ELISA vs. Lateral Flow: A Critical Sensitivity Comparison for Peanut Allergen Detection

This article provides a comprehensive analysis of the sensitivity and operational characteristics of Enzyme-Linked Immunosorbent Assay (ELISA) and Lateral Flow Immunoassay (LFIA) for detecting major peanut allergens, including Ara h...

ELISA vs. Lateral Flow: A Critical Sensitivity Comparison for Peanut Allergen Detection

Abstract

This article provides a comprehensive analysis of the sensitivity and operational characteristics of Enzyme-Linked Immunosorbent Assay (ELISA) and Lateral Flow Immunoassay (LFIA) for detecting major peanut allergens, including Ara h 1, Ara h 2, and Ara h 3. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of these immunoassays, details methodological protocols and real-world applications, discusses troubleshooting and optimization strategies to overcome technical limitations, and presents a rigorous validation and comparative assessment of performance metrics. The synthesis of current research aims to inform method selection for food safety monitoring, clinical diagnostics, and the development of next-generation allergen detection technologies.

Understanding Peanut Allergens and Immunoassay Fundamentals

Peanut allergy is a significant global health concern, potentially triggering severe and life-threatening anaphylactic reactions. The major peanut allergens—Ara h 1, Ara h 2, Ara h 3, and Ara h 6—are seed storage proteins with distinct molecular characteristics and clinical impacts. This review compares the clinical significance of these allergens, focusing on their prevalence, stability, and role in diagnosis. Furthermore, it critically evaluates two primary immunochemical detection methodologies, Enzyme-Linked Immunosorbent Assay (ELISA) and Lateral Flow Immunoassay (LFIA), within the context of peanut allergen research. By synthesizing data on protein stability, IgE reactivity, and assay performance, this guide provides researchers and drug development professionals with a foundation for selecting appropriate analytical tools for allergen detection, risk assessment, and therapeutic development.

Peanut allergy affects an estimated 1-2% of the population in Western nations and typically persists into adulthood, creating a lifelong risk of anaphylaxis for sensitized individuals [1]. The allergic response is an IgE-mediated process where initial exposure to peanut allergens activates T helper 2 (Th2) cells, leading to IgE antibody production. These IgE antibodies bind to Fc epsilon receptors on mast cells and basophils, sensitizing the immune system. Upon re-exposure, the allergen cross-links surface IgE molecules, triggering degranulation and release of inflammatory mediators like histamine and leukotrienes, which cause the clinical symptoms of allergy [2]. The severity of these reactions is influenced by which specific peanut proteins an individual is sensitized to, with certain allergens carrying a higher risk for systemic responses.

Clinical Significance of Major Peanut Allergens

The clinical importance of a peanut allergen is determined by its prevalence of IgE recognition among allergic populations and its inherent biophysical properties, which influence how it interacts with the immune system. The major allergens Ara h 1, Ara h 2, Ara h 3, and Ara h 6 are recognized by the serum IgE of over 50% of peanut-allergic patients and are responsible for the majority of severe reactions [3] [1].

Table 1: Molecular Characteristics and Clinical Prevalence of Major Peanut Allergens

| Allergen | Protein Family | Molecular Function | IgE Recognition Prevalence | Resistance to Digestion | Risk Association |

|---|---|---|---|---|---|

| Ara h 1 | Cupin (7S vicilin) | Seed storage protein, forms trimers and higher oligomers [3] | Major allergen (>50% of patients) [3] | Rapidly hydrolyzed by pepsin [4] | Increased risk of severe symptoms when sensitized [1] |

| Ara h 2 | Prolamin (2S albumin) | Seed storage protein, trypsin inhibitor, 5-helix bundle with 4 disulfide bonds [3] | Major allergen, considered one of the most potent [3] | Highly resistant to pepsin and trypsin [4] | Strongly associated with severe symptoms and anaphylaxis [1] |

| Ara h 3 | Cupin (11S legumin) | Seed storage protein, trypsin inhibitor, forms hexamers [3] | Major allergen (>50% of patients) [3] | Rapidly hydrolyzed by pepsin [4] | Increased risk of severe symptoms when sensitized [1] |

| Ara h 6 | Prolamin (2S albumin) | Seed storage protein, shares 59% sequence identity with Ara h 2 [3] | Major allergen, similar allergenic activity to Ara h 2 [3] | Highly resistant to pepsin [4] | Strongly associated with severe symptoms and anaphylaxis [1] |

Key Differentiators of Clinical Severity

The data in Table 1 reveals critical factors that differentiate the clinical impact of these allergens:

- Protein Stability: Ara h 2 and Ara h 6 demonstrate remarkable stability against digestion due to their dense, disulfide-bonded structures [4] [3]. This resistance allows them to reach the intestinal immune system in a largely intact, immunologically active form, which is a key factor in their potency.

- Abundance vs. Potency: While Ara h 1 and Ara h 3 are abundant storage proteins in peanut, Ara h 2 and Ara h 6 are recognized more frequently and strongly by IgE from peanut-allergic individuals. It is estimated that 97% of peanut allergy patients are sensitized to at least one of Ara h 1, Ara h 2, or Ara h 3 [1]. Despite lower abundance, Ara h 2 and Ara h 6 are considered the most clinically relevant due to their high IgE-binding capacity [5].

- Cross-Reactivity: Ara h 2 and Ara h 6, with their 59% sequence identity and nearly identical 3D structures, show high IgE cross-reactivity. Sensitization to one often implies reactivity to the other, and they are collectively considered the most potent peanut allergens [3].

Detection Methodologies: ELISA vs. Lateral Flow Immunoassays

The accurate detection and quantification of peanut allergens are crucial for food safety, regulatory compliance, and clinical research. ELISA and LFIA are two cornerstone techniques in this field, each with distinct advantages and limitations.

Enzyme-Linked Immunosorbent Assay (ELISA)

ELISA is a widely used laboratory technique known for its high sensitivity, quantitative results, and reliability. It is often considered the reference method for allergen quantification.

- Experimental Protocol for Peanut Allergen Detection: A sensitive and specific competitive ELISA protocol for detecting Ara h 2 has been developed. The method involves coating a microtiter plate with purified Ara h 2. Sample extracts or standards are then mixed with rabbit anti-Ara h 2 polyclonal antibodies and added to the wells. The free antibodies bind to the immobilized Ara h 2. After washing, an enzyme-conjugated secondary antibody (e.g., Goat anti-Rabbit IgG) is added, followed by a colorimetric substrate. The resulting signal is inversely proportional to the allergen concentration in the sample [6] [5].

- Performance Data: The developed competitive Ara h 2 ELISA demonstrates a limit of detection (LOD) of 0.5 ppm (mg/kg) of peanut protein and a quantitative range of 0.8–6.8 ppm. This assay showed superior performance in recovering peanut from processed matrices like fried and high-pressure processed (HPP) pastries compared to some commercial kits [6]. Another ELISA protocol designed for peanut seeds achieved precise quantification of five allergens (Ara h 1, Ara h 2, Ara h 3, Ara h 6, and Ara h 8) across a wide range of concentrations in different peanut genotypes [5].

Lateral Flow Immunoassay (LFIA)

LFIA, or lateral flow test, is a rapid, user-friendly, and portable technology ideal for on-site screening. Its design is typically less complex than ELISA, relying on capillary flow to move the sample across a nitrocellulose membrane containing test and control lines.

- Experimental Protocol: In a typical sandwich format LFIA for allergen detection, the sample is applied to a sample pad. It migrates to a conjugate pad containing colored or fluorescent nanoparticles (e.g., carbon, gold) coated with capture antibodies. If the target allergen is present, it binds to these antibodies. The complex continues to flow along the strip until it reaches the test line, which is immobilized with a second allergen-specific antibody. This results in the capture of the complex and a visible line. A control line confirms the test has functioned correctly [7].

- Performance Data and Innovations: Research into improving LFIAs has yielded very fast assays, with some achieving results in as little as 1 minute, though most are completed within 10 minutes [7]. The limits of detection for multiplexed LFIAs (detecting both hazelnut and peanut) have been reported as low as 0.1 ppm for total hazelnut protein and 0.5 ppm for total peanut protein in buffer, and 0.5-1 ppm for both when spiked into a food matrix [7]. A key innovation is the use of smartphone analysis for result interpretation, which improves objectivity and allows for data transmission [7].

Table 2: Comparative Analysis of ELISA and LFIA for Peanut Allergen Detection

| Feature | ELISA | Lateral Flow Immunoassay (LFIA) |

|---|---|---|

| Format | Microtiter plate, laboratory-based | Compact, single-use strip, portable |

| Assay Time | Several hours | 1 - 20 minutes [7] |

| Data Output | Quantitative | Typically qualitative or semi-quantitative |

| Sensitivity | High (LOD for Ara h 2: 0.5 ppm) [6] | Variable; can be very high (LOD for peanut: 0.5 ppm in matrix) [7] |

| Throughput | High (can run many samples simultaneously) | Low (single sample per strip) |

| Ease of Use | Requires technical expertise and equipment | Simple, minimal training required |

| Multiplexing Capability | Low (typically single analyte per well) | Good, but design is challenging [7] |

| Key Limitation | Time-consuming, not for on-site use | Susceptible to hook effect at high allergen concentrations [7] |

| Ideal Application | Regulatory testing, quantitation, research | Rapid screening, field tests, point-of-care |

IgE-Mediated Allergic Response Pathway

The Scientist's Toolkit: Essential Research Reagents and Materials

The development and execution of reliable immunoassays for peanut allergen detection depend on a suite of critical reagents. The following table details key components used in state-of-the-art protocols.

Table 3: Essential Research Reagents for Peanut Allergen Immunoassays

| Reagent / Material | Function in the Assay | Specific Examples from Literature |

|---|---|---|

| Purified Allergen Standards | Serve as a reference for calibration and quantification; essential for generating standard curves. | Natural Ara h 1, Ara h 2, Ara h 3, Ara h 6, Ara h 8 purified from peanut flour [5]. |

| Monoclonal & Polyclonal Antibodies | Provide the core specificity of the immunoassay; used as both capture and detection antibodies. | Anti-Ara h 2 polyclonal antibodies from rabbits [6]; MAbs 2C12 (Ara h 1), 1E8 (Ara h 3), 3B8 (Ara h 6) [5]. |

| Enzyme Conjugates & Substrates | Enable signal generation in ELISA; an enzyme linked to an antibody catalyzes a colorimetric reaction. | Goat anti-Rabbit IgG conjugated to Horseradish Peroxidase (HRP); ABTS as the chromogenic substrate [5]. |

| Solid-Phase Supports | Provide the surface for immobilizing capture antibodies or antigens. | Microtiter plates for ELISA; Nitrocellulose membranes with specific flow rates (e.g., 140 CN) for LFIA [7] [5]. |

| Labeling Nanoparticles | Act as the signal tag in LFIA, creating a visible line for detection. | Carbon nanoparticles ("Spezial Schwartz 4") used in flow-through and lateral flow assays [7]. |

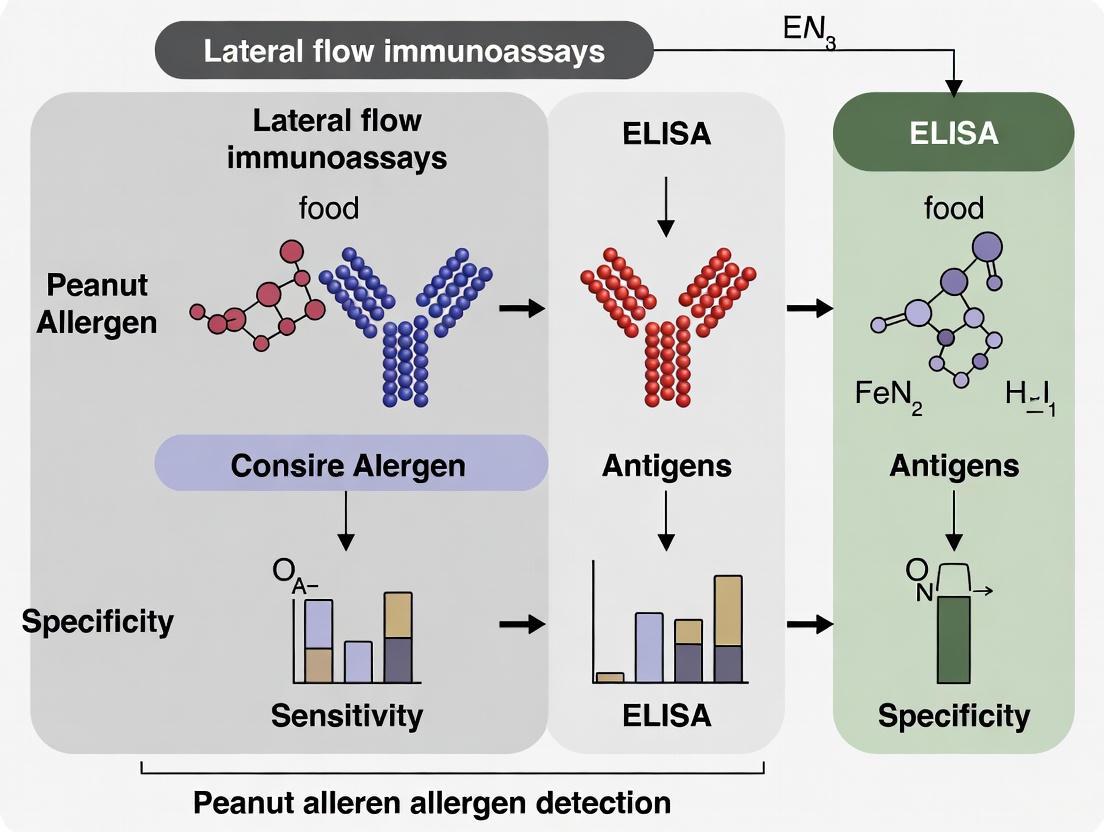

Lateral Flow Immunoassay Workflow

The major peanut allergens Ara h 1, Ara h 2, Ara h 3, and Ara h 6 are of paramount clinical significance, with Ara h 2 and Ara h 6 standing out due to their exceptional stability and potent IgE reactivity. The choice between ELISA and LFIA for their detection is not a matter of superiority but of application. ELISA remains the gold standard for laboratory-based quantification requiring high sensitivity and precision, as evidenced by assays with LODs down to 0.5 ppm. Conversely, LFIA offers an unparalleled advantage in speed and portability for rapid screening, with modern designs achieving results in minutes and approaching the sensitivity of ELISA. For comprehensive risk assessment and product safety, the synergistic use of both methods—using LFIA for initial screening and ELISA for confirmation and quantification—represents the most robust strategy. Future advancements in multiplexing, smartphone-based quantification, and the development of antibodies with even higher affinity and specificity will further empower researchers and clinicians in the ongoing effort to manage and mitigate peanut allergy.

Enzyme-Linked Immunosorbent Assay (ELISA) is a foundational technique in biomedical and food safety research, renowned for its high sensitivity and quantitative capabilities. In the context of peanut allergen detection, ELISA serves as a benchmark against which rapid, point-of-need tests like lateral flow immunoassays (LFIAs) are measured. This guide objectively compares the performance of these two methodologies, providing researchers with critical data to inform their analytical choices.

Core Principles of the ELISA Technique

The fundamental principle of ELISA is the specific binding between an antigen and an antibody, with the signal generated by an enzyme-linked reporter molecule that catalyzes a colorimetric, fluorescent, or chemiluminescent reaction. This signal, measured with a plate reader, is proportional to the amount of target analyte in the sample, enabling precise quantification.

Two primary formats are widely used for allergen detection:

- Sandwich ELISA: Ideal for detecting complex antigens, this format uses a capture antibody immobilized on a plate and an enzyme-conjugated detection antibody. The analyte is "sandwiched" between them, enhancing specificity. It is typically used for quantification in non-processed or mildly processed foods [8] [9].

- Competitive ELISA: Often employed for detecting small molecules or thermally processed allergens, this format involves sample antigens competing with a labeled antigen for a limited number of antibody binding sites. The signal is inversely proportional to the analyte concentration, making it highly effective for detecting degraded allergens in complex matrices [6].

Performance Comparison: ELISA vs. Lateral Flow Immunoassays

Direct comparisons of ELISA and LFIA reveal a consistent performance trade-off between sensitivity and speed. The following tables summarize experimental data from recent peer-reviewed studies.

Sensitivity and Detection Limits for Peanut Allergens

| Target Allergen | Assay Format | Reported Sensitivity (LOD) | Specificity | Source/Kit (if specified) |

|---|---|---|---|---|

| Ara h 1 | Sandwich ELISA | 10 ng/mL | Highly selective; no cross-reactivity with tree nuts | [9] |

| Ara h 1 | Lateral Flow (LFIA) | 500 ng/mL | Highly selective; no cross-reactivity with tree nuts | [9] |

| Ara h 3 | DAS-ELISA | 39.06 ng/mL | Low cross-reactivity; recovery rates 78.48-90.93% | [8] |

| Ara h 3 | Lateral Flow (LFIA) | 1.6 µg/mL (1600 ng/mL) | No cross-reactivity with other proteins | [8] |

| Peanut (via Ara h 2) | Competitive ELISA | 0.5 ppm (mg/kg) peanut protein | Cross-reactivity only with cloves from 45 ingredients tested | In-house developed assay [6] |

| Almond & Peanut | Lateral Flow Microimmunoassay (LFµIA) | Almond: 185 µg/kg; Peanut: 229 µg/kg | 77% selectivity | Multiplexing microarray format [10] |

Comparative Analysis of Operational Characteristics

| Characteristic | ELISA | Lateral Flow Immunoassay (LFIA) |

|---|---|---|

| Quantitative Capability | Fully quantitative, with standard curves and high precision (CVs < 10%) [8] | Primarily qualitative or semi-quantitative; advanced microarray formats enable improved quantification [10] |

| Throughput | High; can process 96+ samples simultaneously in a plate | Low to medium; single tests or small batches |

| Assay Time | Several hours (2-4 hours including incubation and washing steps) [10] | Minutes (typically 10-20 minutes) [10] [9] |

| Ease of Use | Requires trained personnel, multiple liquid handling steps, and plate washing | Simple; minimal training required, often a single-step procedure |

| Infrastructure Needs | Requires plate washers, readers, and laboratory environment | Portable; can be used at the point-of-need with visual or smartphone readout [10] |

| Multiplexing Potential | Low per plate; typically measures one analyte per well | Moderate; can detect multiple allergens on a single strip with dedicated test lines [10] |

| Cost per Test | Lower reagent cost, but higher overall cost when labor and equipment are factored in | Generally higher per-test cost, but lower operational overhead |

Detailed Experimental Protocols

To illustrate the experimental foundation of the data presented, here are detailed methodologies for key studies comparing both techniques.

This protocol outlines the development of a Double Antibody Sandwich (DAS) ELISA to evaluate the reduction of Ara h 3 antigenicity after heat-moisture treatment.

1. Antibody Production:

- Immunogen: Ara h 3 was purified from peanuts. Rabbits were immunized with the antigen to generate polyclonal antibodies.

- Antibody Purification: Antisera from immunized rabbits were purified using a Protein G column to isolate IgG antibodies.

2. Assay Procedure:

- Coating: Microtiter plates were coated with the purified capture antibody and incubated overnight at 4°C.

- Blocking: Plates were blocked with a protein-based blocking buffer (e.g., 4% skimmed milk) for 2 hours at room temperature to prevent non-specific binding.

- Sample Incubation: Samples and standards (heat-treated and native Ara h 3) were added to the wells and incubated.

- Detection Antibody Incubation: An enzyme-conjugated detection antibody (HRP-labeled) was added to form the "sandwich" complex.

- Washing: Plates were washed multiple times with a PBS-Tween buffer between each step to remove unbound material.

- Signal Development: A substrate solution (e.g., TMB) was added. The enzymatic reaction was stopped after a fixed time with a stop solution (e.g., sulfuric acid).

- Quantification: The absorbance was measured at 450 nm. A standard curve was generated from known concentrations of Ara h 3, and sample concentrations were interpolated from this curve.

3. Validation:

- Sensitivity: The limit of detection (LOD) was calculated to be 39.06 ng/mL.

- Precision: Intra-plate and inter-plate coefficients of variation were below 6.79% and 3.05%, respectively.

- Accuracy: Recovery rates from spiked samples ranged from 78.48% to 90.93%.

This protocol describes the development of a monoclonal antibody-based LFIA for rapid peanut detection.

1. Antibody and Conjugate Preparation:

- Antibody Generation: Monoclonal antibodies (MAbs) were generated against the native Ara h 1 protein.

- Conjugate Pad Preparation: Gold nanoparticles (AuNPs) or other labels were conjugated to the purified anti-Ara h 1 monoclonal antibodies.

2. Strip Assembly and Test Principle:

- Sample Pad: The sample is applied here, and the extracted food matrix migrates via capillary action.

- Conjugate Pad: Contains the dried antibody-conjugated labels. The analyte (Ara h 1) binds to the conjugates upon contact.

- Nitrocellulose Membrane: The core reaction site containing two key lines:

- Test Line: Immobilized with a second anti-Ara h 1 antibody (capture antibody) that binds the analyte-conjugate complex.

- Control Line: Immobilized with an anti-species antibody (e.g., anti-mouse) to capture the remaining conjugated antibodies, validating strip function.

- Absorbent Pad: Acts as a sink to wick the fluid through the strip.

3. Assay Execution and Reading:

- The extracted food sample is applied to the sample pad.

- The result is read visually within 10-20 minutes. The appearance of both control and test lines indicates a positive result. The absence of a test line indicates a negative result. The test is invalid if the control line does not appear.

Visualizing the Workflows

The following diagrams illustrate the fundamental workflow and key difference between the two assay formats.

The Scientist's Toolkit: Key Research Reagent Solutions

Successful implementation of these immunoassays relies on specific, high-quality reagents. The table below details essential components.

| Reagent / Material | Critical Function in Assay | Key Considerations |

|---|---|---|

| Capture & Detection Antibodies | Provide the core specificity for the target allergen (e.g., Ara h 1, Ara h 2, Ara h 3). | Specificity, affinity, and isotype are critical. Monoclonal antibodies offer high consistency; polyclonal can increase signal [9]. |

| Enzyme Conjugates | Enzymes like Horseradish Peroxidase (HRP) are linked to detection antibodies to generate a measurable signal. | Conjugation efficiency and enzyme activity stability directly impact assay sensitivity and background noise. |

| Protein Extraction Buffer | Extracts allergenic proteins from complex food matrices for analysis. | Must efficiently solubilize the target protein without degrading its antigenic epitopes, especially from processed foods [8]. |

| Nitrocellulose Membrane | The porous matrix in LFIA where capture antibodies are immobilized at test and control lines. | pore size affects flow rate and sensitivity. Requires precise dispensing of antibodies [10]. |

| Nanoparticle Reporters | Gold nanoparticles or colored latex beads used as labels in LFIA for visual detection. | Size, shape, and surface chemistry affect conjugation efficiency, stability, and visual intensity [10]. |

| Microtiter Plates | The solid phase for ELISA, typically 96-well plates, where the capture antibody is immobilized. | Binding capacity and well-to-well consistency are vital for reproducible quantitative results. |

| Blocking Buffers | Solutions of irrelevant proteins (e.g., BSA, casein, skim milk) used to cover non-specific binding sites. | Effectiveness determines the signal-to-noise ratio by minimizing background. |

The choice between ELISA and lateral flow immunoassay is not a matter of which is superior, but which is most fit-for-purpose. ELISA remains the undisputed gold standard for laboratory-based quantification, offering unparalleled sensitivity, precision, and robustness for compliance monitoring and in-depth research, particularly when analyzing complex or processed food samples [8] [6]. Lateral flow immunoassays provide an indispensable tool for rapid, on-site screening, enabling decision-making at the processing line or in supply chain audits, albeit with higher detection limits [10] [9].

The ongoing development of epitope-specific antibodies [8] and advanced multiplexing lateral flow platforms [10] continues to narrow the performance gap. However, for the core task of sensitive and quantitative allergen detection in a controlled laboratory setting, ELISA maintains its foundational status.

Lateral Flow Immunoassays (LFIAs) represent a cornerstone technology in point-of-care diagnostics, offering an unparalleled combination of speed, portability, and user-friendliness. These paper-based platforms enable the detection and quantification of analytes in complex mixtures within 5-30 minutes, requiring no external equipment or specialized technical expertise [11]. The fundamental principle behind LFIA is simple: a liquid sample moves via capillary action through various zones of polymeric strips containing molecules that interact with the target analyte [11]. First described in the late 1970s, LFIAs gained widespread recognition through home pregnancy tests and have since expanded into clinical diagnostics, food safety, environmental monitoring, and veterinary medicine [11] [12]. Their low development costs, ease of production, long shelf life, and minimal storage requirements make them particularly valuable for resource-limited settings, remote regions, and battlefield medicine [11].

This guide examines the core principles of LFIA technology, with a specific focus on performance comparisons with Enzyme-Linked Immunosorbent Assays (ELISAs) in the critical context of peanut allergen detection. Peanut allergy represents one of the most severe and persistent food allergies, affecting 1-3% of the population in developed countries, where sub-milligram levels of peanut protein can trigger reactions in sensitive individuals [13]. Accurate detection of peanut allergens like Ara h 1, Ara h 2, and Ara h 6 is therefore essential for food safety and public health. We present experimental data, methodological protocols, and technical specifications to provide researchers and drug development professionals with a comprehensive understanding of how LFIAs compare to traditional ELISA methods in sensitivity, specificity, and practical application.

Core Principles and Components of Lateral Flow Immunoassays

Fundamental Architecture and Mechanism

The operational principle of LFIAs centers on capillary action moving a liquid sample through a series of overlapping membranes mounted on a backing card for stability [11]. A typical LFIA device consists of four essential components: sample pad, conjugate pad, nitrocellulose membrane, and absorbent pad [11] [14]. The sample application pad serves as the entry point, where the liquid sample is applied. This pad is often impregnated with buffer salts, proteins, and surfactants that prepare the sample for optimal interaction with detection components [11]. The treated sample then migrates to the conjugate release pad, which contains detection antibodies specific to the target analyte. These antibodies are conjugated to colored or fluorescent particles, most commonly colloidal gold (40-80 nm) or latex microspheres (100-300 μm) [11] [14].

The sample-conjugate mixture continues flowing onto the nitrocellulose membrane, which contains pre-immobilized capture antibodies in defined test and control lines. As the complex passes through these lines, specific binding events occur, generating visible or detectable signals [11]. The control line validates proper assay function, while the test line indicates analyte detection. Finally, the absorbent pad at the terminal end wicks excess fluid, maintaining consistent flow and preventing backflow [11]. The entire process typically completes within 5-30 minutes, with results interpretable by eye or dedicated readers [11].

Assay Formats and Detection Modalities

LFIAs employ primarily three formats tailored to different analytical targets. Sandwich assays are ideal for larger analytes with multiple antigenic sites, such as proteins or whole pathogens. In this format, the target analyte is immobilized between two complementary antibodies - one conjugated to a detector particle and the other immobilized on the test line [11] [15]. The presence of the analyte generates a visible test line, indicating a positive result [11]. Competitive assays are suited for small molecules with single antigenic determinants that cannot bind two antibodies simultaneously. In this format, the analyte in the sample blocks binding sites on test line antibodies, preventing interaction with the labeled conjugate. Thus, a positive result is indicated by the absence or diminished intensity of the test line [11] [15]. Direct detection assays utilize antigens immobilized on the test line to capture specific antibodies from the sample, with signal generation achieved through labeled anti-species antibodies [14].

Recent advancements have introduced sophisticated detection labels beyond traditional colloidal gold. Fluorescent nanoparticles, quantum dots, paramagnetic particles, and gap-enhanced Raman tags (GERTs) offer enhanced sensitivity and quantification capabilities [14] [16]. GERTs, with Raman reporter molecules embedded in nanogaps between metallic core and shell structures, demonstrate exceptional photostability and signal reproducibility, enabling detection limits as low as 0.65 pg/mL for cardiac troponin I - an improvement of 2-3 orders of magnitude over conventional colloidal gold [16]. These innovations address traditional LFIAs' limitations in sensitivity and quantification while maintaining the platform's fundamental advantages.

Table 1: Key Components of a Lateral Flow Immunoassay Strip

| Component | Material Options | Primary Function | Key Considerations |

|---|---|---|---|

| Sample Pad | Cotton, glass fiber, cellulose | Receives sample; distributes evenly; may filter particulates | Wicking rate, volume capacity, pre-treatment requirements |

| Conjugate Pad | Glass fiber, polyester, sintered polyethylene | Stores and releases labeled bioreagents | Stability during drying, conjugate release efficiency |

| Nitrocellulose Membrane | Nitrocellulose with proprietary surfactants | Matrix for immobilizing capture reagents; site for detection | Capillary flow rate, protein binding capacity, uniformity |

| Absorbent Pad | High-density cellulose | Drives fluid flow; wicks excess reagents | Capacity, wicking rate, compatibility with membrane |

Diagram 1: Lateral Flow Immunoassay Workflow and Components. This diagram illustrates the sequential flow of a liquid sample through the key components of a lateral flow test strip, with each component performing specific functions in the assay process.

Sensitivity Comparison: LFIA vs. ELISA for Peanut Allergen Detection

Quantitative Performance Metrics

The comparative analysis between LFIAs and ELISAs for peanut allergen detection reveals a consistent pattern: while ELISAs generally offer superior sensitivity, modern LFIAs have closed this gap significantly through technological advancements. In direct comparisons for walnut trace detection, ELISA demonstrated a sensitivity of 0.25 µg/g of walnut protein in spiked food matrices, whereas LFIA achieved 0.5 µg/g [17]. Both methods exhibited high specificity, with cross-reactivity observed only with pecan nut among 88 food ingredients tested [17]. For peanut allergen Ara h 1 detection, ELISA reached a remarkable sensitivity of 10 ng/mL, while LFIA achieved 500 ng/mL using the same monoclonal antibodies [9].

Recent innovations have substantially enhanced LFIA sensitivity. Surface-enhanced Raman scattering (SERS)-based LFIAs utilizing gap-enhanced Raman tags (GERTs) have demonstrated detection limits approaching 0.65 pg/mL for cardiac troponin I, surpassing conventional fluorescence-based methods and rivaling ELISA sensitivities [16]. This 2-3 order of magnitude improvement over traditional colloidal gold LFIAs highlights the potential of advanced detection methodologies. Furthermore, a novel IgE epitope-specific antibodies-based sandwich ELISA for Ara h 2 detection achieved a limit of detection of 0.98 ng/mL with high accuracy (mean bias of 0.88%) and precision (relative standard deviation <16.50%) [13], showcasing the continued evolution of both technologies.

Table 2: Sensitivity Comparison of ELISA and LFIA for Allergen Detection

| Allergen Target | Assay Type | Detection Limit | Specificity Notes | Reference |

|---|---|---|---|---|

| Walnut Protein (Jug r 1) | Sandwich ELISA | 0.25 µg/g (food matrix) | Cross-reactivity only with pecan nut (88 ingredients tested) | [17] |

| Walnut Protein (Jug r 1) | Lateral Flow Immunoassay | 0.5 µg/g (food matrix) | Identical specificity profile to ELISA | [17] |

| Peanut Ara h 1 | Sandwich ELISA | 10 ng/mL (peanut meal) | No cross-reactivity with tree nut meals (100-0.4 µg/mL) | [9] |

| Peanut Ara h 1 | Lateral Flow Immunoassay | 500 ng/mL (peanut meal) | Identical specificity profile to ELISA | [9] |

| Peanut Ara h 2 | IgE Epitope-specific ELISA | 0.98 ng/mL | Specific to IgE epitopes of Ara h 2 | [13] |

Experimental Protocols and Methodologies

ELISA Protocol for Peanut Allergen Detection

The development of a sensitive ELISA for peanut allergen detection typically follows a sandwich immunoassay format. For Ara h 1 detection, researchers generated monoclonal antibodies against the target protein through hybridoma technology [9]. The optimized protocol involves: (1) coating microplate wells with capture antibody (1-2 µg/mL in carbonate-bicarbonate buffer, pH 9.6) overnight at 4°C; (2) blocking with protein-based blockers (BSA or casein) for 1-2 hours at room temperature; (3) adding samples and standards diluted in PBS-Tween buffer, incubating 1-2 hours; (4) adding detection antibody conjugated to horseradish peroxidase (HRP) or biotin, incubating 1-2 hours; (5) adding substrate solution (TMB or other chromogenic substrates) and incubating 15-30 minutes; and (6) stopping the reaction with acid and measuring absorbance at 450 nm [9] [13]. The entire process requires 4-6 hours with multiple washing steps between each stage.

For enhanced specificity towards allergenic potential, researchers have developed IgE epitope-specific ELISAs. In the case of Ara h 2 detection, this involved generating a monoclonal antibody against a major IgE epitope of Ara h 2 as the capture antibody, and a polyclonal antibody against twelve IgE epitopes of Ara h 2 as the detection antibody [13]. This approach specifically detects IgE-reactive epitopes rather than merely the protein presence, potentially correlating better with clinical allergenicity.

LFIA Protocol for Peanut Allergen Detection

The development of an LFIA for peanut allergen detection shares similarities with ELISA in antibody selection but differs substantially in execution. For Ara h 1 detection, the same monoclonal antibodies used in ELISA were adapted to the lateral flow format [9]. The standard protocol involves: (1) conjugating detection antibodies to colloidal gold nanoparticles (40 nm) through passive adsorption in low ionic strength buffer, followed by blocking with proteins like BSA or casein; (2) applying the conjugate to a glass fiber pad; (3) striping capture antibodies and control antibodies on nitrocellulose membranes at concentrations of 1-3 µg/cm using precision dispensing systems; (4) assembling the component layers (sample pad, conjugate pad, membrane, absorbent pad) on a backing card with 1-2 mm overlaps; and (5) cutting the assembled card into individual test strips [11] [9]. During operation, the sample is applied to the sample pad, migrates through the conjugate pad to solubilize and bind the detection conjugates, and continues flowing across the membrane where test and control lines capture the complexes. Results are typically available within 5-20 minutes.

Critical to LFIA performance is the meticulous selection of membrane properties, particularly the capillary flow time of nitrocellulose membranes, which balances assay speed and sensitivity [15] [18]. Fast-flowing membranes (e.g., Hi-Flow Plus 65) suit speed-critical tests, while slow-flowing membranes (e.g., Hi-Flow Plus 180) benefit high-sensitivity applications requiring longer interaction times [18].

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful development of either ELISA or LFIA for peanut allergen detection requires careful selection of core reagents and materials. Antibodies stand as the most critical component, with monoclonal antibodies generally preferred for their minimal batch-to-batch variability, especially as capture antibodies [15]. For LFIAs intended for commercial production, the substantial antibody quantities required (approximately 1 gram per million tests) make consistent supply and quality paramount [14].

Table 3: Essential Research Reagents for Allergen Immunoassay Development

| Reagent/Material | Function | Key Selection Criteria | Examples/Alternatives |

|---|---|---|---|

| Monoclonal Antibodies | Primary detection and capture reagents | Affinity (fast kon, slow koff), specificity, lot-to-lot consistency | Anti-Ara h 1 MAbs, Anti-Jug r 1 MAbs |

| Polyclonal Antibodies | Detection or control line reagents | Broad epitope recognition, sensitivity, species specificity | Anti-species IgG, epitope-specific pAbs |

| Colloidal Gold Nanoparticles | Visual detection label in LFIA | Particle size (40-80 nm), stability, conjugation efficiency | 40 nm colloidal gold |

| Latex Microspheres | Visual/fluorescent detection label | Size (100-300 μm), dye incorporation, surface chemistry | Estapor Microspheres |

| Nitrocellulose Membranes | Porous matrix for test/control lines | Capillary flow time, protein binding capacity, uniformity | Hi-Flow Plus Membranes |

| Sample/Conjugate Pads | Sample application and conjugate storage | Material composition, wicking rate, compatibility | SureWick Pad Materials |

| HRP Enzymes & Substrates | Signal generation in ELISA | Catalytic efficiency, substrate sensitivity, background | TMB, HRP-Conjugated Antibodies |

Membranes represent another crucial component, with nitrocellulose remaining the gold standard for its optimal balance of capillary flow and protein binding characteristics [11] [18]. The capillary flow time - the time required for liquid to travel through and completely fill a membrane segment - serves as a more accurate selection parameter than pore size alone [11]. For high-sensitivity applications, slower flow rates (e.g., 180-200 seconds for 4 cm) increase interaction times between analytes and capture antibodies, enhancing detection limits [18].

Detection labels significantly influence sensitivity and readout options. While colloidal gold offers intense color and ease of use, fluorescent labels like Estapor Microspheres enable quantitative measurements and multiplexing [18]. For ultimate sensitivity, emerging technologies like gap-enhanced Raman tags (GERTs) provide photostable, reproducible signals with detection limits in the pg/mL range, though they require specialized readers [16]. The choice between these options depends on the specific application requirements regarding sensitivity, quantification needs, equipment availability, and cost constraints.

Lateral Flow Immunoassays and ELISAs represent complementary technologies in peanut allergen detection, each with distinct advantages suited to different applications. ELISAs maintain superiority in laboratory settings where maximum sensitivity, precision, and throughput are paramount, with detection limits reaching 0.98 ng/mL for Ara h 2 using epitope-specific approaches [13]. LFIAs, while generally less sensitive, offer rapid results (5-30 minutes), simplicity of use, and portability for point-of-need testing, detecting walnut traces at 0.5 µg/g in complex food matrices [17]. The core principles of LFIA - capillary flow through porous membranes, specific antibody-antigen interactions, and visual or instrument-based signal detection - make them indispensable tools for field testing, manufacturing facilities, and clinical point-of-care applications.

Technological advancements continue to narrow the sensitivity gap between these platforms. Innovations in label technology, particularly SERS-based tags like GERTs, have enhanced LFIA sensitivity by 2-3 orders of magnitude, approaching ELISA-level performance while maintaining the rapid, portable format [16]. Similarly, the development of epitope-specific antibodies in ELISA formats enables more biologically relevant detection of allergenic potential rather than mere protein presence [13]. For researchers and drug development professionals, the selection between ELISA and LFIA ultimately depends on the specific application requirements, balancing sensitivity needs with operational constraints. As both technologies continue to evolve, their complementary roles in food safety and clinical diagnostics will expand, offering increasingly sophisticated tools for protecting allergic individuals from accidental exposure to peanut allergens.

The accurate detection of food allergens, such as peanut, is paramount for protecting public health. Immunoassays, primarily Lateral Flow Immunoassays (LFA) and Enzyme-Linked Immunosorbent Assays (ELISA), are cornerstone techniques for this purpose. The reliability of the data generated by these methods hinges on a clear understanding and rigorous application of key performance metrics: the Limit of Detection (LOD), Limit of Quantitation (LOQ), Specificity, and Cross-Reactivity. These parameters form the foundation of any robust analytical method, ensuring that results are not only detectable but also accurate, precise, and specific to the target analyte. Within the context of peanut allergen research, comparing these metrics between the rapid, on-site LFA and the laboratory-based, quantitative ELISA is critical for method selection and data interpretation. This guide provides an objective comparison of these technologies, underpinned by experimental data and detailed protocols.

Defining the Core Analytical Metrics

Limit of Blank (LoB), Limit of Detection (LOD), and Limit of Quantitation (LOQ)

The lowest levels of analyte detection and quantification are formally defined by a hierarchy of metrics. The Limit of Blank (LoB) is the highest apparent analyte concentration expected to be found when replicates of a blank sample (containing no analyte) are tested. It is calculated as LoB = mean_blank + 1.645(SD_blank), identifying the threshold above which a signal is unlikely to be merely background noise [19].

The Limit of Detection (LOD) is the lowest analyte concentration that can be reliably distinguished from the LoB. It is determined using both the LoB and test replicates of a sample containing a low concentration of analyte. The formula LOD = LoB + 1.645(SD_low concentration sample) ensures that 95% of measurements at the LOD will correctly be identified as positive [19]. Simpler approaches, accepted by guidelines like ICH Q2(R1), calculate LOD directly based on the standard deviation of the response and the slope of the calibration curve (LOD = 3.3 * σ / S) or by using a signal-to-noise ratio of 3:1 [20].

The Limit of Quantitation (LOQ) is the lowest concentration at which the analyte can not only be detected but also quantified with acceptable precision and trueness (bias). It represents a higher threshold of confidence than the LOD and is calculated as LOQ = 10 * σ / S or defined by a signal-to-noise ratio of 10:1 [19] [20]. The LOQ may be equivalent to the LOD, but is often at a much higher concentration, and it is at this level that predefined goals for bias and imprecision must be met [19].

Specificity and Cross-Reactivity

Specificity refers to an assay's ability to exclusively measure the intended biomarker or analyte without interference from other substances present in the sample matrix [21]. In immunoassays, this characteristic is primarily determined by the antibodies used. A highly specific assay will generate a true positive signal only for the target analyte, minimizing false positives.

Cross-Reactivity is the practical challenge to specificity. It occurs when assay reagents, particularly antibodies, bind to molecules structurally similar to the intended target, leading to a false positive signal [21]. For example, an assay for walnut might show cross-reactivity with pecan nut due to protein similarities [17]. Cross-reactivity is quantitatively expressed as a percentage, calculated by comparing the assay's response to the interfering substance versus its response to the target analyte [22].

Experimental Comparison: LFA vs. ELISA for Peanut Allergens

The following table summarizes experimental data for peanut allergen detection from recent studies, allowing for a direct comparison of LFA and ELISA performance.

Table 1: Comparative Performance Metrics for Peanut Allergen Detection using LFA and ELISA

| Immunoassay Format | Specific Target | Reported LOD | Reported LOQ | Matrix | Assay Time | Key Cross-Reactivity Findings |

|---|---|---|---|---|---|---|

| Lateral Flow (LFµIA) [10] | Total Peanut Protein | 229 µg/kg | Not Specified | Food | 10 min | High selectivity (77%) reported; specific cross-reactants not listed. |

| Lateral Flow (Optimized) [7] | Total Peanut Protein (TPP) | 0.5 ppm (µg/g) | Not Specified | Buffer & Food Matrix | 10 min | No significant cross-reactivity with hazelnut (co-detected). |

| Sandwich ELISA [22] | Synthetic Cannabinoid (JWH-200) | 0.04 ± 0.02 ng mL⁻¹ | Not Specified | Oral Fluids | > several hours | Excellent specificity; cross-reactivity with AM-2233 (5.6%) and AM-1220 (4.7%). |

| Lateral Flow (This Context) [22] | Synthetic Cannabinoid (JWH-200) | 0.08 ± 0.04 ng mL⁻¹ | Not Specified | Oral Fluids | 15 min | Excellent specificity; cross-reactivity with AM-2233 (5.6%) and AM-1220 (4.7%). |

Table 2: Methods for Determining LOD and LOQ [19] [20]

| Evaluation Method | Description | Typical Application | Calculation (Simplified) |

|---|---|---|---|

| Signal-to-Noise (S/N) | Compares analyte signal against baseline noise. | Instrumental methods (e.g., HPLC). | LOD: S/N = 3; LOQ: S/N = 10 |

| Standard Deviation & Slope | Uses the SD of the response and the slope of the calibration curve. | Quantitative methods (e.g., ELISA, photometry). | LOD = 3.3 * (σ/S); LOQ = 10 * (σ/S) |

| Visual Examination | Determination by analyzing samples with known concentrations. | Non-instrumental methods (e.g., microbial inhibition). | Established by observed minimum level. |

Detailed Experimental Protocols

To ensure reproducibility, the core experimental workflows for developing and validating both LFA and ELISA are outlined below.

Protocol 1: Development of a Lateral Flow Immunoassay for Peanut Allergen Detection [10] [7]

- Reagent Preparation: Polyclonal antibodies against peanut protein extracts are raised in rabbits. Antibodies are purified using affinity columns (e.g., HiTrap Protein G HP). Gold nanoparticles (AuNPs) are synthesized and characterized.

- Conjugate Pad Preparation: The purified anti-peanut antibodies are bioconjugated to the AuNPs. This conjugate is dispensed onto a glass fiber pad and dried.

- Membrane Biofunctionalization: A nitrocellulose membrane is printed in a microarray format using a precision dispenser. The following are immobilized:

- Test Zones: Capture antibodies (anti-peanut) at a defined concentration (e.g., 2.0 mg/mL).

- Control Zone: An anti-species antibody (e.g., goat anti-rabbit IgG) to confirm proper flow.

- Hook Effect Spots: Pure peanut protein (e.g., 2.0 mg/mL) to identify high-dose hook effects.

- Assembly: The biofunctionalized membrane, conjugate pad, sample pad, and absorbent pad are assembled onto a laminated backing card and cut into individual strips.

- Assay Procedure: A sample extract (100 µL) is applied to the sample pad. The result is read after 10 minutes, either visually or quantitatively using a smartphone and image analysis software (e.g., Image J).

- Validation: The LOD is calculated as the mean optical density (OD) of the blank + 3 standard deviations (SD). The dynamic range is determined from the calibration curve.

Protocol 2: Enzyme-Linked Immunosorbent Assay (ELISA) [23] [24]

- Coating: A 96-well polystyrene microtiter plate is coated with a capture antibody specific to the target allergen (e.g., 100 µL in carbonate buffer, pH 9.6). The plate is incubated and then washed to remove unbound antibody.

- Blocking: Remaining binding sites on the plate are blocked with a protein solution (e.g., 1% BSA or casein) to reduce nonspecific binding.

- Sample Incubation: Standards (calibrators) and unknown samples are added to the wells. Allergenic proteins in the sample bind to the immobilized capture antibodies. The plate is incubated and washed.

- Detection Antibody Incubation: A second, enzyme-linked detection antibody (e.g., HRP-conjugated) specific to the allergen is added. This forms an antibody-analyte-antibody "sandwich." The plate is incubated and washed again.

- Signal Generation: A substrate solution is added (e.g., TMB for HRP). The enzyme catalyzes a reaction, producing a color change.

- Signal Measurement & Quantification: The reaction is stopped (e.g., with sulfuric acid), and the absorbance is measured with a spectrophotometer. Color intensity is proportional to the allergen concentration, which is determined by interpolation from the standard curve.

Visualizing Metrics and Workflows

Figure 1: Relationship between LoB, LOD, and LOQ. The LOD is statistically derived from both blank and low-concentration sample data, while the LOQ represents a higher threshold for reliable quantification [19].

Figure 2: The impact of specificity and cross-reactivity on assay results. A highly specific assay generates a signal only from the target, while cross-reactivity with similar molecules leads to false positives [21].

Essential Research Reagent Solutions

The performance of any immunoassay is critically dependent on the quality of its reagents. The table below details key materials required for developing and running LFA and ELISA for allergen detection.

Table 3: Essential Research Reagents for Immunoassay Development [23] [22] [10]

| Reagent Category | Specific Examples | Critical Function in the Assay |

|---|---|---|

| Antibodies | Anti-peanut protein polyclonal or monoclonal antibodies; Purified IgG. | Form the core of assay specificity; used for both capture and detection of the target analyte. |

| Solid Supports | Nitrocellulose membrane (LFA); Polystyrene microtiter plates (ELISA). | Provides the surface for immobilizing capture bioreagents and the platform for the assay workflow. |

| Labels & Conjugates | Gold nanoparticles (AuNPs); Horseradish Peroxidase (HRP); Alkaline Phosphatase (AP). | Generates a detectable signal (colorimetric, chemiluminescent) proportional to the analyte concentration. |

| Blocking Buffers | Bovine Serum Albumin (BSA); Casein; Host serum; Commercial protein-free blockers. | Reduces nonspecific binding by blocking unused sites on the solid support, lowering background noise. |

| Buffer Systems | PBS; TBS; Carbonate-Bicarbonate (Coating); with additives like Tween-20. | Maintains optimal pH and ionic strength for immunoreactions; washing removes unbound material. |

| Signal Generation | TMB (HRP substrate); pNPP (AP substrate); Chemiluminescent substrates. | The enzyme acts on the substrate to produce a measurable signal for detection and quantification. |

The choice between Lateral Flow Immunoassay and ELISA for peanut allergen research is not a matter of one being superior to the other, but rather which is fit-for-purpose. The experimental data confirms that ELISA consistently offers superior sensitivity (lower LOD) and provides robust quantification, making it the gold standard for confirmatory laboratory analysis. In contrast, LFA provides a powerful tool for rapid, on-site screening, with moderately higher but still clinically relevant LODs, delivering results in minutes rather than hours. Both methods can achieve high specificity, which is ultimately governed by the quality and selectivity of the antibody reagents used. Researchers must weigh the need for sensitivity and precise quantification against the requirements for speed, cost, and portability when selecting the appropriate analytical platform for their specific application in safeguarding food safety.

Methodologies, Protocols, and Real-World Deployment

Standardized ELISA Protocols for Precise Quantification of Allergens in Food Matrices

The Enzyme-Linked Immunosorbent Assay (ELISA) is a cornerstone analytical technique for the specific detection and quantification of biomolecules, playing an indispensable role in food safety by reliably identifying allergens and ensuring product integrity and regulatory compliance [25]. For researchers and drug development professionals, the selection of an appropriate, standardized ELISA protocol is critical for generating accurate, reproducible data on allergen concentrations in complex food matrices. This is particularly vital within the broader context of analytical method comparison, especially when evaluating the sensitivity of lateral flow immunoassays (LFIA) against the established benchmark of ELISA for challenging targets like peanut allergens. ELISA's high sensitivity and specificity, which accurately mirror the chemical reaction in the body during an allergic response, make it the gold standard for routine allergen screening [25] [26]. The technique's versatility allows for adaptation into various formats—including indirect, direct, sandwich, and competitive ELISA—each with distinct advantages tailored to different analytical needs, such as detecting whole proteins, small molecules, or achieving ultra-low detection limits [25].

ELISA Formats: Principles and Applications

Understanding the fundamental principles and procedural workflows of different ELISA formats is the first step in selecting the right tool for precise allergen quantification.

Comparative Workflow of Common ELISA Formats

The following diagram illustrates the key steps and components in two common ELISA formats: the Sandwich ELISA (often used for large proteins) and the Competitive ELISA (often used for small molecules).

Table 1: Comparison of Major ELISA Formats for Allergen Analysis.

| Format | Principle | Best Suited For | Key Advantage in Allergen Detection |

|---|---|---|---|

| Sandwich ELISA [25] | Two antibodies bind the antigen at different epitopes, "sandwiching" it. | Detecting large, multivalent antigens like food allergens (peanut, egg, milk). | High specificity and sensitivity; ideal for detecting allergens at low concentrations in complex food matrices [25]. |

| Competitive ELISA [25] | Sample antigen and a labeled antigen compete for binding to a limited amount of antibody. | Detecting small molecules (e.g., mycotoxins, pesticides) or monovalent antigens. | Useful for detecting small contaminants where two antibodies cannot bind simultaneously [25]. |

| Indirect ELISA [25] [27] | A primary antibody binds the antigen, and a labeled secondary antibody binds to the primary. | Detecting contaminants and pathogens; immune response monitoring (antibody quantification). | Increased sensitivity and flexibility; allows for signal amplification [25]. |

| Direct ELISA [25] | An enzyme-linked antibody directly detects the immobilized antigen. | Rapid screening of specific foodborne pathogens or allergens in simple samples. | Quick and straightforward, reducing steps and potential errors [25]. |

Experimental Data: Performance Comparison of Commercial Kits

Theoretical principles must be validated with empirical performance data. Studies comparing commercial ELISA kits reveal critical variations in performance based on the target allergen and food matrix.

Kit Performance for Egg Allergen Detection

A 2023 study directly compared seven commercial egg ELISA kits across nine different food matrices, highlighting the profound impact of the matrix on kit performance [28].

Table 2: Recovery Performance of Seven Commercial Egg ELISA Kits Across Various Food Matrices. [28]

| Food Matrix | Number of Kits Performing Within Set Recovery Criteria | Notes on Matrix Interference |

|---|---|---|

| Cookie, Chocolate, Stock Cube, Wine | 7 out of 7 | All kits performed satisfactorily in these matrices. |

| Pasta, Vegetable Drink & Milk, Ice Cream, Salad Dressing | 4 out of 7 | Recovery was acceptable for a majority, but not all, kits. |

| Meat/Meat Replacers | 1 out of 7 | Showed high matrix effects; performance was challenging for most kits. |

The study concluded that while all seven kits could qualitatively detect egg at the clinically relevant VITAL3 ED01 level of 0.2 mg total egg protein, their quantitative performance varied significantly, underscoring the necessity for kit validation in a specific matrix before use [28].

Broader Comparability of Commercial ELISA Kits

The challenge of variability is not limited to allergen testing. A 2017 study comparing four commercial ELISA kits for quantifying corticosterone in rat serum found statistically significant differences in the absolute values obtained from identical samples [29]. While the kits showed high correlation (allowing for relative comparisons within a study), their precision in determining the true concentration was low [29]. This finding reinforces the critical need for researchers to use the same kit and protocol throughout a study and to be cautious when comparing absolute values from different kits.

Standardized and Optimized ELISA Protocols

To ensure reliability and reproducibility, especially for in-house assay development, rigorous optimization and standardization are mandatory. The process involves systematically refining each step of the ELISA procedure [30].

Key Optimization Steps

- Antigen Coating: The concentration of the capture antibody or antigen immobilized on the plate is foundational. The optimal concentration is one that covers the entire well surface in a monolayer, providing the highest specific signal without wasting reagent [30].

- Blocking: After coating, remaining binding sites on the plate must be blocked to prevent nonspecific binding of detection antibodies. Common blocking agents include Bovine Serum Albumin (BSA), non-fat dried milk, or casein. The optimal blocking buffer must be determined empirically to minimize background noise [30].

- Antibody Concentrations: The concentrations of both the capture and detection antibodies are critical. A checkerboard titration, where these concentrations are varied against each other, is the most effective way to identify the optimal dilution that yields a strong signal with low background [31].

- Sample Diluent and Matrix Effects: The sample diluent should match the sample matrix as closely as possible. Components of the sample matrix can interfere with antigen-antibody binding. Spike-and-recovery experiments are essential to assess this interference and ensure accurate quantification [31] [30].

Example Optimized Protocol: Indirect ELISA

An optimized protocol for an indirect ELISA, designed for quantifying virus-specific antibodies but adaptable to other targets, outlines the following key specifications [27]:

- Coating Buffer: 1x DPBS (pH 7.4).

- Blocking & Sample Diluent: 1x DPBS (pH 7.4) with 1% BSA and 0.05% Tween-20, filtered through a 0.22 µm filter.

- Wash Buffer: 1x DPBS (pH 7.4) with 0.05% Tween-20.

- Critical Reagents: Recombinant target protein, specific primary antibody, and HRP-conjugated secondary antibody.

- Quality Controls: Inclusion of pre-characterized positive and negative control samples is required to establish assay cutoff values, sensitivity, and specificity [27].

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for ELISA Development and Execution.

| Reagent / Material | Function | Examples & Notes |

|---|---|---|

| Coated Microplate | Solid phase for immobilizing the capture molecule (antigen or antibody). | Medium-binding, flat-well polystyrene plates are standard [27]. |

| Capture Molecule | Binds and immobilizes the target analyte. | Specific antibody (for Sandwich ELISA) or antigen (for indirect ELISA). Affinity-purified antibodies are recommended for optimal signal-to-noise [31]. |

| Blocking Buffer | Saturates unused binding sites to reduce nonspecific background. | BSA (1-5%), non-fat dried milk, or casein. Must be optimized for each assay [30]. |

| Detection Antibodies | Binds to the target analyte and carries a label for signal generation. | Primary or secondary antibodies conjugated to enzymes like HRP or AP. Recommended concentration: 0.5-5 µg/mL for affinity-purified antibodies [31]. |

| Enzyme Substrate | Reacts with the enzyme to produce a measurable signal (color, light). | TMB (colorimetric-HRP), PNPP (colorimetric-AP), or chemiluminescent substrates for higher sensitivity [31]. |

| Buffers | Provide a stable chemical environment for interactions and washing. | Coating: PBS or carbonate buffer. Wash/Sample Diluent: PBS with 0.05% Tween-20 (PBST) [27]. |

The precise quantification of allergens in food matrices via ELISA remains a sophisticated process that balances robust standardized protocols with the need for matrix-specific optimization. The sandwich ELISA format stands out for its high sensitivity and specificity in detecting proteinaceous allergens like those from peanuts, making it a relevant benchmark for comparing emerging technologies such as lateral flow immunoassays. However, as comparative studies show, researchers must be acutely aware of the significant performance variations that can exist between commercial kits and the profound influence of the food matrix on quantitative results. Therefore, a deep understanding of ELISA principles, coupled with rigorous in-house optimization and validation using standardized protocols and controls, is non-negotiable for generating reliable data that can inform drug development, food safety risk assessments, and regulatory compliance.

LFIA Workflows for Rapid Environmental Monitoring and Surface Swab Testing

Lateral Flow Immunoassays (LFIAs) have emerged as indispensable tools for rapid environmental monitoring and surface swab testing in food safety and allergen control programs. These immunochromatographic tests provide a simple, cost-effective, and rapid means to detect specific analytes in complex samples, making them particularly valuable for on-site verification of sanitation protocols and allergen control measures [32]. Within the broader context of analytical sensitivity, LFIAs are often compared to the more traditional Enzyme-Linked Immunosorbent Assay (ELISA), with each method offering distinct advantages tailored to different application requirements. For peanut allergen research specifically, understanding the performance characteristics of both methodologies is crucial for selecting the appropriate detection strategy based on the needed sensitivity, throughput, and operational constraints [8] [33].

The fundamental principle underlying LFIA technology is the capillary action-driven migration of a liquid sample along a series of porous membranes, facilitating specific antigen-antibody interactions that yield a visually detectable signal, typically within 5-15 minutes [34] [35]. This simple operational workflow, combined with no requirement for specialized equipment or extensive technical training, has positioned LFIAs as the premier platform for point-of-care testing and rapid screening in industrial settings [32] [35]. For allergen management, this translates to the ability to perform immediate swab tests on food contact surfaces and processing equipment to verify cleaning efficacy and prevent cross-contamination events.

Comparative Sensitivity: LFIA Versus ELISA for Peanut Allergen Detection

Quantitative Performance Comparison

The analytical sensitivity of LFIAs and ELISA methods varies significantly based on the target allergen, antibody specificity, and sample matrix. For peanut allergen detection, particularly for the major allergen Ara h 3, recent research provides direct comparative data on method performance.

Table 1: Sensitivity Comparison for Peanut Allergen Detection

| Method Format | Target Allergen | Limit of Detection | Assay Time | Key Applications |

|---|---|---|---|---|

| DAS-ELISA [8] | Ara h 3 | 39.06 ng/mL | Several hours (incl. incubation steps) | Laboratory quantification of processed peanut allergens |

| LFIA [8] | Ara h 3 | 1.6 μg/mL | < 15 minutes | Rapid screening of processed peanut products |

| Commercial ELISA Kits [33] | Various peanut allergens (Ara h 1-6) | Variable; highest recovery with Romer and R-Biopharm kits | Several hours | Laboratory quantification of specific peanut proteins |

| Commercial Allergen LFIAs [32] | Peanut and other food allergens | Matrix-dependent; qualitative/semi-quantitative | 5-15 minutes | Surface swab testing, environmental monitoring |

The data reveals a clear sensitivity gap between the two methodologies, with ELISA demonstrating approximately 40-fold greater sensitivity for Ara h 3 detection compared to LFIA [8]. This differential is consistent across multiple studies comparing immunoassay formats, with ELISA typically achieving detection limits in the low nanogram per milliliter range, while LFIAs generally operate in the microgram per milliliter range [8]. This distinction fundamentally dictates their appropriate applications: ELISA remains the gold standard for quantitative analysis requiring high sensitivity, while LFIAs excel in rapid screening scenarios where immediate results are prioritized over ultimate sensitivity.

Implications for Peanut Allergen Research

The sensitivity differential between these methods significantly impacts their application in peanut allergen research. ELISA's superior detection limits make it essential for characterizing low-level contamination and quantifying allergen reduction during processing techniques like heat-moisture treatment [8]. Research demonstrates that heat-moisture treatment at temperatures exceeding 90°C for more than 20 minutes significantly reduces Ara h 3 antigenicity, with the most substantial decline observed following treatment at 90°C for 30 minutes [8]. Such precise quantification of antigenicity changes requires the sensitivity provided by ELISA methodologies.

Conversely, LFIAs offer distinct advantages for monitoring the effectiveness of sanitation protocols and environmental monitoring programs. Their rapid format enables food production facilities to perform immediate verification of cleaning efficacy on food contact surfaces and processing equipment [32]. Multiple commercial LFIA products are specifically validated for surface swab testing, including the RIDAQUICK series and bioavid Lateral Flow tests for peanut and other allergens [32] [36]. This rapid feedback loop allows for immediate corrective actions when allergen contamination is detected, preventing cross-contamination events before production resumes.

LFIA Workflow for Environmental Monitoring and Surface Testing

Fundamental LFIA Components and Mechanism

The lateral flow immunoassay operates on a elegantly simple principle, incorporating several core components mounted on an inert backing material and typically housed in a plastic cassette for handling convenience [34]. The fundamental architecture consists of:

- Sample Pad: An absorbent pad treated with salts and surfactants to optimize sample composition for subsequent reactions [34] [37].

- Conjugate Pad: Contains detection antibodies specific to the target analyte, labeled with visible particles (typically colloidal gold or colored latex beads) [34] [35].

- Nitrocellulose Membrane: The critical reaction matrix where capture antibodies are immobilized in distinct lines (test and control zones) [34] [37].

- Absorbent Pad: Serves as a fluid sink to maintain consistent capillary flow and prevent backflow [34] [35].

The analytical process follows a sequential flow path driven by capillary action. When a liquid sample is applied to the sample pad, it migrates to the conjugate pad, solubilizing the labeled antibodies. If the target analyte is present, it forms complexes with these detection antibodies. The solution continues to migrate along the nitrocellulose membrane until it reaches the test line, where antibody-antigen complexes are captured, generating a visible signal. The fluid continues to the control line, which captures excess labeled antibodies to confirm proper assay function [34] [35]. For peanut allergen detection, this typically generates results within 5-15 minutes, enabling rapid decision-making [32].

Diagram: Lateral Flow Immunoassay Workflow

Surface Sampling and Testing Protocol

The application of LFIA technology to environmental monitoring and surface swab testing follows a standardized protocol designed to ensure representative sampling and accurate results:

Surface Sampling: Using specialized swabs included with commercial test kits, systematically sample a defined surface area (typically 10x10 cm). The swab is moistened with appropriate extraction buffer to enhance allergen recovery from the surface [32].

Sample Extraction: Transfer the swab to a extraction tube containing specified buffer volume. Vigorously mix the swab in the buffer to elute any captured allergens from the swab matrix [32] [36].

Assay Activation: Apply the extracted sample to the sample well of the LFIA device using the provided transfer pipette. The volume is precisely controlled by the device design [32].

Result Interpretation: After the specified development time (typically 5-15 minutes, depending on the specific test), visually inspect the test and control lines. A visible test line alongside the control line indicates a positive result for allergen contamination. The control line must always appear for the test to be considered valid [32] [35].

For quantitative or semi-quantitative analysis, dedicated readers such as the RIDAQUICK SCAN or smartphone-based applications like the RIDASMART APP can be employed to measure test line intensity, providing objective results and documentation capabilities [32] [38].

Experimental Protocols for LFIA Development and Validation

Antibody Production and Characterization

The foundation of any sensitive LFIA is a highly specific antibody pair capable of recognizing distinct epitopes on the target analyte. For peanut allergen detection, particularly for thermally processed products, this requires specialized antibody development:

- Immunogen Preparation: Purified native or recombinant allergen proteins (e.g., Ara h 3) serve as immunogens. For detecting processed allergens, antibodies targeting epitopes disrupted by heat-moisture treatment may be specifically developed [8].

- Animal Immunization: Immunize host animals (typically rabbits or larger species for polyclonal production) following established protocols. For peanut allergen research described in the search results, rabbit experiments were approved by the Animal Experimentation Ethics Committee, with all animals receiving humane care according to Institutional Animal Care and Use Committee guidelines [8].

- Antibody Characterization: Assess antiserum specificity and titer using immunoassays. Select antibodies recognizing different epitopes for the conjugate and capture lines to avoid competition [8] [34].

LFIA Assembly and Optimization

The assembly process requires precise integration of all components with careful attention to reagent concentrations and membrane characteristics:

- Conjugate Pad Preparation: Label specific antibodies with colloidal gold or other detection moieties. Optimize the conjugate application to the pad to ensure consistent release and stability [34] [37].

- Membrane Coating: Immobilize capture antibodies at the test line position and species-specific anti-immunoglobulin antibodies at the control line using precision dispensing systems [34] [35].

- Assembly and Packaging: Mount all components sequentially on backing cards, ensuring slight overlaps to facilitate continuous capillary flow. House assembled strips in plastic cassettes with sample port and result window [34] [37].

Assay Validation Protocols

Comprehensive validation is essential to establish assay performance characteristics:

- Sensitivity and Limit of Detection: Determine the lowest analyte concentration consistently producing a positive signal. For the Ara h 3 LFIA, this was established at 1.6 μg/mL [8].

- Specificity and Cross-Reactivity: Evaluate assay performance against related allergens and common food matrices to ensure minimal cross-reactivity. The Ara h 3 LFIA demonstrated no cross-reactivity with other proteins [8].

- Stability Studies: Assess shelf life under various storage conditions, with quality LFIAs remaining stable for up to 3 years under controlled humidity [34] [37].

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagent Solutions for Allergen LFIA Development

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Epitope-Specific Antibodies [8] | Recognition of target allergens | Critical for detecting processed allergens; should target epitopes stable after heat treatment |

| Colloidal Gold Nanoparticles [34] [35] | Visual detection label | Most common label; provides strong color with consistent size; ~40nm particles often used |

| Nitrocellulose Membranes [34] [37] | Matrix for capillary flow and antibody immobilization | Pore size affects flow rate and sensitivity; requires specialized dispensing equipment |

| Sample Pads & Conjugate Release Pads [34] [37] | Sample application and conjugate storage | Typically glass fiber; often pre-treated with buffers, surfactants, and stabilizers |

| LFIA Readers [32] [38] | Quantitative result measurement | Include dedicated devices (RIDAQUICK SCAN) or smartphone-based systems (RIDASMART APP) |

| Surface Swab Kits [32] [36] | Environmental sample collection | Specialized swabs with optimized extraction buffers for maximum allergen recovery |

Lateral Flow Immunoassays represent a strategically important technology within the hierarchy of analytical methods for peanut allergen detection and environmental monitoring. While ELISA maintains superiority in sensitivity and quantitative precision, LFIAs offer unparalleled advantages in speed, simplicity, and suitability for on-site testing [8] [33]. The 40-fold sensitivity differential between the methods clearly delineates their respective application spaces: ELISA for precise laboratory quantification of allergen reduction during processing, and LFIA for rapid verification of sanitation efficacy and environmental monitoring [8] [32].

The development of epitope-specific antibodies targeting heat-modified allergens, as demonstrated in recent peanut allergen research, significantly enhances the utility of both methodologies for evaluating processed food products [8]. Furthermore, advancements in reader technologies, particularly smartphone-based quantification systems, are bridging the historical gap between the qualitative nature of LFIAs and the quantitative requirements of comprehensive allergen control programs [32] [38].

For researchers and food safety professionals, the strategic integration of both technologies provides a comprehensive approach to allergen management: LFIA for rapid, high-frequency monitoring of critical control points in processing environments, and ELISA for definitive quantification and method validation. This dual-method approach leverages the respective strengths of each technology to create a robust allergen control system capable of both preventing cross-contamination through immediate feedback and generating definitive data for process validation and regulatory compliance.

Sample preparation is a critical step in food allergen analysis, directly influencing the sensitivity and accuracy of subsequent detection methods like Lateral Flow Immunoassays (LFIAs) and Enzyme-Linked Immunosorbent Assays (ELISAs). The complexity of food matrices, especially following processing, poses significant challenges for efficient allergen extraction. This guide objectively compares key methodologies, focusing on their application in peanut allergen research.

The Impact of Matrix and Processing on Allergen Extraction

The efficiency of allergen extraction is highly dependent on the food matrix and the processing it has undergone. Complex matrices such as chocolate and thermally processed foods (e.g., baked biscuits) are particularly challenging. These matrices can entrap allergenic proteins or introduce interfering compounds that reduce protein solubility and availability for immunoassay detection [39].

For instance, studies optimizing the recovery of 14 specific allergens from incurred food matrices found that chocolate-containing matrices and those subjected to thermal processing consistently yielded lower recovery rates, often below the ideal 50-150% range achieved for less complex foods [39]. Furthermore, thermal processing can induce conformational changes in proteins. For peanut allergen Ara h 3, heat-moisture treatment was shown to significantly reduce its antigenicity by destroying key epitopes, a factor that must be considered when developing detection methods for processed foods [8].

Extraction Buffer Composition and Optimization

The choice of extraction buffer is paramount to disrupt matrix interactions, solubilize allergens, and ensure they are available for immunoassay quantification. Research indicates that a single "universal" extraction buffer is elusive, but optimized formulations can significantly improve recovery across multiple allergens and matrices [39].

The table below summarizes key extraction buffers used for challenging food matrices, as identified in recent research:

Table 1: Composition and Application of Optimized Allergen Extraction Buffers

| Buffer Identifier | Formulation | Key Additives | Reported Performance |

|---|---|---|---|

| Buffer D [39] | 0.05 M sodium carbonate/bicarbonate, pH 9.6 | 10% Fish Gelatine | One of two buffers providing optimized recovery (50-150%) for 14 allergens from complex incurred matrices. |

| Buffer J [39] | PBS, 2% Tween-20, 1 M NaCl, pH 7.4 | 10% Fish Gelatine, 1% PVP (Polyvinylpyrrolidone) | Second optimized buffer for multiplex analysis. Additives combat polyphenol interference in chocolate. |

| Buffer B [39] | PBS, 2% Tween-20, 1 M NaCl, pH 7.4 | 10% Fish Gelatine | Used for improved recovery from challenging matrices. |

| Buffer C [39] | 0.1 M Tris, 1% SDS, 0.1 M sodium sulphite, pH 8.5 | SDS, Sodium Sulphite | A denaturing buffer cited for notable improvements in allergen recovery. |

Additive Functions: Common buffer additives serve specific purposes [39]: