Signal Response | Directly proportional to analyte concentration [21] | Inversely proportional to analyte concentration [21] |

| Result Interpretation | Intuitive (line presence = positive) [21] | Counterintuitive (line absence = positive); requires user training [21] |

| Key Advantage | High specificity and sensitivity; robust signal [20] [21] | Insensitive to the "hook effect"; requires only one antibody type [21] |

| Primary Limitation | Requires two distinct, non-interfering epitopes [22] | Lower absolute signal; more complex optimization [21] |

Performance Comparison and Quantitative Data

The performance characteristics of sandwich and competitive assays differ significantly in sensitivity, dynamic range, and applicability. Research on wheat allergen detection provides concrete examples of these differences.

Performance Metrics for Allergen Detection

The following table summarizes published performance data for both assay formats in food allergen analysis:

| Assay Format | Target Allergen | Detection Platform | Limit of Detection (LOD) | Dynamic Range | Reference |

|---|---|---|---|---|---|

| Sandwich | Wheat Gliadin (in milk) | AuNP-LFIA | Visual LOD: 25 ng/mLCalculated LOD: 6.56 ng/mL | Not specified | [20] |

| Sandwich | α-Lactalbumin (in formula) | Biotin-Streptavidin ELISA | LOD: 1.59 ng/mL | 61.04 ng/mL – 62.50 μg/mL | [23] |

| Competitive | Gluten (in raw materials) | AuNP-LFIA | Visual LOD: 20 ppm (∼20 μg/mL) | Not specified | [3] |

| Sandwich | Gluten | Commercial LFIA Kits (e.g., AgraStrip) | LOD: < 10 ppm (∼10 μg/mL) | Not specified | [3] |

The data demonstrates that sandwich assays generally achieve higher sensitivity (lower LOD) compared to competitive formats for allergen detection. The exceptional sensitivity of the α-lactalbumin sandwich ELISA can be attributed to the biotin-streptavidin amplification system, which significantly enhances the detection signal. [23] Furthermore, sandwich assays can exhibit an extensive dynamic range spanning several orders of magnitude, as evidenced by the three-log range achieved in the α-lactalbumin assay. [23]

Competitive assays, while potentially less sensitive, are perfectly suited for applications with defined threshold limits. For instance, the developed competitive LFIA for gluten meets the Codex Alimentarius standard of 20 ppm for gluten-free foods, providing a rapid, binary result suitable for on-site testing. [3] A key theoretical advantage of competitive assays is their immunity to the "hook effect", a phenomenon in sandwich assays where extremely high antigen concentrations saturate both capture and detection antibodies, leading to a false-negative signal. [21]

Detailed Experimental Protocols

Protocol: Sandwich LFIA for Wheat Gliadin Detection

This protocol is adapted from the work of Hu et al. for the rapid and on-site detection of wheat allergen in milk. [20]

Research Reagent Solutions

| Reagent/Material | Function/Description | Example/Specification |

|---|---|---|

| Anti-Gliadin mAb Pair | Capture (mAb 7) & Detection (mAb 6) antibodies for sandwich formation. [20] | Must recognize distinct, non-overlapping epitopes on gliadin. |

| Colloidal Gold Nanoparticles (AuNPs) | Visual reporter label for detection. [20] [3] | ~20 nm diameter, synthesized by citrate reduction. |

| Nitrate Cellulose Membrane | Porous matrix for capillary flow and antibody immobilization. | Pore size optimized for flow rate and binding capacity. |

| Sample Pad & Absorbent Pad | Sample application and fluid wicking. | Cellulose or glass fiber. |

| Conjugation Buffer | pH optimization for antibody-AuNP conjugation. [3] | Typically 20 mM Borax buffer, pH 8-9. |

| Blocking Buffer | Prevents non-specific binding on the membrane. | Phosphate buffer with 3-5% w/v BSA or sucrose. |

| Running Buffer | Facilitates sample flow and interaction. | PBS with 0.05% Tween-20 and protein stabilizers. |

Step-by-Step Procedure

AuNP-Antibody Conjugate Preparation:

- Synthesize ~20 nm colloidal gold nanoparticles using the citrate reduction method. [3] Characterize by UV-Vis spectroscopy (peak at ~523 nm) and FESEM. [3]

- Adjust the pH of the AuNP solution to 8.0 using 0.1 M K₂CO₃. This is critical for stabilizing the AuNP-antibody interaction. [3]

- Add the detection antibody (e.g., mAb 6) to the pH-adjusted AuNP solution at an optimized concentration (e.g., 1-10 μg/mL). Incubate for 1 hour at room temperature with gentle agitation. [20] [3]

- Block remaining active sites on the AuNPs with a stabilizing agent (e.g., BSA). Purify the conjugate by centrifugation and resuspend in a storage buffer containing sucrose. Dispense onto the conjugate pad and dry.

Strip Assembly:

- Test and Control Line Printing: Dispense the capture antibody (e.g., mAb 7) at a concentration of 1 mg/mL onto the nitrocellulose membrane to form the test line. Dispense a species-specific anti-immunoglobulin antibody to form the control line. Dry the membrane completely. [20]

- Membrane Stacking: Assemble the strip by sequentially overlapping the sample pad, conjugate pad (containing the dried AuNP-antibody conjugate), nitrocellulose membrane (with printed test and control lines), and absorbent pad on a backing card. [20]

Assay Execution:

Result Interpretation

- Positive Result: Both the test line and control line are visible. The intensity of the test line correlates with the gliadin concentration.

- Negative Result: Only the control line is visible.

- Invalid Result: The control line does not appear, indicating a faulty strip or incorrect procedure.

Protocol: Competitive LFIA for Small Allergens

This protocol outlines the development of a competitive LFIA, suitable for small allergenic peptides or molecules where a sandwich format is not feasible. [21]

Key Reagent Solutions

| Reagent/Material | Function/Description | Example/Specification |

|---|---|---|

| Anti-Allergen mAb | Single monoclonal antibody for target recognition. | High affinity and specificity for the target small molecule. |

| Analyte-Protein Conjugate | Competitor molecule immobilized on the test line. | Target analyte conjugated to a carrier protein (e.g., BSA, OVA). |

| Colloidal Gold Nanoparticles (AuNPs) | Visual reporter label. | ~20 nm diameter. |

| Secondary Antibody | For the control line. | e.g., Goat anti-mouse IgG, if mAb is mouse-derived. |

Step-by-Step Procedure

Conjugate Pad Preparation:

Strip Assembly:

- Test Line Printing: Immobilize the analyte-protein conjugate (the competitor) on the nitrocellulose membrane to form the test line. The concentration must be carefully optimized to achieve the desired sensitivity. [21]

- Control Line Printing: Immobilize a secondary antibody (e.g., anti-species IgG) to capture the free AuNP-labeled mAb, forming the control line.

- Assemble the strip components as described in the sandwich protocol.

Assay Execution:

- Apply the liquid sample to the sample pad. The target analyte in the sample and the immobilized competitor on the test line will compete for the limited binding sites on the AuNP-labeled mAb as they migrate. [21]

- Allow the strip to develop for the prescribed time (e.g., 15 minutes).

Result Interpretation

- Positive Result (Analyte present): The test line is faint or absent because the labeled antibody is bound to the sample analyte and cannot bind to the test line competitor. The control line must be visible.

- Negative Result (Analyte absent): Both the test line and control line are visible because the labeled antibody binds to the immobilized competitor on the test line.

- Invalid Result: The control line does not appear.

The selection between sandwich and competitive assay formats is a foundational decision in the development of a gold nanoparticle-based LFIA for wheat allergen research. For intact gliadin and other large protein allergens, the sandwich format offers superior sensitivity, an intuitive readout, and robust performance, as demonstrated by its successful application in detecting gliadin in milk with a LOD as low as 6.56 ng/mL. [20] Conversely, for small allergenic peptides, hydrolyzed proteins, or other single-epitope targets, the competitive format is indispensable, despite its counterintuitive signal interpretation and often lower sensitivity. [21] Mastery of both formats, including their underlying principles, optimization parameters, and limitations, empowers researchers to create highly effective diagnostic tools that enhance food safety and protect consumers with food allergies.

A Step-by-Step Protocol for Developing a Wheat Allergen LFIA

Synthesis and Characterization of Colloidal Gold Nanoparticles (20-40 nm)

Gold nanoparticles (AuNPs) in the 20-40 nm size range represent a critical material class for developing advanced diagnostic platforms due to their strong optical properties and biocompatibility. Within the context of wheat allergen research, specifically targeting gliadin, these AuNPs serve as exceptional signal transducers in lateral flow immunoassays (LFIAs). Their size-dependent optical cross-section provides the high sensitivity required for detecting trace allergens at concentrations mandated by food safety regulations, such as the Codex Alimentarius standard of 20 parts per million (ppm) for gluten-free products [2] [3]. This protocol details the synthesis, functionalization, and characterization of 20-40 nm AuNPs, framing them as essential components for constructing a robust LFIA for gliadin detection.

Synthesis of Monodisperse 40 nm Gold Nanoparticles

Seed-Mediated Growth Method

Seed-mediated growth is the preferred method for producing monodisperse 40 nm AuNPs with a narrow size distribution, offering superior control over final particle size [24] [25].

Experimental Protocol:

Seed Solution Preparation:

- Prepare a 20 mL aqueous solution containing 0.25 mM hydrogen tetrachloroaurate (HAuCl₄) and 0.25 mM trisodium citrate in a clean, glass vial.

- Under vigorous stirring, rapidly add 0.3 mL of a fresh, ice-cold 10 mM sodium borohydride (NaBH₄) solution.

- Continue stirring for 5 minutes. The solution will turn pale pink/orange, indicating the formation of 2-5 nm gold seeds. This seed solution can be stored for several hours at room temperature.

Growth Solution Preparation:

- In a round-bottom flask, add 40 mL of a 0.2 mM HAuCl₄ solution.

- Add 0.2 mL of 1.0 M hydrochloric acid (HCl) to adjust the pH.

- Introduce 0.04 mL of a 10% (w/v) solution of Tannic Acid and 0.24 mL of a 12.5 mM solution of Potassium Carbonate (K₂CO₃).

Particle Growth:

- Under constant stirring, add 0.08 mL of the previously synthesized seed solution to the growth solution.

- Allow the reaction to proceed at a controlled temperature of 25-30°C until the solution color stabilizes to a deep red (approximately 15-30 minutes).

- The growth can be halted by cooling the solution on ice.

Optimized Citrate Reduction Method

A modified Turkevich method can be tuned to reliably generate AuNPs in the 15-40 nm range [24].

Experimental Protocol:

Reaction Setup:

- Bring 50 mL of a 0.5 mM HAuCl₄ solution to a boil under vigorous stirring and reflux conditions.

- Rapidly add 1.0 mL of a 1% (w/v) trisodium citrate solution to the boiling gold salt solution.

- The solution will change color from pale yellow to deep red over several minutes.

Heating and Cooling:

- Continue boiling and stirring for 15 minutes to ensure complete reduction and Ostwald ripening for size focusing.

- Remove the heating mantle and allow the solution to cool to room temperature while stirring continues.

- To achieve the target 40 nm size, the citrate-to-gold ratio, temperature, and addition rate must be meticulously optimized for the specific setup [24].

Table 1: Comparison of Synthesis Methods for 40 nm AuNPs

| Parameter | Seed-Mediated Growth | Citrate Reduction (Optimized) |

|---|---|---|

| Mechanism | Two-step process: nucleation followed by controlled growth | Single-step, thermally-driven co-reduction |

| Size Control | Excellent; precise control via seed number and growth time | Good; achieved by tuning citrate:gold ratio and temperature |

| Size Dispersity | Narrow (PDI < 0.2 achievable) | Moderate to narrow |

| Typical Size Range | 10 - 100 nm | 15 - 40 nm |

| Primary Capping Agent | Variable (often citrate) | Citrate |

| Reproducibility | High with careful control | High with parameter standardization |

Characterization of Gold Nanoparticles

Rigorous characterization is critical to ensure batch-to-batch consistency and predictable performance in the LFIA. ASTM International standard E3269 provides guidelines for characterizing colloidal gold suspensions [26].

Experimental Protocols and Quantitative Data:

UV-Vis Spectroscopy:

- Protocol: Dilute the AuNP colloid appropriately with deionized water and measure the absorbance from 400 to 700 nm.

- Expected Data: A sharp Localized Surface Plasmon Resonance (LSPR) peak is characteristic of monodisperse, spherical particles. For 20 nm AuNPs, the peak is at ~523 nm [3], shifting to ~528 nm for 40 nm AuNPs [24]. The Full Width at Half Maximum (FWHM) of the peak indicates size dispersity.

Dynamic Light Scattering (DLS) and Zeta Potential:

- Protocol: Measure the hydrodynamic diameter and polydispersity index (PDI) of the AuNPs in their storage buffer. For zeta potential, dilute the sample in a low-ionic-strength solution.

- Expected Data: Citrate-capped 20 nm AuNPs have a hydrodynamic diameter of ~23 nm and a PDI of 0.1, indicating high monodispersity [3]. A zeta potential more negative than -30 mV indicates good colloidal stability.

Transmission Electron Microscopy (TEM):

- Protocol: Deposit a drop of diluted AuNP solution onto a carbon-coated copper grid, allow to settle, and wick away excess liquid. Image under appropriate acceleration voltage.

- Expected Data: TEM provides the core diameter and confirms spherical morphology. It is the gold standard for validating size measurements from DLS and UV-Vis.

Table 2: Characterization Parameters for 20 nm and 40 nm AuNPs

| Characterization Technique | Key Parameter | 20 nm AuNPs (Target) | 40 nm AuNPs (Target) |

|---|---|---|---|

| UV-Vis Spectroscopy | LSPR Peak (λmax) | 522 - 525 nm [3] | 527 - 531 nm [24] |

| FWHM | < 50 nm | < 60 nm | |

| Dynamic Light Scattering | Hydrodynamic Diameter | 22 - 25 nm [3] | 42 - 47 nm |

| Polydispersity Index (PDI) | < 0.2 [3] | < 0.2 [24] | |

| Zeta Potential | Surface Charge (in water) | < -35 mV [3] | < -35 mV |

| Transmission Electron Microscopy | Core Diameter | 20 ± 2 nm | 40 ± 3 nm |

The following workflow outlines the integrated process from synthesis to application in LFIA strip development:

Figure 1: Workflow for AuNP Synthesis and LFIA Integration.

Application in Lateral Flow Immunoassay for Wheat Allergen

The primary application within this thesis context is the development of a rapid, on-site LFIA for detecting wheat gliadin in food samples.

Conjugation of Anti-Gliadin Antibodies to 20 nm AuNPs

For LFIA, 20 nm AuNPs are often preferred due to their higher diffusion coefficients and efficient conjugation kinetics [3].

Experimental Protocol:

pH Optimization:

- Adjust the pH of the 20 nm AuNP solution to 8.0 using 0.1 M potassium carbonate (K₂CO₃). This is critical as it ensures the nanoparticle surface is optimally charged for electrostatic adsorption of antibodies without causing aggregation [3].

Antibody Conjugation:

Stabilization and Blocking:

- Add an aqueous solution of bovine serum albumin (BSA) to a final concentration of 1% (w/v) to block any remaining bare gold surface.

- Stir for an additional 30 minutes.

Purification:

- Centrifuge the conjugated AuNPs at 12,000 rpm for 20 minutes at 4°C to remove unbound antibodies and BSA.

- Carefully decant the supernatant and resuspend the red pellet in a storage buffer containing 10 mM Tris-HCl, 1% BSA, and 0.1% sodium azide, pH 8.0.

Quality Control:

- Characterize the conjugated AuNPs by UV-Vis. A successful conjugation is indicated by a red-shift of the LSPR peak from 523 nm to 526-529 nm and an increase in absorbance intensity [3].

LFIA Strip Assembly and Function

The assembled strip operates on a sandwich immunoassay principle.

Experimental Protocol:

Strip Configuration:

- Sample Pad: Pre-treat the cellulose sample pad with buffers to adjust sample pH and filter particulates.

- Conjugate Pad: Saturate the glass fiber conjugate pad with the purified anti-gliadin-AuNP conjugates and dry.

- Nitrocellulose Membrane: Dispense two lines:

- Test Line: Immobilize a second, capture anti-gliadin monoclonal antibody (e.g., mAb 7 [2]).

- Control Line: Immobilize a secondary antibody specific to the host species of the detection antibody.

- Absorbent Pad: Place at the distal end to wick the solution and maintain flow.

Assay Procedure:

- Apply 40 µL of the extracted food sample to the sample pad [2].

- Add running buffer to initiate the flow.

- The sample rehydrates the AuNP-antibody conjugates. If gliadin is present, it binds to the AuNP-antibody.

- The complex migrates and is captured at the test line by the immobilized antibody, forming a sandwich (AuNP-antibody-gliadin-antibody), resulting in a visible red line.

- The excess AuNP-antibody conjugates are captured at the control line, validating the test.

Table 3: Performance Metrics of Gliadin LFIA Using AuNPs

| Performance Metric | Value | Methodology / Note |

|---|---|---|

| Visual Limit of Detection (vLOD) | 25 ng/mL (in negative milk) [2] | Qualitative visual assessment |

| Calculated LOD | 6.56 ng/mL (in negative milk) [2] | Quantitative analysis of test line intensity |

| Detection Limit (Commercial Target) | 20 ppm (Codex standard) [3] | Corresponds to 20 µg/g of gluten |

| Assay Time | 15 minutes [2] [3] | From sample application to result |

| Assay Type | Sandwich Immunoassay | Utilizes two distinct monoclonal antibodies |

The following diagram illustrates the molecular detection mechanism on the LFIA strip:

Figure 2: LFIA Molecular Detection Mechanism.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for AuNP Synthesis and LFIA Development

| Reagent / Material | Function | Application Notes |

|---|---|---|

| Hydrogen Tetrachloroaurate (HAuCl₄) | Gold precursor for nanoparticle synthesis | Use high-purity grade; aqueous solution stability is limited, store as recommended. |

| Trisodium Citrate | Reducing and capping agent | Concentration and addition rate critically control final particle size in citrate synthesis. |

| Anti-Gliadin Monoclonal Antibodies | Specific recognition element for the target allergen | A matched pair (capture & detection) is required for a sandwich assay [2]. |

| Nitrocellulose Membrane | Porous matrix for antibody immobilization and fluid flow | Pore size and flow rate must be optimized for the specific assay. |

| Thiol-Polyethylene Glycol (SH-PEG) | AuNP surface passivation | Improves colloidal stability and reduces non-specific binding in complex matrices [24]. |

| Bovine Serum Albumin (BSA) | Blocking agent | Used to block residual binding sites on AuNPs and the membrane, minimizing background noise. |

| Lateral Flow Strip Components | Platform for the assay | Includes sample, conjugate, and absorbent pads. Assembly must ensure consistent capillary flow. |

Selection and Epitope Mapping of Anti-Gliadin Monoclonal Antibodies

Within the context of wheat allergen research, the selection and precise epitope mapping of anti-gliadin monoclonal antibodies (mAbs) constitute a critical foundational step. This process is paramount for developing robust and reliable detection assays, particularly gold nanoparticle (AuNP)-based lateral flow immunoassays (LFIAs). Gliadin, a primary immunotoxic component of gluten, is characterized by a complex protein structure rich in proline and glutamine, which complicates the development of antibodies with broad reactivity to its diverse epitopes [27] [3]. The identification of mAbs that specifically target clinically relevant, stable epitopes, such as the 33-mer peptide, ensures that diagnostic assays can accurately detect the pathogenic components of gluten that trigger conditions like celiac disease [27] [28]. This document provides detailed application notes and protocols for the selection and epitope characterization of anti-gliadin mAbs, framed specifically for their application in AuNP-LFIA development for wheat allergen detection.

Antibody Selection and Characterization

The generation of high-affinity, specific mAbs begins with careful immunogen design and a rigorous, multi-stage screening process to isolate lead candidates with the desired characteristics for LFIA development.

Immunogen Preparation and Animal Immunization

The goal is to elicit an antibody response against multiple pathogenic epitopes simultaneously. The 33-mer gliadin peptide, which contains several immunodominant epitopes (including DQ2.5-glia-α1a, DQ2.5-glia-α2, and DQ2.5-glia-α1b), serves as an ideal immunogen for this purpose [27].

- Procedure:

- Antigen Complex Formation: Recombinantly express and purify the HLA-DQ2.5 molecule. Complex it with the 33-mer gliadin peptide to form a peptide:HLA-DQ2.5 (pHLA-DQ2.5) immunogen. This structure can help focus the immune response on the native conformation of the epitopes [27].

- Animal Immunization: Immunize New Zealand White (NZW) rabbits with the recombinant HLA-DQ2.5:33mer gliadin complex. Use a standard immunization protocol involving primary immunization with Freund's Complete Adjuvant, followed by booster injections with Freund's Incomplete Adjuvant [27] [2].

- B Cell Isolation: Following immunization, harvest splenocytes or peripheral blood B cells from the immunized animals for hybridoma generation [27].

Primary Screening and Cross-Reactivity Analysis

The initial screening aims to identify a large pool of mAb candidates that bind the immunogen, followed by a critical cross-reactivity assessment to narrow down the leads.

- Materials:

- Ba/F3 cell panels expressing a variety of pHLA-DQ2.5 complexes (including at least 29 distinct gluten epitopes) [27].

- Cell lines expressing other HLA-II molecules (e.g., HLA-DR, HLA-DQ variants) to test for off-target binding [27].

- Primary human B cells from HLA-DQ2.5-positive and negative donors [27].

Procedure:

- High-Throughput Screening: Screen over 40,000 antibody supernatants from B cell cultures for binding to the immunogen (HLA-DQ2.5:33mer) using flow cytometry or ELISA [27].

- Cross-Reactivity Profiling: Test the positive hits for binding to the extensive panel of Ba/F3 cells expressing distinct gluten pHLA-DQ2.5. The ideal lead antibody should demonstrate broad reactivity to numerous pathogenic gluten epitopes while showing minimal binding to non-gluten pHLA-DQ2.5 (e.g., those loaded with human CLIP, HBV, salmonella, or TPO peptides) [27].

- Specificity Confirmation: Validate the specificity of lead antibodies using primary human B cells. The antibody should only bind to HLA-DQ2.5+ B cells when the 33mer gliadin peptide is exogenously loaded, confirming that it does not recognize endogenous peptide complexes [27].

Representative Data: The following table summarizes the idealized binding profile of a broadly reactive, lead anti-gliadin mAb, as exemplified by antibodies like DONQ52 [27]:

Table 1: Example Broadly Reactive Anti-Gliadin mAb Binding Profile

| Target Category | Specific Target Examples | Observed Binding |

|---|---|---|

| Pathogenic Gluten pHLA-DQ2.5 | DQ2.5-glia-α1a, -α2, -ω1, -ω2; DQ2.5-hor-3a; >25 distinct epitopes | Positive [27] |

| Non-Gluten pHLA-DQ2.5 | Human CLIP, Hepatitis B Virus, Salmonella, Mycobacterium bovis, Thyroid Peroxidase | No substantial binding [27] |

| Other HLA-II Molecules | HLA-DR, other HLA-DQ alleles | No substantial binding [27] |

Antibody Engineering for Enhanced Function

Lead mAbs from animal immunization may require protein engineering to improve their function and suitability as therapeutics or diagnostic reagents.

- Procedure:

- Humanization: Humanize the variable regions of the lead rabbit mAbs to reduce immunogenicity for potential clinical applications [27].

- Affinity Maturation: Employ techniques such as site-directed mutagenesis or phage display to generate and screen mutant libraries for variants with enhanced affinity and cross-reactivity [27].

- Formatting for LFIA: For LFIA development, the variable regions of a pair of complementary mAbs can be formatted into a bi-specific IgG. This involves engineering the interface residues of the heavy and light chains to ensure correct pairing. Furthermore, the Fc region can be engineered to reduce binding to Fc gamma receptors and complement C1q, thereby eliminating effector functions that are unnecessary for diagnostics [27].

Epitope Mapping and Structural Analysis

Understanding the precise region on the gliadin peptide that an antibody recognizes (its epitope) is crucial for explaining its cross-reactivity profile and diagnostic utility.

Defining the Core Epitope

A primary goal is to identify the minimal peptide sequence required for antibody binding.

- Materials:

- A series of synthetic gliadin peptides with systematic N- and C-terminal truncations.

- Peptides with single-point alanine (or other amino acid) substitutions.

- Platform for binding analysis (e.g., ELISA, surface plasmon resonance).

- Procedure:

- Truncation Analysis: Test antibody binding against the series of truncated peptides. The shortest peptide that retains full binding capacity defines the core epitope region.

- Alaninine Scanning Mutagenesis: Within the core epitope, systematically replace each residue with alanine and test antibody binding. A significant loss of binding upon substitution of a specific residue identifies it as a critical "hot spot" for the antibody-antigen interaction [27].

- Key Epitope Motif Identification: For gliadin, the proline-rich and glutamine-rich motif (e.g., PQPQLPY) is often the critical pathogenic sequence targeted by mAbs. The G12 antibody, for instance, specifically targets the sequence PQPQLPY, a highly immunotoxic epitope in celiac disease [3].

Structural Characterization of the Antibody-Antigen Complex

For a mechanistic understanding of broad reactivity, structural biology techniques are employed.

- Procedure: