Developing a Quantum-Dot-Based Sandwich Lateral Flow Immunoassay for Shrimp Tropomyosin: A Comprehensive Guide from Principle to Practice

This article provides a comprehensive resource for researchers and scientists developing rapid, sensitive detection methods for the major shrimp allergen, tropomyosin.

Developing a Quantum-Dot-Based Sandwich Lateral Flow Immunoassay for Shrimp Tropomyosin: A Comprehensive Guide from Principle to Practice

Abstract

This article provides a comprehensive resource for researchers and scientists developing rapid, sensitive detection methods for the major shrimp allergen, tropomyosin. It covers the foundational principles of the quantum-dot-based sandwich lateral flow immunoassay (LFIA), detailing the assay's configuration for superior sensitivity and specificity. A step-by-step methodological guide is presented, from probe conjugation to strip assembly, followed by in-depth troubleshooting and optimization strategies to overcome common challenges like photobleaching and background noise. The content concludes with a rigorous validation framework and a comparative analysis against other techniques like ELISA and immuno-PCR, highlighting the assay's performance in detecting tropomyosin in complex, processed food matrices. This guide synthesizes current research to empower professionals in creating robust, point-of-care diagnostic tools for food safety.

Tropomyosin Detection and QD-LFIA Fundamentals: Building the Basis for a Sandwich Assay

Why Tropomyosin is a Critical Public Health Allergen in Shrimp and Shellfish

Tropomyosin is a highly conserved actin-binding protein found in both muscle and non-muscle cells of invertebrate species, with a subunit molecular weight of approximately 33-38 kDa [1]. In the context of public health, invertebrate tropomyosin has been identified as the major allergen in crustacean shellfish, responsible for up to 80% of shrimp allergy cases [2]. This protein exhibits remarkable heat stability and resistance to proteolytic digestion, allowing it to retain its allergenic potential even after food processing and cooking [1]. Shellfish allergy is a significant global health concern, with population studies across Asia showing prevalence rates ranging from 0.17% to 5.23% in different age groups [3].

The public health impact of tropomyosin extends beyond its role as a primary food allergen due to its nature as a pan-allergen - a single protein capable of triggering cross-reactive allergic responses across multiple species [1]. Tropomyosins from shrimp, house dust mites, and cockroaches share high sequence homology, with approximately 81% amino acid similarity between prawns and house dust mites, and 82% similarity between prawns and cockroaches [3]. This molecular similarity creates a significant diagnostic and management challenge in clinical practice, as individuals sensitized to inhaled tropomyosin from environmental sources may display IgE reactivity to shellfish tropomyosin without necessarily experiencing clinical symptoms upon consumption [4] [5].

Molecular Characteristics and Cross-Reactivity Profile

Structural Basis of Allergenicity

Tropomyosin possesses a unique molecular structure that underpins its allergenic potential. The native protein consists of two polypeptide chains arranged in a coiled-coil, rod-like configuration that is almost completely alpha-helical except for short segments of random coil at the N- and C-terminals [1]. These end-region sequences are responsible for the head-to-tail polymerization of the protein and contain critical IgE-binding epitopes [3]. The protein is notably rich in arginine and lysine residues, which contributes to its stability and immunoreactivity [1].

Research has identified multiple IgE-binding epitopes on shrimp tropomyosin (Pen a 1), with sequences 145-164 and 263-280 proposed as major immunoglobulin E epitopes capable of inhibiting IgE-binding reactivity in sera from shrimp-allergic individuals [3]. The conservation of these epitopic regions across invertebrate species forms the molecular basis for the extensive cross-reactivity observed in clinical settings.

Cross-Reactivity Patterns

The cross-reactivity profile of tropomyosin creates a complex clinical landscape, as illustrated in the table below:

Table 1: Cross-Reactivity Patterns of Tropomyosin from Various Species

| Species | Tropomyosin Designation | Sequence Identity to Shrimp Tropomyosin | Clinical Cross-Reactivity |

|---|---|---|---|

| Shrimp | Pen a 1, Pen m 1 | Reference (100%) | Primary sensitizer |

| Crab | Por p 1 | 91-100% | High cross-reactivity |

| Lobster | Hom a 1 | 91-100% | High cross-reactivity |

| House Dust Mite | Der p 10, Blo t 10 | 78.5-81.7% | Significant cross-reactivity |

| Cockroach | Bla g 7 | 82.4% | Significant cross-reactivity |

| Snail | Hel as 1 | 63.7% | Moderate cross-reactivity |

| Vertebrate (Fish) | Ore m 4 | 57.4% | Limited or no cross-reactivity |

While tropomyosins from crustacean shellfish (shrimp, crab, lobster) demonstrate nearly identical sequences and consequently strong IgE cross-reactivity, the cross-reactivity between shellfish and house dust mites, though significant, is less pronounced due to variations in critical IgE epitopes [3]. This explains why individuals with house dust mite sensitivity may exhibit positive IgE tests to shellfish without necessarily experiencing clinical reactions upon ingestion - a phenomenon characterized as asymptomatic sensitization [4] [5].

Public Health Burden and Diagnostic Challenges

Global Prevalence and Clinical Manifestations

Shellfish allergy represents a substantial public health burden worldwide, with varying prevalence across different regions. The clinical presentation of tropomyosin-mediated allergy spans a spectrum from mild oral symptoms to life-threatening anaphylaxis:

Table 2: Global Prevalence and Clinical Features of Shellfish Allergy

| Region/Country | Prevalence | Population Studied | Common Clinical Features |

|---|---|---|---|

| Philippines | 5.12% | Teenagers (14-16 years) | Systemic reactions |

| Singapore | 5.23% | Teenagers (14-16 years) | Oral allergy syndrome predominance |

| Taiwan | 7.71% | Children (4-18 years) | Mixed presentations |

| Thailand | 0.88% | Young children (3-7 years) | Oral symptoms |

| United States | 2.0-6.0% | General population | Systemic reactions |

| Germany | 2.6% (sensitization) | General population | Mostly asymptomatic sensitization |

A unique feature observed in Asian populations is the predominance of milder reactions localized to the oral mucosa, characterized by lip itching and swelling, similar to the oral allergy syndrome seen in pollen-food allergy syndrome [3]. This pattern has been postulated to result from primary sensitization to inhaled house dust mite tropomyosin in warm, humid climates, with subsequent cross-reaction to shellfish tropomyosin upon ingestion [3].

Diagnostic Complications

The high degree of tropomyosin cross-reactivity creates significant challenges in allergy diagnosis. Recent research demonstrates that patients with mite sensitization have higher asymptomatic IgE levels to shellfish, leading to potentially misleading diagnostic results [4] [5]. A 2025 study by Hollstein et al. found that even when tropomyosin-specific IgE (Der p 10 and Pen a 1) levels were below the standard cutoff (<0.35 kU/L), they still explained between 24% and 55% of the variance in IgE against clam, crab, German cockroach, and shrimp [4] [5].

This cross-reactivity can result in false-positive diagnostic tests for shellfish allergy when using whole allergen extracts, particularly in individuals with perennial mite or cockroach allergy [4] [5]. The complexity of tropomyosin-mediated cross-reactivity necessitates component-resolved diagnostics that can distinguish between primary sensitization and cross-reactive responses, enabling more accurate clinical management.

Quantum-Dot-Based Sandwich Lateral Flow Immunoassay for Tropomyosin Detection

Principle and Advantages

The quantum-dot-based sandwich lateral flow immunoassay (LFIA) represents a significant advancement in tropomyosin detection technology, offering a rapid, sensitive, and user-friendly platform for allergen monitoring in food products [2]. This methodology employs carboxylated quantum dots conjugated with anti-tropomyosin polyclonal antibodies as fluorescent probes, leveraging the exceptional optical properties of quantum dots, including narrow emission spectra, wide excitation range, and high fluorescence quantum yield [2].

Compared to conventional gold nanoparticle-based LFIA, the quantum-dot-based approach offers substantially improved sensitivity, with an instrumental detection limit of 0.01 μg mL⁻¹ compared to 0.05-0.5 μg mL⁻¹ for traditional methods [2]. The sandwich assay format is particularly suited for detecting tropomyosin due to the protein's large molecular size, providing better specificity and reduced susceptibility to matrix effects compared to competitive formats [2].

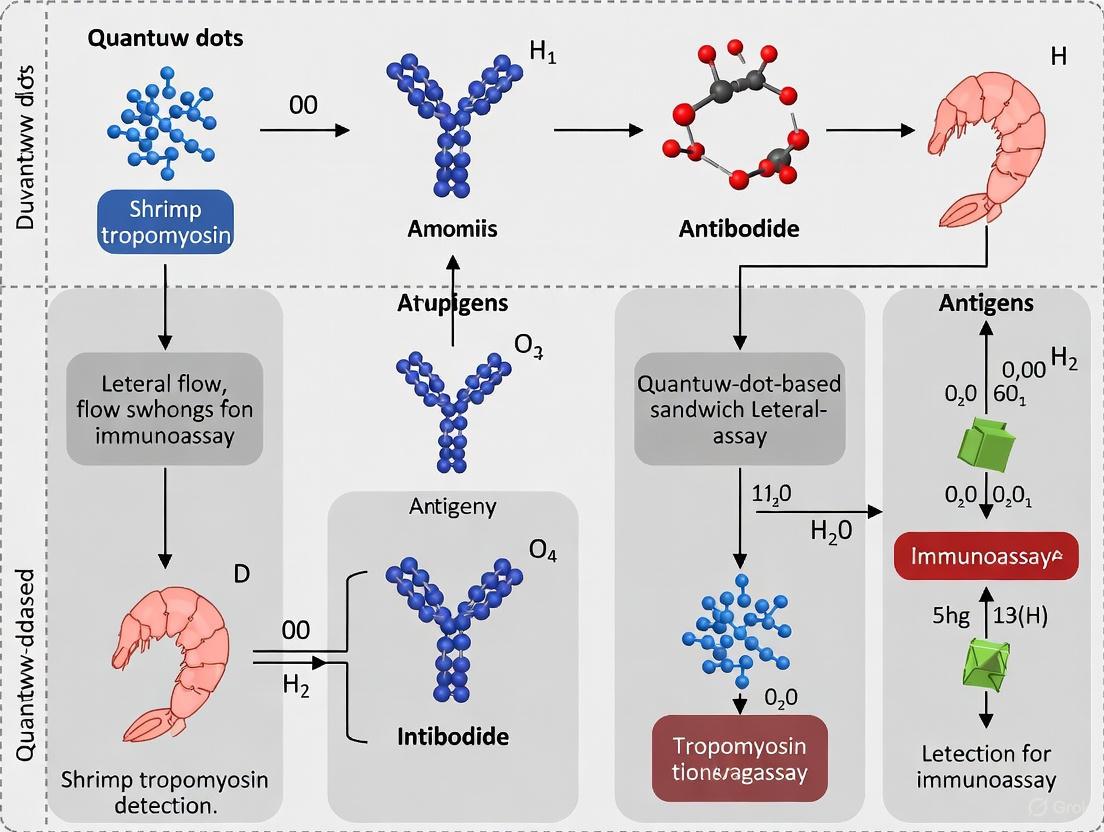

Figure 1: Workflow of QD-based Sandwich LFIA for Tropomyosin Detection

Detailed Protocol for QD-Based Tropomyosin LFIA

Materials and Reagents

Table 3: Essential Reagents for QD-Based Tropomyosin LFIA

| Reagent/Material | Specification | Function/Purpose |

|---|---|---|

| CdSe/ZnS Quantum Dots | Carboxyl-modified, core-shell | Fluorescent signal label |

| Tropomyosin Standard | Recombinant or purified from shrimp | Calibration and quality control |

| Anti-Tropomyosin pAb | Rabbit polyclonal IgG | Detection and capture antibody |

| EDC/Sulfo-NHS | >98% purity | Cross-linking for QD-antibody conjugation |

| Nitrocellulose Membrane | Pore size 8-15 μm | Chromatographic matrix for test/control lines |

| Sample Pad | Glass fiber | Sample application and filtration |

| Conjugate Pad | Glass fiber or polyester | Storage of QD-pAb conjugates |

| Absorption Pad | Cellulose | Fluid movement and waste containment |

| PBS Buffer | 0.01 M, pH 7.4 | Diluent and running buffer |

| Tween-20 | Molecular biology grade | Surfactant to reduce non-specific binding |

Probe Preparation Protocol

Activation of Quantum Dots:

- Dilute carboxylated QDs (CdSe/ZnS) to 2 μM in 0.1 M MES buffer (pH 6.0)

- Add fresh EDC (400 mM) and Sulfo-NHS (100 mM) solutions

- Incubate with gentle shaking for 30 minutes at room temperature

- Purify activated QDs using centrifugal filtration (100 kDa MWCO)

Antibody Conjugation:

- Add anti-tropomyosin polyclonal antibody (1 mg/mL) to activated QDs at 1:50 molar ratio

- Incubate for 2 hours at room temperature with gentle mixing

- Block residual active sites with 1% BSA for 30 minutes

- Centrifuge at 12,000 × g for 10 minutes and resuspend in storage buffer (0.01 M PBS, pH 7.4, with 2% sucrose, 1% BSA, and 0.05% Tween-20)

Conjugate Pad Treatment:

- Apply QD-pAb conjugates to glass fiber conjugate pad at 5 μL/cm

- Dry overnight at 37°C under desiccation

- Store with desiccant at 4°C until use

Strip Assembly and Test Procedure

Strip Configuration:

- Assemble LFIA strip with overlapping components: sample pad (15 mm), conjugate pad (5 mm), NC membrane (25 mm), and absorption pad (20 mm)

- Dispense anti-tropomyosin pAb (1 mg/mL) as test line and goat anti-rabbit IgG (0.5 mg/mL) as control line onto NC membrane using dispense rate of 1 μL/cm

- Dry membranes at 37°C for 12 hours and store with desiccant

Testing Protocol:

- Prepare food samples by homogenizing 1 g of sample with 10 mL of extraction buffer (0.01 M PBS, pH 7.4, 0.5% Tween-20)

- Centrifuge at 10,000 × g for 10 minutes and collect supernatant

- Apply 100 μL of sample extract to the sample pad

- Allow chromatography to proceed for 10 minutes at room temperature

- Visualize results under UV light (365 nm excitation) or using a portable fluorescent reader

Result Interpretation:

- Positive Result: Both test and control lines show fluorescence

- Negative Result: Only control line shows fluorescence

- Invalid Result: No fluorescence at control line, regardless of test line

Performance Characteristics and Validation

The QD-based sandwich LFIA demonstrates excellent analytical performance for tropomyosin detection:

Table 4: Performance Characteristics of QD-Based Tropomyosin LFIA

| Parameter | Performance Value | Comparative Advantage |

|---|---|---|

| Visual Detection Limit | 0.05 μg mL⁻¹ | 10-fold improvement over AuNP-LFIA |

| Instrumental Detection Limit | 0.01 μg mL⁻¹ | Suitable for trace detection |

| Detection Time | <10 minutes | Rapid screening |

| Specificity | No cross-reactivity with non-target species | High specificity for crustacean TM |

| Intra-assay CV | 8.87%-11.9% | Good reproducibility |

| Inter-assay CV | 7.75%-21.12% | Acceptable batch-to-batch variation |

| Matrix Effects | Detected 0.045 μg g⁻¹ in processed foods | Robust performance in complex matrices |

The assay has been successfully validated for detection of tropomyosin in various processed food matrices, including roast fish fillet, boiled meatballs, and steamed meatballs, demonstrating its practical utility for monitoring allergen contamination in food processing environments [2]. The method detected 8 of 9 real food samples that were identified as tropomyosin-positive by validated ELISA methods, confirming its reliability for food safety applications [2] [6].

Research Reagent Solutions Toolkit

Table 5: Essential Research Reagents for Tropomyosin Detection and Analysis

| Reagent/Category | Specific Examples | Research Application |

|---|---|---|

| Antibody Reagents | Rabbit anti-TM pAb, Anti-TM mAb | Capture/detection in immunoassays |

| Labeling Materials | Carboxylated QDs (CdSe/ZnS), Gold nanoparticles | Signal generation in biosensors |

| Cross-linking Reagents | EDC, Sulfo-NHS | Conjugation chemistry for probe preparation |

| Chromatographic Materials | Nitrocellulose membrane (8-15 μm), Glass fiber pads | LFIA strip components |

| Allergen Standards | Recombinant TM, Purified native TM | Assay calibration, quality control |

| Detection Instruments | Portable fluorescent readers, UV lamps (365 nm) | Signal measurement and visualization |

| Buffer Systems | PBS (0.01 M, pH 7.4), MES buffer (pH 6.0) | Extraction, conjugation, and running buffers |

Implications for Public Health and Future Directions

The development of sensitive, rapid detection methods for tropomyosin has significant implications for public health protection, particularly for individuals with shellfish allergy who must strictly avoid allergen exposure. The quantum-dot-based LFIA technology enables food manufacturers to implement effective allergen control programs through rapid monitoring of processing environments and final products, supporting compliance with food allergen labeling regulations such as the Food Allergen Labeling and Consumer Protection Act [2].

Future research directions in tropomyosin detection include the development of multiplexed platforms capable of simultaneously detecting multiple allergens, integration with smartphone-based readout systems for point-of-care testing, and the application of novel nanomaterial labels to further enhance sensitivity [8] [9]. Additionally, the growing understanding of tropomyosin cross-reactivity patterns may inform the development of novel immunotherapeutic approaches for shellfish allergy, potentially leveraging the cross-reactive epitopes to induce desensitization or tolerance to multiple allergen sources [3] [1].

As the prevalence of shellfish allergy continues to rise globally, the availability of reliable, rapid detection methods for tropomyosin will play an increasingly critical role in protecting public health and ensuring the safety of food products for allergic consumers.

The Limitations of Traditional Allergen Detection Methods (ELISA, PCR, and Gold-Nanoparticle LFIA)

The accurate detection of food allergens is a critical public health issue, impacting an estimated 220 million people worldwide who suffer from food allergies [10]. For individuals allergic to crustaceans such as shrimp, tropomyosin (TPM) is the primary allergen, responsible for 72-98% of diagnosed ingestion-related shellfish allergies [10]. This heat-stable protein remains intact even after harsh food processing, posing a significant health risk to consumers [10]. Avoiding allergenic ingredients is the most effective treatment, making reliable detection methods essential for accurate food labeling and consumer protection [10].

Traditional methods for allergen detection include enzyme-linked immunosorbent assays (ELISA), polymerase chain reaction (PCR), and gold nanoparticle-based lateral flow immunoassays (LFIA). While these techniques have formed the backbone of food allergen analysis for years, they possess significant limitations in sensitivity, specificity, and practicality that can compromise their effectiveness in protecting sensitive individuals. This application note critically examines these limitations within the context of developing more advanced detection systems, specifically quantum-dot-based sandwich lateral flow immunoassays for shrimp tropomyosin.

Critical Analysis of Traditional Methods

The table below summarizes the core limitations of three traditional allergen detection methods.

Table 1: Performance Comparison of Traditional Allergen Detection Methods

| Method | Key Limitations | Typical Sensitivity Range | Major Constraints | |

|---|---|---|---|---|

| ELISA | - Moderate sensitivity [10]- Potential for antibody cross-reactivity [11]- Time-consuming procedures [12] | LOD: 27.3 pg/mL (for a developed sandwich ELISA) [10] | - Relies on antibody availability and quality [11]- Not ideal for rapid, on-site testing [12] | |

| PCR | - Detects DNA, not the allergenic protein itself [13]- Protein presence may not correlate with DNA [13]- Requires sophisticated equipment [12] | (Not directly comparable as it targets genetic material) | - Results do not directly confirm the presence of the allergenic protein [13]- Susceptible to inhibition and DNA degradation [13] | |

| Gold-Nanoparticle LFIA | - Lower sensitivity compared to fluorescent labels [14] [15]- Subjective visual interpretation [12] | - Weak color intensity and poor colloid stability [14] | Visual LOD: 0.05 μg/mL for TM [14] | - Less suitable for detecting trace-level contaminants [14] [15]- Qualitative or semi-quantitative at best [12] |

Enzyme-Linked Immunosorbent Assay (ELISA)

ELISA is a widely used biochemical technique for quantifying allergens, but its limitations are notable. The method's moderate sensitivity can be a critical drawback when detecting trace amounts of tropomyosin in processed foods. For instance, while a novel immuno-PCR method demonstrated a Limit of Quantification (LOQ) of 19.8 pg/mL for crustacean TPM, a analogous ELISA had a significantly higher LOQ of 364 pg/mL, making it 20-fold less sensitive [10]. Furthermore, ELISA results are highly dependent on the specificity of the antibodies used. Cross-reactivity with similar proteins from other species, such as mollusks (which have 55-65% TPM sequence similarity with crustaceans), can lead to false-positive results [10] [11]. The assay also involves multiple incubation and washing steps, making it relatively time-consuming and less suitable for rapid, on-site testing compared to lateral flow platforms [12].

Polymerase Chain Reaction (PCR)

PCR targets the genetic material (DNA) of an allergenic source rather than the protein itself. This fundamental aspect is also its primary limitation. The detection of a shrimp gene does not guarantee the presence of the tropomyosin protein, and conversely, the protein could be present without detectable DNA due to processing, leading to inaccurate risk assessment [13]. The technique requires specialized and expensive equipment, including thermal cyclers, and skilled personnel to perform the analysis, confining it to centralized laboratories and eliminating its utility for point-of-care testing [12].

Gold-Nanoparticle-Based Lateral Flow Immunoassay (LFIA)

While conventional AuNP-LFIA offers advantages in speed and cost, it suffers from limited sensitivity. The visual detection limit for TPM in one developed AuNP-LFIA was 0.05 μg/mL, which is insufficient for detecting very low concentrations of allergens that could still trigger a reaction in sensitive individuals [14]. The subjective visual interpretation of the color change on the test line can lead to variations in results between different users [12]. Additionally, the weak color intensity and poor colloid stability of gold nanoparticles can further compromise the assay's reliability and sensitivity [14]. The emergence of fluorescent labels, such as quantum dots, has highlighted these shortcomings, as they offer significantly higher brightness and sensitivity [15].

Experimental Protocols for Method Evaluation

Researchers evaluating or comparing allergen detection methods can use the following standardized protocols to systematically assess their performance.

Protocol for Sandwich ELISA Evaluation of Tropomyosin

This protocol outlines the key steps for developing and validating a sandwich ELISA for shrimp tropomyosin, based on published research [10].

Table 2: Key Reagents for Sandwich ELISA

| Reagent | Function | Example |

|---|---|---|

| Capture Antibody | Binds the target protein to the solid phase | Monoclonal mouse anti-TPM antibody [10] |

| Detection Antibody | Provides specificity for secondary detection | Polyclonal rabbit anti-shrimp TPM antibody [10] |

| Secondary Antibody | Amplifies the detection signal | Alkaline phosphatase-labeled goat anti-rabbit antibody [10] |

| Protein Standard | Enables quantitative calibration | Natural shrimp tropomyosin [10] |

Procedure:

- Coating: Coat a microplate with a monoclonal mouse anti-TPM antibody diluted in an appropriate coating buffer. Incubate overnight at 4°C, then wash and block the plate to prevent non-specific binding.

- Antigen Incubation: Add the sample extract or the TPM standard solution to the plate. Incubate to allow the tropomyosin antigen to be captured by the immobilized antibody. Wash thoroughly to remove unbound materials.

- Detection Incubation: Add a polyclonal rabbit anti-shrimp TPM antibody. This antibody forms a "sandwich" complex with the captured antigen. Wash again.

- Signal Amplification & Readout: Add an alkaline phosphatase-labeled goat anti-rabbit antibody. After a final wash, add an enzyme substrate (e.g., pNPP) that produces a color change. Measure the absorbance with a plate reader.

- Data Analysis: Generate a standard curve from the TPM standard dilutions and use it to calculate the tropomyosin concentration in unknown samples.

Protocol for Traditional AuNP-LFIA Construction

This protocol describes the assembly and testing of a traditional gold nanoparticle-based LFIA for tropomyosin [14] [16].

Procedure:

- Conjugate Pad Preparation: Conjugate anti-TPM polyclonal antibodies to colloidal gold nanoparticles. The particles are typically ~20-40 nm in diameter. Disperse this conjugate onto a glass fiber conjugate pad and dry.

- Membrane Coating: Dispense a capture anti-TPM antibody in a line across a nitrocellulose membrane to form the Test (T) line. Dispense a secondary antibody (e.g., anti-rabbit IgG) to form the Control (C) line.

- Strip Assembly: Assemble the strip by attaching the sample pad, conjugate pad, nitrocellulose membrane, and absorbent pad to a backing card with overlaps to ensure capillary flow.

- Testing: Apply the liquid sample to the sample pad. The sample rehydrates and moves the gold-conjugated antibodies. If TPM is present, it binds to the conjugate and is captured at the T line, forming a visible red band. The excess conjugate is captured at the C line, validating the test.

- Analysis: Interpret the result visually within 10 minutes. The presence of the T line indicates a positive result.

Workflow and Method Selection

The following diagram illustrates the logical decision-making process for selecting an appropriate allergen detection method based on analytical needs.

The Scientist's Toolkit: Research Reagent Solutions

The table below lists essential materials and reagents for developing advanced immunoassays for allergen detection, as identified in the cited research.

Table 3: Essential Research Reagents for Advanced Allergen Immunoassay Development

| Item | Critical Function in Assay Development | Research Context |

|---|---|---|

| Monoclonal Anti-TPM Antibody | Serves as a highly specific capture antibody to ensure the assay binds the correct target protein without cross-reactivity [10]. | Used as the capture antibody in a high-sensitivity immuno-PCR assay [10]. |

| Polyclonal Anti-TPM Antibody | Often used as a detection antibody; recognizes multiple epitopes on the target protein, which can enhance sensitivity [10] [14]. | Key detection antibody in both ELISA and quantum-dot LFIA formats [10] [14]. |

| Carboxylated Quantum Dots (QDs) | Act as fluorescent labels conjugated to detection antibodies; provide superior brightness and photostability for high-sensitivity lateral flow assays [14] [15]. | Used as the signal label in a QD-LFIA for TM, achieving an instrumental LOD of 0.01 μg/mL [14]. |

| Nitrocellulose Membrane | The porous matrix that forms the core of the lateral flow strip, enabling capillary movement of the sample and conjugation of capture antibodies at test lines [12] [16]. | Fundamental component in all lateral flow immunoassay devices [12] [16]. |

| Signature Peptides (e.g., ANIQLVEK) | Unique peptide sequences from the target protein used as standards and references for mass spectrometry-based quantification, enabling high accuracy and specificity [13]. | Selected as the quantitative signature peptide for LC-MS/MS detection of tropomyosin [13]. |

| Conjugation Kits (e.g., EDC/NHS) | Chemical cross-linking kits used to covalently attach biomolecules (like antibodies) to labels (like QDs) or other surfaces efficiently and stably [14]. | Employed for conjugating rabbit anti-TM IgG with carboxylated quantum dots [14]. |

Quantum dots (QDs) are nanoscale semiconductor particles that have emerged as transformative labels in biodetection, particularly in lateral flow immunoassays (LFIAs). Their unique optical properties—including high brightness, broad excitation spectra, narrow, tunable emission, and exceptional photostability—provide a significant advantage over conventional labels like colloidal gold and latex beads. This application note details the quantitative advantages of QDs and provides a detailed protocol for developing a QD-based sandwich LFIA, framed within the context of detecting the major shrimp allergen tropomyosin.

The Core Quantum Dot Advantage: A Quantitative Comparison

The superior performance of QDs stems from their intrinsic physicochemical properties. The table below summarizes the key optical advantages that make them ideal for sensitive applications like allergen detection.

Table 1: Core Optical Properties of Quantum Dots in Biodetection

| Property | Technical Advantage | Quantitative Performance | Impact on LFIA Performance |

|---|---|---|---|

| High Photostability | Resists photobleaching under prolonged illumination; maintains signal integrity. | Minimal PL degradation (14.9% after 10 months); vastly superior to conventional dyes (87.7%) [17]. | Enables repeated scanning, archival of test strips, and reliable quantitative analysis without signal decay. |

| High Fluorescence Intensity & Quantum Yield | High extinction coefficients and efficient radiative recombination. | Fluorescence intensity in pathological tissues: 120 ± 10 AU vs. 50 ± 5 AU in controls [18]. | Provides a high signal-to-noise ratio, enabling lower detection limits and easier visual readout. |

| Broad Excitation / Narrow Emission | Can be excited by a single light source (e.g., UV lamp) while emitting precise, pure colors. | Emission spectra are typically 30-50 nm FWHM, much narrower than organic dyes (>100 nm) [19]. | Reduces background interference, allowing for multiplexing of different targets with distinct QD colors. |

| Signal Intensity & Detection Sensitivity | The brightness enables detection of low-abundance targets. | Instrumental LOD for tropomyosin: 0.01 μg mL⁻¹; Visual LOD: 0.05 μg mL⁻¹ [14] [6]. | Crucial for detecting trace allergens to protect sensitive individuals and meet regulatory requirements. |

Experimental Protocol: QD-based Sandwich LFIA for Shrimp Tropomyosin

This protocol outlines the development of a highly sensitive and rapid sandwich LFIA for the detection of shrimp tropomyosin (TM), leveraging the quantum dot advantage.

Research Reagent Solutions

Table 2: Essential Materials and Reagents

| Item | Function / Description |

|---|---|

| CdSe/ZnS Core-Shell QDs | Semiconductor nanoparticles with high quantum yield and photostability; carboxylated surface for biomolecule conjugation [14]. |

| Tropomyosin (TM) Antigen & Antibodies | The target allergen; requires a matched pair of specific anti-TM antibodies (e.g., rabbit polyclonal IgG) for the sandwich assay [14] [6]. |

| EDC and sulfo-NHS | Cross-linking reagents for activating carboxyl groups on QDs to form stable amide bonds with primary amines on antibodies [14]. |

| Nitrocellulose (NC) Membrane | Porous matrix for capillary flow and immobilization of capture antibodies at Test (T) and Control (C) lines. |

| Sample and Absorbent Pads | Cellulose components to regulate sample flow and wicking capacity, respectively. |

| Conjugate Pad | Glass fiber pad for storing the freeze-dried QD-antibody probes. |

| Fluorescence Reader / UV Lamp | For instrumental quantification or visual detection of the fluorescent signal on the test strip [20]. |

Step-by-Step Procedure

Part A: Conjugation of QDs with Detection Antibody

- Activation: Mix 1 mL of carboxylated QDs (1 mg/mL) with 500 μL of EDC (10 mg/mL) and 500 μL of sulfo-NHS (10 mg/mL). React for 30 minutes at room temperature with gentle shaking to activate the carboxyl groups.

- Purification: Remove excess EDC/NHS by centrifuging the reaction mixture using a centrifugal filter unit (e.g., 100kDa MWCO). Re-suspend the activated QDs in 1 mL of 10 mM borate buffer (pH 7.4).

- Conjugation: Add 100 μg of purified anti-TM antibody to the activated QDs. Incubate the mixture for 2 hours at room temperature or overnight at 4°C with gentle agitation.

- Blocking: Add 100 μL of 1% BSA solution to block any remaining active sites. Incubate for 30 minutes.

- Purification of Conjugates: Purify the QD-antibody conjugates using a centrifugal filter unit to remove unbound antibodies. Re-suspend the final conjugate in a storage buffer (e.g., PBS with 1% BSA, 5% sucrose) and store at 4°C until use.

Part B: Assembly of the Lateral Flow Strip

- Preparation: Affix a backing card onto a flat surface.

- Membrane Coating: Dispense the capture anti-TM antibody (e.g., 1 mg/mL) onto the NC membrane as the Test (T) line. Dispense a species-specific secondary antibody (e.g., goat anti-rabbit IgG) as the Control (C) line. Dry the membrane at 37°C for 1 hour.

- Conjugate Pad Treatment: Apply the purified QD-antibody conjugate to the conjugate pad and dry under vacuum or in a desiccator.

- Assembly: Overlap and attach the sample pad, conjugate pad, NC membrane, and absorbent pad sequentially onto the backing card. Cut the assembled card into individual strips of desired width (typically 3-4 mm) using a strip cutter.

Part C: Detection and Analysis

- Sample Application: Add 100 μL of the sample extract (or TM standard in buffer) to the sample pad.

- Development: Allow the test strip to develop for 10 minutes at room temperature.

- Signal Reading:

- Visual: Under a UV lamp (365 nm), a fluorescent band at the T line indicates a positive result. The intensity correlates with TM concentration [14].

- Instrumental: Use a fluorescence strip reader to quantitatively measure the fluorescence intensity at the T line. Generate a standard curve with known TM concentrations for accurate quantification.

Workflow and Signaling Mechanism

The following diagram illustrates the experimental workflow and the signaling mechanism of the QD-based sandwich LFIA.

Discussion: Implications for Food Safety and Beyond

The integration of QDs into LFIAs, as demonstrated in the tropomyosin detection protocol, marks a significant leap in point-of-care diagnostics. The high photostability ensures that test results can be documented and analyzed long after the initial test run, a critical feature for quality control and record-keeping [17] [21]. The intense fluorescence signal directly translates to the high sensitivity required to detect trace amounts of allergens, such as the 0.045 μg g⁻¹ of incurred TM in processed foods, ensuring the safety of sensitive individuals even in complex food matrices [14] [6]. Furthermore, the narrow emission spectra of QDs open the door for multiplexed detection of several allergens or biomarkers on a single strip, using different QDs emitting distinct colors, thereby increasing the information density of a single test [19] [20].

The quantum dot advantage in fluorescence, photostability, and signal intensity is not merely incremental but foundational, enabling a new generation of highly sensitive, quantitative, and robust lateral flow immunoassays. The detailed protocol and quantitative data provided herein offer a roadmap for researchers and developers to harness these properties, paving the way for advanced diagnostic solutions in food safety, clinical diagnostics, and beyond.

For researchers developing detection assays for large protein targets like shrimp tropomyosin, selecting the appropriate lateral flow immunoassay (LFIA) architecture is a critical first step that determines the assay's fundamental performance characteristics. Lateral flow immunoassays have become cornerstone tools in point-of-care diagnostics and food safety testing due to their unique combination of simplicity, portability, and rapid response [22]. The two principal assay formats—sandwich and competitive—operate on divergent immunological principles and are suited to different classes of analytes.

This application note provides a structured comparison between sandwich and competitive LFIA formats, with specific guidance for researchers developing quantum dot-based immunoassays for large protein allergens such as shrimp tropomyosin. We outline the theoretical foundations of each format, present optimized protocols for quantum dot-based sandwich LFIAs, and provide performance optimization strategies to achieve maximum sensitivity and specificity in food allergen detection.

Fundamental Principles and Format Selection

Sandwich Immunoassay Format

The sandwich immunoassay format is specifically designed for large analytes possessing at least two distinct antigenic epitopes [23]. This architecture employs two antibodies that bind to different epitopes on the target molecule: a detector antibody conjugated to a signal-generating nanoparticle and a capture antibody immobilized on the nitrocellulose membrane at the test line [24]. When the target protein is present in the sample, it forms a molecular "sandwich" complex—captured between the two antibodies—resulting in signal accumulation at the test line that is directly proportional to analyte concentration [23] [24].

The visual and intuitive result interpretation (line presence indicates positive result) makes this format ideal for applications requiring qualitative or semi-quantitative analysis [23]. However, researchers should note the potential for the "hook effect" at extremely high analyte concentrations, where saturation of binding sites can paradoxically cause a decrease in signal intensity [23].

Competitive Immunoassay Format

Competitive immunoassays employ a fundamentally different principle, where the target analyte in the sample competes with a reference antigen (competitor) for a limited number of antibody binding sites [25] [23]. This format is predominantly used for detecting small molecules with single antigenic determinants that cannot simultaneously bind two antibodies [22] [23]. In contrast to sandwich assays, the signal intensity at the test line is inversely proportional to analyte concentration—a stronger line indicates less analyte present, while line disappearance indicates a positive result [24].

This counterintuitive signal interpretation presents usability challenges but offers important advantages for small molecule detection, including immunity to the hook effect and the requirement for only one specific antibody [23].

Comparative Analysis: Sandwich vs. Competitive Formats

Table 1: Comprehensive comparison of sandwich and competitive LFIA formats for protein detection.

| Parameter | Sandwich Format | Competitive Format |

|---|---|---|

| Target Analytes | Large proteins (>5-10 kDa) with multiple epitopes (e.g., tropomyosin) [23] [24] | Small molecules (<1-2 kDa) with single epitopes (e.g., toxins, drugs, cortisol) [23] [26] |

| Signal Interpretation | Direct: Line presence = positive result [23] | Inverse: Line absence = positive result [23] [24] |

| Signal vs. Concentration | Directly proportional [24] | Inversely proportional [24] |

| Antibody Requirements | Two different antibodies recognizing distinct epitopes [27] | One specific antibody [23] |

| Hook Effect | Possible at very high analyte concentrations [23] | Not susceptible [23] |

| Ideal for Tropomyosin | Yes - large protein with multiple epitopes [23] [24] | No - not optimal for large multiepitope proteins [23] |

For researchers targeting large protein allergens such as shrimp tropomyosin (approximately 38 kDa), the sandwich immunoassay format represents the optimal choice [23] [24]. Its structural characteristics provide multiple accessible epitopes for simultaneous antibody binding, enabling the formation of stable sandwich complexes and generating a clear, intuitive positive signal.

Figure 1: Schematic workflow of a quantum dot-based sandwich LFIA for shrimp tropomyosin detection. The target protein forms a complex with quantum dot-labeled antibodies in the conjugate pad, which is subsequently captured by immobilized antibodies at the test line, generating a fluorescent signal.

Protocol: Quantum Dot-Based Sandwich LFIA for Tropomyosin Detection

Materials and Reagents

Table 2: Essential reagents and materials for quantum dot-based sandwich LFIA development.

| Component | Specification | Function/Purpose |

|---|---|---|

| Antibody Pair | Monoclonal anti-tropomyosin antibodies recognizing distinct epitopes [27] | Capture and detection of target protein |

| Quantum Dots | Carboxyl-functionalized, emission 525-605 nm [28] [29] | Fluorescent signal generation |

| Nitrocellulose Membrane | Capillary flow time 135-180 sec/4 cm [27] | Platform for capillary flow and test/control lines |

| Conjugate Pad | Glass fiber, pre-treated with sucrose/trehalose [27] | Stable storage and controlled release of QD-antibody conjugates |

| Sample Pad | Glass fiber/cellulose with buffer salts [22] [27] | Sample application, filtration, and pH adjustment |

| Absorbent Pad | High-capacity cellulose [22] | Drives capillary flow by wicking excess fluid |

| Running Buffer | PBS + 0.1% Tween-20 + 1% BSA, pH 7.4 [27] | Maintains optimal pH and reduces non-specific binding |

Step-by-Step Experimental Procedure

Quantum Dot-Antibody Conjugate Preparation

- Activate Quantum Dots: Disperse 50 μL of carboxyl-functionalized QDs (10 mg/mL) in 450 μL of MOPS buffer (0.02 M, pH 6.5). Add 5 μL of EDC (50 mg/mL) and 5 μL of NHS (75 mg/mL) to activate carboxyl groups. Incubate on ice with sonication for 5 minutes [29].

- Purify Activated QDs: Centrifuge at 13,000 rpm at 18°C for 15 minutes. Discard supernatant and resuspend pellet in 500 μL MES buffer (0.02 M, pH 6.0).

- Antibody Conjugation: Add 20-50 μg of purified anti-tropomyosin detection antibody to activated QDs. Rotate mixture for 2 hours at room temperature.

- Blocking: Add 100 μL of 5% BSA for 30 minutes to block residual reactive sites.

- Purification: Centrifuge conjugate at 13,000 rpm for 15 minutes. Resuspend in storage buffer (0.01 M PBS, pH 7.4, containing 1% BSA and 10% sucrose) [29].

- Quality Assessment: Verify conjugation success using dynamic light scattering to monitor hydrodynamic diameter increase and measure fluorescence retention.

Strip Assembly and Reagent Deposition

- Membrane Preparation: Cut nitrocellulose membrane and mount on adhesive backing card. Ensure overlap of approximately 1-2 mm between all components [27].

- Antibody Deposition: Dispense capture antibody (0.5-1 mg/mL in PBS) and control antibody (anti-species, 1 mg/mL) onto membrane as test and control lines using a non-contact dispenser (e.g., BioDot Quanti BioJet) [27]. Dry overnight at 37°C.

- Conjugate Pad Preparation: Apply QD-antibody conjugate to glass fiber pad using an air-jet dispenser (e.g., BioDot AirJet Quanti). Dry for 2 hours at 37°C with desiccant [27].

- Strip Assembly: Sequentially overlap sample pad, conjugate pad, nitrocellulose membrane, and absorbent pad on backing card. Cut assembled cards into 3-5 mm wide strips using a precision cutter.

Assay Execution and Data Interpretation

- Sample Preparation: Extract shrimp samples in PBS buffer (pH 7.4) containing 0.1% Tween-20. Clarify by centrifugation at 10,000 × g for 5 minutes.

- Assay Procedure: Apply 75-100 μL of sample extract to sample pad. Allow capillary flow to develop for 10-15 minutes [29].

- Signal Detection: Visualize results under UV light (365 nm excitation) or quantify using a portable fluorescence reader.

- Result Interpretation: A visible test line and control line indicates positive result. Only control line visible indicates negative result. No control line indicates invalid test [22].

Optimization Strategies for Enhanced Performance

The 4S Sequential Experimental Design

Implement a structured optimization approach using the 4S method (START, SHIFT, SHARPEN, STOP) to systematically enhance assay sensitivity [25] [26]:

- START: Define parameter space for initial screening experiments—QD:antibody ratio, capture antibody concentration, and conjugate pad loading.

- SHIFT: Refine parameter ranges based on initial results to focus on regions yielding optimal signal intensity.

- SHARPEN: Perform fine-tuning of critical parameters to maximize sensitivity and minimize background.

- STOP: Finalize optimal conditions when further adjustments no longer provide significant improvements [25].

This sequential design of experiments (DoE) approach has demonstrated 500-fold sensitivity improvements in competitive assays and can be similarly applied to sandwich format optimization [26].

Critical Optimization Parameters

- Antibody Pair Selection: Screen multiple antibody combinations to identify pairs with synergistic binding characteristics without cross-interference [27].

- Membrane Selection: Test nitrocellulose membranes with different capillary flow times; slower flow rates typically increase sensitivity by extending antigen-antibody interaction time [27].

- Conjugate Stabilization: Optimize sugar matrix (sucrose/trehalose ratios) in conjugate pad to ensure complete resolubilization while maintaining antibody activity [22] [27].

- Blocking Agents: Evaluate different blocking agents (BSA, casein, fish gelatin) in running buffer to minimize non-specific binding without inhibiting specific interactions [27].

For researchers developing detection assays for large protein targets like shrimp tropomyosin, the sandwich LFIA format provides the optimal architecture, leveraging the multiepitope nature of proteins to create sensitive and intuitive detection systems. The integration of quantum dots as fluorescent reporters significantly enhances sensitivity compared to traditional gold nanoparticles, while the structured optimization approaches outlined enable robust assay development.

By implementing the protocols and optimization strategies described in this application note, researchers can develop highly sensitive and specific quantum dot-based sandwich LFIAs for food allergen detection, contributing to improved food safety and public health protection.

The quantum-dot-based lateral flow immunoassay (QD-LFIA) represents a significant advancement in rapid diagnostic testing, combining the simplicity of lateral flow technology with the high sensitivity of fluorescent quantum dots (QDs). This application note details the core components and methodologies for developing a sandwich QD-LFIA specifically for the detection of shrimp tropomyosin (TM), a major crustacean allergen. The guidance provided herein is essential for researchers and scientists engaged in food allergen detection, enabling the creation of highly sensitive and specific tests for monitoring allergen contamination in food products and production lines [14]. The sandwich format is particularly suitable for detecting large molecules like the 34-39 kDa tropomyosin, offering superior performance compared to competitive formats by minimizing false-negative results and reducing susceptibility to matrix effects [14].

Core Components of a QD-LFIA

Strip Architecture and Material Composition

The lateral flow strip is a multi-layered system where each component plays a critical role in ensuring consistent fluid flow and assay performance. Proper assembly is crucial for achieving reproducible results.

Table 1: Components of a QD-LFIA Strip

| Component | Material | Function | Typical Dimensions |

|---|---|---|---|

| Sample Pad | Glass fiber, cellulose | Receives the liquid sample; may include pre-treatment filters | 15-25 mm |

| Conjugate Pad | Glass fiber, polyester | Stores dried QD-antibody conjugates; releases them upon sample contact | 5-10 mm |

| Diagnostic Membrane | Nitrocellulose | Contains immobilized capture antibodies at test (T) and control (C) lines | 25-30 mm |

| Absorption Pad | Cellulose | Acts as a sink to wick fluid through the strip and ensure complete sample flow | 15-20 mm |

| Backing Card | Plastic, adhesive | Provides structural support for assembling all components | 60-70 mm total |

All components are overlapped and fixed onto an adhesive backing card to form a continuous flow path [30]. The sample pad is often pre-treated with blocking buffers (e.g., containing surfactants like Tween-20, sucrose, and proteins like BSA or casein) to minimize non-specific binding and ensure optimal release of the QD probes [31]. The flowing buffer identified for TM detection is frequently 10 mM PBS containing 1% Tween-20 [32].

Diagram 1: Material flow path and core architecture of a QD-LFIA strip.

Fluorescent Probes: Quantum Dots and Antibody Conjugation

Quantum dots are semiconductor nanocrystals that serve as superior fluorescent labels due to their broad excitation spectra, narrow emission bands, and high photostability. For sandwich QD-LFIA targeting TM, polyclonal antibodies (pAbs) are typically conjugated to carboxylated QDs (e.g., CdSe/ZnS core-shell with emission at 610±5 nm) to form the detection probe [32] [14].

Standard Conjugation Protocol (EDC/sulfo-NHS Chemistry)

This protocol describes the covalent coupling of anti-TM antibodies to QDs via carbodiimide chemistry, which links carboxyl groups on the QD surface to primary amines on the antibody [32] [14].

- Activation of QDs: Dilute carboxylated QDs in 50 mM MES buffer (pH 6.0). Add 10 mM EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) and 5 mM sulfo-NHS (N-Hydroxysulfosuccinimide) to the QD solution. Incubate for 30 minutes at room temperature with gentle mixing to activate the carboxyl groups.

- Purification: Remove excess cross-linkers by centrifuging the reaction mixture using a centrifugal filter unit (e.g., 100 kDa MWCO). Wash twice with 50 mM borate buffer (pH 7.4).

- Antibody Coupling: Resuspend the activated QDs in borate buffer. Add the purified anti-TM polyclonal antibody at a predetermined optimal ratio (e.g., 10-20 µg antibody per 25 µL of QDs). Incubate the mixture for 2 hours at room temperature or overnight at 4°C with slow shaking.

- Blocking: Add 1% BSA to the reaction to block any remaining activated esters. Incubate for 30 minutes.

- Purification of Conjugates: Purify the QD-Ab conjugates by centrifugation as in step 2, washing with a storage buffer (e.g., 10 mM PBS with 2% sucrose, 0.5% Tween-20, and 1% BSA, pH 7.4).

- Storage: Resuspend the final conjugate in storage buffer, dispense onto conjugate pads, and dry at 37°C before assembling into strips or storing at 4°C.

Advanced Protocol: Site-Specific Labeling of Antibodies

Random conjugation can hinder the antigen-binding sites (Fab regions) of antibodies, reducing immunoreactivity. Site-specific labeling directs the QDs to the crystallizable fragment (Fc) region, preserving antigen-binding capacity.

- Preparation of Photoactivated Affinity Protein: A recombinant Protein A Z domain, engineered with the unnatural amino acid p-benzoyl-l-phenylalanine (Bpa), is produced. This protein retains its Fc-binding capability.

- Covalent Fc Binding: Incubate the photoactivated affinity protein with the anti-TM monoclonal antibody. Upon UV irradiation, the Bpa moiety forms a stable covalent bond with the antibody's Fc region.

- QD Coupling: The affinity protein is engineered with a free cysteine handle. This thiol group is then coupled to maleimide-functionalized QDs, achieving site-specific labeling at the Fc terminal.

- Validation: Studies confirm that this directional approach yields labeled antibodies with up to 6 times greater binding affinity for the TM antigen compared to those labeled via the random EDC/sulfo-NHS method [33].

Diagram 2: Comparison of random and site-specific antibody-QD conjugation strategies.

Capture Antibodies and Assay Configuration

A sandwich immunoassay requires a matched pair of antibodies that recognize different epitopes on the target antigen, TM.

- Capture Antibody: A monoclonal or polyclonal anti-TM antibody is immobilized onto the nitrocellulose membrane at the test line (T line). The concentration is critical and must be optimized; for TM detection, a concentration of 0.8 mg/mL has been used effectively [32]. The antibody is dispensed using an automated dispenser (e.g., Biolet XYZ-3060 Quantidispenser) at a rate of 0.5-1 µL/cm.

- Control Line: A secondary antibody (e.g., goat anti-rabbit IgG) is immobilized at the control line (C line) to capture any free QD-labeled detection antibody, validating the assay procedure.

- Membrane Preparation: After dispensing the lines, the membrane is dried, typically at 65°C for 30 minutes, to ensure stable immobilization [31].

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents for Developing a QD-LFIA for Tropomyosin

| Reagent / Material | Function and Importance | Examples / Specifications |

|---|---|---|

| Anti-Tropomyosin Antibodies | Key biorecognition elements. A matched pair (capture & detection) is needed for the sandwich assay. | Monoclonal (capture) and polyclonal (detection) antibodies; specificity for shrimp TM is crucial [14] [10]. |

| Carboxylated Quantum Dots | Fluorescent signal label. Provide high sensitivity and photostability. | CdSe/ZnS core-shell, emission at 610±5 nm, modified with surface carboxyl groups for conjugation [32] [33]. |

| Conjugation Chemicals | Enable covalent attachment of antibodies to QDs. | EDC, sulfo-NHS for standard conjugation; maleimide-functionalized QDs for site-specific labeling [32] [33]. |

| Nitrocellulose Membrane | Porous matrix for capillary flow and immobilization of capture antibodies. | Various pore sizes (e.g., 8-15 µm); critical for defining flow rate and line sharpness [32]. |

| Buffer Components | Maintain optimal pH and ionic strength; reduce non-specific binding. | PBS (10 mM, pH 7.4), Tween-20 (0.05-1%), BSA (1-10%), sucrose (2-4%) as a stabilizer [32] [31]. |

| Tropomyosin Standard | Essential for assay development, optimization, and generating a calibration curve. | Purified natural or recombinant shrimp TM [14] [15]. |

The performance of a QD-LFIA for TM is evaluated based on its sensitivity, specificity, and reproducibility. The following table summarizes performance data from key studies.

Table 3: Performance Comparison of QD-LFIA Formats for Tropomyosin Detection

| Assay Parameter | Competitive QD-LFIA [32] | Sandwich QD-LFIA [14] | Site-Specific Sandwich QD-LFIA [33] |

|---|---|---|---|

| Target Analyte | Crustacean Tropomyosin | Shrimp Tropomyosin | Shrimp Tropomyosin |

| Visual LOD (µg/mL) | 0.5 | 0.05 | 0.054 |

| Instrumental LOD (µg/mL) | 0.05 | 0.01 | Not specified |

| Assay Time | Within 30 min | Within 10 min | Not specified |

| Specificity | Good for crustacean TM | No cross-reactivity with other species except shrimp | High specificity for shrimp TM |

| Key Feature | First QD-LFIA for crustacean TM | Superior sensitivity and speed | Enhanced antibody binding affinity |

The data demonstrates that the sandwich format offers a significant improvement in sensitivity over the competitive format. Furthermore, the site-specific labeling strategy enhances antibody functionality, contributing to the overall assay performance [14] [33].

Advanced Application: Multiplexed QD-LFIA

The QD-LFIA platform can be extended for the simultaneous detection of multiple allergens. A multiplexed LFIA (xLFIA) has been developed for the concurrent detection of crustacean allergens (tropomyosin and sarcoplasmic calcium binding protein) and egg allergen (ovalbumin) on a single strip [15] [34].

- Architecture: Multiple test lines, each coated with a capture antibody specific to a different allergen (anti-TM, anti-SCP, anti-OVA), are positioned on the same nitrocellulose membrane.

- Probes: A mixture of QD-labeled detection antibodies for all targets is applied to the conjugate pad. A single type of QD can be used, with the result read from the position of the T line.

- Optimization: To reduce mutual interference between adjacent T lines, parameters such as antibody coating concentration and the mixture ratio of the different QD-labeled antibodies must be carefully optimized. For the triplex assay, visual detection limits of 0.5 µg/mL for TM, 0.1 µg/mL for SCP, and 0.05 µg/mL for OVA were achieved [15].

The development of a robust QD-LFIA for shrimp tropomyosin relies on the meticulous integration of its core components: a properly assembled strip architecture, highly specific antibody pairs, and brightly fluorescent QD probes. Employing site-specific labeling strategies can dramatically improve antibody binding capacity and assay sensitivity. Furthermore, the platform's versatility allows for expansion into multiplexed assays, providing a powerful tool for comprehensive food allergen monitoring. The protocols and data summarized in this application note provide a solid foundation for researchers to develop and optimize their own QD-LFIA systems for food safety and other diagnostic applications.

A Step-by-Step Protocol: Constructing the QD-Sandwich LFIA for Tropomyosin

This application note details a robust protocol for the covalent conjugation of anti-tropomyosin antibodies to carboxylated quantum dots (QDs) via EDC/NHS chemistry. This synthesis produces a stable fluorescent probe specifically designed for use in a quantum-dot-based sandwich lateral flow immunoassay (LFIA) for the detection of shrimp tropomyosin (TM), the major allergen in shellfish [14]. The exceptional optical properties of QDs—including high quantum yield, photostability, and size-tunable emission—significantly enhance the sensitivity of LFIA platforms, enabling the rapid and accurate detection of trace allergens in processed foods to address critical food safety concerns [14] [35].

The EDC/NHS covalent conjugation chemistry described here offers a significant advantage over passive adsorption methods by creating a stable amide bond between the antibody and the nanoparticle, improving probe consistency and assay performance [35]. Furthermore, we present data demonstrating how site-specific labeling strategies can further optimize antibody performance, maximizing the sensitivity of the final diagnostic assay [33].

The diagram below illustrates the core procedural workflow for the covalent conjugation process.

Key Reagent Solutions

The following table catalogues the essential reagents required for the successful synthesis of the QD-antibody conjugate.

Table 1: Key Research Reagent Solutions

| Reagent / Material | Function / Role in Protocol | Key Considerations |

|---|---|---|

| Carboxylated QDs (e.g., CdSe/ZnS) | Fluorescent core; provides signal for detection and surface carboxyl groups for covalent conjugation. | Ensure water solubility and consistent particle size (e.g., emission at 610±5 nm) [14] [33]. |

| Anti-Tropomyosin Antibodies | Specific biological capture molecule; binds shrimp TM antigen in the LFIA. | Monoclonal antibodies ensure epitope specificity; polyclonal antibodies can increase sensitivity [14] [36]. |

| EDC & Sulfo-NHS | Crosslinking agents; EDC activates QD surface carboxyl groups, forming active ester intermediates stabilized by Sulfo-NHS. | Use fresh preparations in reaction buffers for optimal efficiency [14] [35]. |

| Coupling Buffer (e.g., 50 mM MES, pH 6.0) | Reaction medium; provides optimal pH environment for EDC/NHS chemistry and antibody stability. | Low ionic strength and slightly acidic pH maximize primary amine reactivity and conjugate yield [35]. |

| Size Exclusion Chromatography Media | Purification; separates conjugated QD-antibody probes from unreacted antibodies, free QDs, and chemical byproducts. | Critical for removing aggregates and isolating monodisperse, functional conjugates [35]. |

Comparative Conjugation Methods

While this protocol focuses on the standard EDC/NHS method, other conjugation strategies exist. The following table compares the key approaches, highlighting the performance advantages of site-specific techniques.

Table 2: Comparison of Antibody Conjugation Methods for QD Labeling

| Conjugation Method | Mechanism | Key Advantage | Key Disadvantage | Impact on Antigen Binding Affinity |

|---|---|---|---|---|

| Standard EDC/NHS | Covalent, random orientation; links carboxyl groups on QDs to primary amines (lysine) on antibodies. | Simple, widely applicable protocol. | Random orientation can block antigen-binding sites. | Can be significantly reduced due to steric hindrance. |

| Site-Specific (Fc-Targeted) | Covalent, controlled orientation; uses photoactivated affinity proteins (e.g., Protein A Z domain with Bpa) to bind antibody Fc region, then crosslinks. | Preserves antigen-binding fragment (Fab) activity. | More complex protocol requiring specialized reagents. | Retains up to 6x higher binding affinity compared to random labeling [33]. |

| Streptavidin-Biotin | Non-covalent, controlled orientation; uses high-affinity interaction between streptavidin on QDs and biotinylated antibodies. | Stable interaction; allows for pre-purified component assembly. | Requires an extra biotinylation step; larger complex size. | Generally good, as biotinylation can be directed. |

Detailed Experimental Protocol

Reagent Preparation

- QD Solution: Dilute the stock carboxylated QD solution (e.g., CdSe/ZnS) to a concentration of 1 µM in Coupling Buffer (50 mM MES, pH 6.0).

- Antibody Solution: Prepare a solution of the anti-tropomyosin monoclonal antibody at a concentration of 1-2 mg/mL in a neutral buffer such as PBS. Ensure the antibody is free of carrier proteins like BSA, which contain primary amines and would compete in the reaction.

- Crosslinker Solution: Prepare fresh solutions of EDC (400 mM) and sulfo-NHS (100 mM) in ultra-pure water. These solutions are unstable and must be used immediately.

Conjugation Procedure

- Activation of Carboxyl Groups: To 1 mL of the 1 µM QD solution in a microcentrifuge tube, add 50 µL of the 100 mM sulfo-NHS solution, followed by 50 µL of the 400 mM EDC solution. Mix the reaction mixture gently by pipetting or inverting the tube. Incubate for 30 minutes at room temperature with mild agitation to allow for the formation of amine-reactive sulfo-NHS esters on the QD surface.

- Removal of Excess Crosslinkers: Purify the activated QDs from the reaction mixture using a size exclusion micro-spin column (e.g., equilibrated with 50 mM MES, pH 6.0) according to the manufacturer's instructions. This step is critical to prevent the crosslinking of antibodies to each other.

- Antibody Coupling: Immediately after purification, add a molar excess of the anti-tropomyosin antibody solution to the activated QDs. A typical molar ratio of QD to antibody is 1:50 to 1:100. Mix gently and incubate the reaction for 2 hours at room temperature or overnight at 4°C with continuous agitation.

- Quenching and Blocking: After coupling, quench the reaction by adding 100 µL of 1 M Tris-HCl, pH 7.4, and incubate for 15 minutes. To block any remaining active sites and minimize non-specific binding in the subsequent LFIA, add a blocking agent such as 1% (w/v) Bovine Serum Albumin (BSA) and incubate for an additional 30 minutes.

- Purification of Conjugate: Separate the QD-antibody conjugate from unreacted antibodies and other reagents by size exclusion chromatography (e.g., using a Sephacryl S-300 column) or by density gradient centrifugation. Collect the first colored fluorescent band, which contains the conjugate.

- Storage: Store the purified conjugate in a suitable storage buffer (e.g., PBS with 0.1% BSA and 0.01% sodium azide) at 4°C in the dark. Avoid repeated freeze-thaw cycles.

Performance and Validation

The QD-anti-TM conjugate synthesized via this method is integral to the performance of the sandwich LFIA. When applied to the conjugate pad of the test strip, it enables the rapid and sensitive detection of shrimp tropomyosin. As demonstrated in prior studies, this approach can achieve an instrumental detection limit (IDL) for tropomyosin as low as 0.01 µg/mL and a visual detection limit (VDL) of 0.05 µg/mL, with results available in under ten minutes [14].

The site-specific conjugation method summarized in Table 2 offers a path for further optimization. Research has shown that directionally labeled antibodies can demonstrate a six-fold greater binding affinity for the tropomyosin antigen compared to those labeled via random EDC/NHS chemistry, which could potentially lower the detection limit even further [33].

Troubleshooting Guide

Table 3: Common Issues and Proposed Solutions

| Problem | Potential Cause | Suggested Solution |

|---|---|---|

| Low Conjugation Yield | Inefficient carboxyl group activation; inactive EDC/NHS. | Use fresh crosslinkers and ensure the reaction pH is between 6.0 and 7.0. |

| QD-Antibody Aggregation | Excessive crosslinking; antibody concentration too high. | Optimize the QD-to-antibody ratio; ensure efficient removal of unreacted EDC/NHS before adding antibody. |

| High Background in LFIA | Non-specific binding of the conjugate; incomplete blocking. | Include effective blocking agents (e.g., BSA, casein) during conjugation and in the LFIA running buffer. |

| Reduced Antigen Binding | Random conjugation sterically blocks antibody paratopes. | Consider adopting the site-specific Fc-targeted labeling strategy to orient antibodies correctly [33]. |

This application note details the fabrication protocol for a quantum-dot-based sandwich lateral flow immunoassay (LFIA) strip, specifically developed for the detection of the major shrimp allergen tropomyosin (TM). The content is framed within a broader thesis research context, aiming to provide a rapid, sensitive, and specific on-site detection tool for food safety analysis [2] [6]. The sandwich LFIA format is chosen for its superior performance in detecting large protein allergens like TM, offering reduced susceptibility to false negatives and matrix effects compared to competitive formats [2]. This document provides a standardized procedure for researchers and scientists developing in-house test strips, covering key steps from material selection to final assembly.

The Scientist's Toolkit: Essential Materials and Reagents

The successful development of a consistent and sensitive LFIA strip is contingent on the selection of appropriate materials and reagents. The following table catalogues the essential components, their functions, and key selection criteria.

Table 1: Key Research Reagent Solutions and Materials for LFIA Strip Fabrication

| Component | Function / Explanation | Key Considerations |

|---|---|---|

| Nitrocellulose Membrane | Serves as the analytical platform where capture antibodies are immobilized to form test and control lines [27]. | Capillary flow rate (rise time) critically impacts sensitivity; slower membranes (e.g., Whatman FF120HP) allow more interaction time [37] [27]. |

| Capture & Detector Antibodies | An antibody pair specific to Tropomyosin. The capture antibody is immobilized on the membrane, while the detector antibody is conjugated to the label [27]. | High affinity and specificity are paramount. Pairs should be screened via ELISA first. May be monoclonal, polyclonal, or recombinant [27]. |

| Quantum Dots (QDs) | Fluorescent nanoparticles used as the label for detector antibodies, providing high sensitivity due to their bright and stable fluorescence [2]. | CdSe/ZnS core-shell QDs with carboxyl surface modification allow covalent antibody conjugation via EDC/sulfo-NHS chemistry [2]. |

| Conjugate Release Pad | A pad material that stores the dried QD-antibody conjugates and releases them uniformly upon sample application [27]. | Must be pre-treated with blocking reagents (e.g., sucrose, PVP) and surfactants for stable conjugation storage and even rehydration [27]. |

| Sample Pad | Receives the liquid sample and can pre-filter particulates or adjust sample pH via pre-treatment [27]. | Glass fiber is common. Pre-treatment with buffers, blockers (PVA, PVP), and surfactants (Tween) can improve flow and sensitivity [27]. |

| Backing Card | A plastic-coated, pressure-sensitive adhesive platform that provides structural integrity for assembling all strip components [27]. | Must use diagnostic-grade adhesive to avoid interfering with immunoassay chemistry [37] [27]. |

| Absorbent Sink | A pad at the distal end of the strip that wicks and collects the fluid, maintaining continuous capillary flow across the strip [27]. | Sufficient absorptive capacity and wicking rate are crucial to prevent backflow, which can cause high background or false positives [27]. |

| Running Buffer | The buffer in which the sample is applied or that is used to pre-treat pads. It optimizes pH and sample flow [37]. | Typically neutral pH, low ionic strength buffers (e.g., PBS, Borate) with surfactants (Tween, Triton) to enhance flow and antibody-antigen affinity [37] [27]. |

Experimental Protocols

Conjugation of Detector Antibodies to Quantum Dots

This protocol describes the covalent coupling of anti-TM polyclonal IgG to carboxylated QDs using the EDC/sulfo-NHS chemistry, as employed for the shrimp TM LFIA [2].

Materials:

- Carboxylated CdSe/ZnS QDs (e.g., from Beidajubang Technology Co.)

- Anti-Tropomyosin polyclonal IgG

- 1-Ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC)

- N-hydroxysulfosuccinimide sodium salt (sulfo-NHS)

- 0.01 M MES buffer (pH 6.0)

- 0.01 M PBS buffer (pH 7.4)

- Ultrapure water

- Centrifugal filter units (100 kDa MWCO)

Procedure:

- Activation of QDs: Dilute 1 nmol of carboxylated QDs in 500 µL of 0.01 M MES buffer (pH 6.0). Add 20 µL of freshly prepared EDC solution (10 mg/mL) and 40 µL of sulfo-NHS solution (10 mg/mL). Incubate the mixture for 30 minutes at room temperature with gentle shaking.

- Purification of Activated QDs: To remove excess EDC/sulfo-NHS, transfer the reaction mixture to a 100 kDa centrifugal filter and centrifuge at 12,000 × g for 8 minutes. Discard the flow-through and resuspend the activated QDs in 500 µL of MES buffer. Repeat this wash step once.

- Antibody Conjugation: Immediately add 50 µg of anti-TM IgG to the purified, activated QDs. Adjust the total reaction volume to 1 mL with PBS (pH 7.4). Allow the conjugation to proceed for 2 hours at room temperature with gentle shaking, protected from light.

- Blocking and Purification: Add 100 µL of 1% (w/v) BSA solution to block any remaining active sites and incubate for 30 minutes. To remove unconjugated antibodies, wash the QD-antibody conjugates three times with PBS using centrifugal filters (12,000 × g, 8 min per wash).

- Storage: Finally, resuspend the purified QD-antibody conjugates in 200 µL of storage buffer (0.01 M PBS, pH 7.4, containing 1% BSA, 5% sucrose, and 0.05% sodium azide). Store at 4°C protected from light for future use.

Immobilization of Capture Antibodies on Nitrocellulose Membrane

This section details the precise dispensing of capture antibodies and control line antibody onto the nitrocellulose membrane.

Materials:

- Nitrocellulose membrane (e.g., Whatman FF120HP)

- Anti-Tropomyosin capture antibody (for Test Line)

- Goat anti-rabbit IgG antibody (for Control Line)

- Dispensing buffer (e.g., 0.01 M PBS, pH 7.4)

- BioDot Quanti BioJet or equivalent non-contact dispenser

- Drying oven

Procedure:

- Antibody Preparation: Dilute the anti-TM capture antibody and the goat anti-rabbit IgG antibody to a concentration of 1.0 mg/mL in dispensing buffer. Centrifuge the antibody solutions briefly at high speed to remove any potential aggregates.

- Membrane Preparation: Cut the nitrocellulose membrane to the required size and affix it securely onto the backing card, ensuring no air bubbles are trapped.

- Dispensing Antibody Lines: Using a non-contact dispenser, dispense the anti-TM antibody solution in a fine line to form the Test Line. Parallel to it, dispense the goat anti-rabbit IgG solution to form the Control Line. A typical dispensing rate is 1 µL per cm of membrane length.

- Drying: Immediately after dispensing, dry the membrane for 1 hour at 37°C or overnight at room temperature in a clean, low-humidity environment.

Strip Assembly and Fabrication

This protocol covers the integration of all pre-fabricated components into a functional lateral flow strip.

Materials:

- Backing card with immobilized membrane

- Pre-treated sample pad (e.g., Whatman CF3, treated with buffer containing surfactants and blocking agents)

- Conjugate release pad (e.g., Glass Fiber, pre-treated and sprayed with QD conjugates)

- Absorbent sink pad (e.g., Whatman cellulose fiber)

- Guillotine cutter

Procedure:

- Conjugate Pad Preparation: Spray the QD-antibody conjugate solution onto the pre-treated conjugate release pad using an air-jet dispenser (e.g., BioDot AirJet Quanti) for even application. Dry the pad thoroughly and store desiccated at 4°C.

- Component Overlay: Remove the release liner from the backing card. Overlap the components sequentially onto the adhesive backing card in the following order:

- Absorbent Sink: Place at the distal end of the card, overlapping the nitrocellulose membrane by 1-2 mm.

- Conjugate Pad: Place at the proximal end, overlapping the nitrocellulose membrane by 1-2 mm.

- Sample Pad: Place at the very proximal end, overlapping the conjugate pad by 1-2 mm.

- Lamination and Cutting: Apply light, even pressure across the entire assembly to ensure all components are firmly bonded to the adhesive backing. Finally, cut the large card into individual strips of the desired width (typically 3-5 mm) using a guillotine cutter.

Data Presentation and Performance Metrics

The performance of the fabricated QD-LFIA strip for tropomyosin detection should be characterized using the following key metrics, which can be summarized for easy comparison.

Table 2: Quantitative Performance Data for Tropomyosin QD-LFIA

| Performance Parameter | Result | Experimental Detail / Note |

|---|---|---|

| Visual Detection Limit (VDL) | 0.05 µg/mL | The lowest TM concentration producing a visible test line under ambient light [2]. |

| Instrumental Detection Limit (IDL) | 0.01 µg/mL | The lowest TM concentration detected by a fluorescent strip reader [2]. |

| Assay Time | < 10 minutes | Total time from sample application to result readout [2]. |

| Specificity (Cross-Reactivity) | No cross-reactivity with other species except shrimp | Tested against a panel of other potential food allergens [2]. |

| Intra-Assay Precision (CV) | 8.87% - 11.9% | Coefficient of variation for replicates within the same assay run [2]. |

| Inter-Assay Precision (CV) | 7.75% - 21.12% | Coefficient of variation for replicates across different assay runs [2]. |

Workflow and Logical Diagrams

The following diagrams illustrate the key signaling principle and the comprehensive fabrication workflow.

QD-LFIA Sandwich Assay Principle

LFIA Strip Fabrication Workflow

The detection of food allergens is a critical public health concern, with shrimp tropomyosin (TM) being a major allergen affecting a significant portion of the population. This application note details a rapid, highly sensitive, and specific Quantum-Dot-based Sandwich Lateral Flow Immunoassay (QD-LFIA) for the detection of TM in processed foods. This method fulfills the ASSURED (Affordable, Sensitive, Specific, User-friendly, Rapid/Robust, Equipment-free, and Deliverable to end users) criteria for point-of-care testing (POCT) as recommended by the World Health Organization, enabling detection within a single 10-minute workflow [38].

Principle of the Quantum-Dot-Based Sandwich LFIA

The assay employs a sandwich format, ideal for large protein targets like TM with multiple epitopes. In this configuration, fluorescent CdSe/ZnS quantum dots (QDs) serve as the reporter label, conjugated to anti-TM polyclonal antibodies. When a liquid sample is applied, it migrates via capillary action, rehydrating the QD-antibody conjugates. If TM is present, it binds to these conjugates, forming a complex. This complex continues to flow across a nitrocellulose membrane until it is captured at the test line by a second, immobilized anti-TM antibody, forming a "sandwich" (QD-anti-TM-TM-anti-TM). The accumulation of QDs at the test line produces a fluorescent signal proportional to the TM concentration. A control line confirms the proper function of the assay. The fluorescent signal offers superior sensitivity and a lower limit of detection compared to conventional colorimetric reporters like gold nanoparticles [38] [14].

The schematic workflow below illustrates the key stages of the assay:

Materials and Reagents

Research Reagent Solutions

The following table details the essential materials and reagents required to perform the QD-LFIA.

| Item | Function/Description |

|---|---|

| CdSe/ZnS QDs (Carboxylated) | Fluorescent reporter label; provides high-intensity, stable fluorescence for sensitive detection [14]. |

| Anti-TM Polyclonal Antibodies | Used for both conjugation to QDs (detector antibody) and immobilization on the test line (capture antibody) [14]. |

| EDC & Sulfo-NHS | Cross-linking agents for covalent conjugation of carboxylated QDs to antibodies via carbodiimide chemistry [14]. |

| Nitrocellulose Membrane | The porous matrix through which the sample migrates; contains the immobilized test and control lines [38]. |

| Conjugate Pad | Pad where the QD-antibody conjugates are stored in a dry state until rehydrated by the sample [38]. |

| Sample Pad | The point of sample application; filters out unwanted cellular components from complex samples like food homogenates [38]. |

| Absorbent Pad | Acts as a waste reservoir, wicking the remaining fluid and ensuring continuous capillary flow across the strip [38]. |

| Running Buffer (PBS with Tween 20) | Provides the liquid medium for sample migration and optimal antigen-antibody binding conditions [14]. |

Detailed Experimental Protocol

Conjugation of QDs with Anti-TM Antibodies

This protocol describes the covalent coupling of antibodies to quantum dots using EDC/s-NHS chemistry [14].

- Activation: Mix 1 mL of carboxylated QDs (1 µM) with 100 µL of EDC (10 mg/mL) and 100 µL of sulfo-NHS (10 mg/mL) in MES buffer (0.1 M, pH 6.0). Incubate the mixture for 30 minutes at room temperature with gentle shaking.

- Purification: Remove excess cross-linkers by centrifuging the activated QDs through a 100 kDa molecular weight cutoff filter at 12,000 × g for 10 minutes. Discard the flow-through and resuspend the QDs in 1 mL of borate buffer (0.05 M, pH 7.4).

- Conjugation: Add 100 µg of purified anti-TM polyclonal IgG to the activated QDs. React for 2 hours at room temperature with gentle shaking.

- Blocking: Add 100 µL of 1% (w/v) BSA to block any remaining active sites and incubate for 30 minutes.

- Final Purification: Purify the QD-antibody conjugates by centrifugation as in step 4.2. Resuspend the final conjugate in 1 mL of storage buffer (0.05 M borate buffer, pH 7.4, containing 1% BSA, 5% sucrose, and 0.1% Tween 20).

- Storage: The conjugate can be stored at 4°C for several weeks. For long-term storage, aliquot and freeze at -20°C.

Assembly of the Lateral Flow Strip