AI-Driven Spectroscopy for Allergen Detection: Revolutionizing Safety in Complex Food Matrices

This article explores the transformative integration of artificial intelligence (AI) and advanced spectroscopic techniques for detecting food allergens in complex matrices.

AI-Driven Spectroscopy for Allergen Detection: Revolutionizing Safety in Complex Food Matrices

Abstract

This article explores the transformative integration of artificial intelligence (AI) and advanced spectroscopic techniques for detecting food allergens in complex matrices. Tailored for researchers and scientists, it examines the foundational principles of technologies like Hyperspectral Imaging (HSI), FTIR, and Raman spectroscopy, enhanced by machine learning for non-destructive, real-time analysis. The scope extends to methodological applications, including sensor fusion and aptamer-based platforms, troubleshooting of computational and data challenges, and rigorous validation against conventional methods like ELISA and PCR. By synthesizing current innovations and future trajectories, this review provides a comprehensive resource for advancing food safety protocols and clinical diagnostics.

The New Frontier: Understanding AI and Spectroscopy for Allergen Detection

Immunoglobulin E (IgE)-mediated food allergies (FA) represent a growing global public health challenge, characterized by adverse immune responses upon exposure to specific food allergens [1]. The management of these allergies requires strict dietary avoidance to prevent reactions ranging from moderate symptoms, such as nausea or hives, to severe, life-threatening anaphylaxis [2]. The increasing global prevalence, coupled with the significant social and financial burdens placed on affected families and healthcare systems, underscores a critical need for advancements in detection and management strategies [3] [4]. Emerging technologies, particularly AI-driven spectroscopy, are poised to transform allergen detection by enabling faster, more accurate, and non-destructive analysis of complex food matrices, thereby addressing key challenges in safety and compliance [5] [2].

The Global Burden of Food Allergy

Epidemiological Trends

The prevalence of food allergies has increased significantly in recent decades, with variations observed across different regions and age groups. A large international cross-sectional study (ASSESS FA) developed a standardized methodology to estimate point prevalence across nine countries, revealing a complex epidemiological landscape [1].

Table 1: Global Prevalence of Food Allergies

| Region | Pediatric Population | Adult Population | Notes |

|---|---|---|---|

| United States & Canada | 6.5% - 8.7% | 5.9% - 10.8% | Based on reported FA [1] |

| Europe | 2% - 20% | 1% - 4.7% | Great variation across nations [1] |

| China | 4% - 12% | 7% - 14% | [1] |

| Japan | ~5% (children) | Data not specified | [1] |

| Global Estimate | ~8% (worldwide) | 3-11% (varies by region) | Highest among younger children [1] [2] |

The "big-nine" allergens—wheat (gluten), peanuts, egg, shellfish, milk, tree nuts, fish, sesame, and soybeans—are responsible for the majority of severe allergic reactions [2]. In 2023, the U.S. Food and Drug Administration (FDA) added sesame to its major allergens list, reflecting the evolving understanding of allergenic foods [2]. Furthermore, emerging allergens such as lupin, certain seeds (e.g., mustard), and insect proteins are increasingly recognized as triggers, adding complexity to allergy management [6].

Socio-Economic Impact

The financial and social costs of food allergy are substantial and multifaceted, affecting households, healthcare systems, and society at large.

Table 2: Socio-Economic Burden of Food Allergy

| Cost Category | Description | Impact |

|---|---|---|

| Direct Household Costs | Higher-cost allergen-free foods, medications (e.g., epinephrine auto-injectors), and therapies [3]. | Families face disproportionately higher food costs, exacerbated by recent food inflation [3] [4]. |

| Indirect Household Costs | Time and opportunity losses from managing the condition (e.g., food preparation, medical appointments) [3]. | Increased burden on caregivers, potentially affecting employment and income [3]. |

| Intangible Costs | Impaired health-related quality of life (HRQL), psychological stress, and social isolation [3]. | Significant impairments in quality of life and food allergy anxiety for patients and families [3] [1]. |

| Healthcare System Costs | Medical care, hospitalizations, and dispensation of emergency medications [4]. | Annual economic cost in the US is estimated at $19-$25 billion [2]. |

For families, these burdens are fluid across the lifespan and are exacerbated in an era of rapid change in food allergy management and therapy [3]. The constant vigilance required for food avoidance can lead to anxiety and restrict participation in social activities, which are often centered around food [3] [1].

Current Challenges in Allergen Detection

Conventional allergen detection methods, such as Enzyme-Linked Immunosorbent Assay (ELISA), Polymerase Chain Reaction (PCR), and mass spectrometry, while reliable, present several limitations. These methods can be time-consuming, limited in scope, destructive to samples, and often require extensive sample preparation [5] [2]. A significant challenge is the accurate detection of allergens in processed foods, where proteins may be denatured or altered, reducing the efficiency of antibody-based detection [7] [8]. Furthermore, the need for simultaneous detection of multiple allergens in complex matrices is not adequately met by single-analyte methods, necessitating multiple analyses and increasing time and cost [7]. The reliance on high-quality protein extracts is also a critical factor for accurate quantification in allergy risk assessments [8].

AI-Driven Spectroscopy: A Paradigm Shift in Detection

Technological Foundations

Artificial Intelligence (AI), particularly machine learning (ML) and deep learning, is revolutionizing analytical spectroscopy for allergen detection. These technologies leverage the power of sensors and advanced algorithms to provide rapid, non-destructive, and highly accurate analysis [2]. Key spectroscopic techniques being enhanced by AI include:

- Hyperspectral Imaging (HSI) and Fourier Transform Infrared (FTIR) Spectroscopy: AI models can process the complex spectral data from these non-destructive methods to identify and quantify allergens in real-time without altering food integrity [5].

- Raman Spectroscopy: This technique provides a valuable analytical method for non-destructively measuring molecular structure in biomedical and food samples. When combined with AI, it enables high-sensitivity classification and prediction [9].

- Mass Spectrometry: Coupled with AI, this technology can achieve high sensitivity and specificity by detecting proteotypic peptides across complex food matrices, offering new levels of precision for quantifying specific allergenic proteins [5].

AI models, including Convolutional Neural Networks (CNNs), can reduce the need for rigorous data preprocessing and identify the most important spectral regions for analyzing features of interest, thereby improving classification accuracy [9].

Application Workflow for Allergen Detection

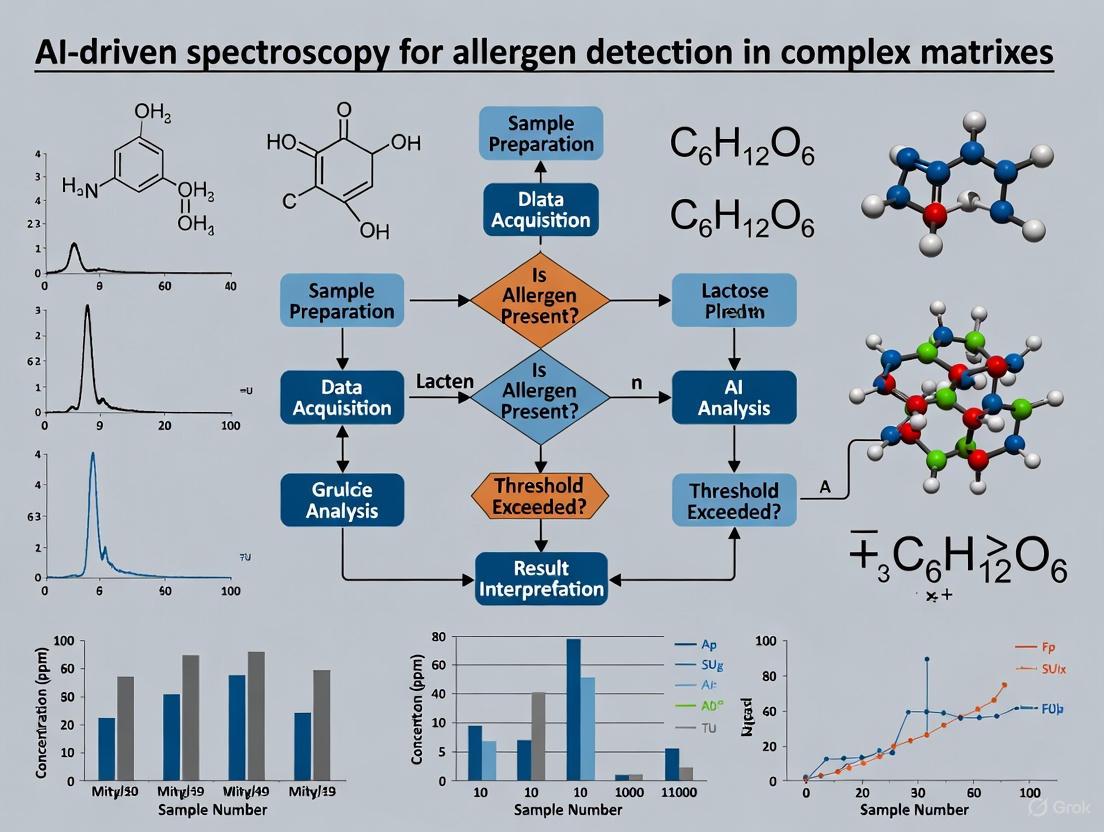

The following diagram illustrates the integrated workflow of AI-driven spectroscopy for detecting allergens in complex food matrices.

Experimental Protocol: AI-Enhanced Spectral Analysis for Allergen Detection

Objective: To identify and quantify specific food allergens in a complex, incurred food matrix using Fourier Transform Infrared (FTIR) spectroscopy coupled with a Convolutional Neural Network (CNN).

Materials & Reagents:

- Food matrix (e.g, baked muffins, dark chocolate, meat sausage)

- Target allergenic food powders (e.g., peanut, milk, egg)

- Phosphate Buffered Saline (PBS) with 0.05% Tween-20

- SDS/β-mercaptoethanol denaturing buffer

- Reflective metal slides for FTIR

Procedure:

- Sample Incurring and Preparation:

- Incur the target allergenic food powder into the selected food matrix at concentrations ranging from 1 to 1000 μg/g (ppm) of the original food [7].

- Homogenize the incurred samples using a blender to ensure uniform distribution.

Protein Extraction (Dual Protocol):

- Buffered-Detergent Extraction: Weigh 1 g of sample and add 10 mL of PBS-Tween (0.05%). Vortex for 2 minutes, then centrifuge at 10,000 × g for 10 minutes. Collect the supernatant [7].

- Reduced-Denatured Extraction: For samples subjected to processing (e.g., baking), weigh 1 g of sample and add 10 mL of SDS/β-mercaptoethanol buffer. Heat at 95°C for 10 minutes, then centrifuge at 10,000 × g for 10 minutes. Collect the supernatant [7] [8].

Spectral Data Acquisition:

- Spot 2 μL of each extract onto a reflective metal slide and allow to air-dry.

- Acquire FTIR spectra in the reflectance mode across the wavenumber range of 4000-600 cm⁻¹. Perform 64 scans per spectrum at a resolution of 4 cm⁻¹.

AI Model Training and Analysis:

- Data Preprocessing: Apply standard normal variate (SNV) transformation to minimize scatter effects. Perform vector normalization on the spectral data [9].

- Model Architecture: Implement a shallow CNN with a single one-dimensional convolutional layer, followed by a max-pooling layer and two fully connected layers.

- Model Training: Split the preprocessed spectral data into training (70%), validation (15%), and test (15%) sets. Train the CNN to classify samples based on allergen presence and concentration. Compare performance against traditional models like Partial Least Squares (PLS) regression [9].

Validation:

- Validate the model's classification accuracy and quantification precision using blinded test sets.

- Confirm detection capability at concentrations comparable to ≤ 10 μg/g in the original food sample, as demonstrated in multi-laboratory validations [7].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Materials for Allergen Detection Research

| Reagent/Material | Function/Application | Example Use in Protocol |

|---|---|---|

| PBS with Tween-20 | Buffered-detergent extraction; solubilizes native proteins for immunoassay-based detection [7]. | Extraction of soluble, non-denatured proteins from food matrices for initial screening [7]. |

| SDS/β-mercaptoethanol Buffer | Reduced-denatured extraction; disrupts disulfide bonds and solubilizes proteins from processed foods [7]. | Extraction of proteins from baked or heat-processed samples where allergens may be denatured [7] [8]. |

| xMAP Microspheres | Color-coded magnetic beads for multiplex immunoassays; allow simultaneous detection of multiple allergens [7]. | Bead-based immunoassay for concurrent detection of 14+ allergens in a single well [7]. |

| Antibody Cocktails | Target-specific antibodies conjugated to beads or labels; provide specificity for allergen identification [7]. | Key component in xMAP FADA or ELISA for binding and detecting specific allergenic proteins [7]. |

| FTIR/Raman Slides | Substrate for spectral analysis; provides a consistent surface for non-destructive measurement [9]. | Holding the sample during spectral data acquisition via FTIR or Raman spectroscopy [9]. |

The rising global prevalence and substantial economic impact of food allergies create a critical need for advanced detection methodologies. The limitations of conventional techniques highlight the necessity for innovative solutions. The integration of Artificial Intelligence with analytical spectroscopy presents a transformative approach, enabling rapid, accurate, and non-destructive detection and quantification of allergens, even within the most complex food matrices. This powerful combination promises to enhance consumer safety, improve regulatory compliance, and ultimately reduce the significant human and economic costs associated with food allergies.

The accurate detection and quantification of target analytes, such as food allergens, pathogens, or therapeutic biomarkers, in complex matrices is a cornerstone of food safety, clinical diagnostics, and pharmaceutical development. Complex biological and food matrices, which can include components like proteins, lipids, carbohydrates, and salts, present a significant challenge for analytical techniques. Conventional methods, including the Enzyme-Linked Immunosorbent Assay (ELISA), Polymerase Chain Reaction (PCR), and mass spectrometry, are widely used but possess inherent limitations that can compromise their performance in these demanding environments. Within the broader context of developing AI-driven spectroscopy for allergen detection, understanding these limitations is crucial. It not only highlights the need for innovative solutions but also helps define the specific performance gaps that new technologies must address. This application note details the key limitations of these established methods, supported by experimental data and protocols, to guide researchers in selecting and developing appropriate analytical strategies.

Limitations of ELISA

The Enzyme-Linked Immunosorbent Assay (ELISA) is a foundational biochemical technique that leverages antibody-antigen interactions for detection. Despite its widespread use, its performance is notably affected by complex sample matrices [10] [11].

Key Limitations and Underlying Causes

- Matrix Interference and Non-Specific Binding: Complex biological matrices, such as serum or food extracts, contain many non-target proteins and other components that can bind non-specifically to the assay surfaces or antibodies. This leads to high background noise, reduced signal-to-noise ratios, and potentially false-positive results [11] [12]. The prolonged incubation times typical of ELISA procedures exacerbate this issue by increasing the opportunity for non-specific binding [12].

- Antibody Cross-Reactivity: The specificity of ELISA is entirely dependent on the antibodies used. These antibodies can exhibit cross-reactivity with structurally similar molecules or protein isoforms that are not the target analyte. This is a significant source of false positives and can obscure the accurate quantification of specific biomarkers or allergenic proteins [13] [11].

- Limited Dynamic Range and Throughput: Traditional ELISA, often conducted in 96-well plates, has a relatively narrow dynamic range, requiring sample dilutions to fit within the standard curve. This process is laborious and consumes valuable sample volumes. Furthermore, the platform is inherently low-throughput, slowing down research and development, particularly in high-demand environments like drug development [12].

Experimental Protocol: Assessing Matrix Interference in Sandwich ELISA

1. Objective: To evaluate the impact of a complex food matrix on the quantification of a target allergenic protein (e.g., Ara h 1 from peanut) using a commercial sandwich ELISA kit.

2. Materials:

- Research Reagent Solutions:

- Commercial Peanut ELISA Kit (includes capture antibody, detection antibody, standards, substrates)

- Peanut-free food matrix extract (e.g., blank chocolate slurry)

- Purified Ara h 1 protein standard

- Microplate washer and reader

- Phosphate-Buffered Saline (PBS) or wash buffer

3. Procedure: a. Sample Preparation: Prepare two sets of calibration standards in duplicate. Set A: Standards are prepared in the kit's provided buffer. Set B: Standards are prepared in the peanut-free food matrix extract. b. Assay Execution: Follow the kit manufacturer's protocol for the sandwich ELISA. This typically involves: coating the plate with a capture antibody, blocking, adding the standards (Sets A and B) and any test samples, adding an enzyme-linked detection antibody, adding a substrate, and finally stopping the reaction. c. Data Analysis: Measure the absorbance of each well. Generate standard curves for both Set A (buffer) and Set B (matrix). Compare the slopes of the two curves. A significant difference in slope indicates the presence of matrix effects—ion suppression if the slope is lower, or enhancement if it is higher.

Limitations of PCR

Polymerase Chain Reaction (PCR) and its quantitative variants (qPCR) are powerful tools for detecting nucleic acids. However, their application to complex matrices is limited by several factors.

Key Limitations and Underlying Causes

- Susceptibility to Inhibitors: Complex matrices such as food, soil, or clinical samples often contain substances that inhibit PCR amplification. These inhibitors include polyphenols, polysaccharides, fats, and salts, which can co-extract with DNA and interfere with the DNA polymerase enzyme. This leads to reduced amplification efficiency, underestimation of target concentration, or false-negative results [14] [15].

- Inability to Detect Non-Nucleic Acid Analytes: A fundamental limitation of PCR is that it can only detect the genetic material of an organism. It cannot directly detect proteins, which are the actual molecules responsible for allergic reactions or many biological functions. Therefore, PCR cannot differentiate between an active, protein-expressing allergen and non-viable genetic material, which is a critical distinction for food safety and clinical diagnosis [13] [2].

- Quantification Challenges in qPCR: Real-time quantitative PCR (qPCR) relies on standard curves for quantification, which can introduce variability. Its performance is also highly dependent on the efficiency of DNA extraction, which can be inconsistent across different complex matrices, further complicating accurate quantification [15].

Experimental Protocol: Evaluating PCR Inhibition in Food Matrices

1. Objective: To assess the presence of PCR inhibitors in a DNA extract from a complex food matrix (e.g., spiced meat) using droplet digital PCR (ddPCR).

2. Materials:

- Research Reagent Solutions:

- DNA extraction kit

- Target DNA standard (e.g., soybean lectin gene)

- ddPCR supermix, droplet generator, and reader

- Assay-specific primers and probes

3. Procedure: a. DNA Extraction: Extract DNA from the complex food matrix following a standardized protocol. b. Sample Setup: Prepare two reactions: - Test Reaction: The extracted DNA from the food matrix. - Control Reaction: A known amount of the target DNA standard spiked into the extracted DNA. c. ddPCR Run: Partition both reactions into thousands of nanodroplets using a droplet generator. Perform PCR amplification on a thermal cycler and analyze the droplets using a reader to count the positive and negative droplets. d. Data Analysis: The concentration of the target is determined directly from the ratio of positive to total droplets, without the need for a standard curve. Recovery is calculated by comparing the measured concentration in the spiked control reaction to the expected concentration. A recovery rate significantly below 100% indicates the presence of PCR inhibitors in the matrix.

Table 1: Quantitative Comparison of Conventional Method Limitations

| Method | Key Limitation | Impact on Sensitivity/Specificity | Throughput & Workflow |

|---|---|---|---|

| ELISA | Matrix interference & antibody cross-reactivity [11] [12] | Reduced specificity; false positives/negatives [13] | Low throughput; long, manual processes (>4 hours) [12] |

| PCR | Susceptibility to inhibitors; cannot detect proteins [14] [13] | False negatives; limited application scope [2] [15] | High throughput possible, but requires extensive sample prep [14] |

| Mass Spectrometry | Matrix effects (ion suppression/enhancement) [16] | Reduced sensitivity & quantitative accuracy [13] [16] | High throughput; complex operation & data processing [13] [11] |

Limitations of Mass Spectrometry

Liquid Chromatography with Tandem Mass Spectrometry (LC-MS/MS) is renowned for its high specificity and sensitivity. However, it is not immune to challenges posed by complex matrices.

Key Limitations and Underlying Causes

- Matrix Effects (ME): This is the most significant challenge for LC-MS/MS in complex matrices. Matrix effects occur when co-eluting compounds from the sample interfere with the ionization of the target analyte in the mass spectrometer source. This can cause either ion suppression (reduced signal) or ion enhancement (increased signal), leading to inaccurate quantification, particularly at low analyte concentrations [13] [16]. The electrospray ionization (ESI) source is especially prone to these effects.

- Complexity and Cost: LC-MS/MS instrumentation is sophisticated, requires highly skilled operators, and involves high capital and maintenance costs. The development of robust methods can be time-consuming, and data processing is often complex, limiting its accessibility for some laboratories [11] [17].

- Limited Multiplexing in ICP-MS: While Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is extremely sensitive for detecting elements, its application in bioanalysis requires conjugating biomarkers to elemental tags. Multiplexed assays (detecting multiple targets at once) can be hampered by spectral overlap, which requires careful planning and advanced instrumentation to overcome [13].

Experimental Protocol: Assessing Matrix Effects in LC-MS/MS

1. Objective: To qualitatively identify regions of ion suppression/enhancement in an LC-MS/MS method for detecting multiple allergenic protein peptides in a processed food sample.

2. Materials:

- Research Reagent Solutions:

- LC-MS/MS system with post-column T-piece infusion capability

- Syringe pump

- Mixed standard solution of target allergenic peptides

- Blank matrix extract (from a food sample known to be free of the target allergens)

3. Procedure: a. System Setup: Connect a syringe pump containing the mixed standard solution to a post-column T-piece. The effluent from the LC column is mixed with the constantly infused standard just before entering the MS ion source. b. LC-MS Analysis: Inject the blank matrix extract onto the LC column. While the blank matrix is eluting, the standard is continuously infused. c. Data Analysis: Monitor the MS signal for the target peptides. A stable signal indicates no matrix effects. A dip in the signal indicates ion suppression, while a peak indicates ion enhancement, occurring at the retention times where interfering compounds from the blank matrix co-elute with the infused analytes.

The limitations of ELISA, PCR, and mass spectrometry in complex matrices are significant and can directly impact patient safety, drug development, and food regulatory decisions. Issues such as matrix interference, susceptibility to inhibitors, antibody cross-reactivity, and ionization suppression underscore the need for more robust analytical platforms.

These challenges provide a clear rationale for the development and adoption of innovative technologies, such as AI-driven spectroscopy. Techniques like Surface-Enhanced Raman Spectroscopy (SERS) and hyperspectral imaging, when coupled with machine learning, offer promising avenues for non-destructive, rapid, and highly specific detection of allergens and other analytes directly in complex matrices [5] [2] [17]. By learning from the shortcomings of conventional methods, researchers can better design and validate these next-generation tools to provide the accuracy, sensitivity, and practicality required for modern analytical challenges.

The detection and identification of allergens in complex food matrices present significant analytical challenges due to the low concentrations of allergenic proteins and the interference from other food components. Conventional methods, such as enzyme-linked immunosorbent assays (ELISA), are reliable but can be time-consuming, require extensive sample preparation, and are not conducive to real-time monitoring [18] [2]. The integration of advanced spectroscopic techniques with Artificial Intelligence (AI) provides a powerful solution for rapid, non-destructive, and accurate allergen detection. These core techniques—Fourier-Transform Infrared (FTIR) spectroscopy, Hyperspectral Imaging (HSI), and Raman spectroscopy—generate rich molecular fingerprint data that AI models can interpret to identify and quantify allergens with high precision. This document details the principles, applications, and standardized protocols for employing these techniques within an AI-driven framework for allergen detection research.

Technique Principles & AI Synergy

Fourier-Transform Infrared (FTIR) Spectroscopy

Principle: FTIR spectroscopy measures the absorption of infrared light by a sample. When IR radiation interacts with the sample, chemical bonds vibrate at specific frequencies, absorbing energy at characteristic wavelengths. The instrument directs a broadband IR beam through an interferometer and then onto the sample. The resulting interferogram, which contains encoded absorption information for all frequencies, is converted into a spectrum using a Fourier Transform algorithm. This spectrum plots absorbance versus wavenumber (cm⁻¹), providing a unique molecular fingerprint based on the vibrational modes of the sample's functional groups (e.g., C=O, N-H) [19] [20].

Synergy with AI: The complex spectral data from FTIR, particularly in the "fingerprint region" (1500–500 cm⁻¹), contains subtle patterns that are ideal for machine learning (ML). AI models, such as support vector machines (SVM) or convolutional neural networks (CNNs), can be trained on libraries of FTIR spectra from known allergenic and non-allergenic samples. Once trained, these models can automatically identify the presence of specific allergens, such as lipid transfer proteins (LTPs) in plant-based foods or gluten in wheat, by recognizing their unique spectral signatures, even in complex mixtures [21] [22].

Raman Spectroscopy

Principle: Raman spectroscopy is based on the inelastic scattering of monochromatic laser light. Most scattered light is at the same energy as the laser source (Rayleigh scattering), but a tiny fraction (~1 in 10⁷ photons) undergoes a shift in energy due to interactions with molecular vibrations. This Raman shift provides information about the vibrational energy levels of the molecules. The resulting spectrum, plotting intensity versus Raman shift (cm⁻¹), offers a complementary molecular fingerprint to FTIR. A key difference lies in the selection rules: Raman spectroscopy is particularly sensitive to symmetric vibrations and non-polar bonds (e.g., C-C, S-S), whereas FTIR is more sensitive to asymmetric vibrations and polar bonds [19] [20].

Synergy with AI: Raman signals can be weak and sometimes obscured by fluorescence. AI algorithms are instrumental in mitigating these issues by filtering noise and extracting the relevant spectral features. Furthermore, ML models can be deployed for the quantitative analysis of allergens, correlating specific Raman peak intensities or overall spectral shapes with allergen concentration. This is especially useful for detecting contaminants like melamine in milk or identifying different food adulterants [21] [22].

Hyperspectral Imaging (HSI)

Principle: HSI is a hybrid technique that combines spectroscopy with digital imaging. It captures a three-dimensional data structure known as a "hypercube," comprising two spatial dimensions (x, y) and one spectral dimension (λ). For each pixel in the image, a full spectrum is acquired across a wide range of wavelengths (e.g., visible to near-infrared). This allows for the simultaneous determination of the chemical composition (from the spectrum) and the spatial distribution of components within a sample [23] [24].

Synergy with AI: The hypercube generates vast, high-dimensional datasets, making it a prime candidate for AI analysis. Deep learning algorithms, particularly CNNs, can process these hypercubes to perform tasks such as:

- Pixel-wise classification: Automatically segmenting an image to identify and map regions contaminated with allergens.

- Spatial quantification: Determining not just if an allergen is present, but also its distribution and concentration across the food sample. This enables the non-destructive inspection of entire food products for contaminants like peanuts or sesame seeds on processing equipment or in finished goods [23] [24].

Comparative Analysis of Techniques

Table 1: Comparative analysis of FTIR, Raman, and HSI for allergen detection.

| Aspect | FTIR Spectroscopy | Raman Spectroscopy | Hyperspectral Imaging (HSI) |

|---|---|---|---|

| Primary Principle | Absorption of infrared light [20] | Inelastic scattering of laser light [20] | Spatial imaging + spectroscopy (reflectance/transmittance) [24] |

| Best For | Organic & polar molecules (C=O, N-H, O-H) [20] | Non-polar molecules (C=C, S-S) & aqueous samples [20] | Mapping spatial distribution of contaminants & quality attributes [23] [24] |

| Water Compatibility | Poor (strong IR absorber) [20] | Excellent (weak Raman scatterer) [20] | Varies with spectral range (e.g., good in NIR) [24] |

| Key Advantage for Allergens | High sensitivity for protein amide bands [22] | Minimal sample prep; can analyze through packaging [20] | Combines visual identification with chemical analysis [23] |

| Main Challenge | Sample preparation (e.g., ATR pressure) | Fluorescence interference [20] | High data volume & computational cost [23] [24] |

| Typical AI Integration | Classification models (SVM, PLS-DA) for spectral fingerprints [21] | Quantitative models for concentration & noise reduction [21] | Deep learning (CNNs) for image segmentation & classification [24] |

Experimental Protocols

General AI-Driven Spectroscopy Workflow

The following diagram illustrates the overarching workflow for applying AI to spectroscopic data for allergen detection.

Protocol 1: FTIR-based Detection of nsLTP Allergens

This protocol outlines the steps for detecting non-specific Lipid Transfer Proteins (nsLTPs) in food samples using FTIR spectroscopy and machine learning [18] [22].

3.2.1 Research Reagent Solutions & Materials

Table 2: Essential materials for FTIR-based allergen detection.

| Item | Function/Description | Example |

|---|---|---|

| FTIR Spectrometer | Instrument for spectral acquisition; equipped with an ATR accessory. | Bruker ALPHA II (ATR) |

| ATR Crystal | Enables minimal sample preparation by measuring evanescent wave absorption. | Diamond crystal |

| Food Samples | Representative samples with and without the target allergen. | Peach, apple, lettuce |

| Cryogrinder | Homogenizes samples to a fine powder for consistent spectral reading. | |

| Software | For spectral preprocessing, machine learning model development, and data analysis. | Python (scikit-learn), Unscrambler |

3.2.2 Step-by-Step Procedure

Sample Preparation:

- Collect a variety of food samples known to contain nsLTPs (e.g., peaches) and samples free of nsLTPs (e.g., lettuce) [18]. Label accordingly.

- Freeze samples with liquid nitrogen and homogenize using a cryogrinder to create a fine, uniform powder.

- Allow the powdered samples to equilibrate to room temperature in a desiccator to minimize moisture interference.

Spectral Data Acquisition:

- Clean the ATR crystal with ethanol and a lint-free cloth and acquire a background spectrum.

- Place a small amount of the powdered sample onto the ATR crystal. Apply consistent pressure to ensure good contact.

- Acquire the FTIR spectrum in the mid-IR range (e.g., 4000–400 cm⁻¹) with a resolution of 4 cm⁻¹. Accumulate 32–64 scans per spectrum to ensure a high signal-to-noise ratio.

- Clean the crystal thoroughly between samples to prevent cross-contamination.

- For a robust model, collect a minimum of several thousand spectra across all sample types to ensure statistical power [18].

Data Preprocessing:

- Savitzky-Golay Smoothing: Apply to reduce high-frequency noise.

- Standard Normal Variate (SNV) or Multiplicative Scatter Correction (MSC): Correct for light scattering effects due to particle size differences.

- Derivative (1st or 2nd): Use to resolve overlapping peaks and enhance spectral features. Second-derivative treatment is particularly useful for analyzing the amide I band for protein secondary structure [24] [22].

AI Model Training & Validation:

- Split the preprocessed dataset into training (e.g., 70%), validation (e.g., 15%), and test (e.g., 15%) sets.

- Train a machine learning classifier, such as a Support Vector Machine (SVM) or Partial Least Squares Discriminant Analysis (PLS-DA), on the training set to distinguish between spectra from nsLTP-containing and nsLTP-free samples.

- Optimize model hyperparameters using the validation set.

- Evaluate the final model's performance on the held-out test set, reporting metrics such as accuracy, precision, recall, and F1-score. A well-validated model can achieve accuracy exceeding 87% for this application [18].

Protocol 2: HSI for Mapping Allergen Cross-Contact on Surfaces

This protocol describes a method for using HSI to detect and visualize the spatial distribution of allergenic residues on food processing surfaces [23] [24].

3.3.1 Workflow for HSI-based Contaminant Mapping

The specific data processing pipeline for HSI analysis is detailed below.

3.3.2 Step-by-Step Procedure

Sample Preparation & Imaging:

- Use sterile swabs to deliberately contaminate a clean, representative food processing surface (e.g., stainless steel) with a known allergen (e.g., peanut powder).

- Create a gradient of contamination levels.

- Set up the HSI system in reflectance mode. Ensure consistent and uniform illumination across the entire field of view.

- Acquire the hypercube of the contaminated surface. The system will capture spatial information (image of the surface) and spectral information (reflectance spectrum for each pixel).

Data Preprocessing:

- Flat-Field Correction: Use images of a white reference (e.g., Spectralon) and a dark current to calibrate and correct the raw hypercube.

- Spectral Preprocessing: Apply techniques like SNV or derivative analysis to the spectral dimension of each pixel to minimize the effects of uneven lighting and highlight chemical features.

Dimensionality Reduction & Model Training:

- Use Principal Component Analysis (PCA) on the spectral data to reduce the number of variables and identify the most informative principal components.

- Manually label pixels in the hypercube as "background," "allergen," etc., to create a ground-truth dataset for training.

- Train a Convolutional Neural Network (CNN) or a pixel-wise classifier (e.g., SVM) on the labeled data. The model will learn to associate specific spectral patterns with the presence of the allergen.

Prediction & Visualization:

- Apply the trained model to the entire, unseen hypercube. The model will classify every pixel.

- Generate a false-color map where each color represents a specific class (e.g., red for allergen, blue for clean surface). This provides an intuitive visualization of the location and extent of allergen contamination [23] [24].

The convergence of FTIR, Raman, and HSI with artificial intelligence creates a formidable toolkit for addressing the critical challenge of allergen detection in complex food matrices. FTIR excels at providing detailed molecular fingerprints of proteins, Raman offers exceptional compatibility with aqueous samples and minimal preparation, and HSI uniquely enables the spatial mapping of contaminants. By following the standardized protocols outlined in this document, researchers and food development professionals can leverage these techniques to develop robust, accurate, and rapid detection systems. The integration of AI not only automates analysis but also unlocks the ability to discern subtle patterns beyond human capability, paving the way for enhanced food safety, improved regulatory compliance, and greater protection for consumers with food allergies.

The integration of artificial intelligence (AI) and machine learning (ML) with spectroscopic techniques is revolutionizing the analysis of complex chemical and biological matrices. In the specific context of food allergen detection, these technologies address critical limitations of traditional methods. Techniques like ELISA and PCR, while reliable, are often time-consuming, limited in scope, and struggle with the complexity of food matrices [5]. AI-enhanced spectral methods provide a paradigm shift towards faster, more accurate, and non-destructive diagnostics, enabling real-time monitoring and data-driven risk management essential for public safety and regulatory compliance [5].

Spectral data acquired from techniques like Fourier-Transform Infrared (FTIR) spectroscopy or Hyperspectral Imaging (HSI) is inherently rich in information but is often affected by environmental noise, instrumental artifacts, and scattering effects [25]. Machine learning and deep learning models excel at overcoming these challenges by performing sophisticated feature extraction and pattern recognition, transforming this complex data into actionable insights for precise allergen identification and quantification.

Core Machine Learning Techniques in Spectral Analysis

The application of ML to spectral data involves several key steps, from preprocessing to final classification or regression. Deep neural networks, in particular, have shown remarkable success. While traditionally trained by adjusting weights in the "direct space" of node connections, innovative approaches now also perform learning in the spectral domain, adjusting the eigenvalues and eigenvectors of network transfer operators, which can lead to superior performance with an identical number of free parameters [26].

For spectral classification, a common practice is transforming one-dimensional spectral vectors into two-dimensional matrix data. This transformation allows the application of powerful, image-oriented deep learning algorithms like Convolutional Neural Networks (CNNs), which are highly proficient at processing spatial information [27] [28]. Studies utilizing this method on reflectance spectra have demonstrated classification accuracies exceeding 99% for plant samples and 94.78% for fruit samples, outperforming traditional algorithms like Support Vector Machines (SVM) [27] [28].

Table 1: Key AI/ML Models for Spectral Data Analysis

| Model Type | Key Function | Typical Application in Spectral Analysis | Reported Performance |

|---|---|---|---|

| Feedforward Neural Network (FNN) [27] | Classification of transformed 2D spectral data | Accurate classification of plant reflectance spectra | Average accuracy of 96.78% (max 99.56%) [27] |

| Convolutional Neural Network (CNN) [28] | Feature extraction and classification of 2D spectral data | Classification of fruit reflectance spectra; hyperspectral image analysis | Accuracy of 94.78% [28] |

| Spectral Domain Learning [26] | Network training in reciprocal space via eigenvalues/eigenvectors | Image classification (e.g., MNIST database) | Superior to standard methods with equal parameters [26] |

| Machine Learning-Empowered FTIR [29] | Metabolic fingerprinting and stratification | Discriminating serum from healthy, allergic, and SIT-treated mice and humans | Successful stratification (correlated with immunological data) [29] |

Application in Allergen Detection: Protocols and Data Presentation

The following protocols outline a streamlined workflow for developing an AI-driven spectral method for allergen detection in a complex food matrix, using peanut allergen Ara h 6 as a model analyte.

Protocol: AI-Enhanced Spectral Analysis for Peanut Allergen Detection

Objective: To quantify the concentration of the peanut allergen Ara h 6 in a baked food matrix using Hyperspectral Imaging (HSI) coupled with a Convolutional Neural Network (CNN).

Principle: HSI captures spatial and spectral information from samples. A CNN model is trained to identify the unique spectral signature of Ara h 6, even at low concentrations and within a complex background, enabling non-destructive and rapid quantification.

Materials and Reagents:

- Food Matrix: Allergen-free cookie dough.

- Allergen Standard: Purified Ara h 6 protein.

- Spectral Instrument: Hyperspectral imaging system (e.g., covering VNIR or SWIR range).

- Reference Method: ELISA kit for Ara h 6 quantification (for model training and validation).

- Software: Deep learning framework (e.g., TensorFlow, PyTorch) or specialized library like

spectrai[30].

Experimental Procedure:

Sample Preparation:

- Spike the allergen-free cookie dough with purified Ara h 6 standard to create a calibration set with concentrations spanning 0-10,000 ppm (mg/kg).

- Bake the cookies according to a standardized protocol.

- Prepare a separate, independent validation set of samples.

Data Acquisition (Spectral and Reference):

- Acquire hyperspectral images of all calibration and validation samples.

- For each calibration sample, homogenize a sub-portion and perform reference analysis using the ELISA kit to determine the actual Ara h 6 concentration [5].

Data Preprocessing (Critical Step):

- Cosmic Ray Removal: Eliminate sharp, spurious spikes from the spectral data [25].

- Baseline Correction: Correct for additive offsets and scattering effects [25].

- Normalization: Scale spectra to minimize effects of path length or light intensity variations [25].

- Transformation to 2D: Convert the preprocessed 1D spectral data from each pixel or region of interest into a 2D matrix format suitable for CNN input [27] [28].

Model Training and Validation:

- Architecture: Design a CNN with input dimensions matching your 2D spectral data. The architecture should include convolutional layers for feature extraction, pooling layers for down-sampling, and fully connected layers for final concentration prediction.

- Training: Train the CNN using the calibration set. The input is the preprocessed 2D spectral data, and the target output is the reference concentration from ELISA.

- Validation: Apply the trained model to the independent validation set. Compare the CNN-predicted concentrations with the reference ELISA values to assess model accuracy.

The workflow for this protocol is summarized in the following diagram:

Performance Metrics and Data

Table 2: Comparison of AI-Spectral Methods with Traditional Allergen Detection Techniques

| Methodology | Key Principle | Detection Limit | Analysis Time | Key Advantage for Allergens |

|---|---|---|---|---|

| ELISA [5] | Antibody-antigen binding | Varies by kit | Hours | High specificity, well-established |

| PCR [5] | DNA amplification | Varies by target | Hours | Detects trace DNA |

| Mass Spectrometry [5] | Detection of proteotypic peptides | ~0.01 ng/mL for specific allergens [5] | Minutes to Hours | High precision, multiplexing capability |

| AI-Empowered FTIR [29] | Metabolic fingerprinting + Deep Learning | Sub-ppm levels possible [25] | Minutes | Rapid, cost-effective, high-throughput |

| AI-Hyperspectral Imaging [5] | Spectral-spatial analysis + ML | Not specified | Minutes (real-time potential) | Non-destructive, provides spatial distribution |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for AI-Driven Spectral Allergen Detection

| Item | Function/Description | Application Example |

|---|---|---|

| Purified Allergen Proteins (e.g., Ara h 3, Ara h 6, Bos d 5) [5] | Serve as analytical standards for spiking experiments and model training. | Creating calibration curves for quantitative analysis. |

| Allergen-Free Food Matrices | Provide a consistent and controlled background for developing and validating detection methods in complex systems. | Simulating real-world food products without endogenous allergen interference. |

| Commercial ELISA Kits | Provide a reference method for obtaining ground-truth concentration data to train and validate ML models. | Quantifying actual allergen levels in homogenized sample sub-portions. |

| Hyperspectral Imaging (HSI) System | Captures both spatial and spectral information from a sample, enabling non-destructive analysis. | Mapping the distribution of an allergen within a solid food product. |

| FTIR Spectrometer [29] | A high-resolution, cost-efficient biophotonic tool for obtaining metabolic or chemical fingerprints. | Rapid serum analysis to stratify healthy, allergic, and SIT-treated individuals [29]. |

| Deep Learning Framework (e.g., spectrai) [30] | Open-source software providing built-in preprocessing, augmentation, and neural network models specifically designed for spectral data. | Streamlining the development and comparison of ML models for spectral classification. |

Visualization of the AI-Spectral Analysis Workflow

The logical relationship between data acquisition, processing, and model application in AI-driven spectral analysis is best understood as an iterative cycle that refines its predictive power with more data. The process begins with raw data collection and culminates in a deployed model, whose outputs can, in turn, inform further data acquisition.

The accurate detection and quantification of food allergens in complex food matrices represents a significant analytical challenge for food safety researchers and the food industry. Conventional methods, including enzyme-linked immunosorbent assays (ELISA) and DNA-based PCR, while reliable, are often time-consuming, destructive, and can struggle with quantifying allergen levels, particularly in processed foods [31] [2]. The “big nine” allergens—milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat, soybeans, and sesame—are responsible for over 90% of severe food allergic reactions, necessitating detection methods of the highest reliability [2] [32]. The integration of Artificial Intelligence (AI) with advanced spectroscopic techniques is emerging as a transformative solution, overcoming the limitations of traditional methods by delivering unprecedented levels of sensitivity, specificity, and operational efficiency [33] [31]. This document details the application notes and experimental protocols for leveraging AI-driven spectroscopy, specifically within the context of allergen detection in complex food matrices, providing researchers with a framework for implementation.

Technical Background and Key Performance Metrics

The synergy between spectroscopy and AI addresses core challenges in allergen detection. Spectroscopic techniques like Fourier Transform Infrared (FTIR) spectroscopy and Hyperspectral Imaging (HSI) generate rich, multidimensional data from food samples non-destructively [5] [31]. However, the complexity of this data, especially against the background signal of a complex food matrix, makes manual interpretation difficult. AI and machine learning (ML) algorithms excel at identifying subtle, non-linear patterns within such large datasets that may be imperceptible to human analysis or traditional statistical methods [33] [34].

- Enhancing Sensitivity: AI models can be trained to recognize the unique spectral signatures of allergenic proteins even at ultra-low concentrations. For instance, Wide Line Surface-Enhanced Raman Scattering (WL-SERS) coupled with AI has demonstrated a tenfold increase in sensitivity, enabling the detection of contaminants like melamine in raw milk at concentrations far below conventional thresholds [33]. This principle is directly applicable to trace allergen detection.

- Improving Specificity: The core of accurate allergen detection lies in distinguishing the target allergenic protein's signal from the background matrix. Convolutional Neural Networks (CNNs) and other deep learning architectures have achieved up to 99.85% accuracy in identifying and classifying adulterants and specific allergens, drastically reducing false positives and negatives [33].

The table below summarizes quantitative performance data for key technologies relevant to this field.

Table 1: Performance Metrics of Advanced Detection Technologies

| Technology | Reported Sensitivity/Detection Limit | Reported Specificity/Accuracy | Key Application in Allergen Detection |

|---|---|---|---|

| AI-Enhanced Spectroscopy (e.g., CNN models) | Not explicitly quantified in results, but enables detection at "trace levels" [33] | Up to 99.85% accuracy in identifying adulterants [33] | Non-destructive identification and quantification of allergens in complex matrices [31] |

| Mass Spectrometry (Multiplexed) | As low as 0.01 ng/mL for specific proteins (e.g., Ara h 6 in peanut) [5] | High specificity for quantifying specific allergenic proteins [5] | Targeted quantification of specific protein allergens (e.g., Ara h 3, Bos d 5) [5] |

| WL-SERS | Tenfold increase vs. conventional methods [33] | Implied high specificity via AI integration [33] | Ultra-sensitive contaminant detection; applicable to trace allergens [33] |

Application Notes & Experimental Protocols

This section provides a detailed workflow and protocol for implementing AI-enhanced Hyperspectral Imaging (HSI) for the non-destructive detection of peanut allergen residues in a complex bakery product matrix.

The following diagram illustrates the integrated experimental and computational workflow, from sample preparation to final prediction.

Detailed Protocol: AI-HSI for Peanut Allergen Detection

Aim: To detect and quantify trace amounts of peanut protein (Ara h 6) in a wheat-based cookie matrix using HSI and a trained CNN model.

I. Materials and Reagents

Table 2: Research Reagent Solutions and Essential Materials

| Item | Function/Description | Supplier Notes |

|---|---|---|

| Peanut Flour (Defatted) | Source of allergenic proteins (Ara h 3, Ara h 6). Defatting improves protein extraction efficiency. | Prepare in-house or source certified reference material. |

| Wheat Flour-Based Cookie Dough | Represents the complex food matrix. | Use a consistent, minimal-ingredient recipe for standardization. |

| Protein Extraction Buffer (e.g., PBS with Tween-20, or Urea-Thiourea-CHAPS buffer [8]) | Efficiently solubilizes proteins from complex, processed matrices for validation. | Optimization is critical; a published optimized method achieved >80% extraction efficiency [8]. |

| LC-MS/MS System | Provides ground truth data for model training by quantifying specific allergenic peptides. | Used for targeted proteomics (e.g., for Ara h 6). |

| Hyperspectral Imaging System (NIR or SWIR range) | Captures spatial and spectral data from samples non-destructively. | Ensure calibration with standard white and dark references before use. |

| AI/ML Software Framework (e.g., Python with TensorFlow/PyTorch, MATLAB) | Platform for developing and training CNN and other ML models. |

II. Step-by-Step Procedure

Step 1: Sample Preparation and Dataset Creation

- Prepare a control batch of wheat-flour cookie dough without peanuts.

- Spike separate batches of dough with finely ground, defatted peanut flour to create a calibration curve with known concentrations (e.g., 0, 1, 5, 10, 50, 100 ppm total peanut protein).

- Bake cookies according to a standardized protocol to simulate processed food conditions.

- For each concentration level, prepare a minimum of n=20 individual cookies to ensure robust dataset size for AI training.

Step 2: Hyperspectral Image Acquisition

- Place each cookie sample on the translation stage of the HSI system.

- Acquire hypercubes for each sample. Typical parameters:

- Spectral Range: 900 - 1700 nm (SWIR) for protein-associated spectral features.

- Spatial Resolution: ~30 μm/pixel.

- Ensure consistent lighting and distance.

- Save raw hyperspectral data cubes for all samples.

Step 3: Ground Truth Validation via Mass Spectrometry

- From each cookie, take a core sample adjacent to the area imaged by HSI.

- Extract proteins using the optimized extraction buffer. Validate extraction efficiency, aiming for >80% to ensure accurate quantification [8].

- Using LC-MS/MS with targeted selected reaction monitoring (SRM), quantify the specific concentration of a marker peptide from the Ara h 6 allergen in each sample [5] [8].

- This LC-MS/MS data provides the definitive, quantitative "ground truth" label for each corresponding HSI data cube.

Step 4: Data Preprocessing and Augmentation

- Preprocessing: Use computational tools (e.g., Python, ENVI) to apply:

- Smoothing (Savitzky-Golay filter) to reduce spectral noise.

- Baseline Correction to remove scattering effects.

- Standard Normal Variate (SNV) normalization to minimize particle size effects.

- Data Augmentation: Artificially expand the training dataset by applying random rotations, translations, and slight spectral distortions to the existing HSI cubes to improve model generalizability.

Step 5: AI Model Training and Validation

- Architecture: Design a Convolutional Neural Network (CNN) with input layers matching the dimensions of your processed HSI data. The architecture should include convolutional layers for feature extraction, pooling layers, and fully connected layers for classification/regression.

- Training: Split the dataset into training (70%), validation (15%), and hold-out test (15%) sets. Train the CNN to map the input HSI data to the ground truth Ara h 6 concentration.

- Validation: Monitor the model's performance on the validation set to prevent overfitting. Key metrics include Root Mean Square Error (RMSE) for quantification and Accuracy/Specificity/Sensitivity for detection.

Step 6: Model Deployment and Prediction

- The trained and validated model can now be used to predict the presence and concentration of peanut allergen in new, unknown cookie samples directly from their HSI data.

- The output is a prediction map showing the spatial distribution and estimated concentration of the allergen within the food matrix.

The Scientist's Toolkit

A summary of the core computational and analytical components required for this research is provided below.

Table 3: Essential Toolkit for AI-Enhanced Spectroscopic Allergen Detection

| Tool Category | Specific Examples | Function in the Workflow |

|---|---|---|

| Spectroscopic Techniques | FTIR Spectroscopy, Hyperspectral Imaging (HSI), Coherent Raman Scattering (CRS) [5] [31] [34] | Non-destructively generates spectral fingerprints of the sample, containing information on molecular composition. |

| AI/ML Models | Convolutional Neural Networks (CNNs), Support Vector Machines (SVM), Artificial Neural Networks (ANN) [33] [34] [35] | Automatically extracts complex features from spectral data, classifies allergens, and quantifies concentrations. |

| Data Preprocessing Tools | Savitzky-Golay Filter, Standard Normal Variate (SNV), Principal Component Analysis (PCA) [34] | Cleans raw spectral data, removes noise and unwanted variance, and reduces dimensionality for more effective modeling. |

| Validation Techniques | Targeted Mass Spectrometry (LC-MS/MS), ELISA [5] [2] [8] | Provides the essential "ground truth" data required to train and validate the accuracy of AI models. |

| Key Reagents | Optimized Protein Extraction Buffers [8], Certified Allergen Reference Materials | Ensures efficient and reproducible recovery of allergenic proteins from complex food matrices for validation. |

Discussion

The integration of AI with spectroscopy represents a paradigm shift in food allergen analysis. The primary advantages are clear: non-destructive testing, dramatically reduced analysis time enabling real-time monitoring, and superior sensitivity and specificity [33] [31]. However, challenges remain for widespread adoption. These include the high computational demand of complex AI models, the initial cost of advanced spectroscopic equipment, a shortage of large, standardized public datasets for training and benchmarking, and the need for sensor stability and miniaturization for inline use in food production facilities [33] [34].

Future research should focus on developing explainable AI to build trust in model predictions, creating open-source spectral data repositories, and innovating in low-power, edge-computing hardware to deploy these systems directly in food manufacturing environments [34] [36]. By addressing these challenges, AI-driven spectroscopic methods are poised to become the gold standard for ensuring food safety and protecting consumers with food allergies.

From Theory to Practice: Implementing AI-Spectroscopy for Precision Allergen Detection

The detection of allergens in complex food matrices represents a significant challenge for food safety and public health. Traditional methods often struggle with the required sensitivity, specificity, and speed. Artificial intelligence (AI), particularly convolutional neural networks (CNNs) and autoencoders, is revolutionizing this field by enhancing the processing of spectral data. These techniques enable the extraction of subtle, meaningful patterns from complex spectroscopic signals, facilitating rapid, non-destructive, and accurate allergen detection directly in food products. This document outlines the application notes and experimental protocols for implementing these AI-driven spectral analysis techniques within a research context focused on allergen detection.

Core AI Architectures and Applications

Convolutional Neural Networks (CNNs) for Feature Extraction

CNNs excel at processing structured data with spatial hierarchies, making them ideal for analyzing spectral and image-based data from spectroscopic instruments. In allergen detection, CNNs automatically learn and identify discriminative features from raw spectral inputs, bypassing the need for manual feature engineering.

A prominent application involves classifying pollen particles using data from a Rapid-E single particle detector, which captures multi-modal optical fingerprints including scattered light patterns and fluorescence spectra. A deep learning model based on CNN architecture was developed to distinguish between different pollen classes, which is crucial for individuals with allergies [37]. The model utilizes three data modalities:

- Scattering: Sensed with 24 detectors, providing morphological properties.

- Spectrum: A 32-detector fluorescence spectrum revealing chemical properties.

- Lifetime: Fluorescence lifetime measured at four spectral ranges.

The CNN processes this multi-dimensional input to perform accurate classification, demonstrating how CNNs can integrate complex, heterogeneous spectral data for biological particle identification [37].

Autoencoders for Anomaly Detection and Data Compression

Autoencoders (AEs) are unsupervised neural networks designed for efficient data encoding and reconstruction. They learn a compressed representation (encoding) of input data and then attempt to reconstruct the original input from this representation. The reconstruction error is minimized during training.

The Convolutional Autoencoder (CAE), a variant using convolutional layers, is particularly effective for signal and image data. In condition monitoring, a CAE was trained to reconstruct spectrograms of normal operation data from a complex technical system. The model was then evaluated based on the reconstruction error when presented with anomalous samples; a high error indicates a potential fault [38]. This same principle is directly transferable to allergen detection, where a CAE trained on spectral data from "allergen-free" samples can flag anomalies corresponding to allergen contamination.

Another advanced implementation, the Convolutional Autoencoder-WaveGAN (CAE-WaveGAN), leverages a CAE for feature extraction from time-series signals, which is then used by a Generative Adversarial Network (GAN) generator to synthesize high-fidelity data. While demonstrated for ECG signals, this architecture holds promise for generating realistic spectral data to augment limited datasets in spectroscopic applications [39].

Experimental Protocols for Allergen Detection

This section provides a detailed methodology for developing an AI model to detect food allergens using Near-Infrared Spectroscopy (NIRS), based on a validated research study for detecting non-specific Lipid Transfer Proteins (nsLTPs) [18].

Protocol: AI-Driven Allergen Detection Using NIRS

Objective: To develop and validate a machine learning model for detecting specific allergens (e.g., nsLTPs) in various food samples using NIRS data.

Materials and Equipment:

- Scientific-grade NIRS spectrometer

- Diverse food samples (with and without the target allergen)

- Standard computational hardware (GPU recommended)

- Python programming environment with key libraries (e.g., Scikit-learn, TensorFlow/PyTorch, Pandas, NumPy)

Procedure:

Step 1: Sample Preparation and Spectral Data Collection

- Sample Selection: Obtain a range of food samples. Label each sample as "allergen present" or "allergen absent" based on definitive identification using authoritative allergen databases (e.g., AllergenOnline, WHO/IUIS Allergen Nomenclature) [18].

- Contamination Control: Thoroughly clean all equipment (e.g., knives, trays, tweezers) with distilled water and sterilize between samples to prevent cross-contamination. Use gloves during handling [18].

- Spectral Acquisition: For each food sample, collect spectral measurements. Place the sample in the spectrometer and allow a 10-second pause for system stabilization. Collect both absorbance and reflectance spectral data at three distinct positions on each sample. Save the raw data for each measurement in individual

.txtfiles [18].

Step 2: Database Construction and Preprocessing

- Automated Data Structuring: Develop Python scripts to automatically parse the

.txtfiles, extract the spectral data, and compile it into a structured.csvfile. The final database should contain spectral features as columns and individual measurements as rows, with a final column for the class label (Truefor allergen present,Falsefor absent) [18]. - Data Preprocessing: Clean the dataset to handle any missing values or noise. Apply spectral preprocessing techniques such as Standard Normal Variate (SNV) or Savitzky-Golay smoothing to reduce scattering effects and enhance spectral features.

Step 3: Model Training and Optimization

- Data Partitioning: Split the structured dataset into training, validation, and test sets (e.g., 70/15/15 ratio).

- Model Selection and Training: Implement a machine learning model, such as a Support Vector Machine (SVM) or a CNN. Train the model using the training set, optimizing hyperparameters (e.g., learning rate, number of layers, kernel type) via cross-validation on the validation set.

- Iterative Optimization: Refine the model architecture and hyperparameters iteratively to improve detection accuracy based on performance on the validation set [18].

Step 4: Model Validation and Performance Assessment

- Quantitative Evaluation: Use the held-out test set to evaluate the final model's performance. Calculate standard metrics including accuracy, F1-score, precision, and recall.

- Benchmarking: The model achieving an accuracy of 87% and an F1-score of 89.91% for nsLTP detection demonstrates a successful outcome, indicating high potential for enhancing food safety [18].

Workflow Visualization

The following diagram illustrates the end-to-end experimental workflow for AI-enhanced spectral allergen detection:

Quantitative Performance Data

The following tables summarize key quantitative findings from relevant studies employing AI for analysis in food safety, health, and related spectroscopic applications.

Table 1: Performance Metrics of AI Models in Allergen and Biosensing Applications

| AI Model | Application / Target | Key Performance Metrics | Source |

|---|---|---|---|

| Machine Learning (SVM) | nsLTP allergen detection in food via NIRS | Accuracy: 87%, F1-Score: 89.91% | [18] |

| AI-Assisted Biosensors | Foodborne pathogen detection in various matrices | Accuracy exceeding 95% in some cases | [40] |

| AI for Skin Test Reading | Allergy diagnostics (PRICK test) | High sensitivity and specificity; time savings of 40 min/patient | [41] |

Table 2: Performance of Autoencoder-based Models in Signal Processing and Monitoring

| AI Model | Application Context | Key Performance Metrics | Source |

|---|---|---|---|

| Convolutional Autoencoder (CAE) | Condition Monitoring (Anomaly Detection) | Accuracy: 97.22%, Precision: 93.88% | [38] |

| CAE-WaveGAN | Synthetic 12-lead ECG Signal Generation | PSNR improvement: 19.8%, SSIM enhancement: 59.3% vs. baseline | [39] |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for AI-Enhanced Spectral Allergen Detection

| Item Name | Function / Purpose | Example / Specification |

|---|---|---|

| Scientific-Grade NIRS Spectrometer | Captures near-infrared spectral signatures (absorbance/reflectance) from food samples. | Configured for the specific wavelength range of interest. |

| Allergen Reference Databases | Provides ground-truth labels for model training by confirming allergen presence/absence in specific foods. | AllergenOnline, WHO/IUIS Allergen Nomenclature database. |

| Data Preprocessing Library | Software tools for spectral cleaning, normalization, and feature enhancement. | Python Scikit-learn, SciPy. |

| Deep Learning Framework | Provides environment for building, training, and validating CNN and autoencoder models. | TensorFlow, PyTorch, Keras. |

| Molecularly Imprinted Polymer (MIP) Electrodes | Biorecognition element for electrochemical detection of specific allergen tracers. | Used in electrochemical sensors for soy allergen (genistein) detection [42]. |

Technical Deep Dive: Convolutional Autoencoder Architecture

For researchers seeking to implement a CAE for anomaly detection in spectral data, the following diagram and description detail a proven architecture.

Architecture Workflow:

- Input: The raw spectral data (e.g., a 1D NIRS signal) is fed into the network.

- Encoder: Composed of consecutive 1D convolutional (Conv1D) and pooling layers. This segment extracts hierarchical features and progressively downsamples the input, creating a compressed representation in the bottleneck layer.

- Latent Space: This is the most compressed layer of the network, containing the essential features needed to reconstruct the input. In anomaly detection, the model learns the representation of "normal" spectra here.

- Decoder: Mirrors the encoder structure, using upsampling and transposed convolutional layers to reconstruct the original input signal from the latent space representation.

- Output and Loss: The reconstructed signal is compared to the original input. The mean squared error (MSE) is a typical loss function used to train the network by minimizing this reconstruction error. During application, a high reconstruction error for a new sample indicates a significant deviation from the trained "normal" data, suggesting a potential anomaly (e.g., allergen contamination) [38].

The demand for faster, more accurate, and scalable food safety monitoring has never been greater, particularly for detecting allergens and pathogens in complex food matrices [5]. Traditional methods like ELISA (Enzyme-Linked Immunosorbent Assay) and PCR (Polymerase Chain Reaction), while reliable, are time-consuming, destructive, and limited in scope for real-time processing environments [5] [2]. Emerging non-destructive technologies, particularly Hyperspectral Imaging (HSI) and Fourier Transform Infrared (FTIR) spectroscopy, are poised to transform the landscape of in-line food safety control. These techniques, when integrated with artificial intelligence (AI), enable real-time, non-destructive detection of contaminants such as allergens and pathogens without altering food integrity [5] [43]. This document details the application and protocols for implementing HSI and FTIR within an AI-driven framework for enhanced food safety monitoring.

Hyperspectral Imaging (HSI) combines conventional imaging and spectroscopy to obtain both spatial and spectral information from a sample, generating a three-dimensional data cube known as a hypercube (two spatial dimensions, one spectral dimension) [23] [44]. This allows for pixel-by-pixel analysis of spectral information, making it ideal for heterogeneous food samples [43].

Fourier Transform Infrared (FTIR) spectroscopy is a versatile, non-destructive analytical technique that measures the absorption of infrared light by molecules, providing a molecular fingerprint of the sample [45] [46]. Its speed and specificity make it suitable for both qualitative identification and quantitative analysis [45].

Table 1: Comparative Analysis of HSI and FTIR for In-Line Food Safety Control

| Feature | Hyperspectral Imaging (HSI) | Fourier Transform Infrared (FTIR) Spectroscopy |

|---|---|---|

| Primary Output | Spatial map of spectral variations (Hypercube) [44] | Molecular absorption spectrum (Fingerprint) [46] |

| Information Gained | Chemical composition + spatial distribution [23] [43] | Chemical composition and molecular structure [45] |

| Key Strength | Detecting contaminants & defects on surfaces; analyzing heterogeneous samples [44] [43] | High-specificity identification and quantification of compounds [45] [46] |

| Typical In-Line Mode | Reflectance [44] | Attenuated Total Reflectance (ATR) [46] |

| AI Integration | Machine learning for image analysis & classification [23] [47] | Machine learning for spectral interpretation & quantification [48] [47] |

| Sample Throughput | High (e.g., conveyor belt scanning) [43] | Very High (rapid data collection) [45] [46] |

| Allergen Detection | Promising for identifying particulate contamination [5] | Direct identification of allergenic proteins via fingerprinting [5] [2] |

| Pathogen Identification | Early detection of microbial colonies [43] | High-accuracy identification via Raman spectroscopy (a related technique) combined with ML [48] |

Experimental Protocols

Protocol for HSI-Based Allergen and Contaminant Detection

This protocol outlines the procedure for configuring an HSI system to detect and identify foreign contaminants, such as allergen particles, on food surfaces.

1. System Configuration and Calibration

- Hardware Setup: Utilize a push-broom or line-scanning HSI system mounted above a conveyor belt. The system should include a tungsten halogen light source for uniform illumination in the visible to short-wave infrared range (400-1000 nm or 1000-2500 nm, depending on the target analyte) and a CCD or InGaAs camera [44].

- Calibration: Perform radiometric calibration (dark and white reference) before each operation to minimize sensor noise and illumination irregularities. The dark reference is acquired with the lens covered, and the white reference is acquired using a standard reflectance panel (e.g., Spectralon) [44].

2. Data Acquisition

- Spectral Range Selection: For organic materials like allergens, the near-infrared (NIR) region (900-1700 nm) is often most informative due to absorption related to chemical bonds (O-H, C-H, N-H) [43].

- Image Capture: As samples move on the conveyor belt, continuously capture hyperspectral images. Ensure a consistent sample-to-camera distance and belt speed to maintain spatial and spectral integrity [44] [43].

3. Data Preprocessing and AI Model Application

- Hypercube Construction: Assemble the captured line scans into a 3D hypercube using the system's software [44].

- Spectral Preprocessing: Apply preprocessing techniques to the raw spectra to remove scattering effects and enhance the chemical signal. Common methods include Savitzky-Golay smoothing and Standard Normal Variate (SNV) normalization [23].

- Contaminant Identification: Input the preprocessed hypercube into a pre-trained machine learning model. For optimal results, a supervised model like a Support Vector Machine (SVM) or Convolutional Neural Network (CNN) should be used to classify each pixel as "pure food" or "contaminant" based on its spectral signature [23] [47]. The model outputs a spatial map highlighting the location and identity of the contaminant.

Protocol for FTIR Spectroscopy for Allergen Protein Detection

This protocol describes using FTIR spectroscopy, specifically in ATR mode, for the rapid screening of allergenic proteins in liquid or homogenized food samples.

1. Sample Presentation

- Sample Preparation: For solid or complex matrices, homogenize a small sample with an appropriate buffer (e.g., phosphate-buffered saline) to create a liquid slurry or extract. This ensures consistent contact with the ATR crystal. Minimal preparation is a key advantage [45] [46].

- Loading: Pipette a few microliters of the liquid sample or extract directly onto the ATR crystal of the FTIR spectrometer.

2. Spectral Collection

- Instrument Setup: Use an FTIR spectrometer equipped with a diamond ATR accessory. The system should be purged with dry air or nitrogen to minimize interference from atmospheric water vapor and CO₂ [46].

- Background Scan: Collect a background spectrum with a clean, dry ATR crystal before loading the sample.

- Sample Scan: Acquire the sample spectrum with a resolution of 4 cm⁻¹ and accumulate 32-64 scans to achieve a high signal-to-noise ratio. This process typically takes seconds [45] [46].

3. Analysis and Quantification

- Preprocessing: Process the acquired absorbance spectrum by applying a linear baseline correction and vector normalization.

- Spectral Analysis: Employ a quantitative model, such as Partial Least Squares Regression (PLSR) or a Random Forest Regressor, to correlate specific absorption bands (e.g., amide I and II bands around 1650 cm⁻¹ and 1550 cm⁻¹, indicative of proteins) with allergen concentration [23] [47]. The AI model is trained on spectra from samples with known allergen concentrations.

Table 2: Key Research Reagent Solutions for HSI and FTIR Experiments

| Item | Function | Example Application |

|---|---|---|

| Tungsten Halogen Lamp | Provides broad-spectrum illumination for HSI systems [44]. | Essential for generating reflectance data across UV, Vis, and NIR ranges. |

| Spectralon Reflectance Panel | A near-perfect diffuse reflector used for white reference calibration in HSI [44]. | Critical for correcting inhomogeneities in the light source and sensor. |

| ATR Crystal (Diamond/ZnSe) | The internal reflection element in FTIR that contacts the sample [46]. | Enables direct, non-destructive analysis of solids, liquids, and gels with minimal prep. |

| Purge Gas (Dry N₂) | Inert gas used to purge the optical path in an FTIR spectrometer [46]. | Eliminates spectral interference from atmospheric water vapor and CO₂. |

| Chemometric Software | Software for multivariate data analysis (e.g., PCA, PLSR, SVM) [23] [47]. | Extracts meaningful information from complex HSI and FTIR datasets. |

The Scientist's Toolkit: Essential Materials

Table 3: The Scientist's Toolkit: Essential Research Reagents and Materials

| Item | Function | Application Context |

|---|---|---|

| Tungsten Halogen Lamp | Provides broad-spectrum illumination for HSI systems across UV, Vis, and NIR ranges [44]. | Essential for generating consistent reflectance data in HSI setups. |

| Spectralon Reflectance Panel | A near-perfect diffuse reflector used for white reference calibration in HSI [44]. | Critical for correcting for inhomogeneities in the light source and sensor response. |

| ATR Crystal (Diamond/ZnSe) | The internal reflection element in FTIR that contacts the sample [46]. | Enables direct, non-destructive analysis of solids, liquids, and gels with minimal preparation. |

| Purge Gas (Dry N₂) | Inert gas used to purge the optical path in an FTIR spectrometer [46]. | Eliminates spectral interference from atmospheric water vapor and CO₂, ensuring data purity. |

| Chemometric Software | Software for multivariate data analysis (e.g., PCA, PLSR, SVM) [23] [47]. | Extracts meaningful chemical information from complex HSI and FTIR datasets. |

The integration of HSI and FTIR spectroscopy with AI-driven data analysis represents a paradigm shift in non-destructive, real-time food safety control. HSI excels in providing spatial recognition of contaminants on food surfaces, while FTIR offers high-specificity molecular identification. The protocols outlined herein provide a framework for researchers and industry professionals to implement these powerful technologies for in-line allergen detection, ultimately contributing to a safer, more transparent, and efficient food supply chain. Future work should focus on enhancing model interpretability (Explainable AI) and standardizing validation frameworks to foster widespread regulatory and industrial adoption [47].

Aptamer-based biosensors (aptasensors) represent a transformative technology in analytical science, leveraging the high specificity and affinity of nucleic acid aptamers for target recognition. These biosensors are increasingly integrated with electrochemical and optical transduction platforms, enabling rapid, sensitive, and cost-effective detection of analytes ranging from small molecules to entire cells [49]. Their utility is particularly pronounced in complex analytical scenarios, such as food allergen detection, where they offer significant advantages over traditional antibody-based methods, including superior stability, ease of synthesis and modification, and lower production costs [49] [50].