Advanced Chromatography Methods for Fatty Acid Profiling in Foods: From Foundational Principles to Clinical Applications

This article provides a comprehensive overview of modern chromatography techniques for fatty acid analysis in food matrices, tailored for researchers, scientists, and drug development professionals.

Advanced Chromatography Methods for Fatty Acid Profiling in Foods: From Foundational Principles to Clinical Applications

Abstract

This article provides a comprehensive overview of modern chromatography techniques for fatty acid analysis in food matrices, tailored for researchers, scientists, and drug development professionals. It explores the fundamental principles of fatty acid nomenclature and separation science, details established and emerging methodologies including GC-FID, GC-MS, UPLC-HRMS, and their applications across diverse food samples. The content addresses critical troubleshooting aspects for method optimization, presents rigorous validation protocols, and offers comparative analysis of technique performance. By synthesizing current research and technological advancements, this resource aims to support the selection, development, and implementation of robust analytical strategies for food quality assessment, nutritional research, and the exploration of diet-health relationships.

The Fundamentals of Fatty Acids and Core Chromatographic Separation Principles

Fatty acids are fundamental biochemical components in food research, serving crucial roles in nutritional science, food quality assessment, and metabolic studies. Within the context of chromatography methods for fatty acid profiling in foods, precise nomenclature and classification form the foundational knowledge required for accurate analytical interpretation. Fatty acids are primarily categorized based on their chemical structure, specifically the presence and number of double bonds in their hydrocarbon chains. This classification system delineates four primary groups: saturated fatty acids (SFA), monounsaturated fatty acids (MUFA), polyunsaturated fatty acids (PUFA), and trans fatty acids [1] [2].

Understanding these classifications is critical for researchers and scientists employing chromatographic techniques, as the chemical structure directly influences the fatty acid's behavior during separation, detection, and quantification. The following sections provide detailed definitions, structural characteristics, common examples, and dietary sources for each category, supported by standardized tables and analytical workflows relevant to food science research.

Definition and Classification of Fatty Acids

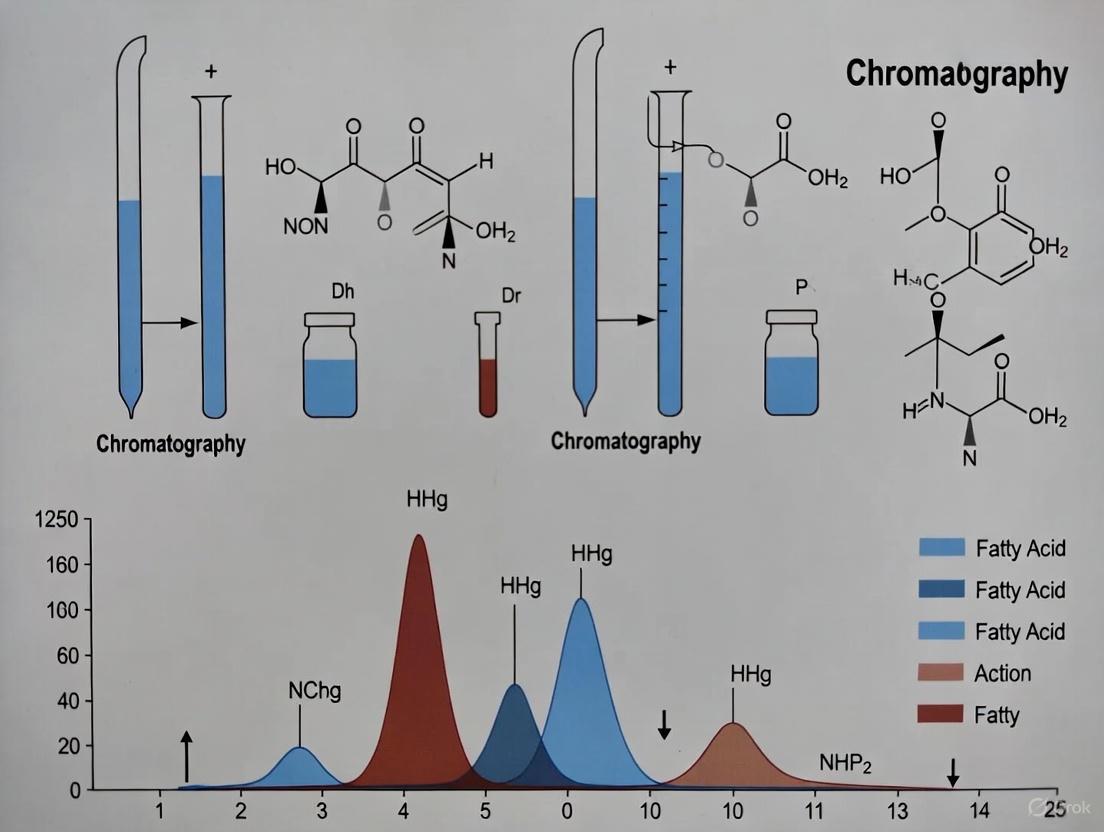

The following diagram illustrates the logical classification of fatty acids based on their chemical structure, a key concept for planning chromatographic profiling.

Saturated Fatty Acids (SFA)

Saturated fatty acids (SFA) are aliphatic carboxylic acids characterized by a hydrocarbon chain with no carbon-carbon double bonds. The term "saturated" indicates that the carbon atoms are fully saturated with hydrogen atoms, containing the maximum possible number [3] [2]. This structure allows for close molecular packing, typically rendering them solid at room temperature [1] [3].

In chromatographic profiling, SFAs are generally more stable under high-temperature conditions used in Gas Chromatography (GC) due to their lack of reactive double bonds. The table below summarizes common SFAs, their systematic and trivial names, and typical dietary sources encountered in food analysis.

Table 1: Common Saturated Fatty Acids in Food Analysis

| Trivial Name | Systematic Name | Lipid Number | Typical Food Sources |

|---|---|---|---|

| Lauric Acid | n-Dodecanoic acid | 12:0 | Palm kernel oil, nutmeg [2] |

| Myristic Acid | n-Tetradecanoic acid | 14:0 | Palm kernel oil, nutmeg, dairy fats [3] [2] |

| Palmitic Acid | n-Hexadecanoic acid | 16:0 | Olive oil, animal lipids [3] [2] |

| Stearic Acid | n-Octadecanoic acid | 18:0 | Cocoa butter, animal fats [3] [2] |

Monounsaturated Fatty Acids (MUFA)

Monounsaturated fatty acids (MUFA) contain exactly one carbon-carbon double bond in their hydrocarbon chain [1] [4]. The double bond is most commonly in the cis configuration, which introduces a kink in the molecular chain, lowering the melting point compared to SFAs and making them liquid at room temperature [1] [2].

The most prevalent MUFA in the diet is oleic acid (18:1 n-9), a key component of the Mediterranean diet [1] [4]. From an analytical perspective, the single double bond makes MUFAs less susceptible to oxidation during sample storage and preparation than PUFAs, but more so than SFAs. The following table outlines key MUFAs relevant to food profiling.

Table 2: Common Monounsaturated Fatty Acids in Food Analysis

| Trivial Name | Systematic Name | Lipid Number | Typical Food Sources |

|---|---|---|---|

| Palmitoleic Acid | cis-9-hexadecenoic acid | 16:1 (n-7) | Marine algae, macadamia oil [1] [2] |

| Oleic Acid | cis-9-octadecenoic acid | 18:1 (n-9) | Olive oil, canola oil, avocados, nuts [1] [4] [2] |

| Vaccenic Acid | cis-11-octadecenoic acid | 18:1 (n-7) | Meat, dairy products (in small amounts) [1] |

Polyunsaturated Fatty Acids (PUFA)

Polyunsaturated fatty acids (PUFA) are structurally defined by the presence of two or more carbon-carbon double bonds in their backbone [5] [6]. The double bonds are typically separated by a methylene group (-CH₂-), a pattern known as "methylene-interrupted" [5]. This structure gives PUFAs a curved, flexible shape, significantly lowering their melting point and increasing membrane fluidity when incorporated into phospholipids [7].

PUFAs are highly susceptible to lipid peroxidation and oxidative degradation due to the presence of multiple double bonds, especially when exposed to heat, light, and oxygen [5]. This is a critical consideration during sample preparation and analysis, as it can lead to the formation of degradation products that interfere with accurate profiling. A major subclassification of PUFAs is based on the position of the first double bond from the methyl end (omega end) of the molecule, leading to the nutritionally and analytically distinct omega-3 (n-3) and omega-6 (n-6) families [5] [6]. Some PUFAs are essential fatty acids, meaning they cannot be synthesized by the human body and must be obtained from the diet [6] [7].

Table 3: Common Polyunsaturated Fatty Acids in Food Analysis

| Category | Trivial Name | Systematic Name | Lipid Number | Status |

|---|---|---|---|---|

| Omega-6 | Linoleic Acid (LA) | cis-9, cis-12-octadecadienoic acid | 18:2 (n-6) | Essential [5] [7] |

| Arachidonic Acid (AA) | cis-5, cis-8, cis-11, cis-14-eicosatetraenoic acid | 20:4 (n-6) | Conditional [5] | |

| Omega-3 | α-Linolenic Acid (ALA) | cis-9, cis-12, cis-15-octadecatrienoic acid | 18:3 (n-3) | Essential [5] [7] |

| Eicosapentaenoic Acid (EPA) | cis-5, cis-8, cis-11, cis-14, cis-17-eicosapentaenoic acid | 20:5 (n-3) | Conditional [5] | |

| Docosahexaenoic Acid (DHA) | cis-4, cis-7, cis-10, cis-13, cis-16, cis-19-docosahexaenoic acid | 22:6 (n-3) | Conditional [5] |

Trans Fatty Acids

Trans fatty acids are a specific type of unsaturated fatty acid where the hydrogen atoms adjacent to the carbon-carbon double bond are on opposite sides (the trans configuration) [2]. This configuration straightens the molecule, making it behave more like a saturated fat, such as being solid at room temperature [8].

The primary health concern associated with trans fats is their negative impact on blood lipid profiles: they raise low-density lipoprotein (LDL, "bad") cholesterol and lower high-density lipoprotein (HDL, "good") cholesterol [8]. The main source of harmful trans fats in the modern diet is industrially produced partially hydrogenated oils (PHOs), though small amounts also occur naturally in meat and dairy from ruminant animals [8] [2]. The most common industrial trans fat is elaidic acid, the trans isomer of oleic acid [1]. Their analysis requires careful chromatographic separation from their cis isomers.

Analytical Protocol: Fatty Acid Profiling in Food Matrices

Accurate fatty acid profiling is essential for food quality, safety, and nutritional labeling. The following section outlines a detailed protocol for the extraction and analysis of fatty acids from food matrices, incorporating improvements for efficiency and environmental impact.

Workflow for Fatty Acid Analysis

The entire process, from sample preparation to data analysis, is visualized in the following workflow diagram.

Detailed Experimental Methodology

Sample Preparation and Lipid Extraction

- Homogenization: Weigh approximately 100 mg of a representative, homogenized food sample (e.g., cheese, ground nuts) into a glass vial [9]. For solid matrices, freeze-drying and fine grinding may be necessary to ensure homogeneity.

- Initial Dissolution: Dissolve the sample in 10 mL of hexane and vortex thoroughly to ensure complete dissolution of the lipid content [9].

Fatty Acid Extraction (Improved Protocol PE6)

This step separates Free Fatty Acids (FFAs) from triacylglycerols for specific analysis or can be adapted for total lipid extraction.

- Transfer the 10 mL hexane sample solution to a 50 mL separating funnel.

- Add a mixture of 10 mL acetonitrile and 5 mL of 0.02 M phosphate buffer (pH 12) [10] [9]. A solvent-to-buffer ratio greater than 2:1 is critical for high extraction efficiency.

- Shake the funnel vigorously for 5 minutes to facilitate the transfer of FFAs into the aqueous-organic solvent mixture [9].

- Allow the layers to separate completely. Recover the lower aqueous layer (Fraction 1).

- Repeat the extraction of the upper organic layer two more times, pooling the aqueous layers (Fractions 2 & 3) for a comprehensive recovery of FFAs [9].

- The improved PE6 protocol has been verified to be more efficient for extracting short, medium, and long-chain fatty acids and presents a higher greenness profile by reducing solvent use and environmental impact [10].

Derivatization: Formation of Fatty Acid Methyl Esters (FAMEs)

Fatty acids must be derivatized to more volatile FAMEs for Gas Chromatography (GC) analysis.

- Evaporation: Evaporate the pooled extraction fractions to complete dryness under a gentle stream of nitrogen gas at room temperature [9].

- Saponification: Add 1.5 mL of 0.5 M methanolic sodium hydroxide to the dry residue. Heat the mixture at approximately 100°C for 7 minutes [9].

- Esterification: After cooling, add 2 mL of Boron Trifluoride (BF₃) in methanol (12-14% w/v). Heat the mixture again at ~100°C for 5 minutes to form the FAMEs [9].

- Extraction of FAMEs: Let the mixture cool. Add 2 mL of hexane and 5 mL of a saturated sodium chloride (NaCl) solution. Shake for 5 minutes and allow phases to separate.

- Recovery: Transfer the upper hexane layer (containing FAMEs) to a new vial. Re-extract the lower layer with another 2 mL of hexane. Pool the hexane extracts and evaporate to dryness under nitrogen.

- Reconstitution: Reconstitute the dry FAME extract in 1 mL of GC-grade hexane and transfer to a GC vial for analysis [9].

GC-FID Analysis

- GC System: Use a Gas Chromatograph equipped with a Flame Ionization Detector (FID).

- Column: A high-polarity capillary column, such as a CP-Sil 88, SP-2560, or equivalent (100 m x 0.25 mm i.d., 0.20 µm film thickness), is recommended for optimal separation of geometric and positional isomers.

- Carrier Gas: Helium or Hydrogen.

- Temperature Program: A temperature gradient is typically used. Example: Initial oven temperature 140°C, hold for 5 min, ramp at 4°C/min to 240°C, and hold for 20-30 min.

- Injection: Split or splitless injection mode can be used depending on concentration. Injector temperature should be ~250°C; detector temperature ~260°C.

- Identification & Quantification: Identify FAMEs by comparing their retention times with those of certified FAME reference standards. Quantify using internal or external standard methods with calibration curves.

The Scientist's Toolkit: Key Research Reagents

Table 4: Essential Reagents for Fatty Acid Profiling via GC-FID

| Reagent / Material | Function / Purpose | Application Notes |

|---|---|---|

| BF₃-Methanol Solution | Catalyst for transesterification of fatty acids into volatile methyl esters (FAMEs) for GC analysis. | Critical for derivatization. Handle with care in a fume hood due to toxicity [9]. |

| FAME Reference Standards | Certified calibration standards for identifying and quantifying individual fatty acids based on retention time. | Essential for accurate peak assignment and quantification. A C4-C24 mix is typical. |

| Polar Capillary GC Column | Stationary phase for separating fatty acid isomers based on chain length, degree, and geometry of unsaturation. | Columns like CP-Sil 88 or SP-2560 are industry standards for detailed fatty acid profiling. |

| Acetonitrile & Phosphate Buffer | Solvent system for liquid-liquid extraction of free fatty acids from oil samples. | The PE6 protocol uses this for efficient, greener extraction of a wide range of FAs [10] [9]. |

The precise nomenclature and classification of fatty acids into SFA, MUFA, PUFA, and trans fats provide the essential lexicon for interpreting chromatographic data in food research. The experimental protocols detailed herein, particularly the improved PE6 extraction method, offer a pathway to accurate, reproducible, and more environmentally sustainable fatty acid profiling. Mastery of these definitions and methodologies empowers researchers to effectively assess food quality, authenticate products, investigate the role of lipids in health and disease, and ensure compliance with nutritional labeling regulations, thereby forming a critical foundation for advancements in food science and nutritional chemistry.

Chromatography, literally meaning "color writing," stands as the most versatile and pervasive technique in analytical chemistry today [11] [12] [13]. Its journey from a simple method for separating plant pigments to the cornerstone of modern analytical science, particularly in food analysis, is a story of scientific ingenuity. This article traces the historical evolution of chromatography, framing it within the context of its crucial application in fatty acid profiling for food research. For researchers and drug development professionals, understanding this evolution is key to selecting and optimizing methods for accurate lipid analysis, which is fundamental to nutritional labeling, food safety, and health-related studies [10] [14]. The development of chromatography has been characterized by peaks of activity in different techniques, which can be conceptualized as distinct "Ages" of advancement [13].

Table 1: The Evolutionary "Ages" of Chromatography

| Era | Dominant Technique | Key Innovation | Primary Impact |

|---|---|---|---|

| Early 1900s | Column Adsorption | Tsvet's use of calcium carbonate columns | First separation of plant pigments (xanthophylls, carotenes, chlorophylls) [11] |

| 1940s-1950s | Partition & Paper Chromatography | Martin and Synge's partition method | Separation of amino acids and other organic chemicals with slight differences in partition coefficients [11] |

| 1950s-1960s | Gas Chromatography (GC) | Prediction and realization of GC by Martin, James, and Cremer | Efficient separation of volatile compounds, leading to widespread adoption and new detectors (FID, ECD) [11] |

| 1960s-Present | High-Performance Liquid Chromatography (HPLC) | Use of small sorbent particles and pressure | Fast, efficient liquid chromatography for a wide range of compounds, including non-volatile and thermally labile molecules [11] [12] [15] |

| 1980s-Present | Process & Affinity Chromatography | Development of robust resins and specific ligands (e.g., Protein A) | Industrial-scale purification of biotherapeutics like monoclonal antibodies [12] [15] |

The Early Foundations: Tsvett and Column Chromatography

The first true chromatography is universally attributed to the Russian-Italian botanist Mikhail Tsvet [11] [12] [13]. In 1901, Tsvet applied his observations to column fractionation methods, using a liquid-adsorption column containing calcium carbonate to separate plant pigments such as chlorophyll and carotenoids [11]. He formally named the technique "chromatography" in 1906 in a German botanical journal [11]. Tsvet's work elegantly demonstrated the core principle of chromatography: the differential adsorption of mixture components as they pass through a stationary phase, leading to their separation [11] [12]. Despite its elegance, Tsvet's method saw little practical use for several decades until the next wave of innovation.

The Revolution of Partition Chromatography

Chromatography methods changed little until the landmark work of Archer John Porter Martin and Richard Laurence Millington Synge in the 1930s and 1940s [11]. By combining chromatography with the principles of countercurrent solvent extraction, they developed partition chromatography [11]. Their key innovation was using silica gel to hold water stationary while an organic solvent flowed through the column, allowing the separation of chemicals based on their differing partition coefficients between two liquid solvents [11]. This work, for which they were awarded the Nobel Prize in Chemistry in 1952, was foundational. In pursuit of easier methods for identifying amino acids, Martin and Synge also developed paper chromatography, which became a fundamental tool in biochemical research and was instrumental in Fred Sanger's determination of the amino acid sequence of insulin [11].

The Advent of Gas Chromatography and High-Performance Liquid Chromatography

The principles established by Martin and Synge set the stage for the next major leaps forward. In their seminal 1941 paper, they predicted that the mobile phase "need not be a liquid but may be a vapor," foreshadowing the development of gas chromatography (GC) [11]. Martin, in collaboration with Anthony T. James, began developing GC in 1949, and by his 1952 Nobel lecture, he announced the successful separation of a wide variety of natural compounds [11]. The ease and efficiency of GC spurred rapid adoption and the development of new detection methods, including the flame ionization detector (FID) and the electron capture detector [11]. The coupling of mass spectrometers to gas chromatographs in the late 1950s further expanded its analytical power [11] [14].

Similarly, Martin and Synge's work suggested that using small sorbent particles and pressure could produce fast liquid chromatography techniques [11]. This concept led to the development of high-performance liquid chromatography (HPLC), which became widely practical in the late 1960s [11] [12]. The first commercial HPLC machine was produced in 1967, and over the following decades, it became a ubiquitous tool in laboratories worldwide, enabling the high-resolution separation of increasingly complex molecules [12] [13] [15].

Application Notes: Chromatography in Fatty Acid Profiling for Food Research

The historical evolution of chromatography is deeply intertwined with its applications in food science, particularly in the accurate profiling of fatty acids (FAs), which are essential for nutritional assessment and food quality [10] [14].

Gas Chromatography for Fatty Acid Methyl Esters (FAMEs)

GC-FID is the gold standard for fatty acid analysis in food chemistry [10] [14]. Since fatty acids are non-volatile, they are first converted to volatile fatty acid methyl esters (FAMEs) before GC analysis [14]. A typical workflow involves lipid extraction, saponification to liberate free fatty acids, and derivatization using a catalyst like boron trifluoride (BF₃) to form FAMEs [9] [14]. The FAMEs are then separated on a GC equipped with a polar capillary column (e.g., wax-type) and quantified using an FID [14]. This method is capable of profiling fatty acids from C4:0 to C24:1, separating cis and trans isomers, and is required for compliance with labeling regulations like the U.S. Nutrition Labeling Education Act (NLEA) [14] [16].

Table 2: Key Analytical Techniques for Fatty Acid Profiling

| Technique | Principle | Key Applications in Food Research | Performance Notes |

|---|---|---|---|

| GC-FID | Separation of volatile FAMEs based on boiling point and polarity; detection via ionization in a hydrogen flame. | - Full fatty acid profiling (C4:0 to C24:1) [14]- Quantification of cis/trans isomers [14] [16]- Nutrition labeling and food quality control [10] | - Requires derivatization [14]- High sensitivity and reproducibility [16]- Considered the reference method |

| HPLC-PDA | Separation of underivatized FAs using a pressurized liquid mobile phase and a stationary phase; detection by ultraviolet light absorption. | - Analysis of short-chain/volatile fatty acids (VFAs) [17]- Fermentation broth analysis [17]- Time-dependent studies in food and environmental samples [17] | - No derivatization required [17]- Faster analysis times for specific SCFAs (~8 minutes) [17]- Lower chromatographic cost for targeted analyses [17] |

Detailed Protocol: GC-FID Analysis of Fatty Acids in Cheese

The following protocol is adapted from modern research aiming to develop faster, more efficient, and environmentally friendly extraction methods [10].

1. Sample Preparation and Lipid Extraction:

- Accurately weigh ~100 mg of homogenized cheese sample.

- Add a known amount of an internal standard (e.g., C19:0 fatty acid) to compensate for variability in preparation and analysis [14].

- Extract the total fat using a suitable solvent system (e.g., a mixture of hexane and isopropanol) via vigorous shaking or sonication.

- Centrifuge the mixture and collect the organic layer containing the lipids.

2. Saponification and Derivatization to FAMEs:

- Transfer the lipid extract to a reaction vial and evaporate the solvent under a stream of nitrogen.

- Add 1.5 mL of 0.5 N methanolic sodium hydroxide and heat at ~100°C for 7 minutes to saponify the triglycerides and liberate free fatty acids [9].

- After cooling, add 2 mL of 12-14% BF₃ in methanol and heat again at ~100°C for 5 minutes to form the FAMEs [9].

- Cool the mixture and add 2 mL of hexane and 5 mL of a saturated NaCl solution. Shake vigorously and allow the phases to separate.

- Recover the upper hexane layer containing the FAMEs for GC analysis.

3. GC-FID Analysis:

- Inject 1 µL of the FAME-hexane solution into a GC system equipped with a highly polar capillary column (e.g., 100 m x 0.25 mm ID, 0.20 µm film thickness).

- Use helium as the carrier gas.

- Employ a temperature program: for example, hold at 100°C for 2 min, ramp at 4°C/min to 240°C, and hold for 15 min.

- Maintain the FID temperature at 260°C.

- Identify fatty acids by comparing the retention times of sample peaks to those of certified FAME standards.

- Quantify results using the internal standard method and report as % weight/weight of the sample or as triglyceride equivalents for nutrition labels [14].

Emerging Methods: HPLC for Short-Chain Fatty Acids

While GC dominates, HPLC methods are being developed for specific applications. A 2025 study detailed an underivatized HPLC method with photodiode array (PDA) detection for analyzing six short-chain fatty acids (SCFAs)—formic, acetic, propionic, butyric, isovaleric, and valeric acids—in fermentation broth and similar samples [17]. This method is characterized by:

- No derivatization required, making it less cumbersome [17].

- Short analysis time of approximately 8 minutes [17].

- A gradient elution with a flow rate of 1–2.5 mL/min [17].

- Low limits of detection (LOD), ranging from 0.0003 to 0.068 mM [17].

This HPLC-PDA method provides a cost-effective and time-efficient alternative for analyzing these specific SCFAs in aqueous food and environmental samples [17].

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Research Reagent Solutions for Fatty Acid Analysis by GC-FID

| Reagent/Material | Function | Example / Specification |

|---|---|---|

| Internal Standard | Compensates for variability in extraction, derivatization, and injection; enables accurate quantification. | C19:0 (Nonadecanoic acid) or C23:0, of known high purity [14] |

| Derivatization Reagent | Catalyzes the conversion of free fatty acids into volatile Fatty Acid Methyl Esters (FAMEs). | Boron Trifluoride in Methanol (12-14% BF₃) [9] or Trimethylsilyl-diazomethane (TMS-DM) [16] |

| Saponification Reagent | Hydrolyzes triglycerides to liberate free fatty acids from the glycerol backbone. | Methanolic Sodium Hydroxide (0.5 N NaOH in methanol) [9] |

| GC Capillary Column | The stationary phase for separating FAMEs based on their chain length, saturation, and geometry. | Highly polar column (e.g., wax-type, 100m length) for resolving cis/trans isomers [14] [16] |

| Certified FAME Standards | Used to identify sample components by matching retention times and for calibration. | A certified mixture of 37 FAMEs, or individual isomers like elaidic acid (C18:1 trans-9) [16] |

From Tsvett's elegant separation of plant pigments on a calcium carbonate column to the sophisticated, automated GC and HPLC systems of today, chromatography has undergone a remarkable evolution. Each breakthrough, from the partition principle of Martin and Synge to the development of GC and HPLC, has expanded our analytical capabilities. In food research, this history directly enables the precise and reliable fatty acid profiling that is crucial for understanding nutrition, ensuring food quality, and complying with regulatory standards. As the field continues to advance, driven by the needs for higher throughput, better sustainability, and the analysis of novel food matrices, the foundational principles of chromatography remain as relevant as ever.

Visual Workflows

Diagram 1: Fatty Acid Analysis Workflow

Diagram 2: Technique Evolution and Food Science Applications

Within food research, the precise analysis of fatty acid (FA) profiles is critical for assessing nutritional value, authenticity, and safety. Chromatography stands as the cornerstone technique for such separations, with High-Performance Liquid Chromatography (HPLC) and Gas Chromatography (GC) being the most prominent methods. The fundamental difference between them lies in the nature of the mobile phase: GC employs a gas, while HPLC uses a liquid. This choice dictates the types of analytes that can be separated, the required sample preparation, and the selection of an appropriate detection system. This application note details the core principles, method protocols, and detector selection for both techniques within the context of fatty acid profiling in food matrices, providing researchers with a clear framework for method development.

Core Principles and Comparative Analysis

Fundamental Separation Mechanisms

In all chromatography, separation occurs as analytes distribute themselves between a stationary phase and a mobile phase. Analytes that spend more time in the mobile phase elute faster, while those with greater affinity for the stationary phase are retained longer [18]. The specific mechanisms at play differ between GC and HPLC:

- Gas Chromatography (GC): The mobile phase is an inert carrier gas (e.g., Helium, Hydrogen). Separation of volatile fatty acid derivatives is primarily based on their volatility and interaction with the stationary phase, which is a liquid polymer coated on the inner wall of a capillary column [18]. In GC, the high temperatures used to vaporize analytes make it unsuitable for underivatized or thermally labile compounds.

- High-Performance Liquid Chromatography (HPLC): The mobile phase is a liquid solvent or mixture pumped at high pressure. A common mode for FA analysis is Reversed-Phase HPLC, where the stationary phase is non-polar (e.g., C18) and the mobile phase is polar. Separation is based on the hydrophobicity of the fatty acids; more non-polar FAs have a stronger affinity for the non-polar stationary phase and thus longer retention times [19]. HPLC can analyze a wider range of compounds, including underivatized and thermally unstable species.

Liquid vs. Gas Chromatography: A Side-by-Side Comparison for Fatty Acid Analysis

The table below summarizes the key characteristics of both techniques for fatty acid profiling.

Table 1: Comparative Analysis of HPLC and GC for Fatty Acid Profiling

| Feature | Gas Chromatography (GC) | High-Performance Liquid Chromatography (HPLC) |

|---|---|---|

| Mobile Phase | Inert gas (He, H₂, N₂) [18] | Liquid solvents (e.g., Acetonitrile, Methanol, Water buffers) [19] |

| Separation Principle | Volatility & partitioning into liquid stationary phase [18] | Polarity/hydrophobicity (Reversed-Phase), size, charge [19] [18] |

| Typical Sample Prep for FAs | Derivatization required (e.g., methyl ester formation) to increase volatility [20] [21] | Derivatization optional; can analyze underivatized free fatty acids [17] |

| Analysis Time | ~30 minutes (including derivatization) [20] | Can be very fast (e.g., <8 minutes for short-chain FAs) [17] |

| Key Strengths | High resolution, excellent for complex FA mixtures, robust and quantitative with FID, well-established methods [19] [20] | Analysis of thermolabile FAs, no derivatization needed in some cases, faster run times, compatible with a wider range of detectors [17] [19] |

| Key Limitations | Limited to volatile/derivatized compounds, high temperatures may degrade sensitive FAs [19] | Generally lower resolution than GC for complex FA mixtures, solvent consumption [19] |

| Ideal for Food Applications | Comprehensive profiling of total fatty acid methyl esters (FAMEs), authenticity studies, nutritional labeling [20] | Rapid analysis of free fatty acids (FFA) indicating spoilage, underivatized SCFA analysis, oxidized or labile fatty acids [17] [22] |

Experimental Protocols for Fatty Acid Profiling

Protocol 1: GC-MS Analysis of Fatty Acids in Milk Powder (as Fatty Acid Methyl Esters - FAMEs)

This protocol, adapted from a study on special formula milk powder, outlines a robust method for total fatty acid analysis [20].

Table 2: Research Reagent Solutions for GC-MS Protocol

| Item | Function |

|---|---|

| Sodium Methoxide in Methanol | Base catalyst for transesterification of lipids into FAMEs [20]. |

| Internal Standard Solution | Compound added in known quantity to correct for losses during sample prep and injection variability (e.g., deuterated FAME) [23]. |

| n-Heptane or Hexane | Organic solvent for lipid extraction and dissolving FAMEs for injection [20]. |

| GC Capillary Column | Fused-silica column with polar stationary phase (e.g., polyethylene glycol) for separating FAMEs [20] [21]. |

Workflow Diagram: GC-MS Fatty Acid Analysis

Procedure:

- Lipid Extraction: Accurately weigh ~1 g of milk powder. Extract lipids using a suitable method (e.g., Mojonnier or Folch extraction).

- Derivatization: Transfer the extracted lipids to a reaction vial. Add an internal standard (e.g., C13:0 FAME) and 1-2 mL of sodium methoxide in methanol (0.5 M). Heat at ~50°C for 10-15 minutes to convert lipids to FAMEs [20].

- Extraction of FAMEs: After cooling, add 2 mL of heptane and vortex mix. The upper heptane layer containing the FAMEs is recovered.

- GC-MS Analysis:

- Column: Polar capillary column (e.g., 60 m x 0.25 mm ID, 0.25 µm film).

- Injection: 1 µL, split mode (10:1) [20].

- Oven Program: Start at 60°C, ramp to 180°C, then to 240°C at 3-5°C/min.

- Carrier Gas: Helium, constant flow.

- Detection: Mass Spectrometer (MS) in Electron Impact (EI) mode. Identification is by comparison of retention times and mass spectra to authentic standards. Quantification uses internal standard calibration [20].

Method Performance (from literature): This method demonstrated good linearity (R² > 0.9959), precision (RSD 0.41-3.36%), and recovery (90-108%) for determining FAs in milk powder, offering a faster and cheaper alternative to some standard methods [20].

Protocol 2: HPLC-PDA Analysis of Underivatized Short-Chain Fatty Acids

This protocol, based on recent research, describes a fast, underivatized method for quantifying short-chain fatty acids (SCFAs) in fermentation broth, food, or waste samples [17].

Table 3: Research Reagent Solutions for HPLC-PDA Protocol

| Item | Function |

|---|---|

| Mobile Phase Buffer | Aqueous phosphate or acetate buffer, pH ~2-3. Controls ionization of acidic analytes, improving peak shape [17]. |

| HPLC Solvent (Acetonitrile) | Organic modifier in the mobile phase. Gradient elution with buffer achieves separation [17]. |

| Short-Chain Fatty Acid Standards | Pure reference materials (e.g., Acetic, Propionic, Butyric acid) for method calibration and identification [17]. |

Workflow Diagram: HPLC-PDA Short-Chain Fatty Acid Analysis

Procedure:

- Sample Preparation: Centrifuge liquid samples (e.g., fermentation broth) and dilute the supernatant with mobile phase. Filter through a 0.22 µm or 0.45 µm membrane filter.

- HPLC-PDA Analysis:

- Column: Reversed-Phase C18 column (e.g., 150 mm x 4.6 mm, 5 µm).

- Mobile Phase: (A) Aqueous buffer (e.g., 20 mM phosphate, pH 2.5) and (B) Acetonitrile.

- Gradient Elution: Start at 5% B, increase to 50% B over 7 minutes [17].

- Flow Rate: 1.0 - 2.5 mL/min [17].

- Column Temperature: Maintained at 30-40°C [17].

- Detection: Photodiode Array (PDA) detector at 210 nm, where the carboxyl group absorbs [17].

- Quantification: Use an external standard calibration curve prepared from pure SCFA standards. The method's low limits of detection (0.0003-0.068 mM) allow for sensitive quantification in complex aqueous matrices [17].

Detector Selection and Advanced Detection Strategies

The choice of detector is critical for achieving the required sensitivity and specificity.

Table 4: Common Detectors in Fatty Acid Chromatography

| Detector | Compatible Technique | Principle | Key Advantages | Considerations for FA Analysis |

|---|---|---|---|---|

| Flame Ionization (FID) | GC | Measures ions produced when solutes are burned in a H₂/air flame [23]. | Robust, wide linear dynamic range, universal response to carbon atoms [19]. | The gold standard for quantitative GC-FA analysis; requires derivatization. |

| Mass Spectrometry (MS) | GC, HPLC | Ionizes analyte molecules and separates them by their mass-to-charge ratio (m/z) [21]. | Provides structural identity and confirmation; high specificity and sensitivity [20] [22]. | Can be used for both GC and HPLC; enables definitive identification of FAs and isomers. |

| Photodiode Array (PDA)/UV | HPLC | Measures absorption of UV or visible light by analytes [17]. | Non-destructive, can provide spectral information for peak purity. | For underivatized FAs, low wavelengths (200-210 nm) must be used, limiting solvent choice [17]. |

| Fluorescence (FLD) | HPLC | Measures light emitted by fluorescent derivatives after UV excitation. | Extremely high sensitivity and selectivity [19]. | Requires pre-column derivatization of FAs with a fluorescent tag (e.g., phenacyl esters) [19]. |

Advanced Strategy: Derivatization for Enhanced Detection To improve volatility for GC or to enhance sensitivity for HPLC (especially with FLD), fatty acids are often derivatized. Common reagents include:

- GC: Boron trifluoride in methanol to create FAMEs.

- HPLC: Phenacyl bromide to create UV-absorbing esters, or other reagents like 4-(dimethylamino)benzoylhydrazine (DABA) for mass spectrometry sensitivity boosts [19] [22]. Isotope-coded derivatization reagents (e.g., DABA/d6-DABA) allow for relative quantification and can increase MS sensitivity by over 500-fold [22].

Both GC and HPLC are powerful yet distinct tools for fatty acid profiling in food research. GC, particularly GC-MS or GC-FID, remains the superior method for high-resolution, comprehensive analysis of total fatty acid composition following derivatization. In contrast, HPLC offers distinct advantages for rapid analysis of underivatized free or short-chain fatty acids and is indispensable for studying thermally labile compounds. The decision between the two should be guided by the specific analytical question—whether it is the complete FA profile or a targeted analysis of specific fatty acid classes—taking into account factors like required throughput, sensitivity, and available instrumentation.

In the field of food science research, the chromatographic profiling of fatty acids is fundamental for assessing nutritional quality, sensory attributes, and product stability. A critical initial methodological decision revolves around the specific analyte form: Free Fatty Acids (FFA) versus Total Fatty Acids (TFA). This distinction is paramount, as these two targets provide different information and require distinct analytical approaches, primarily due to their chemical state within the food matrix.

Free Fatty Acids (FFA) are the non-esterified, carboxylic acid forms that result from the hydrolysis of triglycerides. Their quantification is essential as they serve as key indicators of lipid hydrolysis (rancidity), significantly impacting flavor and aroma, particularly in dairy and fermented products [24]. In contrast, Total Fatty Acids (TFA) represent the complete pool of fatty acids, encompassing those esterified in complex lipids like triglycerides, phospholipids, and cholesteryl esters, in addition to the free forms. TFA profiling provides the comprehensive fatty acid signature of a food, which is crucial for nutritional labeling and understanding the global fat composition [14] [24].

The core differentiator in their analysis is the requirement for derivatization. While FFA analysis can sometimes be performed directly, derivatization is a mandatory step for TFA to liberate and convert all esterified fatty acids into a uniform, volatile, and chromatographically amenable form.

Table 1: Core Comparison Between FFA and TFA Profiling

| Feature | Free Fatty Acid (FFA) Profiling | Total Fatty Acid (TFA) Profiling |

|---|---|---|

| Analytical Target | Non-esterified fatty acids | All fatty acids (free & esterified in triglycerides, phospholipids, etc.) |

| Information Provided | Lipid hydrolysis, rancidity, sensory impact | Comprehensive nutritional profile, fat composition |

| Core Derivatization Requirement | Optional for some methods (e.g., LC-MS); used for volatility in GC | Mandatory to break down ester bonds and create uniform derivatives |

| Key Sample Prep Steps | Extraction of free lipids; potential purification | Total lipid extraction; saponification/transesterification |

| Ideal for | Quality control, shelf-life studies, fermented product analysis | Nutritional labeling, dietary studies, fundamental composition analysis |

Methodological Approaches and Derivatization Strategies

The choice of analytical technique dictates the derivatization strategy. Gas Chromatography (GC)-based methods, the most widely used for fatty acid profiling, universally require the conversion of fatty acids into volatile derivatives, most commonly Fatty Acid Methyl Esters (FAMEs) [14] [16]. In contrast, Liquid Chromatography-Mass Spectrometry (LC-MS) methods can often analyze FFA directly, albeit frequently with derivatization employed to enhance sensitivity and detection [25] [26].

Derivatization for Gas Chromatography (GC) Analysis

For TFA analysis via GC, the process begins with the transesterification of the extracted total lipids. This can be achieved through acid- or base-catalyzed methylation, which cleaves the glycerol backbone of triglycerides and methylates the freed fatty acids. A robust protocol involves a two-step process: saponification to release all fatty acids from their esterified forms, followed by methylation using a reagent like trimethylsilyl-diazomethane (TMS-DM) to create FAMEs [16]. This method is noted for its accuracy in quantifying a wide range of fatty acids, including trans fatty acid isomers [16].

For FFA analysis via GC, a targeted extraction of free lipids is first performed. The extracted FFA can then be directly methylated without a saponification step, as they are already in the free acid form.

Analysis via Liquid Chromatography-Mass Spectrometry (LC-MS)

LC-MS offers a powerful alternative, especially for FFA profiling. Its key advantage is the ability to analyze FFA without derivatization, as volatility is not a requirement. However, derivatization is still frequently used to improve ionization efficiency and sensitivity. For instance, an optimized LC-MS method uses an isopropanol:methanol (1:1, v/v) solvent for FFA extraction and achieves accurate quantification using isotopically labelled internal standards [27]. Advanced techniques like stable isotope derivatization coupled with LC-MS (ID-LC-QQQ-MS) have been developed for enhanced analysis. This method derivatizes the carboxyl groups of FFAs with isotope reagents, forming trimethylaminoethyl esters (FA-TMAE), which allows for highly sensitive and reliable non-targeted profiling and quantification in complex biological samples [25].

Table 2: Overview of Key Derivatization and Analysis Methods

| Method | Principle | Derivatization Agent | Key Application | Advantages |

|---|---|---|---|---|

| GC-FID/GC-MS | Conversion to volatile derivatives (FAMEs) for separation | Base (e.g., NaOCH₃) or Acid catalyst, TMS-DM | TFA profiling; FFA profiling after extraction | High resolution, universal detection (FID), robust quantification |

| LC-MS (Underivatized) | Direct separation and mass-based detection | Not required | Targeted FFA profiling | Avoids derivatization step; direct analysis of native compounds |

| LC-MS with Derivatization | Enhanced ionization and sensitivity for mass spec | Isotope tags (e.g., for ID-LC-QQQ-MS), TMAE reagents | Sensitive and specific FFA profiling, complex matrices | Improved sensitivity, enables use of isotope internal standards |

Detailed Experimental Protocols

Protocol 1: Profiling of Total Fatty Acids via GC-FID

This protocol details the analysis of TFA as FAMEs using GC, adapted from established methodologies [16] [24].

Workflow Overview:

Step-by-Step Procedure:

- Total Lipid Extraction: Weigh 0.5-1 g of homogenized food sample into a glass tube. Add 20 mL of a chloroform:methanol (2:1, v/v) mixture. Homogenize vigorously for 2 minutes. Add 4 mL of 0.9% saline solution (or water), vortex, and centrifuge at 3000 rpm for 10 minutes to achieve phase separation. Carefully recover the lower, organic (chloroform) layer containing the total lipids. Evaporate the solvent under a gentle stream of nitrogen.

- Saponification & Transesterification: Re-dissolve the extracted lipid in 2 mL of n-hexane. Add 1 mL of 0.5 N sodium methoxide (NaOCH₃) in methanol. Vortex and incubate at 50°C for 30 minutes to transesterify the triglycerides. For complete methylation of all free acids, add 1 mL of trimethylsilyl-diazomethane (TMS-DM, 2M in n-hexane) and incubate at room temperature for a further 30 minutes.

- FAME Extraction & Purification: Stop the reaction by adding 2 mL of deionized water. Extract the formed FAMEs by adding 3 mL of n-hexane, vortexing for 1 minute, and centrifuging. Transfer the upper (n-hexane) layer to a new, clean glass vial. Evaporate the extract to near dryness under nitrogen and reconstitute in 1 mL of n-hexane for GC analysis.

- GC-FID/GC-MS Analysis: Inject 1 µL of the FAME solution in split mode (e.g., 10:1). Use a high-polarity capillary GC column (e.g., CP-Sil 88, 100 m x 0.25 mm i.d., 0.20 µm film) for optimal separation of cis/trans isomers. The temperature program should be optimized for the chain length range; a typical program is: hold at 140°C for 5 min, ramp at 4°C/min to 240°C, and hold for 15 min. Use Helium as the carrier gas. Identify FAMEs by comparison with certified standards and quantify using internal standardization (e.g., C15:0 or C17:0 triglyceride) [16] [24].

Protocol 2: Quantification of Free Fatty Acids via LC-MS

This protocol focuses on the accurate quantification of specific FFAs using LC-MS, minimizing exogenous contamination [27] [26].

Workflow Overview:

Step-by-Step Procedure:

- Minimizing Contamination (Critical Step): Use glass vials whenever possible. Pre-wash all glassware with methanol under ultrasonication for 10 minutes to remove exogenous FFA contaminants, which can leach from plastics and solvents [26].

- Targeted FFA Extraction: Weigh or transfer a representative sample (e.g., 100 µL of milk, 100 mg of flour) into the pre-washed glass tube. Add a mixture of isotopically labelled internal standards (e.g., d³-palmitic acid and d³-stearic acid) to correct for recovery and matrix effects. Extract FFAs by adding 2 mL of a chilled chloroform:methanol (2:1, v/v) mixture. Vortex for 2 minutes and centrifuge at 5000 rpm for 10 minutes. Collect the organic layer and evaporate to dryness under nitrogen.

- LC-MS/MS Analysis: Reconstitute the dried extract in 100 µL of methanol. Analyze using an LC system coupled to a triple quadrupole mass spectrometer. Chromatographic separation can be achieved on a C8 or C18 column (e.g., XBridge BEH C8, 4.6 x 100 mm, 3.5 µm) using an isocratic or gradient elution with water and acetonitrile, both modified with 0.1% formic acid. Operate the MS in negative electrospray ionization (ESI-) mode. Use Multiple Reaction Monitoring (MRM) for high sensitivity and selectivity, monitoring specific precursor ion > product ion transitions for each target FFA and its corresponding internal standard [27] [26].

- Quantification: Quantify individual FFA concentrations using the internal standard method, constructing calibration curves from the ratio of the analyte peak area to the isotope-labelled internal standard peak area.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents and Materials for Fatty Acid Profiling

| Reagent/Material | Function & Role in Analysis | Example Use-Cases |

|---|---|---|

| Chloroform-Methanol Mixtures | Universal solvent system for total lipid extraction (Folch, Bligh & Dyer methods). | Total lipid extraction from diverse food matrices prior to TFA derivatization [24]. |

| Methyl-tert-butyl ether (MTBE) | Alternative organic solvent for liquid-liquid extraction; forms top layer for easier recovery. | FFA extraction, minimizing contamination from aqueous phase [26]. |

| Sodium Methoxide (NaOCH₃) | Base catalyst for transesterification of triglycerides into FAMEs. | Core derivatization step in TFA profiling for GC analysis [16]. |

| Trimethylsilyl-diazomethane (TMS-DM) | Derivatizing agent for methylating free carboxylic acid groups. | Ensures complete methylation of FFAs after saponification in TFA analysis [16]. |

| Isotope-Labelled Internal Standards | (e.g., d³-palmitic acid, ¹³C-FFAs); corrects for losses during prep and matrix effects in MS. | Essential for accurate quantification in targeted LC-MS/MS and ID-LC-QQQ-MS methods [27] [26]. |

| Polar Capillary GC Columns | (e.g., 100m CP-Sil 88, SP-2560); separates geometric and positional FA isomers. | Critical for resolving complex mixtures, including cis/trans FAME isomers in TFA profiles [16] [24]. |

Methodologies in Practice: GC, LC-MS, and Derivatization Strategies for Food Analysis

Fatty acid profiling is a fundamental technique in food science research, essential for determining the nutritional quality, authenticity, and safety of food products [28] [29]. Gas chromatography-mass spectrometry (GC–MS) has emerged as a powerful tool for this purpose, capable of providing high resolution and sensitivity for quantifying low molecular weight and volatile compounds [30]. However, the accurate quantification of fatty acids via GC–MS requires their prior conversion into more volatile Fatty Acid Methyl Esters (FAMEs). This application note details optimized protocols for FAME creation using acid and base catalysis, framed within the context of food science methodologies. We provide a comprehensive comparison of extraction and derivatization techniques, complete with quantitative performance data and ready-to-use workflows for food research and drug development professionals.

Experimental Protocols

Protocol 1: Dual-Catalysis Derivatization for Complex Food Lipids (Modified EN ISO 12966-2:2017)

This protocol, adapted for fish tissue and special formula milk powder, uses sequential base and acid catalysis to efficiently methylate a wide range of fatty acids, including free fatty acids and those bound in triglycerides [20] [31].

- Reagents: Sodium methoxide (NaOCH₃) in methanol (0.2 mol/L), Methanolic HCl (1 M) or Methanolic H₂SO₄ (1 M), Internal Standard (e.g., C23:0 Methyl Ester, 1000 µg/mL in acetone), Isooctane or Methyl tert-butyl ether (MTBE), Sodium chloride solution (0.4 g/mL).

- Procedure:

- Weigh approximately 20 mg of freeze-dried, homogenized sample into a reaction tube.

- Add 200 µL of internal standard and 2 mL of sodium methoxide solution.

- Heat the mixture at 100°C (or boil) for 20 minutes for base-catalyzed transesterification.

- Cool the sample. Using phenolphthalein as a pH indicator, neutralize the mixture with 1 M methanolic HCl (or H₂SO₄).

- Add a 0.2 mL excess of the methanolic acid and heat again at 100°C for 5 minutes for acid-catalyzed esterification of free fatty acids.

- Cool the sample, add 4 mL of sodium chloride solution, and shake for 15 minutes.

- Add 1 mL of extraction solvent (isooctane or MTBE) and mix thoroughly.

- Centrifuge at 500 x g for 5 minutes to separate phases.

- Transfer the organic (upper) layer to an amber GC vial for analysis [31].

Protocol 2: Solid Catalyst Esterification for High-Free-Fatty-Acid Feedstocks

This method is suitable for low-cost, high-free-fatty-acid (FFA) feedstocks like palm fatty acid distillate (PFAD), utilizing a reusable solid acid catalyst, which is more environmentally friendly than homogeneous acids [32].

- Reagents: High-FFA feedstock (e.g., PFAD), Methanol, Solid acid catalyst (e.g., ZrFeTiO tripartite oxide).

- Procedure:

- Combine PFAD with methanol at a 3:1 methanol-to-PFAD weight ratio in a pressurized reactor.

- Add 3 wt.% of the solid ZrFeTiO catalyst (calcined at 600°C).

- Heat the reaction mixture to 170°C and maintain for 5 hours with continuous stirring.

- After the reaction, separate the catalyst from the product mixture by filtration.

- The catalyst can be regenerated by calcination and reused for up to four successive cycles with stable conversion [32].

Protocol 3: One-Step Base Derivatization for Rapid Analysis (EN ISO 12966-3:2016)

This is a rapid, single-step method suitable for quality control and high-throughput analysis, where derivatization occurs during the GC injection [31].

- Reagents: Methyl tert-butyl ether (MTBE), Trimethylsulfonium hydroxide (TMSH) solution, Internal Standard.

- Procedure:

- Extract the sample by shaking vigorously for 10 minutes in 1 mL of MTBE.

- Centrifuge the sample to obtain a clear supernatant.

- Place 120 µL of the supernatant into an amber GC vial.

- Add 10 µL of internal standard and 250 µL of TMSH solution.

- Mix the vial contents thoroughly. The FAMEs are formed in the hot GC injector [31].

The following tables summarize the performance characteristics of the different FAME creation and analysis methods discussed.

Table 1: Performance Validation of GC-MS Method for Fatty Acids in Special Formula Milk Powder [20]

| Validation Parameter | Reported Performance |

|---|---|

| Linearity (Correlation Coefficients) | 0.9959 – 0.9997 |

| Precision (Relative Standard Deviation, RSD) | 0.41% – 3.36% |

| Stability (RSD) | 1.01% – 4.91% |

| Repeatability (RSD) | 1.02% – 3.81% |

| Spiked Recovery Rate | 90.03% – 107.76% |

Table 2: Comparison of FAME Yields from Fish Liver Using Different Derivatization Methods [31]

| Method | Key Characteristics | Reported Outcome |

|---|---|---|

| M1: NaOCH₃ + H₂SO₄, Isooctane | Standard method (EN ISO 12966-2:2017) | Baseline yields |

| M2: NaOCH₃ + HCl, Isooctane | Replaces H₂SO₄ with safer HCl | Improved yields over M1 |

| M3: NaOCH₃ + HCl, MTBE | Uses HCl and less toxic MTBE | Highest fatty acid yields and internal standard recovery |

| M4: Chloroform/MeOH + H₂SO₄ | Classical lipid extraction | Lower yields than M3; uses toxic chloroform |

| M5: MTBE + TMSH | Rapid one-step method (EN ISO 12966-3:2016) | Fastest, but lowest yields among all methods |

Table 3: Performance of SCFA Extraction Methods in Fecal Samples (GC-MS) [30]

| Extraction Method | Key Advantages | Recovery & Precision |

|---|---|---|

| H₃PO₄-Butanol | Superior for valeric and butyric acid; good linearity & sensitivity for isobutyric acid. | Valeric acid recovery: ~101%; Intra-day RSD: 0.92–5.67% |

| SPME | Highest extraction efficiency for acetic, propionic, and isobutyric acid; no derivatization. | Acetic acid recovery: 81–94%; Minimal sample preparation |

Workflow Visualization

The following diagram illustrates the decision-making pathway for selecting the appropriate sample preparation protocol based on research goals and sample type.

The Scientist's Toolkit: Essential Research Reagents

Table 4: Key Reagents for FAME Creation and GC-MS Analysis

| Reagent / Material | Function / Purpose |

|---|---|

| Sodium Methoxide (NaOCH₃) | Base catalyst for transesterification of triglycerides. |

| Methanolic HCl or H₂SO₄ | Acid catalyst for esterification of free fatty acids. |

| Trimethylsulfonium Hydroxide (TMSH) | Rapid, one-step base derivatization agent. |

| Solid Acid Catalyst (e.g., ZrFeTiO) | Heterogeneous catalyst for esterification; reusable and less corrosive. |

| Internal Standard (e.g., C23:0 ME) | Quantification standard to correct for losses during sample preparation. |

| Methyl tert-butyl ether (MTBE) | Solvent for lipid extraction and FAME isolation; less toxic alternative to chloroform. |

The choice of FAME creation protocol directly impacts the accuracy, efficiency, and scope of fatty acid profiling in food research. For comprehensive analysis of complex food matrices like fish tissue or milk powder, the dual-catalysis method (Protocol 1) is recommended due to its high yields and ability to handle both free and bound fatty acids. The modified version using HCl and MTBE offers a safer and more effective alternative [31]. For specialized, high-FFA industrial feedstocks, solid acid catalysis (Protocol 2) provides an environmentally friendly and highly effective solution [32]. Finally, for high-throughput quality control where maximum yield may be secondary to speed, the one-step TMSH method (Protocol 3) is optimal. By selecting the appropriate method as outlined in these protocols and supported by the provided performance data, researchers can ensure robust and reliable fatty acid analysis for food and nutritional sciences.

Isotope-coded derivatization (ICD) represents a cutting-edge approach in analytical chemistry that significantly enhances the sensitivity, specificity, and quantitative capabilities of mass spectrometry (MS)-based analyses. This technique involves the use of chemically identical reagents labeled with different stable isotopes to tag target analytes, thereby improving ionization efficiency and enabling precise relative quantification [33]. Within the framework of chromatography methods for fatty acid profiling in food research, ICD addresses two fundamental challenges: the inherently poor ionization efficiency of many metabolites and lipids in electrospray ionization (ESI) sources, and the limited availability of costly, stable isotope-labeled internal standards for every potential analyte [33].

The core principle of ICD, also termed isotope-coded ESI-enhancing derivatization (ICEED), involves introducing different isotope-coded moieties to metabolites. One derivative form can then serve as an internal standard, effectively minimizing matrix effects and improving data accuracy [33]. Furthermore, the derivatization process itself can dramatically improve ESI efficiency, modify fragmentation patterns in MS/MS, and optimize chromatographic behavior, leading to substantially enhanced sensitivity and specificity across various detection modes [33]. This technical note details the application of these advanced reagents, with a specific focus on fatty acid analysis in food matrices, providing structured protocols and performance data to guide research implementation.

Key Reagent Systems and Their Mechanisms

Research Reagent Solutions

The successful application of isotope-coded derivatization hinges on selecting appropriate reagent systems tailored to the target analytes and instrumentation.

Table 1: Essential Isotope-Coded Derivatization Reagents for Fatty Acid Analysis

| Reagent Name | Chemical Characteristics | Primary Application | Key Advantage |

|---|---|---|---|

| DABA/d6-DABA [22] | 4-(Dimethylamino)benzoylhydrazine / deuterated version | UPLC-HRMS profiling of FFAs in edible oils | Boosts MS sensitivity by 528–3,677-fold; enables rapid derivatization (35°C, 30 min) |

| D3-Methyl Chloroformate (D3-MCF) [34] | Isotope-coded methylating reagent | GC-MS analysis of esterified lipids in serum | Facilitates preparation of internal standards via isotope-coded derivatization; compatible with PICI-MS |

| ICEED Reagents (General) [33] | Various structures with stable isotope tags | LC/ESI-MS analysis of metabolites in biological samples | Improves ESI efficiency, enables differential analysis and absolute quantification of metabolites |

Operational Mechanisms and Strategic Advantages

Isotope-coded derivatization reagents function through several complementary mechanisms that collectively enhance analytical performance. First, they significantly improve ionization efficiency in ESI-MS by incorporating permanently charged or easily ionizable moieties into the analyte structure. This leads to lower detection limits and increased signal intensity for target compounds [33]. Second, the use of stable isotope-coded pairs (e.g., ^2H, ^13C, ^15N) allows for accurate relative quantification by providing internal standards with nearly identical chemical properties that co-elute chromatographically but are distinguished by mass differences in the MS detector [22] [33].

Additionally, these reagents can alter fragmentation patterns to produce more characteristic product ions for selective reaction monitoring (SRM) or multiple reaction monitoring (MRM) experiments, thereby enhancing analytical specificity [33]. The derivatization process also modifies the hydrophobicity of polar metabolites, potentially improving retention and separation on reversed-phase chromatography columns and reducing matrix effects [33]. Finally, by serving as multiplexed internal standards, isotope-coded derivatives compensate for sample preparation losses, matrix suppression effects, and instrument variability, leading to superior quantitative accuracy and precision compared to underivatized analyses [34].

Experimental Protocols

Comprehensive Workflow for Fatty Acid Profiling

The following workflow diagram outlines the complete analytical procedure for fatty acid profiling using isotope-coded derivatization, from sample preparation to data analysis:

Protocol 1: DABA/d6-DABA Derivatization for Free Fatty Acids in Edible Oils

This protocol describes a highly sensitive method for profiling free fatty acids (FFAs) in edible oils using DABA/d6-DABA isotope-coded derivatization, based on a recently published study [22].

Materials and Reagents

- DABA and d6-DABA derivatization reagents: Synthesized via a two-step process [22]

- Internal standard: d6-DABA-derivatized pentadecanoic acid (C15:0) [22]

- Solvents: HPLC-grade methanol, acetonitrile, and water

- Edible oil samples: Rapeseed, peanut, soy, corn, and olive oils

- Equipment: UPLC system coupled to high-resolution mass spectrometer, maintained at optimal performance

Derivatization Procedure

- Weighing: Precisely weigh 50 mg of edible oil sample into a glass vial.

- Internal Standard Addition: Add 100 μL of d6-DABA-derivatized pentadecanoic acid internal standard solution (concentration: 1 μg/mL).

- Derivatization Reaction: Add 200 μL of DABA derivatization reagent solution to the sample mixture.

- Incubation: Vortex the mixture thoroughly and incubate at 35°C for 30 minutes.

- Dilution: After reaction completion, dilute the derivatized sample with 1 mL of acetonitrile.

- Analysis: Centrifuge at 10,000 × g for 5 minutes and transfer the supernatant to an LC vial for UPLC-HRMS analysis.

UPLC-HRMS Parameters

- Column: C18 reversed-phase column (2.1 × 100 mm, 1.7 μm)

- Mobile Phase: A: 0.1% formic acid in water; B: 0.1% formic acid in acetonitrile

- Gradient: 5% B to 95% B over 15 minutes, hold for 5 minutes

- Flow Rate: 0.3 mL/min

- MS Detection: High-resolution mass spectrometer with ESI source in positive ion mode

- Data Acquisition: Full-scan MS with parallel reaction monitoring for targeted FFAs

Protocol 2: GC-PICI-MS with Isotope-Coded Derivatization for Esterified Lipids

This protocol details a validated GC-MS method for quantifying fatty acids exclusively bound in esterified lipids, utilizing isotope-coded derivatization with D3-methyl chloroformate [34].

Materials and Reagents

- Internal standards: Methyl heptadecanoate-D33 (MeC17:0-D33) and D3-methyl chloroformate (D3-MCF) [34]

- Transmethylation reagent: Sodium methoxide solution (25 wt.% in methanol) [34]

- Extraction solvents: tert-Butyl methyl ether (MTBE), isooctane, n-hexane

- Sample material: Human serum (5 μL sufficient) or food lipid extracts

- Equipment: GC-MS system with positive ion chemical ionization (PICI) capability, isobutane reagent gas

Sample Preparation and Derivatization

- Lipid Extraction: Perform Folch extraction (MTBE/methanol/water) on 5 μL of human serum or food sample.

- Transmethylation: Add 500 μL sodium methoxide solution (25% in methanol) to dried lipid extract in tert-butyl methyl ether.

- Incubation: Heat at 50°C for 15 minutes for base-catalyzed transmethylation of esterified lipids.

- Isotope Coding: Prepare internal fatty acid trideuteromethyl esters (D3-FAME) through isotope-coded derivatization with D3-labeled methylchloroformate/methanol medium.

- Mixing: Combine transmethylated serum extract with the D3-FAME internal standard mixture.

- Re-extraction: Re-extract FAMEs in isooctane prior to GC-MS analysis.

GC-PICI-MS Parameters

- Column: Polar capillary column (e.g., wax-type or highly polar stationary phase)

- Oven Program: 50°C (hold 1 min) to 240°C at 10°C/min, hold for 10 min

- Injection: Splitless mode at 250°C

- PICI Conditions: Isobutane reagent gas, selected ion monitoring (SIM) mode

- Quantification: Monitor characteristic ions for each FAME and corresponding D3-labeled internal standard

Performance Data and Analytical Validation

Quantitative Performance of DABA Derivatization for Edible Oils

The DABA/d6-DABA derivatization method has been rigorously validated for the analysis of free fatty acids in edible oils, demonstrating exceptional performance characteristics [22].

Table 2: Analytical Performance of DABA Derivatization for Free Fatty Acid Profiling

| Performance Metric | Result | Experimental Conditions |

|---|---|---|

| Sensitivity Enhancement | 528–3,677-fold increase | Compared to underivatized FFAs [22] |

| Limit of Detection (LOD) | 0.04–10 ng/mL | Across 42 different FFAs [22] |

| Linearity | R = 0.9914–0.9993 | For quantified FFAs [22] |

| Precision & Repeatability | RSD ≤ 13.0% | For all detected FFAs [22] |

| Number of FFAs Identified | 42 compounds | In five edible oil types [22] |

| Exclusion of False Positives | 47.5% of initial proposals | Via multidimensional identification [22] |

Fatty Acid Composition in Edible Oils

Application of the DABA derivatization method to various edible oils revealed distinct fatty acid profiles, highlighting the technique's quantitative capabilities.

Table 3: Prominent Free Fatty Acids in Edible Oils Quantified via DABA Derivatization

| Edible Oil Type | Predominant Fatty Acids | Concentration (ng/mL) | Notable Features |

|---|---|---|---|

| Rapeseed Oil | Linoleic acid | 117,525.5 | Predominance of polyunsaturated fatty acids [22] |

| Peanut Oil | Linoleic acid | 525,880.0 | Highest linoleic acid content among tested oils [22] |

| Soy Oil | Stearic acid | 21,255.2 | Notable saturated fatty acid content [22] |

| Corn Oil | Stearic acid | 29,349.7 | Similar profile to soy oil [22] |

| Olive Oil | Palmitic acid | 97,834.5 | Predominance of saturated fatty acids [22] |

Applications in Food Science Research

The implementation of isotope-coded derivatization techniques in food science research provides substantial advantages for fatty acid profiling. The exceptional sensitivity enhancement achieved through DABA derivatization (increases of 528–3,677-fold) enables detection of trace-level free fatty acids that are often undetectable with conventional methods [22]. This sensitivity is crucial for monitoring lipid oxidation products, assessing oil quality, and detecting adulteration.

The high-throughput capabilities of these methods allow for comprehensive profiling of complex food matrices, with one study identifying 42 different free fatty acids in edible oils while effectively excluding false positives through multidimensional identification criteria [22]. Furthermore, the precision and linearity of ICD-based quantification (RSD ≤ 13.0%, R = 0.9914–0.9993) ensure reliable data for nutritional labeling, quality control, and regulatory compliance in food production [22].

Isotope-coded derivatization also facilitates the analysis of challenging geometric isomers, though specialized chromatographic separation may still be required to resolve cis/trans and double bond isomers in complex food samples [22] [16]. When combined with comprehensive multidimensional gas chromatography (GC×GC), these techniques provide unparalleled separation power for complex fatty acid mixtures in food products [35].

Troubleshooting and Technical Considerations

Optimization Strategies

Successful implementation of isotope-coded derivatization requires attention to several technical aspects. For DABA/d6-DABA derivatization, maintaining the reaction temperature at 35°C for exactly 30 minutes is critical for achieving complete derivatization without decomposition [22]. The sodium methoxide-catalyzed transmethylation step in the GC-MS protocol requires strictly anhydrous conditions to prevent poor recoveries of fatty acid methyl esters, particularly for esterified lipids [34].

Method validation should include assessment of linearity, precision, accuracy, and recovery according to FDA guidelines or equivalent standards, using certified reference materials such as NIST SRM 2378 Fatty Acids in Frozen Human Serum where applicable [34]. For complex food matrices, a multidimensional identification approach incorporating isotope ratio analysis, retention time prediction, isotope peak matching, and carbon count-based retention behavior significantly enhances identification confidence and excludes false positives [22].

Limitations and Complementary Techniques

While isotope-coded derivatization provides exceptional sensitivity, certain limitations should be considered. The DABA/d6-DABA method does not resolve cis/trans and double bond isomers, requiring complementary techniques such as highly-polar GC columns or silver-ion chromatography for complete stereochemical characterization [22] [16]. Some derivatization reagents may exhibit steric hindrance with certain analytes, as observed with TPP (triphenyl pyrilium) which failed to react with L-DOPA and glycine [36].

Alternative techniques such as capillary electrophoresis (CZE-UV) offer advantages for specific applications, including absence of derivatization requirements, shorter analysis times, and lower solvent consumption, particularly for screening elaidic acid as a marker for industrial trans-fatty acids in non-dairy foods [37]. For short-chain fatty acid analysis, improved HPLC methods with photodiode array detection have been developed that eliminate derivatization requirements entirely while maintaining low detection limits (0.0003-0.068 mM) and short analysis times (7.6 minutes) [17].

Isotope-coded derivatization techniques represent a powerful advancement in mass spectrometry-based fatty acid analysis for food research. The dramatic sensitivity enhancements (500–3,000-fold), excellent linearity, and robust quantitative performance demonstrated by reagents such as DABA/d6-DABA provide analytical chemists with unprecedented capabilities for characterizing lipid composition in complex food matrices. These methods effectively address fundamental challenges in metabolite analysis by improving ionization efficiency, enabling precise isotope-ratio-based quantification, and compensating for matrix effects and instrument variability.

The protocols detailed in this application note provide researchers with comprehensive methodologies for implementing these advanced techniques in food science laboratories. When properly optimized and validated, isotope-coded derivatization enables comprehensive fatty acid profiling that supports food quality assessment, nutritional labeling accuracy, adulteration detection, and research on the relationship between dietary lipids and health outcomes. As the field advances, further development of novel derivatization reagents with enhanced specificity and compatibility with high-throughput analytical platforms will continue to expand the applications of these powerful techniques in food science and beyond.

Ultra-Performance Liquid Chromatography coupled to High-Resolution Mass Spectrometry (UPLC-HRMS) has emerged as a powerful analytical platform in modern food research, particularly for the comprehensive analysis of lipids and fatty acids in complex matrices. This technology combines exceptional separation efficiency with accurate mass measurement capabilities, enabling researchers to characterize intricate lipidomes with unprecedented detail and sensitivity. Within food science, UPLC-HRMS has become indispensable for profiling nutritional components, authenticating products, tracing geographical origins, and monitoring quality, providing a molecular-level understanding of food composition that informs both nutritional science and product development.

The application of UPLC-HRMS to fatty acid profiling represents a significant advancement over traditional analytical methods, offering the ability to simultaneously identify and quantify hundreds to thousands of lipid species in a single analysis. This technical note explores the diverse applications of UPLC-HRMS in food research, with a specific focus on fatty acid analysis, and provides detailed protocols and reference data to support method implementation in research laboratories.

Application Scope in Food Research

Comprehensive Lipid Profiling in Diverse Food Matrices

UPLC-HRMS enables extensive characterization of lipid profiles across various food commodities, providing crucial data for nutritional assessment and product differentiation. In dairy research, a non-targeted lipidomics approach has been employed to systematically characterize ten milk types from eight animal species, resulting in the identification of 640 lipid species spanning triglycerides, phospholipids, sphingolipids, ceramides, and wax esters [38].

Table 1: Lipid Diversity in Characteristic Milk Types Identified by UPLC-HRMS

| Milk Source | Total Lipids Identified | Predominant Lipid Classes | Notable Features | Potential Applications |

|---|---|---|---|---|

| Camel | Highest diversity | Phospholipids, sphingolipids | Superior emulsifying properties and stability | Functional dairy development |

| Mare | NA | Polyunsaturated fatty acids | Rich in linoleic acid and alpha-linolenic acid | Health-focused dairy products |

| Donkey | Lowest total content | Cholesterol esters, PUFA | Suitable for low-fat formulations | Low-fat functional dairy |

| Goat | Balanced composition | Medium-chain fatty acids | Enhanced digestibility | Nutritional products |

| Buffalo | High abundance | Triglycerides, wax esters | High energy density | Rich dairy products |

| Yak | NA | Ceramides, saturated FA | Adaptation to high-altitude environments | Specialty products |

| Jersey/Holstein | Similar profiles | Balanced lipid classes | Stable composition | Versatile dairy development |

The lipidomic analysis revealed significant differences in lipid types and abundances among the milk samples, with camel milk exhibiting the highest lipid diversity and notable enrichment in phospholipids and sphingolipids that confer superior emulsifying properties and stability [38]. This comprehensive profiling capability provides a molecular foundation for developing tailored, functional dairy products with specific nutritional and technological properties.

Targeted Free Fatty Acid Analysis in Edible Oils

A novel UPLC-HRMS method incorporating isotope-coded derivatization has been developed specifically for analyzing free fatty acids (FFAs) in edible oils. Using 4-(dimethylamino)benzoylhydrazine (DABA) and d6-4-(dimethylamino)benzoylhydrazine (d6-DABA) reagents synthesized via a two-step process, this approach selectively derivatizes FFAs at 35°C in 30 minutes, considerably enhancing mass spectrometry sensitivity by 528–3,677-fold, with limits of detection ranging from 0.04–10 ng/mL [22].

The method enabled the profiling of 42 FFAs in five common edible oils, with key FFAs including palmitic, stearic, linoleic, arachidonic, and linolenic acids. The analysis revealed distinct FFA profiles across different oil types, with linoleic acid predominating in rapeseed oil (117,525.5 ng/mL) and peanut oil (525,880.0 ng/mL), stearic acid being notable in soy oil (21,255.2 ng/mL) and corn oil (29,349.7 ng/mL), and palmitic acid predominating in olive oil (97,834.5 ng/mL) [22].

Table 2: predominant Free Fatty Acids in Edible Oils Quantified by UPLC-HRMS

| Edible Oil Type | Predominant FFAs | Concentration (ng/mL) | Methodological Notes |

|---|---|---|---|

| Rapeseed Oil | Linoleic acid | 117,525.5 | Isotope-coded derivatization boosted sensitivity 528-3677x |

| Peanut Oil | Linoleic acid | 525,880.0 | LODs: 0.04-10 ng/mL |

| Soy Oil | Stearic acid | 21,255.2 | 42 FFAs profiled with 47.5% false positives excluded |

| Corn Oil | Stearic acid | 29,349.7 | Derivatization: 35°C for 30 min |

| Olive Oil | Palmitic acid | 97,834.5 | d6-DABA derivatized pentadecanoic acid as internal standard |

Marine Lipid Characterization

UPLC-HRMS has demonstrated exceptional utility in profiling marine-derived lipids, which are particularly rich in omega-3 polyunsaturated fatty acids (n-3 PUFAs). In a comprehensive study of Pacific saury (Cololabis saira), researchers employed UPLC-ESI-MS/MS to investigate fatty acid composition and lipid profiles across different fish parts (meat, head, and viscera) [39].

The analysis identified 5,752 lipid molecules, with glycerophospholipids representing the most numerous lipid type (45.58%), and phosphatidylcholine (PC) emerging as the main differential subclass. The study revealed that the crude fat content varied significantly across different parts: meat (5.81%), head (10.90%), and viscera (19.46%). Notably, the content of n-3 PUFAs in the head (34.58%) was significantly higher than in the meat (29.40%) and viscera (27.95%), highlighting the potential for targeted utilization of fish processing by-products [39].

Archaeological and Food History Applications

Interestingly, UPLC-HRMS has also found application in archaeological studies of ancient food residues. A dual-platform metabolomics approach (GC-MS & UPLC-HRMS) was used to detect organic residues absorbed in pottery from the Peiligang site in China, dating back 8000 years [40]. This novel application demonstrated the ability to identify a wide range of metabolites, including evidence of herbal spices used as flavor enhancement in ancient food preparation, providing unprecedented insights into early culinary practices and pottery function differentiation.

Detailed Experimental Protocols

Protocol 1: Comprehensive Lipid Profiling of Milk Samples

Sample Preparation

- Extraction Method: Modified Bligh and Dyer method [38]

- Sample Volume: 2 mL of raw milk

- Reagents: 4 mL methanol, 1.6 mL water, 4 mL chloroform

- Procedure: Vortex thoroughly, incubate at room temperature for 30 minutes, centrifuge at 2000 rpm for 15 minutes

- Phase Separation: Collect lower organic layer, repeat extraction twice with 4 mL chloroform

- Solvent Evaporation: Combine organic phases, evaporate under nitrogen stream

- Storage: Store dried extracts at -80°C until analysis

UPLC-HRMS Analysis Conditions

- Column: Accucore C18 (2.6 μm, 2.1 × 150 mm)

- Mobile Phase A: MeCN:H₂O (60:40, v/v) with 0.1% HCOOH and 10 mM CH₃COONH₄

- Mobile Phase B: IPA:MeCN (90:10, v/v) with 0.1% HCOOH and 10 mM CH₃COONH₄

- Gradient Program:

- 0-2 min: 30% B

- 2-5 min: 30-43% B

- 5-5.1 min: 43-55% B

- 5.1-11 min: 55-70% B

- 11-16 min: 70-99% B

- 16-18 min: 99% B

- 18-18.1 min: 99-30% B

- 18.1-20 min: 30% B

- Flow Rate: 0.35 mL/min

- Column Temperature: 40°C

- Injection Volume: 5 μL

Mass Spectrometry Parameters

- Instrument: Thermo Orbitrap Q Exactive HF-X mass spectrometer