FDA MDVIP Method Validation: A Complete Guide for Food and Drug Research Scientists

This guide provides researchers, scientists, and drug development professionals with a comprehensive overview of the FDA Foods Program's Method Development, Validation, and Implementation Program (MDVIP).

FDA MDVIP Method Validation: A Complete Guide for Food and Drug Research Scientists

Abstract

This guide provides researchers, scientists, and drug development professionals with a comprehensive overview of the FDA Foods Program's Method Development, Validation, and Implementation Program (MDVIP). It covers the foundational principles of method validation, detailed application procedures for chemical and microbiological techniques, troubleshooting for compliance, and comparative analysis of validation levels. The article synthesizes current FDA guidelines, compendia of validated methods, and future regulatory directions to equip professionals with the knowledge to develop, implement, and optimize analytical methods that meet stringent FDA standards for food and feed safety.

Understanding the FDA MDVIP: Foundations for Robust Analytical Method Development

The Method Development, Validation, and Implementation Program (MDVIP) is the U.S. Food and Drug Administration's standardized framework for ensuring the scientific integrity and regulatory reliability of analytical methods used across its Foods Program [1]. Established under the former Office of Foods and Veterinary Medicine (OFVM) and now managed by the FDA Foods Program Regulatory Science Steering Committee (RSSC), the MDVIP represents a coordinated effort to maintain the highest standards in food safety testing [1]. The program brings together experts from FDA's Center for Food Safety and Applied Nutrition (CFSAN), Office of Regulatory Affairs (ORA), Center for Veterinary Medicine (CVM), and National Center for Toxicological Research (NCTR) to oversee all aspects of analytical method lifecycle management [1].

The primary mission of MDVIP is to ensure that FDA regulatory laboratories use properly validated methods for analyzing food products, with a strong preference for methods that have undergone multi-laboratory validation (MLV) where feasible [1]. This commitment to rigorous validation supports the FDA's broader public health mission to protect consumers from foodborne hazards, chemical contaminants, and other food safety risks through science-based regulatory decisions. The program operates under clearly defined governance structures with separate coordination for chemistry and microbiology disciplines through Research Coordination Groups (RCGs) and Method Validation Subcommittees (MVS) [1]. The RCGs provide overall leadership and coordinate guideline development, while MVSs are responsible for approving validation plans and evaluating results [1].

MDVIP Organizational Structure and Workflow

The MDVIP operates through a well-defined organizational structure that separates oversight responsibilities while maintaining coordination between disciplines. The program's workflow ensures that methods progress systematically from development through implementation, with appropriate validation checkpoints at each stage.

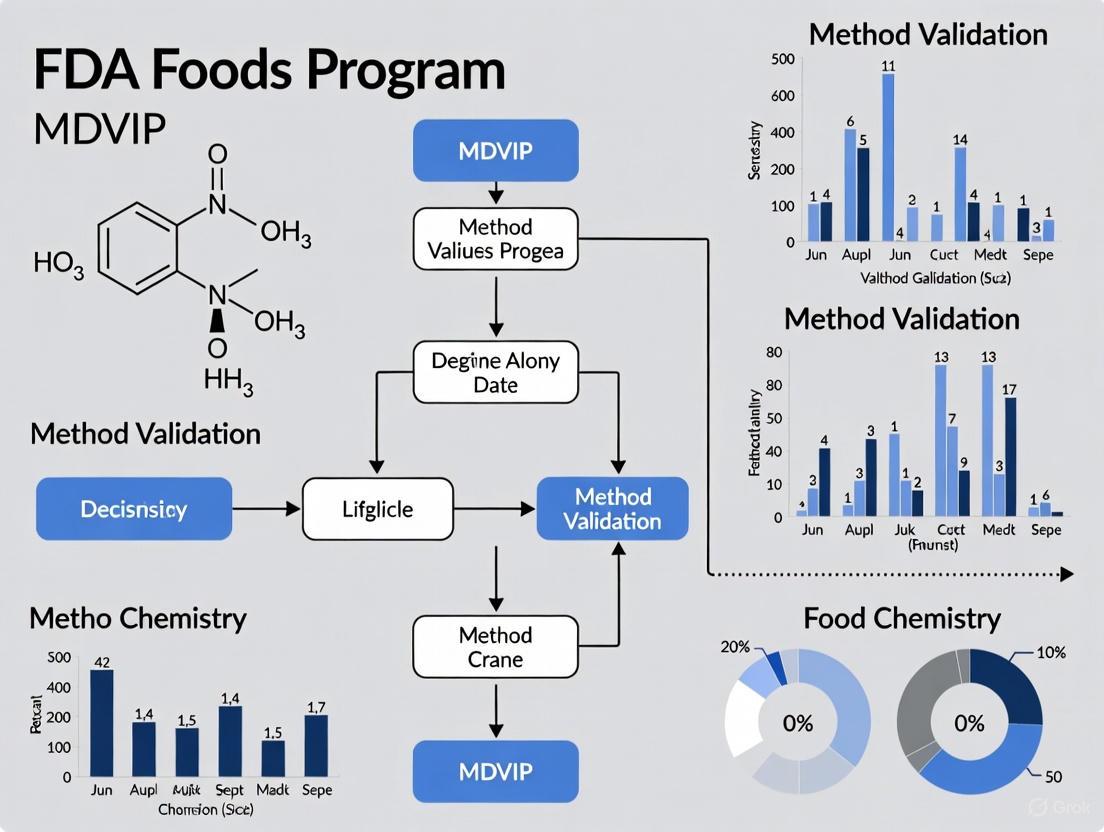

Figure: MDVIP Governance and Method Progression Workflow

The organizational structure begins with the Regulatory Science Steering Committee (RSSC) providing overall program oversight [1]. Below this central committee, two specialized groups manage the technical workflow: the Research Coordination Groups (RCGs) that provide leadership and coordinate guideline development, and Method Validation Subcommittees (MVS) that approve validation plans and evaluate results [1]. This structure ensures specialized oversight for chemistry, microbiology, and DNA-based methods while maintaining consistent standards across disciplines.

The method progression workflow moves through four distinct phases: method development, validation, implementation, and finally inclusion in the official Foods Program Compendium of Analytical Laboratory Methods [2]. At each stage, methods must meet specific criteria established in the MDVIP validation guidelines before advancing. This systematic approach ensures that only properly validated methods with defined validation statuses are used in FDA regulatory laboratories for food safety testing and enforcement actions [1] [2].

Method Validation Guidelines and Criteria

Validation Tiers and Acceptance Criteria

The MDVIP has established comprehensive validation guidelines that define specific criteria for different types of analytical methods and validation levels. These guidelines provide the technical framework for evaluating method performance characteristics and determining whether methods meet FDA standards for regulatory use.

Table: MDVIP Method Validation Levels and Criteria

| Validation Level | Description | Typical Use Cases | Posting Duration in Compendium |

|---|---|---|---|

| Level 1: Emergency Use | Limited validation for urgent public health needs | Response to emerging contaminants or outbreak investigations | 1 year [2] |

| Level 2: Single Laboratory Validation | Full validation within one laboratory | Method development and initial validation | Up to 2 years [2] |

| Level 3: Single Lab + Independent Lab | SLV plus verification by an independent laboratory | Higher-stakes applications requiring verification | Varies by discipline |

| Level 4: Multi-Laboratory Validation (MLV) | Full collaborative study across multiple laboratories (e.g., 10 labs) | Gold standard for regulatory methods | Indefinitely for chemical methods [2] |

The MDVIP guidelines establish tiered validation levels that reflect the extent of validation testing and the appropriate regulatory applications for each level [2]. For chemical methods, the program has developed specific acceptance criteria for confirmation of identity using exact mass data, reflecting the sophisticated instrumentation used in modern food safety laboratories [1]. The validation guidelines address fundamental performance characteristics including specificity, accuracy, precision, limit of detection, limit of quantitation, linearity, and robustness, with specific acceptance criteria tailored to different analytical techniques and food matrices.

For microbiological methods, the MDVIP validation levels follow a similar tiered approach but with specific adaptations for biological methods [2]. Level 1 represents emergency use methods, Level 2 includes single laboratory validation, Level 3 adds independent laboratory verification, and Level 4 represents full multi-laboratory validation studies [2]. The majority of microbiological methods included in the official compendium have achieved Level 4 (MLV) status, reflecting the program's emphasis on robust validation for foodborne pathogen detection [2].

Compendium Integration and Method Lifecycle

Successfully validated methods are incorporated into the FDA Foods Program Compendium of Analytical Laboratory Methods, which serves as the official repository of validated methods for FDA regulatory laboratories [2]. The Compendium is divided into chemical methods documented in the Chemical Analytical Manual (CAM) and microbiological methods primarily found in the Bacteriological Analytical Manual (BAM) [2].

The posting duration for methods in the CAM varies according to their validation status, creating a systematic approach to method lifecycle management [2]. Methods with full multi-laboratory validation status are posted indefinitely, while methods with single-laboratory validation are posted for up to two years [2]. Methods developed for emergency needs with limited validation are posted for one year, and older methods judged to have validation status equivalent to MLV are posted for three-year renewable terms [2]. This tiered posting system ensures that methods undergo periodic re-evaluation while providing regulatory laboratories with access to both established and emerging methodologies.

Experimental Protocols and Methodologies

Representative Chemical Method Protocol

Method C-010.03: Determination of 30 Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) in Food Using LC-MS/MS

This method exemplifies the sophisticated analytical approaches developed under MDVIP oversight for chemical contaminant analysis [2]. The protocol employs liquid chromatography-tandem mass spectrometry (LC-MS/MS) to detect and quantify 30 different PFAS compounds in various food matrices.

Sample Preparation Workflow:

- Homogenization: Food samples are thoroughly homogenized to ensure representative sub-sampling

- Extraction: PFAS compounds are extracted using organic solvents (typically acetonitrile) with mechanical shaking

- Cleanup: Solid-phase extraction (SPE) using specific sorbents to remove matrix interferences

- Concentration: Extracts are concentrated under gentle nitrogen stream

- Reconstitution: Samples are reconstituted in injection solvent compatible with LC-MS/MS analysis

Instrumental Analysis Parameters:

- Chromatography: Reverse-phase LC separation using C18 column with methanol-water or acetonitrile-water gradient

- Mass Spectrometry: Triple quadrupole MS/MS operating in multiple reaction monitoring (MRM) mode

- Quantification: Isotope dilution method using stable isotopically labeled internal standards for each analyte

Validation Data Requirements:

- Linearity: Minimum R² > 0.995 across calibrated range

- Accuracy: 70-120% recovery for most analytes

- Precision: Relative standard deviation < 20% for replicates

- Limit of Quantification: Substance-specific based on signal-to-noise ratio > 10:1

Representative Microbiological Method Protocol

Molecular Detection of Cyclospora cayetanensis in Fresh Produce Using Real-Time PCR

This method demonstrates the application of molecular biology techniques for pathogen detection, validated at MDVIP Level 4 (multi-laboratory validation) [2].

Sample Processing Workflow:

- Elution: Produce samples (typically 25g) are immersed in elution buffer with mechanical agitation

- Concentration: Centrifugation or filtration to concentrate oocysts

- DNA Extraction: Commercial DNA extraction kits with mechanical disruption (bead beating)

- Purification: Additional cleanup steps to remove PCR inhibitors common in produce matrices

Molecular Detection Parameters:

- Amplification: Real-time PCR targeting specific Cyclospora DNA sequences

- Controls: Internal amplification control to detect inhibition, positive and negative controls

- Cycling Conditions: Optimized annealing temperature and cycle number for sensitivity/specificity balance

- Analysis: Threshold cycle (Ct) determination with validated cutoff values

Validation Performance Characteristics:

- Specificity: No cross-reactivity with other common foodborne parasites

- Sensitivity: Detection limit established through inclusivity testing

- Robustness: Consistent performance across different produce types (leafy greens, berries, herbs)

- Reproducibility: Interlaboratory concordance > 90% in multi-laboratory study

Essential Research Reagent Solutions

The implementation of MDVIP-validated methods requires specific research reagents and reference materials that meet strict quality standards. These essential materials form the foundation for reliable and reproducible analytical results in food safety testing.

Table: Essential Research Reagents for MDVIP-Validated Methods

| Reagent Category | Specific Examples | Function and Technical Specifications |

|---|---|---|

| Certified Reference Standards | Stable isotopically labeled internal standards (e.g., ¹³C-labeled PFAS, chloramphenicol-d5) | Quantification via isotope dilution mass spectrometry; purity >98% [2] |

| Molecular Biology Reagents | PCR master mixes, DNA extraction kits, oligonucleotide primers/probes | Pathogen detection via real-time PCR; minimal inhibition, high sensitivity [2] |

| Chromatography Supplies | LC-MS/MS columns (C18, HILIC), guard columns, mobile phase additives | Separation of analytes from matrix interferences; stable retention times [2] |

| Sample Preparation Materials | Solid-phase extraction cartridges, QuEChERS kits, filtration devices | Matrix cleanup and analyte concentration; high recovery rates [2] |

| Quality Control Materials | Certified reference materials, in-house quality control samples | Method verification and continuous quality assurance [2] |

| Microbiological Media | Selective agars, enrichment broths, chromogenic substrates | Pathogen isolation and identification; specificity and sensitivity validation [2] |

Analytical Instrumentation Platforms

The execution of MDVIP-validated methods requires sophisticated instrumentation platforms capable of delivering the sensitivity, specificity, and reproducibility demanded for regulatory analysis. The following instrumentation represents the core technological infrastructure supporting modern food safety testing.

Figure: Analytical Instrumentation Workflow in Food Safety Testing

The instrumentation workflow begins with sample preparation, then branches into three main analytical pathways: chemical analysis, microbiological analysis, and elemental analysis [2]. Liquid chromatography-tandem mass spectrometry (LC-MS/MS) serves as the workhorse for chemical contaminant analysis, providing the sensitivity and selectivity required for monitoring pesticides, pharmaceuticals, mycotoxins, and industrial chemicals in complex food matrices [2]. Inductively coupled plasma-mass spectrometry (ICP-MS) delivers exceptional sensitivity for elemental analysis, capable of detecting toxic and nutrient elements at parts-per-billion levels [2]. For microbiological analysis, real-time PCR systems enable rapid detection and identification of foodborne pathogens with high specificity, while traditional culture methods remain important for confirmation and isolation [2]. All instrumentation must undergo rigorous qualification and ongoing performance verification to ensure the reliability of analytical data supporting regulatory decisions.

The Method Development, Validation, and Implementation Program represents the FDA's comprehensive, science-based approach to ensuring the analytical methods used to protect the food supply are technically sound, rigorously validated, and consistently applied. Through its structured governance, tiered validation framework, and systematic compendium management, MDVIP creates a foundation of methodological reliability that supports the FDA's public health mission. The program continues to evolve, incorporating new analytical technologies and addressing emerging food safety challenges while maintaining the high standards expected of regulatory science. For researchers and food testing professionals, understanding MDVIP principles and protocols is essential for developing methods that meet regulatory requirements and contribute to the broader goal of ensuring food safety.

The Methods Development, Validation, and Implementation Program (MDVIP) establishes the foundational framework for analytical laboratory methods within the FDA Foods Program. This program ensures that FDA laboratories employ rigorously validated methods to support the agency's regulatory mission for food safety and nutrition [1]. The MDVIP mandates collaboration on the development, validation, and implementation of analytical methods, with a primary goal of ensuring the use of properly validated methods and, where feasible, those that have undergone multi-laboratory validation (MLV) [1]. The governance and operational processes for this program were initially developed under the former Office of Foods and Veterinary Medicine (OFVM) and are now managed by the Regulatory Science Steering Committee (RSSC) [1]. The program's activities are disciplined through specific Research Coordination Groups (RCGs) and Method Validation Subcommittees (MVS) for chemical and microbiological analytical methods [1].

MDVIP Governance Structure

The MDVIP operates under a structured governance model designed to centralize coordination and maintain scientific rigor. The overall leadership and execution of the program are distributed between two key entities and their subordinate groups.

Table: MDVIP Governing Bodies and Their Primary Functions

| Governing Body | Primary Function | Composition |

|---|---|---|

| Regulatory Science Steering Committee (RSSC) | Manages the overall MDVIP; provides agency-wide oversight and collaboration [1]. | Members from FDA's Center for Food Safety and Applied Nutrition (CFSAN), Office of Regulatory Affairs (ORA), Center for Veterinary Medicine (CVM), and National Center for Toxicological Research (NCTR) [1]. |

| Research Coordination Groups (RCGs) | Provide overall leadership and a coordinating role in developing/updating guidelines and posting methods [1]. | Discipline-specific groups for chemistry and microbiology. |

| Method Validation Subcommittees (MVS) | Responsible for approving validation plans, evaluating validation results, and updating validation guidelines [1]. | Discipline-specific groups operating under the RCGs. |

The logical flow and reporting relationships within the MDVIP governance structure can be visualized as follows:

Core Functional Roles in Method Validation

The Regulatory Science Steering Committee (RSSC)

The RSSC serves as the central managing body for the MDVIP. Its core function is to foster and mandate collaboration across the FDA's various centers and offices. Comprising members from CFSAN, ORA, CVM, and NCTR, the RSSC ensures that method development and validation activities are aligned with the broader regulatory objectives of the Foods Program [1]. By overseeing the MDVIP, the RSSC guarantees that a unified, agency-wide approach is applied to analytical method science, thereby promoting consistency and reliability in regulatory testing [1].

Research Coordination Groups (RCGs) and Method Validation Subcommittees (MVS)

The RCGs and MVSs are the operational engines of the MDVIP, with separate groups for chemistry and microbiology disciplines. The Research Coordination Groups (RCGs) hold the overall leadership for their respective disciplines, coordinating the end-to-end process of method development, guideline updates, and the public posting of validated methods [1]. The Method Validation Subcommittees (MVSs) are tasked with the technical oversight of the validation process itself. Their responsibilities are critical and include approving validation plans before work begins and conducting a rigorous evaluation of the validation results against predefined criteria [1]. Furthermore, the MVSs play a major role in drafting and updating the official method validation guidelines used by the program [1].

Method Validation Guidelines and Compendia

Under the MDVIP framework, the RCGs and MVSs have developed and maintained comprehensive validation guidelines. These documents standardize the validation process across FDA laboratories. The output of this validated work is curated in publicly accessible compendia, which detail the performance status and appropriate use of each method.

- Validation Guidelines: The MDVIP has established specific validation guidelines for chemical, microbiological, and DNA-based analytical methods [1]. This includes developed acceptance criteria for confirming the identity of chemical residues using exact mass data [1].

- The Foods Program Compendium: The Compendium is the official repository for analytical methods with a defined validation status for use in FDA regulatory laboratories [2]. Its structure differs slightly by discipline:

- Chemical Analytical Manual (CAM): Contains chemical methods at all validation levels, with posting durations based on the level of validation achieved (e.g., one year for emergency use methods, indefinitely for multi-laboratory validated methods) [2].

- Microbiological Methods: Primarily consists of the Bacteriological Analytical Manual (BAM), which mainly contains multi-laboratory validated methods. Other MLV methods pending inclusion in the BAM are also listed [2].

Table: Method Validation Levels and Status in the FDA Compendium

| Discipline | Validation Level | Posting Duration in Compendium | Key Examples |

|---|---|---|---|

| Chemistry | Multi-laboratory Validated (MLV) | Indefinitely | Determination of Mycotoxins, PFAS, Arsenic Speciation [2]. |

| Single-Laboratory Validation | Up to 2 years | Method C-013.01 for Glyphosate [2]. | |

| Emergency Use | 1 year | (Specific methods subject to renewal) [2]. | |

| Microbiology | Level 4: Multi-laboratory Validation (MLV) | Included in BAM or listed pending addition | Detection of Cyclospora, Salmonella screening, Listeria identification [2]. |

Experimental Protocols for Method Validation

The validation of methods under the MDVIP follows a rigorous, structured protocol. The following workflow outlines the general steps from method conception through to regulatory application, highlighting the decision points and reviews by the MVS and RCG.

Detailed Methodology for a Multi-Laboratory Validation Study

A Multi-Laboratory Validation (MLV) study represents the most rigorous level of validation. The process for a chemical or microbiological method involves the following detailed steps, as guided by the MDVIP guidelines [2]:

- Validation Plan Approval: Before any testing begins, a detailed validation plan is drafted. This plan must be submitted to and approved by the relevant Method Validation Subcommittee (MVS) [1]. The plan outlines the objective, scope, performance characteristics to be measured, acceptance criteria, and participating laboratories.

- Inter-laboratory Testing: The approved method is distributed to a minimum of 10 independently operating laboratories for chemical methods, ensuring statistical significance [2]. These laboratories analyze a common set of blinded, homogeneous samples that are fortified with the target analyte(s) across a range of concentrations and in various relevant food matrices.

- Data Collection and Analysis: Each participating laboratory returns raw data and calculated results to a study director. The data is analyzed for key validation parameters:

- Precision: Calculated as the relative standard deviation (RSD) between results from the different laboratories.

- Accuracy: Determined by measuring the percent recovery of the known, fortified analyte concentrations across the different laboratories and matrices.

- Specificity/Selectivity: Evidence that the method can distinguish the analyte from other components in complex food matrices.

- Limit of Detection (LOD) and Quantification (LOQ): The lowest level at which the analyte can be reliably detected and measured, respectively.

- MVS Review of Validation Results: The complete dataset and statistical analysis are submitted to the MVS for evaluation. The MVS assesses whether the results meet the pre-defined acceptance criteria outlined in the validation plan and the Foods Program Method Validation Guidelines [1].

- Method Inclusion in Compendium: Upon successful MVS approval, the Research Coordination Group (RCG) provides final approval for the method to be posted in the appropriate compendium (e.g., CAM or BAM) for use by FDA regulatory laboratories [1] [2].

The Scientist's Toolkit: Key Reagents and Materials for Method Validation

The following table details essential materials and reagents used in the development and validation of analytical methods for food safety, as exemplified by methods in the Chemical Analytical Manual (CAM).

Table: Key Research Reagent Solutions for Food Safety Methods

| Reagent/Material | Function in Analytical Method | Example of Use |

|---|---|---|

| Stable Isotope-Labeled Internal Standards | Correct for matrix effects and losses during sample preparation; enable highly accurate quantification via mass spectrometry [2]. | Determination of mycotoxins using Stable Isotope Dilution Assay (SIDA) in corn and peanut butter [2]. |

| Certified Reference Materials (CRMs) | Calibrate instruments and verify method accuracy by providing a known quantity of analyte with a certified purity and concentration [2]. | Quantification of toxic elements (As, Cd, Pb) in food, as seen in Method C-008.01 [2]. |

| Molecular Detection Assays (qPCR) | Amplify and detect specific DNA sequences of pathogens with high sensitivity and specificity in real-time [2]. | Screening of Salmonella in foods and environmental surfaces [2]. |

| Chromatography Columns (HPLC, LC) | Separate individual analytes from complex food matrices before detection, reducing interference and improving accuracy [2]. | Speciation of arsenic in rice products (C-007.01) and determination of sulfites in food (C-004.04) [2]. |

| Sample Preparation Kits (e.g., QuEChERS) | Streamline and standardize the extraction and clean-up of analytes from complex food matrices, improving reproducibility [2]. | Screening of Polycyclic Aromatic Hydrocarbons (PAHs) in seafood [2]. |

The MDVIP's governance structure, with the Regulatory Science Steering Committee (RSSC) providing strategic oversight and the Research Coordination Groups (RCGs) and Method Validation Subcommittees (MVSs) executing technical coordination and review, is fundamental to the scientific integrity of the FDA Foods Program. This disciplined framework ensures that every analytical method used in regulatory decision-making undergoes a transparent, rigorous, and multi-layered validation process. For researchers and drug development professionals, understanding this governance is critical. It underscores the level of evidence required for methods to be deemed acceptable for regulatory use and provides a model for robust analytical method development and validation in their own work, ultimately ensuring the safety and integrity of the food supply.

The Methods Development, Validation, and Implementation Program (MDVIP) establishes the foundational framework for analytical method governance within the FDA Foods Program. Developed under the former Office of Foods and Veterinary Medicine and now managed by the FDA Foods Program Regulatory Science Steering Committee (RSSC), the MDVIP represents a collaborative effort across multiple FDA centers and offices, including the Center for Food Safety and Applied Nutrition (CFSAN), Office of Regulatory Affairs (ORA), Center for Veterinary Medicine (CVM), and National Center for Toxicological Research (NCTR) [1].

The primary objective of this framework is to ensure that FDA laboratories consistently use properly validated methods, with a strong institutional preference for those that have undergone multi-laboratory validation (MLV) where feasible [1]. This commitment to validation rigor directly supports the Foods Program's regulatory mission to protect public health through scientifically robust analytical data. The MDVIP governance structure separates management for chemistry and microbiology disciplines through Research Coordination Groups (RCGs) and Method Validation Subcommittees (MVS), ensuring specialized oversight while maintaining consistent standards across analytical domains [1].

MDVIP Governance and Validation Guidelines

Governance Structure

The MDVIP operational structure employs a disciplined, tiered approach to method validation management, with distinct roles and responsibilities clearly allocated between coordinating and validation-specific entities.

Table: MDVIP Governance Entities and Responsibilities

| Entity | Primary Role | Key Responsibilities |

|---|---|---|

| Research Coordination Groups (RCGs) | Overall program leadership | Coordinate method development/updates; maintain guidelines; post methods [1]. |

| Method Validation Subcommittees (MVS) | Validation oversight | Approve validation plans; evaluate validation results; update validation guidelines [1]. |

| Regulatory Science Steering Committee (RSSC) | Program management | Cross-center oversight of MDVIP implementation [1]. |

Validation Guidelines

Under the MDVIP framework, the FDA has developed and continues to maintain comprehensive validation guidelines tailored to different analytical methodologies. These guidelines establish standardized criteria for assessing method performance characteristics across various scientific disciplines:

- Chemical Methods Guidelines: Provide validation protocols for chemical residue and contaminant analysis, including specific acceptance criteria for confirmation of chemical identities using exact mass data [1].

- Microbiological Methods Guidelines: Outline validation requirements for pathogen detection methods, with defined validation levels ranging from emergency use to full collaborative studies [2].

- DNA-Based Methods Guidelines: Establish validation standards for molecular analytical techniques, including species identification and genetically modified organism detection [1].

These guidelines ensure that methods adopted by FDA regulatory laboratories demonstrate analytical robustness, reproducibility, and fitness-for-purpose within their intended regulatory contexts [1].

Multi-Laboratory Validation (MLV) Protocols

MLV Study Design

Multi-laboratory validation represents the most rigorous validation level within the MDVIP framework, designed to demonstrate method performance across multiple independent laboratories. The standard MLV study design for microbiological methods typically involves ten participating laboratories to comprehensively assess inter-laboratory reproducibility [2]. For chemical methods, the MLV process follows similar principles with study designs tailored to specific analytical challenges and matrix considerations.

The MLV protocol systematically evaluates key method performance characteristics through a structured approach:

- Pre-study validation: The candidate method must first demonstrate satisfactory performance in a single laboratory setting, establishing foundational validation parameters.

- Collaborative study design: A statistically sufficient number of laboratories (typically 8-10) analyze identical, homogenized samples representing relevant matrices and analyte concentrations.

- Data collection and analysis: Participating laboratories follow standardized protocols to generate data for calculating precision estimates (repeatability and reproducibility) and determining method robustness.

- Independent review: Method Validation Subcommittees evaluate the collaborative study results against pre-established acceptance criteria for the intended application.

MLV Method Implementation

Successfully validated MLV methods are incorporated into official FDA compendia for regulatory use. The Chemical Analytical Manual (CAM) permanently lists chemical methods that have completed multi-laboratory validation, providing indefinite access to these validated procedures [2]. Similarly, the Bacteriological Analytical Manual (BAM) serves as the primary repository for MLV microbiological methods, representing the "gold standard" for FDA's microbiological analyses of foods and cosmetics [2].

Methods that have completed the MLV process but await formal incorporation into the BAM are listed separately in the FDA Foods Program Compendium of Analytical Methods, ensuring their availability to regulatory laboratories despite administrative processing delays [2]. This implementation pathway guarantees that only methods demonstrating adequate performance across multiple laboratory environments are utilized for critical regulatory decisions.

Validation Levels and Technical Requirements

Validation Hierarchy

The MDVIP framework recognizes that not all methods require or can immediately achieve full multi-laboratory validation. The program therefore establishes a tiered validation hierarchy with distinct technical requirements at each level, particularly well-defined for microbiological methods.

Table: Microbiological Method Validation Levels under MDVIP

| Validation Level | Description | Typical Use Cases |

|---|---|---|

| Level 1 | Emergency Use | Rapid response to emerging threats; limited validation; 1-year posting in Compendium [2]. |

| Level 2 | Single Laboratory Validation | Initial validation within one lab; up to 2-year posting [2]. |

| Level 3 | Single Lab + Independent Lab | Enhanced validation with one independent laboratory verification [2]. |

| Level 4 | Multi-Laboratory Validation (MLV) | Full collaborative study (10 labs); gold standard; permanent inclusion in manuals [2]. |

For chemical methods, a similar but distinct hierarchy exists within the CAM, where methods with single-laboratory validation are posted for up to two years, while those judged to have validation status equivalent to MLV are posted for three-year renewable terms [2]. Methods developed for emergency needs with limited validation are posted for one year, balancing the need for rapid response with validation rigor [2].

Technical Performance Parameters

Regardless of validation level, methods must demonstrate acceptable performance across standardized technical parameters. For chemical methods, these typically include:

- Accuracy: Demonstrated through recovery studies using certified reference materials or spiked samples at relevant concentration ranges.

- Precision: Measured as repeatability (within-laboratory) and reproducibility (between-laboratory) expressed as relative standard deviation.

- Specificity/Selectivity: Ability to unequivocally identify and quantify the analyte in the presence of potentially interfering compounds.

- Linearity and Range: The method's response proportionality to analyte concentration across the validated working range.

- Limit of Detection (LOD) and Quantitation (LOQ): The lowest concentrations that can be reliably detected and quantified, respectively.

- Robustness: Capacity to remain unaffected by small, deliberate variations in method parameters.

For elemental analysis methods, demonstrated performance characteristics include exceptional sensitivity, as shown in representative detection limits for heavy metals using EAM techniques [3]:

Table: Example Detection Limits for Heavy Metals Using EAM Techniques

| Heavy Metal | LOD (ppb) | LOQ (ppb) |

|---|---|---|

| Arsenic | 1.3 | 11.6 |

| Cadmium | 0.4 | 3.7 |

| Lead | 1.2 | 10.9 |

Experimental Protocols for Method Validation

Protocol for Mycotoxin Determination

Method Title: Determination of Mycotoxins in Corn, Peanut Butter, and Wheat Flour Using Stable Isotope Dilution Assay (SIDA) and Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) [2]

Scope: Simultaneous detection and quantification of multiple mycotoxins including aflatoxins B1, B2, G1, G2; deoxynivalenol; fumonisins B1, B2, B3; HT-2 toxin; ochratoxin A; T-2 toxin; and zearalenone.

Experimental Workflow:

- Sample Preparation: Representative samples are homogenized and fortified with stable isotopically-labeled internal standards.

- Extraction: Mycotoxins are extracted using a solvent system optimized for multiple analyte classes.

- Cleanup: Employing solid-phase extraction or dispersive SPE to remove matrix interferents.

- Derivatization: Where necessary, chemical derivatization is performed to enhance detection sensitivity.

- Analysis: LC-MS/MS analysis with chromatographic separation optimized for each mycotoxin class.

- Quantification: Using stable isotope dilution assay for accurate quantification, correcting for matrix effects and recovery variations.

Key Quality Controls:

- Use of isotopically-labeled internal standards for each analyte class

- Matrix-matched calibration standards

- Procedural blanks and quality control materials at multiple concentrations

- Demonstration of specificity against potentially interfering compounds

Protocol for PFAS Determination

Method Title: Determination of 30 Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) in Food using Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) [2]

Scope: Simultaneous detection and quantification of 30 perfluoroalkyl and polyfluoroalkyl substances in various food matrices.

Experimental Workflow:

- Sample Extraction: Liquid samples are diluted and filtered; solid samples are extracted using organic solvents with mechanical agitation.

- Cleanup: Solid-phase extraction using polymers that selectively retain PFAS compounds while removing lipid and protein interferents.

- Concentration: Extracts are concentrated under gentle nitrogen evaporation to prevent loss of volatile PFAS.

- Analysis: High-performance liquid chromatography with tandem mass spectrometry (HPLC-MS/MS) using reversed-phase chromatography with ammonium acetate or ammonium hydroxide in the mobile phase.

- Detection: Negative electrospray ionization with multiple reaction monitoring (MRM) for each target PFAS compound.

Technical Innovations:

- Advanced column materials for improved chromatographic separation

- High-resolution mass spectrometry for unambiguous identification

- Optimized solid-phase extraction protocols achieving high recovery rates (typically >85%)

- Demonstrated method sensitivity at parts-per-trillion levels

Analytical Workflows and Visualization

The method validation process follows structured pathways from development through implementation, with distinct workflows for different method types. The following diagrams illustrate these standardized processes.

Diagram 1: MDVIP Validation Pathway. This workflow illustrates the progressive validation levels within the MDVIP framework, culminating in permanent inclusion in official FDA compendia after successful multi-laboratory validation [2].

Diagram 2: MLV Study Design. This workflow shows the structure of a multi-laboratory validation study, demonstrating how homogenized reference materials and standardized protocols enable assessment of inter-laboratory reproducibility [2].

Essential Research Reagents and Materials

Successful implementation of validated methods requires carefully selected reagents and reference materials that meet strict quality standards. The following table details essential materials for FDA food testing methodologies.

Table: Essential Research Reagents for Food Testing Methods

| Reagent/Material | Technical Function | Application Examples |

|---|---|---|

| Stable Isotope-Labeled Internal Standards | Correct for matrix effects and recovery variations; enable precise quantification | Mycotoxin analysis using SIDA; pesticide residue quantification [3] |

| Certified Reference Materials | Method validation; accuracy determination; quality control | Elemental analysis; nutrient quantification; contaminant verification [3] |

| Selective Solid-Phase Extraction Sorbents | Matrix interference removal; analyte concentration; sample cleanup | PFAS analysis; drug residue testing; pesticide multiresidue methods [3] |

| Chromatography Columns & Mobile Phases | Compound separation; matrix component resolution; detection enhancement | LC-MS/MS analysis of chemical contaminants; mycotoxin determination [2] |

| Pathogen Selective Media & Molecular Reagents | Microbial enrichment; nucleic acid amplification; pathogen identification | BAM procedures; real-time PCR detection of Salmonella, Listeria, Cyclospora [2] |

| Quality Control Materials | Continuous method performance verification; inter-laboratory comparability | All regulatory methods at every validation level [1] |

Compendium Integration and Regulatory Application

The FDA Foods Program Compendium

The FDA Foods Program Compendium of Analytical Laboratory Methods serves as the official repository for methods with defined validation status that are currently used by FDA regulatory laboratories [2]. The Compendium is organized into distinct sections for chemical and microbiological methods, reflecting their different historical development and validation approaches.

For chemical methods, the Chemical Analytical Manual (CAM) contains methods that FDA regulatory laboratories use to determine food and feed safety [2]. The CAM employs a transparent version control system where version numbers (.01, .02, .03, etc.) designate major revisions, allowing users to track method updates and improvements [2]. The CAM inclusion criteria vary based on validation status:

- MLV-Validated Methods: Listed indefinitely in the CAM

- Single-Laboratory Validated Methods: Posted for up to two years

- Emergency Use Methods: Posted for one year with limited validation

- Legacy Methods: Judged equivalent to MLV standards posted for three-year renewable terms [2]

Regulatory Implementation

Validated methods within the Compendium support diverse regulatory functions across the FDA Foods Program, including:

- Compliance Monitoring: Routine surveillance of food products for chemical contaminants, pesticide residues, and toxic elements [2]

- Pathogen Detection: Microbiological monitoring for foodborne pathogens including Salmonella, Listeria, and Cyclospora [2]

- Food Authenticity: Verification of food composition and species identification, such as DNA-based seafood identification [4]

- Emergency Response: Rapid deployment of methods for emerging contaminants and food safety incidents [2]

The integration of properly validated methods into regulatory practice creates a robust scientific foundation for public health protection, ensuring that regulatory decisions are based on analytically sound data regardless of the laboratory performing the analysis.

The MDVIP framework represents a comprehensive, science-based approach to ensuring analytical quality throughout the FDA Foods Program. By establishing clear validation guidelines, implementing tiered validation levels with multi-laboratory validation as the gold standard, and maintaining transparent compendia of validated methods, the program creates a systematic infrastructure for generating reliable analytical data. This rigorous approach to method validation provides the scientific foundation for protecting public health through accurate food safety monitoring, regulatory compliance actions, and rapid response to emerging food safety threats. As analytical technologies evolve and new food safety challenges emerge, the MDVIP's structured yet flexible framework continues to ensure that FDA's regulatory laboratories utilize properly validated methods fit for their intended purpose.

The Methods Development, Validation, and Implementation Program (MDVIP) is the cornerstone regulatory framework ensuring the reliability and accuracy of analytical methods used within the FDA Foods Program [1]. Established under the former Office of Foods and Veterinary Medicine (OFVM) and now managed by the FDA Foods Program Regulatory Science Steering Committee (RSSC), the MDVIP commits its members to collaborate on the development, validation, and implementation of analytical methods to support the Foods Program's regulatory mission [1]. A primary goal is to ensure that FDA laboratories use properly validated methods, with a preference for those that have undergone multi-laboratory validation (MLV) where feasible [1].

The governance and execution of these validation processes are managed separately for chemistry and microbiology disciplines through Research Coordination Groups (RCGs) and Method Validation Subcommittees (MVS) [1]. The RCGs provide overall leadership and coordination in developing guidelines and posting methods, while the MVSs are responsible for approving validation plans, evaluating validation results, and updating the validation guidelines [1]. This structured approach ensures that all methods—chemical, microbiological, and DNA-based—used in FDA regulatory laboratories to analyze food and feed safety meet stringent, predefined validation criteria before implementation [1] [2].

MDVIP Governance and Structural Framework

Organizational Oversight and Responsibilities

The MDVIP operates under a sophisticated governance structure designed to facilitate cross-center collaboration and scientific rigor. The program is overseen by the Regulatory Science Steering Committee (RSSC), which comprises members from key FDA components: the Center for Food Safety and Applied Nutrition (CFSAN), the Office of Regulatory Affairs (ORA), the Center for Veterinary Medicine (CVM), and the National Center for Toxicological Research (NCTR) [1]. This interdisciplinary representation ensures that method validation processes address diverse regulatory needs and scientific perspectives.

The operational work is distributed between two primary groups:

- Research Coordination Groups (RCGs): Assume overall leadership of the program and provide coordinating roles in developing and updating guidelines and posting methods [1].

- Method Validation Subcommittees (MVS): Responsible for approving validation plans, evaluating validation results, and playing a major role in updating validation guidelines [1].

This separation of coordination and validation functions ensures both efficient program management and rigorous scientific evaluation of proposed methods. The MVSs provide the technical expertise to assess whether methods meet the predefined validation criteria, while the RCGs ensure these validated methods are properly implemented and maintained within the FDA's laboratory network.

The Compendium of Analytical Laboratory Methods

The FDA Foods Program Compendium of Analytical Laboratory Methods ("the Compendium") serves as the official repository for methods that have a defined validation status and are currently used by FDA regulatory laboratories [2]. The Compendium is divided into distinct sections for chemical and microbiological methods, reflecting their different historical approaches and validation requirements.

For chemical methods, the Chemical Analytical Manual (CAM) lists validated methods that FDA regulatory laboratories use to determine food and feed safety [2]. Methods in the CAM are categorized based on their validation level, with posting durations determined accordingly:

- Emergency Use Methods: Developed due to an emergency need with limited validation, posted for one year [2].

- Single-Laboratory Validation: Posted for up to two years [2].

- Multi-Laboratory Validated Methods: Listed indefinitely in the CAM [2].

- Older Methods judged equivalent to multi-laboratory validation: Posted for three years [2].

For microbiological methods, the Bacteriological Analytical Manual (BAM) is the primary component, containing the agency's preferred laboratory procedures for microbiological analyses of foods and cosmetics [2]. The BAM primarily contains multi-laboratory validated methods, with newly validated methods posted on the FDA website until they can be formally added to the BAM [2].

Chemical Method Validation Guidelines

Core Validation Parameters for Chemical Methods

Chemical method validation under the FDA Foods Program requires demonstrating that a method is fit for its intended purpose through assessment of specific performance characteristics [5]. These parameters establish the foundational integrity of any analytical procedure and are consistent with internationally recognized guidance such as ICH Q2(R2) [5].

The table below summarizes the key validation characteristics and their definitions:

| Characteristic | Definition | Relevance in Food Analysis |

|---|---|---|

| Accuracy | The closeness of test results to the true value [5]. | Confirms the method measures the target contaminant or nutrient without bias in specific food matrices. |

| Precision | The degree of agreement among individual test results when the procedure is applied repeatedly [5]. | Assessed as repeatability (same conditions) and intermediate precision (different days, analysts); crucial for reproducible monitoring. |

| Specificity | The ability to unequivocally assess the analyte in the presence of components that may be expected to be present [5]. | Essential for accurately quantifying chemical residues in complex food matrices without interference. |

| Limit of Detection (LOD) | The lowest concentration of an analyte in a sample that can be reliably detected [5]. | Critical for screening methods targeting unauthorized substances or contaminants at trace levels. |

| Limit of Quantification (LOQ) | The lowest concentration of an analyte that can be quantitatively determined with acceptable precision and accuracy [5]. | Used for assays quantifying low-level components where precise concentration data is required. |

| Linearity & Range | The ability to elicit test results proportional to analyte concentration across an interval with acceptable performance [5]. | Defines the operational limits for quantifying analytes from low to high concentrations in various foods. |

| Robustness | The capacity of a procedure to remain unaffected by small, deliberate variations in method parameters [5]. | Confirms method reliability under normal operational variations in different laboratory environments. |

Experimental Protocols for Chemical Method Validation

The validation process for chemical methods involves specific experimental protocols to generate data for each validation parameter:

Accuracy Assessment: Typically determined using spiked recovery experiments in blank food matrices [5]. Known quantities of the analyte are added to the matrix at multiple concentrations (covering the method's range), and the measured values are compared to the true values. Recovery percentages are calculated and must fall within predefined acceptable limits (often 70-120% for trace analysis). Certified reference materials (CRMs) are used when available to provide additional accuracy verification [5].

Precision Evaluation: Conducted through replicate analysis experiments [5]. Repeatability is assessed by analyzing multiple aliquots of a homogeneous sample in the same laboratory by the same analyst using the same equipment within a short time frame. Intermediate precision is evaluated by having different analysts perform the analysis on different days or with different equipment in the same laboratory. The results are expressed as relative standard deviation (RSD%) with lower values indicating better precision.

Specificity Testing: For stability-indicating methods, forced degradation studies are performed by intentionally exposing the sample to various stress conditions (heat, humidity, acid, base, light) to ensure the method can separate the analyte from its degradation products [5]. Chromatographic methods must demonstrate baseline separation of the target analyte from potential interferences present in the food matrix.

Linearity and Range Determination: Established by analyzing a series of standard solutions at different concentration levels (typically 5-8 points) across the expected concentration range [5]. The results are plotted as detector response versus concentration, and statistical methods are used to evaluate the linear relationship. The range is confirmed by demonstrating that the method provides acceptable accuracy, precision, and linearity across the specified interval.

Application in FDA Foods Program: Chemical Contaminant Analysis

The FDA's chemical method validation principles are applied across various food safety programs, as evidenced by methods listed in the Chemical Analytical Manual (CAM). The table below highlights selected validated methods for chemical contaminant analysis:

| Program Area | Principal Analytes | Method # | Analytical Technique |

|---|---|---|---|

| Aquaculture drugs | Chloramphenicol and nitrofuran metabolites | C-011.01 | LC-MS/MS with microwave-assisted derivatization and automated SPE [2] |

| Chemical contaminants | 30 perfluoroalkyl and polyfluoroalkyl (PFAS) compounds | C-010.03 | Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) [2] |

| Mycotoxins | Aflatoxins, deoxynivalenol, fumonisins, etc. | C-003.03 | Stable Isotope Dilution Assay (SIDA) and LC-MS/MS [2] |

| Seafood | Polycyclic aromatic hydrocarbons (PAHs) | C-002.01 | QuEChERS-based extraction and HPLC with fluorescence detection [2] |

| Toxic elements | Arsenic species in rice and rice products | C-007.01 | High Performance Liquid Chromatography-Inductively Coupled Plasma-Mass Spectrometry [2] |

Diagram 1: Chemical Method Validation Workflow. The process begins with method development and proceeds through systematic assessment of key validation parameters before inclusion in the Chemical Analytical Manual (CAM).

Microbiological Method Validation Guidelines

Distinct Validation Approaches for Microbiological Methods

While sharing the same fundamental objectives of accuracy and reliability, microbiological method validation presents unique challenges not encountered in chemical analysis due to the inherent variability of living organisms [5]. The MDVIP has established a tiered validation system for microbiological methods consisting of four distinct levels [2]:

Level 1: Emergency Use: Methods implemented for urgent public health situations with limited validation, intended for temporary use during outbreak investigations or emerging pathogen concerns [2].

Level 2: Single Laboratory Validation: Methods validated within a single laboratory, demonstrating basic performance characteristics but requiring further validation for broader application [2].

Level 3: Single Laboratory Validation Plus Independent Laboratory Validation Study: Methods validated in a primary laboratory with verification through an independent laboratory study, providing greater confidence in transferability [2].

Level 4: Full Collaborative Multi-laboratory Validation (MLV) Study: Methods validated through comprehensive collaborative studies typically involving 10 laboratories, representing the highest level of validation assurance [2]. Virtually all methods included in the microbiological methods portion of the Compendium have MLV status [2].

Key Validation Parameters for Microbiological Methods

The validation of microbiological methods focuses on parameters that address the specific challenges of detecting and quantifying living organisms in complex food matrices:

Specificity Testing: Involves challenging the method with a comprehensive panel of both target (positive) and non-target (negative) organisms, including closely related species [5]. This ensures the method is both highly sensitive (correctly identifying true positives) and selective (correctly excluding non-target organisms).

Limit of Detection (LOD) in Microbiological Context: Expressed as a probabilistic measure rather than a continuous concentration [5]. Typically assessed using the Most Probable Number (MPN) technique or through confirmation of method equivalence to recognized standards like ISO 16140 [5]. The LOD represents the lowest number of colony-forming units (CFU) per gram or volume that can be reliably detected (e.g., with 95% probability).

Sample Enrichment and Recovery Validation: Critical for methods involving selective enrichment steps [5]. Validation must demonstrate the method's capacity to consistently recover and amplify low numbers of target organisms from large sample volumes, including those that may be sub-lethally damaged from food processing or cleaning procedures.

Robustness and Ruggedness: Evaluates method performance under variations in critical parameters such as incubation temperatures, times, media lots, and analyst technique [5]. This ensures the method remains reliable across different laboratory environments and operational conditions.

Application in FDA Foods Program: Pathogen Detection Methods

The Bacteriological Analytical Manual (BAM) serves as the primary repository for validated microbiological methods used by the FDA. The table below presents selected microbiological methods with MLV status:

| Matrix | Analyte(s) | Method/Resource | Validation Status |

|---|---|---|---|

| Multiple | Foodborne pathogens | Bacteriological Analytical Manual (BAM) | BAM Standard [2] |

| Multiple | Cyclospora | Molecular Detection of Cyclospora cayetanensis in Fresh Produce Using Real-Time PCR | MDVIP Level 4 (multi-laboratory) [2] |

| Multiple | Salmonella | Screening of Salmonella in Foods and on Environmental Surfaces by Real-Time Quantitative PCR (qPCR) | MDVIP Level 4 (multi-laboratory) [2] |

| Multiple | Listeria | Molecular Verification of Listeria spp. isolates and Identification of L. monocytogenes Serogroups Using Real-Time PCR | MDVIP Level 4 (multi-laboratory) [2] |

| Animal foods | Salmonella | Screening of Salmonella in Animal Food by Loop-mediated Isothermal Amplification (LAMP) | MDVIP Level 4 (multi-laboratory) [2] |

| Agricultural water | Cyclospora cayetanensis | Dead-End Ultrafiltration (DEUF) for Detection from Agricultural Water | MDVIP Level 4 (multi-laboratory) [2] |

Diagram 2: Microbiological Method Validation Tiers. Methods progress through four validation levels, with full multi-laboratory validation (Level 4) required for inclusion in the Bacteriological Analytical Manual (BAM).

DNA-Based Method Validation Guidelines

Regulatory Framework for DNA-Based Methods

DNA-based method validation within the FDA Foods Program follows specific guidelines developed under the MDVIP framework [1]. These methods are particularly important for applications such as species identification in seafood and detection of genetically modified organisms [4]. The validation approach for DNA-based methods incorporates elements from both chemical and microbiological validation paradigms, addressing the unique characteristics of nucleic acid analysis.

For seafood identification, FDA researchers use DNA sequencing technology to definitively determine the species of fish being analyzed [4]. The agency has established a Single Laboratory Validated Method for DNA-Barcoding for the species identification of fish, which is available on FDA's DNA-based Seafood Identification page [4]. This method validation includes establishing a reference database of known species and validating the procedure for accurate species identification across a wide range of seafood products.

Special Considerations for DNA-Based Method Validation

Validation of DNA-based methods requires addressing specific parameters relevant to nucleic acid analysis:

Specificity and Cross-Reactivity: Methods must demonstrate the ability to distinguish between target and non-target sequences, including closely related species or genetic variants. This involves testing against a comprehensive panel of relevant organisms.

Sensitivity and Limit of Detection: Establishing the minimum number of target DNA copies that can be reliably detected, accounting for factors such as DNA degradation in processed foods and potential PCR inhibitors in complex food matrices.

Inhibition Testing: Validation must include assessment of method performance in the presence of potential PCR inhibitors commonly found in food matrices, with demonstration of effective mitigation approaches.

Quantification Performance: For quantitative DNA-based methods (qPCR), validation includes establishing linearity, dynamic range, efficiency, and reproducibility of quantification across the intended measurement range.

The FDA has also developed acceptance criteria for confirmation of identity of chemical residues using exact mass data through members of the MDVIP, which represents an advanced application of molecular characterization techniques [1].

Quality Assurance and Method Lifecycle Management

Laboratory Quality Management Systems

The FDA Foods Program employs comprehensive quality management systems to ensure the ongoing reliability of validated methods. The CFSAN Laboratory Quality Assurance Manual (LQM), now in its 4th Edition (2019), contains policies and instructions related to laboratory quality assurance in CFSAN [4]. This manual serves as a central resource for understanding CFSAN's quality system and provides guidance on quality concepts, principles, and practices [4].

Additionally, the ORA Laboratory Manual provides FDA personnel with information on internal procedures to be used as agency policy for testing consumer products, training of laboratory staff, report writing, safety, research, review of private laboratory reports, and court testimony [4]. These quality systems ensure that validated methods are implemented consistently and maintained properly across all FDA regulatory laboratories.

Method Lifecycle Management

Assay validation is not a one-time event but rather the first stage in a continuous lifecycle management process [5]. This comprehensive approach includes:

Method Validation: The formal, comprehensive study establishing performance characteristics following guidelines such as ICH Q2(R2) [5].

Method Verification/Transfer: Procedures to demonstrate a validated method performs acceptably when transferred to a different laboratory or instrument, ensuring inter-laboratory consistency [5].

Ongoing System Suitability: Routine checks conducted immediately before sample analysis to ensure the system (instrumentation, reagents, columns) is operating as expected [5]. These tests are a continuous part of quality assurance/quality control (QA/QC).

Revalidation/Periodic Review: Minor changes (e.g., reagent supplier, minor instrument upgrade) require partial revalidation, while significant changes (e.g., new sample matrix, different instrument principle) require full revalidation [5]. Even without changes, periodic review confirms the method remains current and effective.

This lifecycle approach aligns with modern quality management principles and ensures that analytical procedures remain robust and reliable throughout their operational use.

Essential Research Reagents and Materials

The successful implementation of validated methods requires specific, high-quality research reagents and materials. The table below details key components essential for methods across chemical, microbiological, and DNA-based analyses:

| Reagent/Material | Function | Application Context |

|---|---|---|

| Certified Reference Materials (CRMs) | Provide traceable standards for calibration and accuracy determination [5]. | Chemical assays for contaminant quantification; establishing calibration curves. |

| Stable Isotope-Labeled Internal Standards | Compensate for matrix effects and analytical variability in mass spectrometry [2]. | LC-MS/MS methods for mycotoxins, drug residues, and contaminants using Stable Isotope Dilution Assay (SIDA). |

| Selective Enrichment Media | Promote growth of target microorganisms while inhibiting competitors [5]. | Microbiological methods for pathogen detection; recovery of sub-lethally damaged cells. |

| Molecular Detection Primers/Probes | Enable specific amplification and detection of target DNA sequences [2]. | Real-time PCR methods for pathogen detection; DNA barcoding for species identification. |

| Solid Phase Extraction (SPE) Cartridges | Clean-up and concentrate analytes from complex food matrices [2]. | Sample preparation for chemical contaminant analysis; reducing matrix interference. |

| Chromatography Columns | Separate analytes based on chemical properties prior to detection [2]. | HPLC and LC-MS/MS methods for chemical contaminants, drug residues, and toxins. |

| Enzymes and Master Mixes | Facilitate DNA amplification in molecular assays [2]. | PCR-based detection methods for pathogens and DNA-based identification. |

| Quality Control Strains/Cultures | Verify method performance for microbiological assays [5]. | Positive and negative controls in pathogen detection methods; maintaining assay validity. |

Emerging Trends and Future Directions

The FDA Foods Program continues to evolve its method validation frameworks to address emerging public health challenges and incorporate technological advancements. The agency has published a list of guidance topics under development, with expected publication as drafts or finals by the end of December 2025 [6]. Several of these forthcoming guidances directly impact analytical method development and application:

Action Levels for Cadmium and Inorganic Arsenic: Draft guidance documents addressing action levels for these toxic elements in food intended for babies and young children will influence method development priorities and validation requirements for elemental analysis [6] [7].

Preventive Controls for Chemical Hazards: Chapter 12 of the Hazard Analysis and Risk-Based Preventive Controls guidance will provide direction on controlling chemical hazards in human food, necessitating validated methods for verification and validation of these controls [6].

Food Traceability Rule: The forthcoming draft guidance on the Food Traceability Rule will include questions and answers that may influence method development for tracking and identifying foods throughout the supply chain [6].

Additionally, the recent classification of the DNA-based test to measure minimal residual disease in hematological malignancies into class II (special controls) by the FDA demonstrates the expanding application of DNA-based analytical methods in regulatory science, potentially informing future approaches for food analysis [8].

The FDA's ongoing commitment to method validation is evidenced by its continuous updating of the Foods Program Compendium of Analytical Laboratory Methods and its adherence to the MDVIP processes, ensuring that regulatory methods keep pace with scientific advancements and emerging food safety challenges [1] [2].

The FDA Foods Program Compendium of Analytical Laboratory Methods serves as the authoritative repository of validated analytical procedures currently employed by FDA regulatory laboratories to ensure the safety and integrity of the food supply [2]. This compendium represents the practical implementation of the Methods Development, Validation, and Implementation Program (MDVIP), which establishes the scientific and regulatory framework for method validation within the FDA Foods Program [1]. For researchers, scientists, and drug development professionals working in food safety and regulatory science, understanding the structure, content, and governance of this compendium is essential for developing compliant analytical approaches and interpreting regulatory findings.

The compendium is strategically divided into distinct methodological disciplines, primarily separating chemical methods documented in the Chemical Analytical Manual (CAM) from microbiological methods centered around the Bacteriological Analytical Manual (BAM) [2]. This division reflects the different validation requirements and analytical approaches needed for these distinct disciplinary areas. A key aspect of the compendium is its dynamic nature; it is "updated continuously" to incorporate newly validated methods and archive obsolete procedures, ensuring that it always reflects current regulatory science practice [2].

Compendium Structure and Organization

Chemical Analytical Manual (CAM)

The Chemical Analytical Manual (CAM) constitutes the chemical methods component of the Compendium, containing procedures that FDA regulatory laboratories use to determine food and feed safety [2]. Methods within the CAM undergo rigorous validation based on their intended use and regulatory application. The validation status determines their posting duration within the manual, creating a tiered system that reflects methodological maturity and validation rigor:

- Emergency Use Methods: Developed for urgent needs with limited validation, posted for one year

- Single-Laboratory Validated Methods: Posted for up to two years

- Multi-laboratory Validated Methods: Listed indefinitely once fully validated

- Legacy Methods: Older methods judged equivalent to multi-laboratory validation, posted for three years [2]

This structured approach ensures transparency regarding the validation status of each method while facilitating the continuous improvement of analytical approaches. Each method includes a cover page with comprehensive information about its scope, application, and any extensions to new analytes, matrices, or platforms [2].

Microbiological Methods and the Bacteriological Analytical Manual (BAM)

The microbiological portion of the Compendium primarily consists of the Bacteriological Analytical Manual (BAM), which represents the agency's preferred laboratory procedures for microbiological analyses of foods and cosmetics [2] [9]. The BAM differs from the CAM in that it primarily contains multi-laboratory validated methods that have undergone extensive validation [2]. The manual is organized into chapters covering general procedures, specific pathogen detection methods, microbial toxin analysis, and additional specialized techniques.

A unique aspect of the microbiological compendium is the handling of method updates. When new methods are validated for use in FDA laboratories, there is often a delay before they are formally added to the BAM. During this interim period, these methods are listed separately on FDA's website until their incorporation into the manual [2]. This mechanism ensures that regulatory laboratories have access to the most current methodologies even during the BAM revision process.

Method Validation Framework (MDVIP)

Governance and Oversight

The Methods Development, Validation, and Implementation Program (MDVIP) provides the foundational governance for all methods within the Compendium [1]. This program operates under the auspices of the FDA Foods Program Regulatory Science Steering Committee (RSSC), which includes members from FDA's Center for Food Safety and Applied Nutrition (CFSAN), Office of Regulatory Affairs (ORA), Center for Veterinary Medicine (CVM), and National Center for Toxicological Research (NCTR) [1]. This cross-agency representation ensures that method validation approaches align with the broader regulatory science objectives of the FDA Foods Program.

The MDVIP structure employs specialized committees to manage the technical aspects of method validation. Research Coordination Groups (RCGs) provide overall leadership and coordinate the development and updating of validation guidelines, while Method Validation Subcommittees (MVS) are responsible for approving validation plans and evaluating validation results [1]. This dual-committee structure ensures both scientific rigor and regulatory relevance throughout the method validation process.

Validation Tiers and Requirements

The MDVIP establishes a multi-tiered validation framework that differs slightly between chemical and microbiological methods, reflecting their distinct technical requirements:

Microbiological Method Validation Levels:

- Level 1: Emergency Use

- Level 2: Single Laboratory Validation

- Level 3: Single Laboratory Validation Plus Independent Laboratory Validation Study

- Level 4: Full Collaborative Multi-laboratory Validation (MLV) Study [2]

For microbiological methods, virtually all procedures included in the Compendium have achieved MLV status, representing the highest validation standard [2]. This emphasis on multi-laboratory validation ensures consistency and reliability across FDA's regulatory laboratory network.

Chemical methods follow the FDA Foods Program Guidelines for the Validation of Chemical Methods, with the 2014 institution of these guidelines representing a significant milestone in standardizing chemical method validation across the program [2]. The chemical validation approach accommodates a broader range of validation statuses while maintaining rigorous standards for each tier.

Key Analytical Methodologies

Chemical Analytical Methods

The CAM contains rigorously validated methods for analyzing diverse chemical compounds in food matrices, employing advanced instrumentation and sample preparation techniques. These methods target specific analytes across multiple program areas relevant to food safety, with representative examples illustrating the technical sophistication of current regulatory analytical chemistry:

Table: Selected Chemical Analytical Methods from CAM

| Program Area | Principal Analytes | Method Number | Key Analytical Technique |

|---|---|---|---|

| Mycotoxins | Aflatoxins, deoxynivalenol, fumonisins | C-003.03 | Stable Isotope Dilution Assay (SIDA) with LC-MS/MS |

| Toxic Elements | Arsenic species | C-006.01 | HPLC-ICP-MS |

| Pesticides | Glyphosate, Glufosinate | C-013.01 | Harmonized Method for Detection and Quantitation |

| Food Additives | Sulfites | C-004.04 | LC-MS/MS |

| PFAS | 30 perfluoroalkyl and polyfluoroalkyl compounds | C-010.03 | LC-MS/MS |

| Seafood Contaminants | Polycyclic aromatic hydrocarbons (PAHs) | C-002.01 | QuEChERS-based Extraction with HPLC-Fluorescence |

The technical complexity of these methods is exemplified by Method C-003.03 for mycotoxin analysis, which employs stable isotope dilution assay (SIDA) combined with liquid chromatography-tandem mass spectrometry (LC-MS/MS) to simultaneously quantify multiple mycotoxins in corn, peanut butter, and wheat flour [2]. This approach uses isotopically-labeled internal standards for each target analyte to correct for matrix effects and recovery losses, providing exceptional accuracy and precision in complex food matrices.

Microbiological Analytical Methods

The BAM contains comprehensive procedures for detecting, enumerating, and identifying pathogenic microorganisms, spoilage organisms, and microbial toxins in foods and cosmetics. These methods incorporate both traditional culture-based approaches and modern molecular techniques, reflecting the evolution of food microbiology:

Table: Selected Microbiological Methods from BAM

| Analyte | Chapter | Method Title | Key Technological Features |

|---|---|---|---|

| Salmonella | 5 | Salmonella | Cultural and molecular confirmation methods |

| Listeria monocytogenes | 10 | Listeria monocytogenes | Cultural, biochemical, and molecular identification |

| Cyclospora cayetanensis | 19B | Detection using Real-time PCR | Molecular detection from fresh produce |

| Enteric Viruses | 26 | Concentration, Extraction and Detection | Virus concentration and molecular detection |

| Cronobacter | 29 | Cronobacter | Molecular identification and characterization |

| Staphylococcal Enterotoxins | 13B | Detection Methods | Immunoassay and molecular methods |

The BAM's approach to pathogen detection is exemplified by the recently updated Chapter 5 for Salmonella detection (updated May 2024), which incorporates both traditional culture-based isolation and modern confirmation techniques including real-time PCR and the GalaxyTrakr SeqSero2 Workflow for serotype prediction [9]. This integration of classical and cutting-edge methods provides both regulatory certainty and improved turnaround time for critical food safety analyses.

Experimental Protocols and Workflows

Chemical Method Workflow: Mycotoxin Analysis

The determination of mycotoxins using Stable Isotope Dilution Assay (SIDA) and LC-MS/MS (Method C-003.03) represents a sophisticated approach to quantifying multiple fungal toxins simultaneously in complex food matrices [2]. The experimental protocol follows a meticulously optimized workflow:

Sample Preparation: The method employs microwave-assisted extraction with solvents optimized for multiple mycotoxin classes, simultaneously adding stable isotope-labeled internal standards for each target analyte. This critical step accounts for variability in extraction efficiency and matrix effects [2].

Sample Cleanup: Extracts undergo purification using solid-phase extraction (SPE) cartridges or dispersive SPE (dSPE) sorbents to remove interfering compounds from the food matrix. The specific cleanup approach is optimized for each food matrix (corn, peanut butter, wheat flour) to balance recovery and purity [2].

Instrumental Analysis: Analysis is performed using LC-MS/MS with electrospray ionization in multiple reaction monitoring (MRM) mode. The chromatographic separation is optimized to resolve isobaric mycotoxins and their metabolites, while the MS/MS detection provides the specificity needed for accurate quantification in complex matrices [2].

Quantification: Quantification is based on the ratio of native analyte to stable isotope-labeled internal standard, correcting for matrix effects and recovery losses. This approach provides exceptional accuracy and precision compared to external calibration methods [2].

Microbiological Method Workflow: Pathogen Detection

The detection of Salmonella in foods (BAM Chapter 5) exemplifies the integrated approach combining cultural, biochemical, and molecular methods that characterizes many BAM procedures [9]:

Pre-enrichment: Samples are homogenized in a non-selective broth medium to resuscitate stressed cells and allow recovery of the target organism. This critical step enables detection of low levels of injured pathogens that might otherwise escape detection [9].

Selective Enrichment: Aliquots from pre-enriched samples are transferred to selective broth media that inhibit competing microflora while promoting growth of the target pathogen. The method typically employs multiple selective media to maximize detection sensitivity [9].

Isolation and Presumptive Identification: Selective enrichment cultures are streaked onto differential and selective agar media. Presumptive positive colonies are selected based on characteristic appearance and subjected to biochemical screening tests [9].

Confirmation: Presumptive positive isolates are confirmed using a combination of biochemical tests and molecular methods. The BAM specifically incorporates real-time PCR confirmation and the GalaxyTrakr SeqSero2 Workflow for serotype prediction, representing the integration of modern genomic tools into traditional microbiological analysis [9].

Research Reagent Solutions and Essential Materials