Advanced Techniques for Analyzing Dietary Fiber Composition in Whole Foods: A Comprehensive Guide for Biomedical Research

This article provides researchers, scientists, and drug development professionals with a comprehensive overview of modern techniques for analyzing the complex composition of dietary fiber in whole foods.

Advanced Techniques for Analyzing Dietary Fiber Composition in Whole Foods: A Comprehensive Guide for Biomedical Research

Abstract

This article provides researchers, scientists, and drug development professionals with a comprehensive overview of modern techniques for analyzing the complex composition of dietary fiber in whole foods. It explores the fundamental chemistry of diverse fiber subtypes, details established and emerging methodological approaches from enzymatic-gravimetric to advanced spectroscopic and chromatographic techniques, and addresses key challenges in analysis and standardization. The content further offers comparative insights for method validation, emphasizing the critical role of precise fiber characterization in understanding its impact on gut microbiota, metabolic health, and the development of targeted nutritional therapies.

Understanding Dietary Fiber Complexity: From Basic Definitions to Biochemical Diversity

The precise definition of dietary fiber is fundamental to research in nutrition, food science, and health. The journey from the simplistic concept of "crude fiber" to the sophisticated, physiologically-oriented CODEX Alimentarius definition represents a significant evolution in scientific understanding. This framework aligns dietary fiber classification with its demonstrated health benefits, moving beyond mere chemical structure to encompass function and physiological impact [1]. For researchers analyzing fiber composition in whole foods, this evolution has direct implications for methodological selection, data interpretation, and the physiological relevance of analytical results. This application note details the key definitions, standardized protocols, and modern classification frameworks essential for contemporary dietary fiber analysis.

The Evolution of Dietary Fiber Definitions

From Crude Fiber to Dietary Fiber Hypothesis

The initial concept of fiber in food analysis was "crude fiber" (CF). This term referred to the residue of plant food remaining after sequential extraction with dilute acid and alkali, intended to simulate human digestion [2]. This method, developed in the 19th century, significantly overlooks key fiber components such as soluble polysaccharides, and consequently undervalues the true fiber content of foods, often by 50% or more [3].

A paradigm shift occurred in the 1970s with the articulation of the "dietary fiber hypothesis" by researchers like Trowell. This hypothesis proposed that undigested carbohydrates, more extensive than just crude fiber, acted as a protective factor against certain colonic disorders and metabolic diseases prevalent in Western societies [2]. This spurred the need for a new definition and more comprehensive analytical methods that could accurately reflect the total indigestible plant matter in food.

The Modern Consensus and CODEX Alimentarius Definition

To promote international harmonization in food labeling and composition tables, the CODEX Alimentarius Commission established a comprehensive definition in 2009 [1]. This definition has been widely adopted and forms the basis for many national regulations.

The CODEX definition states that dietary fiber consists of carbohydrate polymers with ten or more monomeric units that are not hydrolyzed by endogenous enzymes in the human small intestine. This includes three categories:

- Edible carbohydrate polymers naturally occurring in the food as consumed.

- Carbohydrate polymers obtained from food raw materials by physical, enzymatic, or chemical means.

- Synthetic carbohydrate polymers [1].

A critical footnote allows national authorities to include carbohydrates with a degree of polymerization (DP) between 3 and 9 (e.g., resistant oligosaccharides). Furthermore, for isolated or synthetic fibers, a proven physiological health benefit must be demonstrated by generally accepted scientific evidence [1].

Table 1: Comparison of Key Dietary Fiber Definitions Post-CODEX

| Organization | Definition Highlights | Key Components Included |

|---|---|---|

| CODEX (2009) | Carbohydrate polymers (DP ≥ 3 or 10) not hydrolyzed in the small intestine; requires proof of physiological benefit for synthesized or extracted fibers. | All non-digestible CHO polymers; includes RS, RO, and allows for DP 3-9. |

| Health Canada (2010) | Naturally occurring edible carbohydrates (DP > 2) of plant origin; includes "Novel Dietary Fibers" with demonstrated physiological effects. | Resistant oligosaccharides, resistant starch, resistant maltodextrins. |

| EFSA (2009) | All non-digestible carbohydrates plus lignin. | Non-starch polysaccharides, resistant starch, resistant oligosaccharides, lignin. |

| AACCI (2001) | Edible parts of plants or analogous carbohydrates resistant to digestion; promotes beneficial physiological effects. | Polysaccharides, oligosaccharides, lignin, and associated plant substances. |

Table 2: Comparative Analytical Outcomes: Crude Fiber vs. Dietary Fiber This table illustrates how different analytical methods recover varying components, leading to significant differences in reported values.

| Analytical Method | Components Measured | Components NOT Measured (Lost in Analysis) | Typical Outcome vs. True Fiber Content |

|---|---|---|---|

| Crude Fiber | Primarily cellulose and some lignin. | Most hemicellulose, pectins, gums, mucilages, and other soluble fibers. | Underestimates actual dietary fiber content by 50% or more [3]. |

| Total Dietary Fiber | All non-digestible carbohydrates (cellulose, hemicellulose, pectin, gums, beta-glucans, resistant starch, etc.) and lignin. | None; aims for complete recovery of all indigestible components. | Provides a comprehensive measure of total fiber as defined by CODEX and IOM. |

Advanced Analytical Frameworks and Techniques

Moving Beyond Soluble vs. Insoluble: A New Classification Framework

While the soluble vs. insoluble dichotomy is useful, it is insufficient for predicting the specific physiological effects of different fibers. A modern, comprehensive framework proposes categorizing fibers based on a set of five key properties that more accurately capture their functional diversity [4]:

- Backbone Structure

- Water-Holding Capacity

- Structural Charge

- Fiber Matrix

- Fermentation Rate [4]

This multi-faceted approach allows researchers to better understand and predict how a fiber will behave in the gastrointestinal tract and the health outcomes it may influence, such as attenuating insulin secretion, lowering serum cholesterol, or modulating gut microbiota [4].

Analytical Techniques for Fiber Composition

Fiber analysis requires a combination of methods for accurate identification and quantification. The choice of method depends on the research objective, fiber type, and required precision.

Table 3: Analytical Techniques for Fiber Identification and Quantification

| Technique Category | Specific Methods | Primary Application & Function |

|---|---|---|

| Chemical/Solubility | Dissolution methods, Solubility testing (e.g., acetone, sulfuric acid, formic acid, cuprammonium solution) [5] [6]. | Fiber quantitative analysis; relies on differential solubility of fiber components in specific solvents. |

| Microscopic | Optical microscopy, Electron microscopy [5] [7]. | Fiber qualitative identification and microstructural examination. |

| Spectroscopic | Infrared Spectroscopy (IR), Near-Infrared (NIR) Spectroscopy, UV-visible spectroscopy [5]. | Identification of chemical functional groups; rapid, green analysis of blended components. |

| Physical/Other | Combustion method, Density gradient method, Melting point method, Elemental/End group analysis [5]. | Aiding in fiber identification and characterization through physical properties. |

Experimental Protocols for Fiber Analysis

Protocol 1: Crude Fiber Determination (Weende Method)

This protocol outlines the historical method for crude fiber analysis, which remains a reference point for understanding the evolution of fiber analytics [8] [3].

Principle: The sample is subjected to sequential digestion with boiling dilute sulfuric acid and dilute sodium hydroxide solutions. The organic residue remaining after incineration is considered crude fiber.

Workflow:

Research Reagent Solutions:

- Dilute Sulfuric Acid (1.25% H₂SO₄): Hydrolyzes and removes most proteins and soluble sugars, and some hemicellulose.

- Dilute Sodium Hydroxide (1.25% NaOH): Solubilizes and removes lignin, some hemicellulose, and remaining protein.

- Petroleum Ether: Used in sample preparation for defatting prior to digestion.

- Muffle Furnace: Used for high-temperature ashing to determine the inorganic residue mass.

Protocol 2: Total Dietary Fiber Analysis (CODEX-Type Method)

This protocol summarizes the enzymatic-gravimetric methods approved by CODEX (e.g., AOAC 991.43, 2009.01, 2011.25) for the determination of total, soluble, and insoluble dietary fiber, which align with the modern physiological definition [1].

Principle: The sample is treated with heat-stable α-amylase, protease, and amyloglucosidase to remove starch and protein. The insoluble fiber is filtered, washed, and weighed. The soluble fiber is precipitated with ethanol, filtered, and weighed. The total dietary fiber is the sum of insoluble and soluble fiber residues, corrected for protein and ash.

Workflow:

Research Reagent Solutions:

- Heat-Stable α-Amylase (e.g., from Bacillus licheniformis): Simulates salivary and pancreatic amylase to hydrolyze starch into smaller dextrins and sugars.

- Protease (e.g., from Aspergillus oryzae): Digests and removes protein that could otherwise be measured as part of the fiber residue.

- Amyloglucosidase: Further hydrolyzes starch dextrins into glucose, ensuring complete starch removal.

- Ethanol (78-80% v/v): Precipitates soluble dietary fiber polymers (e.g., pectins, beta-glucans) out of the aqueous enzymatic digest for gravimetric measurement.

- Crucibles (e.g., fritted glass, FIBREBAGs): For filtration of the fiber residue; consistent porosity is critical for reproducible results [8].

Protocol 3: Detailed Fiber Composition via Van Soest Method

For a more detailed breakdown of fiber sub-fractions, particularly in plant-based foods and feeds, the Van Soest method is widely used [8]. It provides values for Neutral Detergent Fiber (NDF), Acid Detergent Fiber (ADF), and Acid Detergent Lignin (ADL), allowing for the estimation of hemicellulose, cellulose, and lignin.

Principle: Sequential treatment with neutral and acid detergents, followed by strong acid, selectively dissolves and removes specific fiber components. The mass of the remaining residue at each stage corresponds to a specific fiber fraction.

Workflow and Fraction Calculation:

Research Reagent Solutions:

- Neutral Detergent Solution: Contains sodium lauryl sulfate, EDTA, sodium borate, and disodium hydrogen phosphate; dissolves plant cell contents (proteins, sugars, lipids) and pectins, leaving a residue of NDF (Hemicellulose + Cellulose + Lignin).

- Acid Detergent Solution: Contains cetyltrimethylammonium bromide in sulfuric acid; dissolves hemicellulose, leaving a residue of ADF (Cellulose + Lignin).

- Sulfuric Acid (72% w/w): Hydrolyzes and dissolves cellulose, leaving a residue of ADL (Lignin).

- Alpha-Amylase: Added during NDF analysis to ensure complete removal of starch.

The definition and analysis of dietary fiber have progressed substantially from the basic concept of crude fiber. The adoption of the CODEX definition represents a global consensus that prioritizes physiological outcomes over purely chemical properties. For researchers, this means employing analytical methods that capture the full spectrum of dietary fiber as defined today—including resistant oligosaccharides and starch—and being aware that the simple soluble/insoluble classification is being supplemented by more predictive, multi-property frameworks. Accurate and comprehensive fiber analysis, using the appropriate protocols detailed herein, is crucial for investigating the structure-function relationships of fiber and advancing our understanding of its critical role in human health.

Dietary fiber, defined as the remnants of plant cells resistant to hydrolysis by human alimentary enzymes, comprises a complex group of biochemical components with diverse chemical structures and physiological effects [9]. These components, primarily classified into cellulose, hemicellulose, lignin, pectin, gums, and mucilages, form the fundamental architecture of plant cell walls and serve as intercellular cementing substances [9]. The most widely accepted classification differentiates these components based on their solubility in water and fermentability: water-insoluble/less fermented fibers (cellulose, hemicellulose, lignin) and water-soluble/well fermented fibers (pectin, gums, mucilages) [9]. Understanding the distinct characteristics, sources, and analytical approaches for each component is essential for research on their health benefits, functional properties in food systems, and applications in product development.

Table 1: Fundamental Characteristics of Key Dietary Fiber Components

| Component | Chemical Description | Main Food Sources | Key Functional Properties |

|---|---|---|---|

| Cellulose | Linear chain of several thousand glucose units with β-1,4 glucosidic linkages [9] | Plants (vegetables, sugar beet, various brans) [9] | Insoluble in strong alkali; provides mechanical strength; increases fecal bulk [9] |

| Hemicellulose | Cell wall polysaccharides with backbones of β-1,4 glucosidic linkages, branched, contain xylose, galactose, mannose, arabinose [9] | Cereal grains [9] | Soluble in dilute alkali; influences hydration and fermentation [9] |

| Lignin | Non-carbohydrate, complex cross-linked phenylpropane polymer [9] | Woody plants [9] | Very inert, resists bacterial degradation; associated with crude fiber [9] [10] |

| Pectin | Complex polysaccharides with D-galacturonic acid as principal component [9] | Fruits, vegetables, legumes, sugar beet, potato [9] | Water-soluble, gel-forming; slows gastric emptying, hypoglycemic properties [9] |

| Gums | Highly branched polysaccharides secreted at site of plant injury [9] | Leguminous seeds (guar, locust bean), seaweed extracts (carrageenan), microbial gums (xanthan) [9] | Gel-forming, bind water; used as stabilizers in food and pharmaceuticals [9] |

| Mucilages | Branched polysaccharides synthesized by plant to prevent seed desiccation [9] | Plant extracts (gum acacia, gum karaya, gum tragacanth) [9] | Hydrophilic, act as stabilizers; similar functional properties to gums [9] |

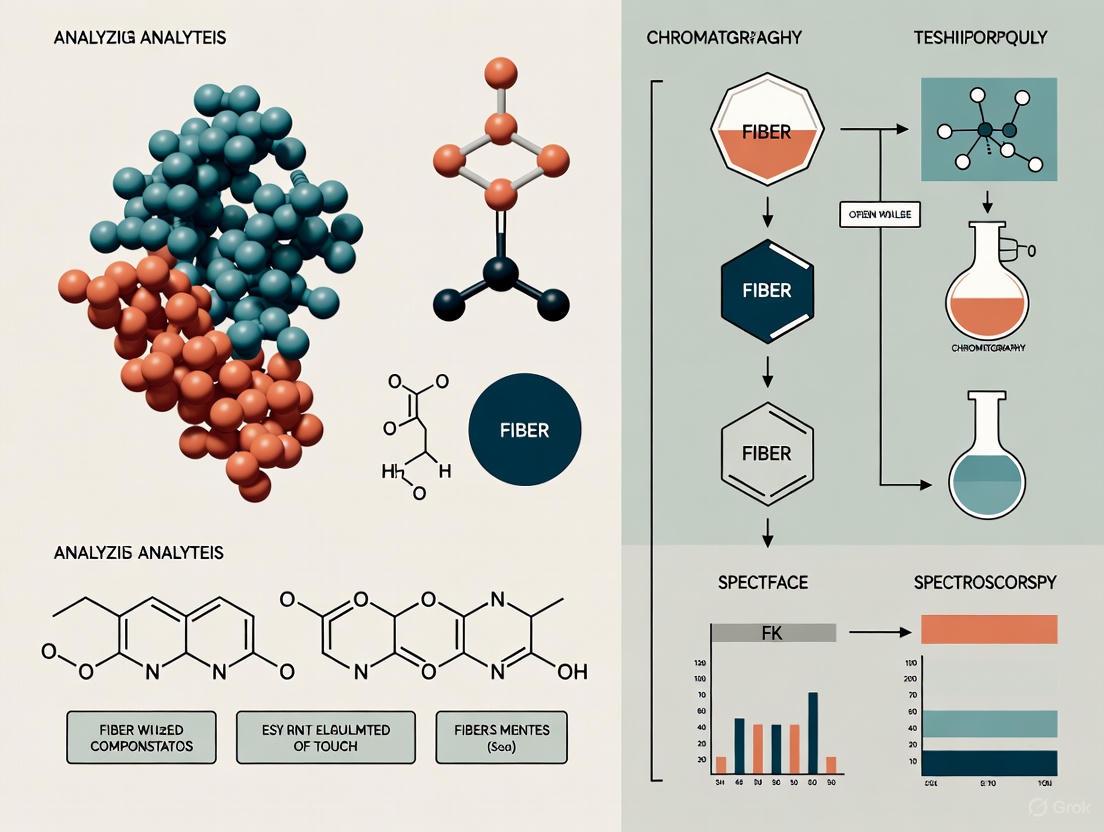

Analytical Workflow for Fiber Composition Analysis

A comprehensive analysis of dietary fiber composition in whole foods requires a sequential workflow that progresses from sample preparation and fractionation to the identification and quantification of individual components. The following diagram illustrates the integrated analytical pathway, combining established gravimetric methods with advanced characterization techniques.

Detailed Experimental Protocols

Protocol 1: Determination of Total, Soluble, and Insoluble Dietary Fiber

This protocol is based on the enzymatic-gravimetric reference methods (AOAC 991.43 / AACC 32-07.01) for the standardized quantification of dietary fiber fractions [11].

- Principle: Duplicate dried food samples undergo sequential enzymatic digestion using heat-stable alpha-amylase, protease, and amyloglucosidase to remove protein and starch. The resulting mixture is filtered to isolate Insoluble Dietary Fiber (IDF). The filtrate and water washings are combined and precipitated with ethanol to isolate Soluble Dietary Fiber (SDF). The residues are corrected for protein and ash content [11].

- Materials:

- Enzymes: Heat-stable α-amylase (e.g., from Bacillus licheniformis), protease (e.g., from Bacillus subtilis), amyloglucosidase (e.g., from Aspergillus niger) [11].

- Buffers: MES-TRIS buffer or phosphate buffer for pH control during digestion [11].

- Solvents: Ethanol (78%, 95%), acetone for precipitation and washing [11].

- Equipment: Water bath, analytical balance, fritted crucibles, drying oven, muffle furnace [11].

- Procedure:

- Sample Preparation: Grind sample to pass through a 0.3-0.5 mm screen. If fat content exceeds 10%, perform defatting with petroleum ether [11].

- Enzymatic Digestion: Weigh duplicate 1 g samples into beakers. Add 40 mL of MES-TRIS buffer (pH 8.2) and 50 µL of heat-stable α-amylase. Gelatinize in a boiling water bath for 15-30 minutes. Cool, adjust pH to 7.5, add 100 µL of protease, and incubate at 60°C for 30 minutes. Cool, adjust pH to 4.3, add 200 µL of amyloglucosidase, and incubate at 60°C for another 30 minutes [11].

- Filtration and IDF Isolation: Filter the digest through a pre-weighed fritted crucible. Wash the residue with warm water (70°C). Retain the filtrate and washings for SDF analysis. Dry the residue (IDF) overnight at 105°C, cool, and weigh [11].

- SDF Precipitation and Isolation: Combine the filtrate and washings. Add four volumes of 95% ethanol preheated to 60°C. Precipitate for 1 hour at room temperature. Filter through a second pre-weighed crucible. Wash the residue (SDF) successively with 78% ethanol, 95% ethanol, and acetone. Dry overnight at 105°C, cool, and weigh [11].

- Protein and Ash Correction: Analyze one duplicate residue for protein (e.g., by Kjeldahl or Dumas method) and the other duplicate for ash by incineration at 525°C [11].

- Calculations:

- IDF (%) = [Weight of IDF residue - (Weight of protein + Weight of ash)] / Sample weight × 100

- SDF (%) = [Weight of SDF residue - (Weight of protein + Weight of ash)] / Sample weight × 100

- TDF (%) = IDF (%) + SDF (%)

Protocol 2: Monosaccharide Composition Analysis by ¹H NMR Spectroscopy

This protocol details a high-throughput method for determining the monosaccharide composition of hydrolyzed dietary fiber fractions, providing structural insights beyond gravimetric quantification [12].

- Principle: Dietary fiber fractions obtained from the AOAC 991.43 method are hydrolyzed with trifluoroacetic acid (TFA) to break down polysaccharides into constituent monosaccharides. The hydrolyzate is directly analyzed using quantitative ¹H NMR spectroscopy without derivatization or neutralization. The anomeric proton signals of each monosaccharide are used for identification and quantification [12].

- Materials:

- Reagents: Trifluoroacetic acid (TFA, 2N in D₂O), Deuterium oxide (D₂O), Sodium 3-(trimethylsilyl)propionate-2,2,3,3-d₄ (TSP) as an internal standard [12].

- Monosaccharide Standards: Glucose, Galactose, Mannose, Xylose, Arabinose, Rhamnose, Fucose, Ribose, Glucuronic acid, Galacturonic acid for signal identification and method validation [12].

- Equipment: NMR spectrometer (400 MHz or higher), NMR tubes, precision pH meter, heated block or oven for hydrolysis, vacuum concentrator [12].

- Procedure:

- Sample Hydrolysis: Transfer the isolated IDF or SDF residue to a hydrolysis vial. Add 2 mL of 2N TFA. Hydrolyze at 121°C for 1-2 hours. Cool the hydrolyzate and concentrate to dryness using a vacuum concentrator [12].

- NMR Sample Preparation: Reconstitute the dried hydrolyzate in 0.6 mL of 2N TFA in D₂O containing 0.1 mM TSP. Vortex thoroughly and transfer to a 5 mm NMR tube [12].

- ¹H NMR Acquisition: Acquire ¹H NMR spectra at a controlled temperature (e.g., 25°C or 37°C). Use a sufficiently long relaxation delay (d1 > 5 × T1) to ensure quantitative conditions. Collect 64-128 scans [12].

- Spectral Processing and Analysis: Process the FID with exponential line broadening (0.3-1.0 Hz). Manually phase and baseline-correct the spectrum. Reference the spectrum to the TSP signal at 0.0 ppm. Identify monosaccharides based on their characteristic anomeric proton chemical shifts [12].

- Quantification:

- The concentration of each monosaccharide is calculated using the formula:

C_mono = (A_mono / N_mono) × (N_TSP / A_TSP) × (C_TSP / 9)whereC_monois the concentration of the monosaccharide,A_monois the integrated area of its anomeric proton signal,N_monois the number of protons contributing to that signal (typically 1 for anomeric protons),A_TSPis the integrated area of the TSP peak,N_TSPis the number of protons in TSP (9), andC_TSPis the known concentration of TSP [12].

- The concentration of each monosaccharide is calculated using the formula:

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Dietary Fiber Analysis

| Reagent/Material | Function in Analysis | Specific Application Example |

|---|---|---|

| Heat-stable α-amylase | Hydrolyzes starch into dextrins during gelatinization step [11] | Standard enzymatic digestion in AOAC 991.43 for TDF [11] |

| Protease | Digests and removes protein from the sample [11] | Standard enzymatic digestion in AOAC 991.43 for TDF [11] |

| Amyloglucosidase | Hydrolyzes dextrins and starch fragments to glucose [11] | Final step in enzymatic starch removal [11] |

| MES-TRIS Buffer | Maintains stable pH during enzymatic digestion [11] | Preferred buffer in AACC Method 32-07.01 [11] |

| Microcrystalline Cellulose (MCC) | Stationary phase for chromatographic fractionation [13] | DP-based separation of oligosaccharides using aqueous ethanol mobile phases [13] |

| Lichenase & β-Glucosidase | Specific enzymatic hydrolysis of (1→3)(1→4)-β-D-glucan [11] | Quantification of β-glucan in oat and barley fractions (AACC Method 32-23.01) [11] |

| Trifluoroacetic Acid (TFA) in D₂O | Hydrolyzes polysaccharides and provides acidic medium for NMR analysis [12] | Sample preparation for ¹H qNMR monosaccharide analysis [12] |

| TSP (Internal Standard) | Chemical shift reference and quantitation standard in NMR [12] | Absolute quantification of monosaccharides in ¹H qNMR method [12] |

Advanced Techniques for Structural Characterization

Spectroscopic Methods: FT-IR and Raman Spectroscopy

Fourier-Transform Infrared (FT-IR) and Raman spectroscopy are complementary vibrational techniques used to study the molecular structure and interactions of dietary fiber components within complex food matrices.

- FT-IR Spectroscopy: This technique measures absorption of infrared light, providing information on molecular vibrations and functional groups. In fiber research, it is particularly useful for analyzing protein secondary structure (e.g., Amides I and II bands) in fortified breads and studying interactions between added fibers (like pectin), polyphenols, and native bread components [14]. For example, conformational changes in wheat gluten, such as a shift from β-turns to β-sheets upon addition of pectin and polyphenols, can be detected [14].

- Raman Spectroscopy: This technique measures inelastic scattering of monochromatic light, providing a molecular fingerprint. It is non-destructive, requires minimal sample preparation, and is less affected by water, making it ideal for analyzing native starch and gluten structures in wheat flour, dough, and baked products [15]. It can probe short-range molecular order in starch and protein conformations, providing insights into the impact of processing on the food's molecular architecture [14] [15].

Chromatographic Fractionation and Analysis

Chromatographic techniques are crucial for separating and quantifying specific fiber components and their molecular populations.

- Chromatographic Fractionation with MCC: Flash chromatography using microcrystalline cellulose (MCC) as a stationary phase and aqueous ethanol as a mobile phase can separate oligosaccharides, such as maltooligosaccharides (MOS), based on their degree of polymerization (DP) in a food-grade manner [13]. This is vital for preparing defined DP fractions for sensory testing or studying structure-function relationships.

- High-Performance Anion-Exchange Chromatography (HPAEC): This method, often coupled with pulsed amperometric detection (PAD), is used for the precise quantification of specific carbohydrates. Official methods (e.g., AACC 32-31.01) employ HPAEC-PAD to analyze fructans and oligofructose in processed foods and raw materials [11].

The classification of dietary fiber has traditionally relied on a simplistic binary system of "soluble" versus "insoluble." This framework, while useful for basic nutritional guidance, fails to capture the structural and functional diversity of dietary fibers and their complex physiological effects in the human body [4]. Current research demonstrates that this binary classification does not accurately predict the full range of health outcomes associated with different fiber types, as solubility alone provides an incomplete picture of fiber's behavior in the gastrointestinal tract [4] [16]. A more comprehensive understanding requires the integration of additional physicochemical properties, particularly fermentability, which directly influences fiber's interaction with the gut microbiota and subsequent production of health-relevant metabolites like short-chain fatty acids (SCFAs) [16].

This paradigm shift recognizes that soluble fibers are not uniformly soluble but exhibit important variations in qualities such as fermentability, capacity to attenuate insulin secretion, and ability to lower serum cholesterol [4]. Similarly, insoluble fibers demonstrate varying degrees of fermentability and water-holding capacity that influence their physiological effects [17]. This article presents an advanced framework for fiber classification that integrates solubility with fermentability and other key characteristics, providing researchers with refined analytical approaches for investigating fiber composition in whole foods and their health impacts.

Beyond Solubility: A Multidimensional Classification Framework

Limitations of the Traditional Solubility-Based Classification

The conventional division of dietary fiber into soluble and insoluble categories, while entrenched in nutritional science and labeling, presents significant limitations for predicting physiological outcomes:

- Oversimplification of Complex Structures: The binary system overlooks the molecular diversity of fiber structures and their structure-function relationships [4].

- Inconsistent Correlation with Function: Solubility does not consistently predict physiological effects such as cholesterol reduction, glycemic response modulation, or prebiotic activity [18].

- Methodological Variability: Analytical results for fiber solubility can vary considerably depending on extraction methods, temperature, pH, and other external factors [19].

- Neglect of Microbial Interactions: The traditional classification fails to adequately account for variations in fermentability, which directly determines fiber's impact on gut microbiota composition and metabolic output [16].

Toward a Comprehensive Classification System

A more nuanced classification framework has been proposed that incorporates five key constituents: backbone structure, water-holding capacity, structural charge, fiber matrix, and fermentation rate [4]. This multidimensional model more accurately captures the structural and functional diversity of dietary fibers, enabling better prediction of their health benefits. Within this framework, three characteristics emerge as particularly critical for understanding fiber's physiological behavior: solubility, viscosity, and fermentability [18]. These properties are interrelated yet distinct, each contributing to fiber's functional capabilities in the gastrointestinal environment.

Table 1: Key Characteristics for Advanced Fiber Classification

| Characteristic | Definition | Physiological Implications | Research Considerations |

|---|---|---|---|

| Solubility | Ability to dissolve in water [18] | Determines dispersal in GI tract; generally increases fermentability [19] | Highly dependent on extraction method, temperature, pH [19] |

| Viscosity | Resistance to flow; thickness of hydrated fiber [18] | Impacts gastric emptying, nutrient absorption, satiety [16] | Not all soluble fibers are viscous (e.g., FOS, GOS) [19] |

| Fermentability | Extent of microbial metabolism in large intestine [16] | Determines SCFA production, microbial selection, gas production [17] | Rate of fermentation (slow vs. fast) affects tolerability [18] |

Analytical Methods for Fiber Characterization

Methodological Approaches for Fiber Analysis

The accurate characterization of dietary fiber in whole foods requires sophisticated analytical techniques that can distinguish between multiple fiber fractions. Two primary methodological approaches have been developed:

- Enzymatic-Gravimetric Methods: These procedures attempt to reflect the material that enters the large intestine by removing starch, protein, and fat, then obtaining a residue that is dried and weighed [20]. Correction is made for any remaining protein and ash, with results expressed as a proportion of the starting material. Key methods include AOAC 985.29 (Prosky method) and its variants [20] [21].

- Enzymatic-Chemical Methods: These approaches chemically characterize the carbohydrate content of fiber after removing available carbohydrates and fat [20]. Various procedures enable carbohydrates to be measured as constituent monosaccharides or as groups of monosaccharide types, including the Englyst and Uppsala methods [20] [22].

Advanced Analytical Separation

Modern analytical frameworks have evolved to categorize dietary fibers into three distinct fractions based on solubility and molecular weight:

- Insoluble High Molar Weight Dietary Fibers (IHMWDF): Including resistant starches and traditional insoluble fibers [21].

- Soluble High Molar Weight Dietary Fibers (SHMWDF): Comprising viscous soluble fibers like pectins, β-glucans, and gums [21].

- Low Molar Weight Dietary Fibers (LMWDF): Typically non-viscous soluble fibers including fructooligosaccharides (FOS), galactooligosaccharides (GOS), and other prebiotic oligosaccharides [19] [21].

Table 2: Standardized Analytical Methods for Dietary Fiber Characterization

| Method | Principle | Components Measured | Applications | Limitations |

|---|---|---|---|---|

| AOAC 985.29 (Prosky) | Enzymatic-gravimetric | Total dietary fiber | General food analysis; nutrition labeling | Incomplete for some novel fibers [21] |

| AOAC 991.43 | Enzymatic-gravimetric | Total, soluble, and insoluble dietary fiber | Foods and food products with little or no starch | Variable starch removal [20] |

| AOAC 2011.25 | Enzymatic-chemical-gravimetric | IHMWDF, SHMWDF, LMWDF | Comprehensive analysis of all fiber fractions | Requires advanced equipment [21] |

| Englyst Method | Enzymatic-chemical | Non-starch polysaccharides | Research on fiber components | Does not include lignin [20] |

Experimental Protocols for Fiber Fermentation Analysis

In Vitro Cecal Fermentation Model

This protocol evaluates the fermentation characteristics of different dietary fiber sources using an in vitro cecal fermentation model, adapted from the methodology published in LWT [17].

Research Reagent Solutions

Table 3: Essential Reagents for In Vitro Fermentation Studies

| Reagent/Material | Specifications | Function in Protocol |

|---|---|---|

| Dietary Fiber Substrates | ≥90% purity; characterized for SDF/IDF ratio | Test substrates for fermentation characteristics |

| Cecal Inoculum | Fresh cecal content from animal models (e.g., pigs) | Source of complex gut microbiota |

| Anaerobic Buffer Solution | pH 6.8-7.0; containing macrominerals, microminerals, and resazurin indicator | Maintains anaerobic conditions and physiological pH |

| Reducing Solution | Cysteine-HCl + Na₂S | Establishes and maintains anaerobic environment |

| SCFA Standard Mix | Acetate, propionate, butyrate, isobutyrate, valerate, isovalerate | Quantitative analysis of fermentation metabolites |

| Ammonia Nitrogen Assay Kit | Commercially available kit (e.g., Berthelot method) | Quantifies protein fermentation metabolites |

Step-by-Step Procedure

Substrate Preparation: Weigh 1.0 g (±0.001 g) of each test fiber substrate into separate fermentation vessels. Include appropriate blanks (no substrate) and controls (reference substrates like inulin and cellulose).

Inoculum Preparation: Collect fresh cecal content from animal models (preferably pigs as human digestion model) and dilute 1:10 with anaerobic buffer solution. Filter through cheesecloth and maintain under CO₂ atmosphere at 39°C.

Fermentation Initiation: Add 100 mL of diluted inoculum to each fermentation vessel under continuous CO₂ flushing. Seal vessels with one-way pressure release valves.

Incubation: Incubate vessels in a shaking water bath at 39°C with continuous agitation (100 rpm) for 24 hours.

Gas Production Measurement: Record total gas production using pressure transducers or water displacement methods at 2, 4, 6, 8, 12, and 24 hours.

Termination and Sample Collection:

- For SCFA analysis: Collect 1 mL fermentation fluid, acidify with 25% metaphosphoric acid, and centrifuge at 10,000 × g for 10 minutes.

- For ammonia nitrogen: Collect 2 mL fermentation fluid, centrifuge at 10,000 × g for 10 minutes, and analyze immediately.

- For microbial analysis: Preserve 1 mL fermentation fluid in DNA/RNA shield for subsequent metagenomic analysis.

Analytical Measurements:

- Quantify SCFAs using gas chromatography with flame ionization detection.

- Determine ammonia nitrogen concentration using commercial assay kits.

- Analyze microbial composition via 16S rRNA sequencing or shotgun metagenomics.

Data Interpretation and Analysis

The fermentation characteristics of different fibers can be evaluated through multiple parameters:

- Fermentation Rate: Calculate from gas production kinetics using modeling approaches.

- SCFA Profile: Determine molar ratios of acetate, propionate, and butyrate.

- Ammonia Nitrogen Reduction: Indicator of protein fermentation suppression.

- Microbial Community Shifts: Analyze changes in taxonomic composition and diversity.

Diagram 1: Experimental workflow for in vitro fiber fermentation analysis. The integrated approach assesses multiple fermentation parameters to develop comprehensive fiber fermentation profiles. Character count: 98.

Interrelationship Between Solubility and Fermentability

Complex Correlation Patterns

While solubility and fermentability are often correlated, their relationship is not absolute, with significant exceptions that demonstrate the need for independent measurement of both properties:

- Generally Fermentable Soluble Fibers: Most soluble fibers are readily fermented by gut microbiota, including inulin, pectins, β-glucans, and gums [19]. These fibers typically show rapid fermentation kinetics and substantial SCFA production [17].

- Notable Exceptions: Some soluble fibers demonstrate limited fermentability, including psyllium and methylcellulose, which remain relatively intact through the gastrointestinal tract despite their solubility [19].

- Variable Insoluble Fiber Fermentability: While most insoluble fibers are minimally fermented, some forms, particularly resistant starches, can be substantially metabolized by specialized microbial taxa [23].

- Structural Complexity Effects: The rate and extent of fermentation are influenced by molecular complexity beyond solubility, including glycosidic linkages, side chains, and crystalline structure [4].

Implications for Experimental Design

The complex relationship between solubility and fermentability necessitates careful consideration in research design:

- Independent Measurement: Researchers should independently assess both solubility and fermentability rather than inferring one from the other.

- Temporal Dynamics: Fermentation rate (slow vs. fast) may have important physiological consequences independent of total fermentability [18].

- Microbial Ecology: Different fiber structures select for distinct microbial taxa with specialized carbohydrate-active enzymes, influencing community-level metabolic output [24].

Diagram 2: Interrelationships between fiber properties and physiological effects. Solubility, fermentability, and viscosity interact to influence multiple health outcomes through distinct and overlapping mechanisms. Character count: 99.

The integration of solubility and fermentability in dietary fiber classification provides a powerful framework for advancing whole foods research. This refined approach enables researchers to:

- Predict Physiological Effects: More accurately anticipate the health impacts of different fiber types based on multiple physicochemical properties rather than solubility alone.

- Design Targeted Interventions: Develop fiber-specific nutritional approaches for modulating gut microbiota composition and metabolic output.

- Interpret Complex Food Matrices: Better understand how fibers behave in whole food contexts where multiple fiber types interact with other food components.

- Advance Personalized Nutrition: Account for individual variations in microbiota composition that influence fiber fermentability and health outcomes.

As research in this field evolves, the comprehensive characterization of dietary fibers—integrating solubility, fermentability, viscosity, and other physicochemical properties—will be essential for unlocking the full health potential of whole foods and developing targeted nutritional strategies for disease prevention and management.

Dietary fiber research has gained significant momentum over the past decade, with DP3+ polymers (carbohydrates with a degree of polymerization of three or more) emerging as crucial components in nutritional science and functional food development [25]. These medium-chain and long-chain carbohydrates are recognized for their low digestibility and diverse physiological effects, including improved glucose homeostasis and enhanced gut health [26] [27]. The global research landscape reflects this importance, with China and the United States leading publication output and journals like Nutrients and Food Chemistry frequently featuring fiber research [25].

This Application Note details the structural characteristics of DP3+ polymers and establishes the mechanistic link between their molecular configuration and physiological functions. We provide standardized protocols for analyzing these relationships within broader research on fiber composition in whole foods, enabling researchers to quantify structure-function dynamics for both basic science and applied drug development.

Molecular Characterization of DP3+ Polymers

Structural Definitions and Classification

DP3+ polymers encompass a range of carbohydrate structures characterized by their glycosidic linkages and polymerization degree:

- Definition: Carbohydrate compositions containing three or more monomeric units linked by glycosidic bonds [26].

- Key Features: Reduced sugar content (often <25%) and low digestibility compared to traditional nutritive sweeteners like glucose, fructose, and maltose [26].

- Functional Attributes: These polymers contribute reduced caloric value (approximately 1 kcal/gram) while providing desirable functional properties in food matrices, such as improved viscosity profiles and reduced hardening in finished products [26].

Comparative Structural Analysis

Table 1: Molecular Characteristics of DP3+ Polymers and Reference Compounds

| Compound | Average DP | Glycosidic Linkages | Molecular Weight Profile | Key Structural Features |

|---|---|---|---|---|

| DP3+ Polymers | 3-20+ | Mixed (α-1,4; α-1,6; β-1,3) | Broad distribution | Reduced sugar content (<25%), low digestibility |

| Traditional Syrups | 1-20+ | Predominantly α-1,4 | Varies by DE | High sugar content (>25%), highly digestible |

| Polydextrose | ~12 | Mixed, random | ~2000 Da | Highly branched complex polymer |

| GOS from B. bifidum | 3-8 | β-1,3 and β-1,4 preferred | 500-1300 Da | Reduced allergenicity potential |

| Resistant Maltodextrin | 10-30 | Mixed (α-1,4; α-1,6) | 1500-5000 Da | Partial resistance to digestion |

Chromatographic analyses reveal distinct molecular signatures for various DP3+ polymers. The unique GOS pattern produced by β-galactosidase from B. bifidum shows preference for β-1→3 linkages, potentially reducing allergenicity risks compared to other glycosidic arrangements [28]. Similarly, specialized carbohydrate compositions demonstrate controlled molecular weight distributions that optimize functionality while maintaining low digestibility [26].

Physiological Effects and Mechanisms of Action

Metabolic and Glucose Homeostasis Benefits

DP3+ polymers exert significant effects on metabolic parameters, particularly in individuals with overweight and obesity:

Table 2: Physiological Effects of DP3+ Polymers and Dietary Fibers

| Physiological Parameter | Effect Size | Statistical Significance | Clinical Relevance |

|---|---|---|---|

| Fasting Glucose | -0.07 mmol/L | P = 0.0005 | Moderate improvement in glucose regulation |

| Fasting Insulin | -5.89 pmol/L | P = 0.0004 | Reduced pancreatic beta-cell demand |

| HOMA-IR | -0.38 | P < 0.00001 | Improved insulin sensitivity |

| HbA1c | Significant reduction | P < 0.05 | Long-term glucose control |

| Insulin AUC | Significant reduction | P < 0.05 | Postprandial insulin response improvement |

Meta-analyses of randomized controlled trials demonstrate that single isolated fibers (including DP3+ polymers) significantly improve fasting insulin, HOMA-IR, HbA1c, and insulin area under the curve (AUC) [27]. These effects stem from multiple mechanisms, including delayed carbohydrate absorption, fermentation products, and modulation of gut hormone secretion.

Gut Health and Microbiome Interactions

The low digestibility of DP3+ polymers enables their passage to the colon where they serve as substrates for microbial fermentation:

- SCFA Production: Fermentation generates short-chain fatty acids (acetate, propionate, butyrate) that influence host metabolism [25].

- Microbial Modulation: DP3+ structures selectively promote beneficial bacteria, including bifidobacteria [28].

- Barrier Function: Butyrate production enhances colonic barrier integrity and exerts anti-inflammatory effects [25].

These mechanisms collectively contribute to the role of DP3+ polymers in managing metabolic syndrome, cardiovascular risk factors, and potentially colorectal cancer through induction of cancer cell apoptosis and inhibition of inflammatory pathways [25].

Signaling Pathways and Molecular Mechanisms

The following pathway diagram illustrates the key physiological mechanisms through which DP3+ polymers exert their health benefits:

Diagram 1: Physiological pathways of DP3+ polymer effects. DP3+ polymers resist digestion, undergo microbial fermentation to SCFAs, which then mediate systemic benefits through neural, endocrine, and immunomodulatory pathways.

Analytical Protocols for Structure-Function Analysis

Chromatographic Profiling of DP3+ Polymers

Objective: To separate and quantify DP3+ polymer composition in food and biological samples.

Materials:

- High-performance liquid chromatography (HPLC) system with refractive index detector

- Carbohydrate analysis column (e.g., amine-bonded silica, 250 × 4.6 mm, 5 μm)

- DP standard solutions (DP1-DP20)

- Mobile phase: Acetonitrile/water (65:35 v/v)

- Sample preparation: Dilute samples to 10-20 mg/mL and filter (0.45 μm)

Procedure:

- Equilibrate column with mobile phase at 1.0 mL/min

- Inject 10 μL of standard solutions to establish calibration curve

- Inject test samples and record retention times and peak areas

- Identify DP regions based on standard retention times (DP3+: typically 8-25 minutes)

- Calculate percentage distribution of DP3-DP7, DP8-DP15, and DP16+ fractions

- Compare chromatographic profiles pre- and post-digestion to assess resistance

Data Interpretation: The method effectively distinguishes DP3+ polymers from mono- and disaccharides. Chromatograms should show clear separation of oligosaccharide fractions, enabling quantification of the specific DP ranges associated with physiological effects [26].

In Vitro Digestibility Assessment

Objective: To evaluate the low digestibility characteristic of DP3+ polymers.

Materials:

- Simulated gastric fluid (SGF): 0.32% pepsin in 0.08 M HCl

- Simulated intestinal fluid (SIF): 1% pancreatin in 0.1 M NaHCO₃

- Water bath with shaking (37°C)

- Trichloroacetic acid (10% solution)

- DNS reagent for reducing sugar analysis

Procedure:

- Incubate sample (5 mL of 10% solution) with SGF (5 mL) for 30 minutes at 37°C with agitation

- Neutralize with 0.5 mL 1M NaHCO₃

- Add SIF (5 mL) and incubate for additional 120 minutes

- Remove aliquots (1 mL) at 0, 30, 60, 120 minutes

- Precipitate enzymes with TCA, centrifuge, and analyze supernatant for reducing sugars

- Calculate percentage of resistant material based on reducing sugar release

Data Interpretation: True DP3+ dietary fibers typically show <20% hydrolysis after 120 minutes of intestinal digestion, significantly lower than digestible carbohydrates (>80% hydrolysis) [26].

Fermentation Potential and SCFA Analysis

Objective: To quantify the production of short-chain fatty acids from DP3+ polymer fermentation.

Materials:

- Anaerobic chamber

- Fecal inoculum from healthy donors

- Fermentation medium (carbon-free)

- Gas chromatography system with FID detector

- Capillary column for organic acid analysis

Procedure:

- Prepare fecal slurry (10% w/v) in anaerobic phosphate buffer

- Add sample (1% w/v) to fermentation medium in anaerobic tubes

- Inoculate with fecal slurry (10% v/v) and incubate at 37°C for 24h

- Collect samples at 0, 6, 12, 24h for SCFA analysis

- Acidify samples with metaphosphoric acid, centrifuge, and inject supernatant to GC

- Quantify acetate, propionate, and butyrate against standard curves

Data Interpretation: DP3+ polymers with higher fermentation rates produce significant SCFAs within 6-12 hours, with butyrate production particularly relevant for colon health benefits [28] [25].

Research Reagent Solutions

Table 3: Essential Research Reagents for DP3+ Polymer Analysis

| Reagent/Category | Specific Examples | Function/Application |

|---|---|---|

| Reference Standards | DP3-DP20 oligosaccharide standards; GOS standards; Resistant maltodextrin standards | Chromatographic calibration and peak identification |

| Enzymatic Assay Kits | β-Galactosidase from B. bifidum; Simulated gastric and intestinal fluids; Amyloglucosidase | Digestibility assessment; In vitro models |

| Chromatography Supplies | HPLC columns (amine-bonded, HILIC); GC columns for SCFA analysis; SPE cartridges | Molecular separation and quantification |

| Cell-Based Assay Systems | Caco-2 intestinal cells; HEK-293 transfected cells; HT-29 MTX mucus-producing cells | Absorption studies; Receptor binding assays |

| Microbial Culturing | Fecal inoculum preparation kits; Selective media for Bifidobacterium; Anaerobic culture systems | Fermentation potential assessment |

Application Notes for Specific Research Scenarios

Formulating Reduced-Sugar Food Products

When incorporating DP3+ polymers as sugar replacers:

- Viscosity Matching: Select DP3+ compositions with viscosity profiles similar to target applications (e.g., 43 DE corn syrup equivalent) [26].

- Sugar Reduction: DP3+ polymers from specialized enzymatic processing can achieve >35% sugar reduction while maintaining sensory properties [28].

- Product Stability: Monitor hardening tendencies in baked goods and adjust DP distribution (balance of DP3-DP7 vs DP8+) to maintain soft texture during shelf life [26].

Clinical Trial Design for Metabolic Studies

When evaluating DP3+ polymers in human subjects:

- Dosing Strategy: Base doses on previously effective levels from meta-analyses (typically 10-15g/day for isolated fibers) [27].

- Endpoint Selection: Include HOMA-IR, fasting insulin, and HbA1c as primary endpoints for metabolic studies.

- Subject Stratification: Consider BMI, baseline glucose tolerance, and habitual fiber intake as potential effect modifiers.

Advanced Structural Characterization

For comprehensive DP3+ polymer analysis:

- Linkage Analysis: Employ GC-MS following permethylation to characterize glycosidic linkages.

- Size Exclusion Chromatography: Couple with multi-angle light scattering for absolute molecular weight determination.

- NMR Spectroscopy: Utilize 1H and 13C NMR for structural elucidation of novel DP3+ polymers.

The relationship between molecular structure and physiological function in DP3+ polymers represents a critical frontier in nutritional science and functional food development. Through precise characterization of degree of polymerization, glycosidic linkage patterns, and molecular weight distribution, researchers can predict and optimize the health benefits of these compounds. The protocols and analytical frameworks provided herein enable systematic investigation of these structure-function relationships, supporting advancements in evidence-based fiber research for metabolic health and chronic disease prevention.

The continued expansion of dietary fiber research, with particular focus on DP3+ polymers and their specific mechanisms of action, promises to yield novel ingredients and therapeutic approaches for managing the increasing global burden of metabolic diseases [25].

In whole foods research, a comprehensive understanding of dietary fiber extends beyond its traditional role as a non-digestible carbohydrate to encompass its function as a carrier for bioactive compounds. The analytical quantification of fiber and the evaluation of its functional properties are fundamentally influenced by its biological origin and the conditions to which it is subjected. This Application Note details the primary sources of variability in plant fiber composition—namely, plant species and genotype, stage of ripeness, and growing conditions. It provides validated protocols for the quantitative analysis of fiber, enabling researchers to generate precise and reproducible data critical for nutritional studies and drug development.

Variability in Fiber Composition: Quantitative Data

The composition and mechanical properties of dietary fiber are not constant; they vary significantly based on genetic, developmental, and environmental factors. The data below summarize key sources of this variability.

Table 1: Impact of Plant Species, Ripeness, and Growing Conditions on Fiber

| Source of Variability | Subject of Study | Key Finding | Quantitative Impact | Reference |

|---|---|---|---|---|

| Species & Genotype | 1177 flax accessions (fibre flax vs. linseed) | Stem fibre content range | 9.0% to 35.0% (dry matter basis) | [29] |

| Species & Genotype | North American linseed vs. European fibre flax | Average fibre content difference | 22.2% vs. 24.3% | [29] |

| Ripeness Stage | Bananas (controlled lot, unripe to overripe) | Total Dietary Fiber (AOAC 2011.25) | Unripe: ~18 g/100g; Ripe: 4-5 g/100g; Overripe: ~2 g/100g | [30] |

| Ripeness Stage | Bananas (controlled lot) | Traditional Fiber (AOAC 991.43) | Constant at ~2 g/100g, irrespective of ripeness | [30] |

| Growing Conditions | Flax fibers (different years & regions) | Effect on fiber yield & tensile strength | Significant influence; precipitation during early growth impacts tensile strength | [31] |

| Growing Conditions | Flax plants | Optimal accumulated temperature for harvest | 850–1100 °C | [31] |

Experimental Protocols for Fiber Analysis

Protocol: Determination of Total Dietary Fiber Using AOAC 2011.25

1. Principle: This modified enzymatic-gravimetric method (mEG) quantifies high-molecular-weight dietary fiber (HMWDF) and low-molecular-weight dietary fiber (LMWDF) in alignment with the Codex Alimentarius definition. It is particularly crucial for materials containing non-digestible oligosaccharides (e.g., fructans) or resistant starch, which are not fully measured by older methods [32] [30].

2. Reagents and Equipment:

- Enzymes: Heat-stable α-amylase, protease, amyloglucosidase.

- Solvents: Ethanol (78%, 95%), acetone.

- Buffers: Phosphate buffer (pH 6.0).

- Equipment: Analytical balance, drying oven, muffle furnace, fritted crucibles, water bath, pH meter.

3. Procedure:

- Digestion: Incubate a homogenized sample (1 g ± 0.1 g) with phosphate buffer. Sequentially treat with:

- Heat-stable α-amylase (for starch gelatinization and breakdown).

- Protease (for protein digestion).

- Amyloglucosidase (for further starch hydrolysis).

- Precipitation: Add ethanol to the digest to precipitate soluble fiber.

- Filtration: Filter the mixture through pre-weighed fritted crucibles.

- Washing: Wash the residue with 78% ethanol, 95% ethanol, and acetone.

- Drying and Weighing: Dry the crucible and residue overnight at 105°C. Weigh to determine the mass of HMWDF.

- Protein and Ash Correction: Analyze one residue sample for protein (e.g., by Kjeldahl) and another for ash by incineration (525 °C for 5 h).

- LMWDF Analysis: The filtrate from the precipitation step is concentrated and analyzed by HPLC-RID to quantify LMWDF (e.g., fructans with DP 3-9).

4. Calculation:

TDF (g/100g) = HMWDF + LMWSDF

Where HMWDF = [Crucible residue weight - (Protein + Ash)] / Sample weight

Protocol: Assessing the Impact of Growing Conditions on Flax Fiber Tensile Strength

1. Principle: This protocol uses the Impregnated Fiber Bundle Test (IFBT) to evaluate the tensile strength of flax fiber bundles, which is influenced by variety, weather conditions, and retting practices [31].

2. Reagents and Equipment:

- Fibers: Scutched flax fibers from defined varieties and growing conditions.

- Impregnation Resin: A suitable, low-viscosity polymer resin (e.g., epoxy).

- Equipment: Universal tensile testing machine, climate-controlled chamber, sample preparation jigs.

3. Procedure:

- Fiber Conditioning: Condition fiber bundles at standard temperature and humidity (e.g., 23°C, 50% RH) for 24 hours.

- Specimen Preparation: Impregnate conditioned fiber bundles with resin to ensure load transfer between elementary fibers. Cure the resin completely.

- Tensile Testing: Mount the impregnated fiber bundle onto the tensile tester with a calibrated gauge length. Apply a constant crosshead displacement rate until failure. Record the force-displacement data.

- Data Analysis: Calculate tensile strength from the maximum load and the initial cross-sectional area of the fiber bundle. Perform statistical analysis (e.g., ANOVA) to determine the significance of factors such as variety, cultivation region, and retting duration.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Fiber Composition Analysis

| Research Reagent / Material | Function in Analysis |

|---|---|

| Heat-stable α-amylase | Enzymatically hydrolyzes gelatinized starch into shorter dextrins during TDF analysis. |

| Amyloglucosidase | Further hydrolyzes dextrins into glucose, ensuring complete removal of digestible starch. |

| Protease | Digests and removes protein components that could otherwise be weighed as fiber residue. |

| Fritted Crucibles (porosity 2) | For the filtration and collection of the insoluble dietary fiber residue after enzymatic digestion. |

| HPLC with RID | Used in the AOAC 2011.25 method to identify and quantify low-molecular-weight soluble dietary fibers (e.g., fructans). |

| Standardized Fiber Bundles | Provide a consistent and biologically relevant form factor for biomechanical tensile tests (IFBT). |

| Impregnation Resin (e.g., Epoxy) | In IFBT, ensures uniform stress distribution across elementary fibers in a bundle during tensile testing. |

Workflow and Relationship Diagrams

Figure 1: A workflow diagram illustrating the key sources of variability in plant fiber composition and the corresponding analytical methods used to quantify their impact.

Analytical Methodologies in Practice: From Gold-Standard Assays to Cutting-Edge Techniques

The accurate quantification of dietary fiber is fundamental to nutritional science, food labeling, and clinical research. The enzymatic-gravimetric method has served as the cornerstone technique for fiber analysis, with AOAC Official Method 985.29 representing the historical benchmark for decades [33] [20]. Developed by Prosky and colleagues, this method became the primary approach for measuring total dietary fiber (TDF) in foods and was widely adopted for nutritional labeling and regulatory purposes [20]. However, as scientific understanding of dietary fiber evolved, particularly with the adoption of the physiologically relevant Codex Alimentarius definition in 2009, methodological limitations became apparent [33]. This recognition prompted the development of more comprehensive approaches, culminating in the recent introduction of AOAC Official Method 2022.01, which represents a significant advancement in fiber analytics by integrating enzymatic-gravimetric principles with liquid chromatography to fully align with contemporary definitions [34].

The progression from AOAC 985.29 to 2022.01 reflects a paradigm shift from measuring fiber as a simple gravimetric residue to a sophisticated analysis that captures the complete spectrum of dietary fiber components as defined by Codex, including low molecular weight soluble fibers that were not quantified in earlier methods [33] [35]. This technical evolution is crucial for researchers investigating the relationship between fiber consumption and human health, particularly in whole foods research where the complete fiber profile influences gut microbiome composition and metabolic outcomes [24] [36].

Methodological Foundations and Comparative Analysis

AOAC 985.29: The Foundational Protocol

Historical Context and Development

AOAC 985.29 emerged from collaborative efforts in the 1980s to standardize dietary fiber measurement. Prior to its development, fiber analysis relied on crude fiber methods that severely underestimated fiber content by losing soluble components, or the Van Soest detergent methods designed for animal feeds that were inadequate for human nutrition [20]. The Prosky method (985.29) introduced a physiological simulation approach using enzymes to remove digestible components, leaving the non-digestible fiber residue for gravimetric quantification [33] [20].

Principle and Mechanism

The method operates on the principle of simulating human digestive processes through sequential enzymatic treatments. A heat-stable α-amylase is first employed at high temperature to gelatinize and hydrolyze starch, followed by protease treatment to solubilize proteins, and finally amyloglucosidase (AMG) to break down any remaining starch fragments to glucose [33]. The insoluble dietary fiber (IDF) is collected via filtration, while soluble dietary fiber (SDF) is precipitated from the filtrate using 78% aqueous ethanol and collected through a second filtration [33] [20]. The combined weight of IDF and SDF precipitates (SDFP), corrected for residual protein and ash, constitutes the TDF value [33].

Components Measured

This method effectively captures high molecular weight dietary fiber components, including:

- Cellulose and hemicelluloses from plant cell walls [33]

- Pectins and gums that precipitate in 78% ethanol [33]

- Lignin and associated plant compounds [33] [20]

- A portion of resistant starch (primarily RS3) [33]

However, it fails to account for certain physiologically important fiber components, particularly soluble dietary fiber that remains soluble in 78% ethanol (SDFS), such as inulin, fructooligosaccharides (FOS), galactooligosaccharides (GOS), and polydextrose [33] [35]. Additionally, it does not completely measure all forms of resistant starch (RS1, RS2, RS4) under its hydrolysis conditions [33].

AOAC 2022.01: The Integrated Modern Protocol

Advancements and Technical Innovations

AOAC 2022.01 was developed specifically to address the limitations of earlier methods and fully align with the Codex Alimentarius definition of dietary fiber [34]. This method represents an integration and modification of AOAC 2017.16, extending its capability to separately measure insoluble, soluble precipitable, and soluble non-precipitable fiber fractions [34]. The key innovation lies in its combination of enzymatic-gravimetric principles with liquid chromatography, creating a comprehensive analytical approach.

Principle and Mechanism

The method begins with enzymatic digestion using pancreatic α-amylase (PAA), amyloglucosidase (AMG), and protease under conditions that closely simulate the human small intestine environment, providing more physiologically relevant resistant starch measurement compared to 985.29 [33] [34]. The digestate is filtered to isolate insoluble dietary fiber (IDF), which is determined gravimetrically. The filtrate containing soluble fiber is treated with 78% ethanol to precipitate soluble dietary fiber that precipitates (SDFP), which is collected by filtration and weighed [34]. The remaining soluble dietary fiber that stays soluble (SDFS) in the ethanolic solution, consisting primarily of low molecular weight fibers (DP≥3), is recovered and quantified using liquid chromatography [34]. The sum of IDF, SDFP, and SDFS provides the total dietary fiber value that fully complies with the Codex definition.

Components Measured

This integrated approach captures the complete spectrum of dietary fiber components:

- All high molecular weight dietary fibers measured by AOAC 985.29 [34]

- Low molecular weight dietary fibers (DP≥3) that remain soluble in 78% ethanol, including inulin, FOS, GOS, and polydextrose [34]

- All categories of resistant starch (RS1, RS2, RS3, RS4) due to more physiological digestion conditions [33] [34]

- Non-digestible oligosaccharides with degree of polymerization ≥3 [34]

Table 1: Comparative Analysis of AOAC 985.29 and AOAC 2022.01

| Parameter | AOAC 985.29 | AOAC 2022.01 |

|---|---|---|

| Definition Alignment | Trowell definition [33] | Codex Alimentarius definition [33] [34] |

| Enzymes Used | Heat-stable α-amylase, protease, amyloglucosidase [33] | Pancreatic α-amylase, amyloglucosidase, protease [33] [34] |

| Starch Digestion Conditions | High temperature (100°C) incubation [33] | Physiological temperature (37°C) simulating small intestine [33] [34] |

| SDFS Measurement | Not measured [33] | Quantified via liquid chromatography [34] |

| Resistant Starch Coverage | Primarily RS3 [33] | All forms (RS1, RS2, RS3, RS4) [33] |

| Molecular Weight Range | High molecular weight only [33] [35] | High and low molecular weight (DP≥3) [34] |

| Analytical Technique | Gravimetric only [33] [20] | Integrated enzymatic-gravimetric-liquid chromatography [34] |

| Throughput | High for HMWDF [20] | Moderate (includes LC analysis) [34] |

Table 2: Method Performance Characteristics Based on Validation Studies

| Performance Metric | AOAC 985.29 | AOAC 2022.01 |

|---|---|---|

| Precision (CV) | ~4-5% for cracker biscuits [37] | <3.60% RSDr for TDF [34] |

| Accuracy (Recovery) | 101-110% for fortified samples [37] | Meets AOAC requirements for reproducibility [34] |

| Linearity | Excellent (R²=0.9999) [37] | Robust across diverse matrices [34] |

| Reproducibility (RSDR) | Established in interlaboratory studies [20] | 4.55-9.26% for TDF [34] |

| Applicable Matrices | Most food products [20] | Cereals, vegetables, health foods, chocolate, beans [34] |

Experimental Protocols

Detailed Protocol: AOAC 985.29

Reagents and Equipment

- Enzymes: Heat-stable α-amylase (≥3,000 U/mL), protease (≥350 U/mL), amyloglucosidase (≥3,000 U/mL) [33]

- Buffers: Phosphate buffer (0.08M, pH 6.0) [20]

- Laboratory Equipment: Water bath (100°C and 60°C), filtration apparatus with crucibles, drying oven, muffle furnace, desiccator [33] [37]

- Chemicals: 78% ethanol solution, acetone, diatomaceous earth [33]

Step-by-Step Procedure

- Sample Preparation: Grind sample to pass through 0.3-0.5mm screen. Defat if fat content exceeds 10% [33] [37].

- Enzymatic Digestion:

- Filtration: Filter using crucible with celite, wash residue with 10mL 70°C water [33]

- IDF Determination: Transfer residue to crucible, dry at 105°C overnight, weigh, then ash at 525°C, reweigh [33]

- SDFP Determination: Precipitate filtrate with 4 volumes 95% ethanol, incubate 1h at room temperature, filter, wash with 78% ethanol, 95% ethanol, and acetone [33]

- Calculations:

- %IDF = (residue weight - protein weight - ash weight) / sample weight × 100

- %SDFP = (precipitate weight - protein weight - ash weight) / sample weight × 100

- %TDF = %IDF + %SDFP [33]

Detailed Protocol: AOAC 2022.01

Reagents and Equipment

- Enzymes: Pancreatic α-amylase (specific activity defined), amyloglucosidase, protease [34]

- Buffers: Specific pH buffers for physiological simulation [34]

- Chromatography System: HPLC with appropriate columns (e.g., NH2 or C18) and detectors (RI or ELSD) [34]

- Internal Standard: Diethylene glycol for quantification [34]

Step-by-Step Procedure

- Sample Preparation: Duplicate test portions treated identically [34]

- Physiological Digestion:

- IDF Determination: Filter digestate, wash residue, determine IDF gravimetrically after correction for protein and ash [34]

- SDFP Determination: Precipitate IDF filtrate with 78% aqueous ethanol, filter, wash, determine gravimetrically [34]

- SDFS Determination:

- Calculations:

- %TDF = %IDF + %SDFP + %SDFS

- Apply response factors and internal standard correction for SDFS [34]

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Materials for Enzymatic-Gravimetric Fiber Analysis

| Item | Specification Requirements | Function in Protocol |

|---|---|---|

| Heat-stable α-amylase | ≥3,000 U/mL [33] | Starch hydrolysis at high temperature in AOAC 985.29 [33] |

| Pancreatic α-amylase | Defined specific activity [34] | Physiological starch digestion in AOAC 2022.01 [33] [34] |

| Amyloglucosidase (AMG) | ≥3,000 U/mL [33] | Hydrolysis of starch dextrins to glucose [33] |

| Protease | ≥350 U/mL (pH 6.0 at 37°C) [33] | Protein digestion and removal [33] |

| Liquid Chromatography System | HPLC with appropriate columns [34] | Quantification of SDFS in AOAC 2022.01 [34] |

| Internal Standard | Diethylene glycol [34] | Quantification reference for chromatographic analysis [34] |

| Filtration Apparatus | Crucibles with celite aid [33] | Separation of insoluble fiber fraction [33] |

| pH Adjustment Solutions | HCl, NaOH for precise pH control [33] | Maintain optimal enzyme activity conditions [33] |

| Precipitation Solvents | 78% ethanol, 95% ethanol, acetone [33] | Soluble fiber precipitation and washing [33] |

| Muffle Furnace | Capable of 525°C [33] | Ash determination for correction factors [33] |

Applications in Whole Foods Research

The methodological evolution from AOAC 985.29 to 2022.01 has significant implications for whole foods research. The comprehensive fiber profiling enabled by AOAC 2022.01 provides researchers with more accurate data for correlating specific fiber fractions with physiological outcomes [35]. Recent intervention studies demonstrate that increased fiber consumption from whole foods alters gut microbiome composition, increasing known fiber-degrading microbes such as Bifidobacterium and Lactobacillus [24]. The ability to accurately measure the complete spectrum of dietary fiber, including low molecular weight soluble fibers that serve as substrates for specific microbial taxa, enables more precise correlations between fiber intake and microbial metabolic activities [24] [36].

Furthermore, the distinction between soluble and insoluble fiber fractions is crucial for understanding their differential health effects. Soluble fibers contribute to blood glucose attenuation and cholesterol lowering, while insoluble fibers primarily influence laxation and bowel function [35] [36]. The development of comprehensive fiber categories databases that include soluble, insoluble, and resistant starch components provides valuable tools for analyzing dietary intake in relation to health outcomes [35]. This detailed fiber characterization is particularly relevant for whole foods plant-based dietary patterns, where diverse fiber sources contribute to the documented health benefits including reduced cardiovascular disease risk, improved weight management, and enhanced glycemic control [36].

The progression from AOAC 985.29 to AOAC 2022.01 represents significant advancement in dietary fiber analytics, moving from a method that captured primarily high molecular weight fiber components to an integrated approach that fully aligns with the Codex Alimentarius definition. While AOAC 985.29 remains historically important and suitable for certain applications, AOAC 2022.01 provides the comprehensive analysis required for contemporary nutritional research, particularly in whole foods and gut microbiome studies where complete fiber characterization is essential. The integration of enzymatic-gravimetric principles with liquid chromatography in AOAC 2022.01 enables researchers to accurately quantify the complete spectrum of dietary fiber components, supporting more precise investigations of structure-function relationships and physiological impacts of different fiber fractions in human health and disease.

The comprehensive analysis of dietary fiber composition in whole foods presents a significant analytical challenge due to the complex matrix and the diverse chemical nature of fiber components, including both high molecular weight (HMW) and low molecular weight (LMW) fractions. This application note details a robust high-performance liquid chromatography (HPLC) method for the precise separation and quantification of individual fiber constituents. Within the context of whole foods research, this protocol enables accurate nutritional labeling, supports research on the health impacts of specific fiber types, and aids in the formulation of functional food products with targeted nutritional benefits.

Dietary fiber encompasses plant-based carbohydrates that resist digestion in the human small intestine. Accurate analysis is crucial as different fiber components—soluble LMW fibers (e.g., from oats and legumes) and insoluble HMW fibers (e.g., from whole grains and bran)—impart distinct health benefits, including improved glycemic control, enhanced gut health, and reduced risk of chronic diseases [38]. Traditional gravimetric methods, while useful for total fiber content, lack the specificity to resolve individual components. This document establishes a detailed HPLC-based protocol to enhance specificity in fiber analysis, providing researchers with a powerful tool for dissecting the complex fiber profile of whole foods.

Key Analytical Parameters and Instrumentation

The following table summarizes the optimized parameters for the HPLC analysis of dietary fiber components, consolidating critical data for method replication.

Table 1: Optimized HPLC Parameters for Dietary Fiber Analysis

| Parameter | Specification |

|---|---|

| Analytical Scope | Separation and quantification of Low Molecular Weight (LMW) and High Molecular Weight (HMW) dietary fiber fractions [38]. |

| Sample Preparation | Enzymatic hydrolysis (e.g., AOAC 991.43 or 2009.01) to remove proteins and non-fiber carbohydrates [38]. |

| Mobile Phase | Acetonitrile/water with 0.1% acetic acid additive to enhance ionization efficiency in MS-detection [39]. |

| Detection Sensitivity (LC-MS/MS) | Limits of Detection (LOD): 0.01 – 16.7 ng/mL in Multi Reaction Monitoring (MRM) mode for various dye classes, demonstrating high sensitivity for trace analysis [39]. |

| Key Advantage | Accurate quantification of specific fiber components for nutritional labeling, product development, and health claims research [38]. |

Experimental Protocol

Sample Preparation

- Homogenization: Finely grind the whole food sample to ensure a homogeneous and representative sub-sample.

- Enzymatic Digestion: Following established official methods (e.g., AOAC 991.43), treat the sample with enzymes such as amylase, protease, and amyloglucosidase to sequentially remove starch and proteins [38].

- Precipitation: Add ethanol to the digest to precipitate HMW dietary fiber fractions.

- Filtration and Reconstitution: Separate the precipitate via filtration. The filtrate containing LMW dietary fibers and the precipitated HMW fraction are then prepared for injection by dissolving in the appropriate mobile phase [38].

HPLC-MS/MS Analysis

- Chromatographic Separation:

- Utilize a suitable reversed-phase column (e.g., C18).

- Employ a binary mobile phase system: (A) water with 0.1% acetic acid and (B) acetonitrile with 0.1% acetic acid.

- Apply a gradient elution from 5% to 100% B over a defined period to effectively separate various fiber components based on their hydrophobicity.

- Mass Spectrometric Detection:

- Ionization: Use Electrospray Ionization (ESI) in either positive or negative mode, optimized for the target analytes.

- Data Acquisition: Operate the tandem mass spectrometer in Multi Reaction Monitoring (MRM) mode for high sensitivity and selectivity.

- Optimization: For each target fiber component or marker, optimize the MS parameters (precursor ion, product ion, collision energy, etc.) by direct infusion of standards [39].

Data Analysis

- Identify fiber components by comparing their retention times and MRM transitions with those of authentic standards.

- Construct calibration curves using standard solutions for absolute quantification of LMW and HMW fiber fractions.

- Report the concentration of individual fiber components in the original food sample.

Workflow Visualization

The following diagram illustrates the complete experimental workflow from sample preparation to final analysis.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Essential Materials for HPLC Analysis of Fiber Components

| Item | Function / Application |

|---|---|

| Enzyme Kits (Amylase, Protease) | Digest and remove starch and protein interferents from the food matrix [38]. |

| HPLC-MS/MS Grade Solvents | Acetonitrile, water, and acetic acid for mobile phase preparation, ensuring minimal background noise and optimal ionization [39]. |

| Dietary Fiber Standards | Certified reference materials for both LMW and HMW fractions for system calibration and quantification [38]. |

| Solid Phase Microextraction (SPME) Fibers | An alternative sample preparation technique for concentrating specific analytes; coatings like PAN/C18 are stable in LC solvents [40]. |

| Capillary-Channeled Polymer (C-CP) Fibers | A novel stationary phase for LC columns offering low back-pressure and high flow rates, potentially useful for preparative-scale separation of fiber components [41]. |

In the field of whole foods research, accurately determining fiber composition is critical for understanding nutritional value, health impacts, and dietary interventions. Traditional wet chemistry methods for fiber analysis, such as the AOAC 985.29 and 991.43 methods, are well-recognized for their reliability but are typically time-consuming, labor-intensive, and require specialized facilities and staff [42]. These destructive methods also consume chemical reagents and generate waste, making them less suitable for high-throughput analysis or rapid quality control [43].

Fourier Transform Infrared (FTIR) and Near-Infrared (NIR) spectroscopy have emerged as powerful alternatives, offering rapid, non-destructive, and chemical-free analysis while requiring minimal sample preparation [42]. FTIR spectroscopy utilizes the mid-infrared region (MIR, 4000-400 cm⁻¹) to probe fundamental molecular vibrations, providing detailed information about chemical functional groups and enabling differentiation between even similar molecular structures [44]. In contrast, NIR spectroscopy (750-2500 nm) measures overtones and combinations of these fundamental vibrations, making it particularly effective for quantifying constituents in complex mixtures like food matrices [42] [44].

This application note details the use of FTIR and NIR spectroscopy for the rapid, non-destructive profiling of fiber composition in whole foods, providing structured protocols, performance comparisons, and practical implementation guidelines for researchers.

Technical Comparison: FTIR vs. NIR for Fiber Analysis

The choice between FTIR and NIR spectroscopy depends on the specific analytical requirements, as each technique offers distinct advantages and limitations for fiber analysis in food research.

Table 1: Technical Comparison between FTIR and NIR Spectroscopy for Food Fiber Analysis

| Parameter | FTIR (Mid-Infrared) | NIR (Near-Infrared) |

|---|---|---|